Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Communication and Instrumentation Systems interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Communication and Instrumentation Systems Interview

Q 1. Explain the difference between analog and digital signals in instrumentation.

Analog and digital signals represent information differently in instrumentation. An analog signal is a continuous representation of a physical quantity, like the temperature measured by a thermocouple. Its value can take on any value within a range. Think of a dial on an old-fashioned speedometer – it smoothly moves across the numbers. In contrast, a digital signal is a discrete representation, using binary code (0s and 1s). The temperature sensor’s reading is converted into a specific numerical code, representing a specific range of temperatures. Think of a digital speedometer showing only whole numbers. Analog signals are susceptible to noise and drift, while digital signals are more resistant to these issues but require Analog-to-Digital Conversion (ADC) and Digital-to-Analog Conversion (DAC) for interfacing with analog components.

Example: Imagine measuring the level of water in a tank. An analog sensor might output a voltage directly proportional to the water level; a higher voltage indicates a higher level. A digital sensor would convert the water level to a digital code, for example, 0010 for a low level and 1100 for a high level. The choice between analog and digital depends on factors such as required accuracy, noise immunity, and cost.

Q 2. Describe various types of sensors and their applications.

Sensors are the foundation of any instrumentation system. They transform physical phenomena (temperature, pressure, light, etc.) into measurable electrical signals. There are countless types, but some common ones include:

- Temperature Sensors: Thermocouples (measure temperature difference), RTDs (Resistance Temperature Detectors – change resistance with temperature), thermistors (similar to RTDs but with a more significant resistance change).

- Pressure Sensors: Strain gauges (measure pressure based on deformation), piezoelectric sensors (generate voltage when subjected to pressure), capacitive sensors (measure pressure based on capacitance change).

- Flow Sensors: Differential pressure flow meters (measure pressure difference across a restriction), ultrasonic flow meters (measure transit time of sound waves in a fluid), turbine flow meters (measure rotation speed caused by fluid flow).

- Level Sensors: Ultrasonic sensors (measure distance to liquid surface), capacitive level sensors (measure capacitance change as liquid level rises), float switches (a simple on/off level detection).

- Light Sensors: Photodiodes (convert light to current), photoresistors (change resistance with light intensity), phototransistors (similar to photodiodes but with built-in amplification).

Applications: These sensors are ubiquitous; examples include temperature control in ovens and refrigerators, pressure measurement in pipelines and weather stations, flow monitoring in water treatment plants, liquid level detection in tanks, and light sensing in cameras and streetlights.

Q 3. What are the different communication protocols used in industrial automation?

Industrial automation utilizes various communication protocols to exchange data between devices. The choice depends on factors such as speed, distance, reliability, and cost. Some common protocols include:

- Profibus: A fieldbus used extensively in process automation for connecting sensors, actuators, and PLCs. It offers high speed and reliability.

- Ethernet/IP: A widely used industrial Ethernet protocol offering high bandwidth and flexibility. It’s increasingly prevalent due to its ability to integrate various devices and its familiarity to IT personnel.

- Modbus: A simple, robust, and widely supported serial communication protocol used in various industrial applications for communication between PLCs and other devices.

- Profinet: Another popular industrial Ethernet protocol that integrates seamlessly with Siemens automation systems. Offers real-time capabilities.

- CAN (Controller Area Network): Often found in automotive and embedded systems, suitable for applications needing robustness and deterministic communication.

Example: A manufacturing plant may use Profibus to connect sensors and actuators on the factory floor to PLCs, while Ethernet/IP is used for higher-level communication between PLCs and a SCADA system.

Q 4. Explain the function of a Programmable Logic Controller (PLC).

A Programmable Logic Controller (PLC) is an industrial computer designed for automation applications. It’s a ruggedized, reliable device that receives input from sensors, processes this information according to a programmed logic, and sends output commands to actuators. Think of it as the brain of a machine or process.

Function: A PLC uses a programming language (like Ladder Logic) to define the relationships between inputs and outputs. For example, if a temperature sensor (input) detects a temperature exceeding a threshold, the PLC might activate a cooling system (output). PLCs handle tasks like monitoring, controlling, and coordinating industrial processes, often in harsh environments. They’re highly reliable and easily reprogrammed to adapt to changing requirements.

Example: In a bottling plant, a PLC monitors sensor data (e.g., bottle level, cap presence, fill level) to control the filling, capping, and labeling processes. If a bottle isn’t properly filled, the PLC rejects it.

Q 5. How does a Supervisory Control and Data Acquisition (SCADA) system work?

A Supervisory Control and Data Acquisition (SCADA) system is a software and hardware system used to monitor and control industrial processes, often spread over large geographical areas. It provides a centralized view of multiple PLCs and other equipment.

How it Works: SCADA systems collect data from PLCs, remote terminal units (RTUs), and other devices through communication networks. This data is presented via a human-machine interface (HMI), which provides operators with real-time information and control capabilities. Operators can view process variables (e.g., temperature, pressure, flow), receive alarms, and make adjustments to maintain optimal operation. SCADA systems often include features such as data logging, historical trending, and reporting.

Example: A power utility uses a SCADA system to monitor voltage levels, power generation, and distribution across its entire network. Operators can remotely control generators, switchgear, and other equipment to ensure reliable power delivery.

Q 6. Describe different types of industrial networks (e.g., Profibus, Ethernet/IP).

Industrial networks connect various devices in an automation system. Different networks offer different capabilities and are chosen based on needs:

- Profibus: A fieldbus offering high speed and reliability, suitable for real-time control applications in process automation. It uses a master-slave architecture.

- Ethernet/IP: An industrial Ethernet protocol, highly flexible and scalable, allowing for easy integration of various devices. It uses TCP/IP for communication.

- Profinet: Another industrial Ethernet protocol developed by Siemens, known for its real-time capabilities and seamless integration within Siemens automation systems.

- Modbus TCP/IP: A variation of the Modbus protocol that leverages Ethernet for communication, extending its reach and scalability.

- Foundation Fieldbus: A digital fieldbus emphasizing process automation and sophisticated device integration.

Example: A large manufacturing facility might use Ethernet/IP for high-speed data exchange between PLCs and servers and Profibus for real-time control of individual machines.

Q 7. What is signal conditioning and why is it necessary?

Signal conditioning is the process of modifying a sensor’s output signal to make it suitable for use by other instrumentation components. Raw sensor signals are often weak, noisy, or incompatible with the input requirements of data acquisition systems.

Why it’s Necessary: Signal conditioning addresses various issues:

- Amplification: Weak signals from sensors are amplified to a usable level.

- Filtering: Noise (random fluctuations) is removed or reduced using filters.

- Linearization: Many sensors have non-linear responses; linearization techniques convert this non-linear output to a linear one for easier processing.

- Isolation: Isolation techniques prevent ground loops and protect equipment from high voltages.

- Conversion: Analog signals might need to be converted to digital form (ADC) for digital processing or vice-versa (DAC).

Example: A thermocouple produces a small mV-level signal that is amplified and filtered to remove noise before being converted to a digital value by an ADC for processing by a PLC. Without signal conditioning, the weak and noisy thermocouple signal would be unreliable and unsuitable for processing.

Q 8. Explain the concept of feedback control and its importance.

Feedback control is a fundamental concept in automation where the output of a system is measured and used to adjust the input, maintaining a desired setpoint. Think of it like a thermostat: it measures the room temperature (output) and adjusts the heating/cooling (input) to keep the temperature at your desired setting (setpoint).

Its importance lies in maintaining stability, accuracy, and efficiency. Without feedback, a system would be open-loop, prone to significant variations and potentially dangerous deviations from the desired operating conditions. For example, in a chemical reactor, precise temperature control is crucial for safety and product quality. Feedback control ensures that any temperature fluctuations are quickly corrected, preventing runaway reactions or degradation of the product.

A simple example is a PID (Proportional-Integral-Derivative) controller. It uses three terms: Proportional action (responds to the current error), Integral action (compensates for accumulated error), and Derivative action (predicts future error based on the rate of change). This combination provides robust and accurate control.

Q 9. How do you troubleshoot a faulty instrument in a process control system?

Troubleshooting a faulty instrument involves a systematic approach. First, I’d visually inspect the instrument for obvious issues like loose connections, physical damage, or indicator lights suggesting a problem. Then, I’d check the instrument’s calibration, comparing its readings against a known standard. A deviation beyond the acceptable tolerance indicates a calibration issue.

Next, I’d examine the instrument’s wiring and connections, ensuring continuity and proper grounding. This often involves using a multimeter to measure voltage, current, and resistance at various points in the circuit. I would also check the instrument’s power supply to make sure it is receiving the correct voltage and current.

If the problem persists, I would consult the instrument’s documentation for troubleshooting guides and diagnostic codes. Many instruments provide self-diagnostic capabilities, indicating the specific fault. Finally, if the issue cannot be resolved, I might need to replace the faulty component or contact technical support for further assistance. Documentation throughout the process is crucial for future reference.

Q 10. What are the different types of control valves and their characteristics?

Control valves are crucial components in process control, regulating the flow of fluids or gases. Several types exist, each with unique characteristics:

- Globe Valves: These are widely used due to their simplicity and versatility. They use a plug or ball to restrict flow. They are good for throttling (precise flow control) but can exhibit higher pressure drops.

- Ball Valves: These offer on/off or quick-opening control. They are relatively inexpensive but not ideal for precise flow regulation.

- Butterfly Valves: These utilize a rotating disc to control flow. They’re compact and provide quick on/off control, suitable for large-diameter pipelines. They are not suitable for precise throttling and may exhibit higher wear.

- Diaphragm Valves: These are commonly used for corrosive or viscous fluids. The diaphragm isolates the valve internals from the process fluid, increasing its lifespan. However, they might exhibit lower flow capacity compared to others.

- Pinch Valves: These utilize a flexible sleeve to pinch off the flow, offering good on/off control and ability to handle slurries.

The selection of a specific valve type depends on factors such as the application’s specific needs (flow rate, pressure, fluid properties, and control requirements), cost considerations, and maintenance requirements.

Q 11. Describe the different types of transducers used in measurement systems.

Transducers are devices that convert one form of energy into another, enabling the measurement of physical parameters. Common types include:

- Thermocouples: These convert temperature differences into voltage. They are rugged, widely used, and available in various ranges.

- Resistance Temperature Detectors (RTDs): These measure temperature by sensing changes in electrical resistance. They offer high accuracy and stability.

- Thermistors: These are semiconductor devices whose resistance changes significantly with temperature. They are very sensitive but have a limited temperature range.

- Strain Gauges: These measure strain (deformation) by detecting changes in electrical resistance when stretched or compressed. Widely used in load cells and pressure sensors.

- Pressure Transducers: Many types exist, such as piezoelectric (convert pressure to electric charge), capacitive (change in capacitance), and potentiometric (change in resistance). These measure pressure.

- Flowmeters: Various flowmeters exist, including orifice plates (measure pressure drop), rotameters (variable area flow meters), and ultrasonic flowmeters (measure flow velocity using sound waves).

- Level Sensors: These detect the level of fluids in tanks, using methods such as ultrasonic, capacitive, or float-based techniques.

The choice of transducer depends on the parameter being measured, the required accuracy, the operating conditions (temperature, pressure), and cost.

Q 12. Explain the concept of calibration and its importance in instrumentation.

Calibration is the process of comparing an instrument’s readings to a known standard, adjusting it to ensure accurate measurements. It’s like verifying a weighing scale using known weights. Without calibration, instruments can drift from their true values, leading to inaccurate data and potentially costly errors or safety hazards.

Importance:

- Ensures Accuracy: Calibration verifies the instrument’s accuracy, making sure it produces reliable results.

- Reduces Errors: By correcting for drift and inaccuracies, calibration minimizes errors in measurements.

- Enhances Safety: In critical applications (e.g., chemical plants), inaccurate measurements can compromise safety. Calibration is crucial to prevent accidents.

- Meets Standards: Many industries have regulations requiring regular calibration for compliance and traceability.

Calibration procedures typically involve comparing the instrument’s readings against certified standards, documenting the deviations, and making adjustments to minimize errors. Calibration intervals depend on the instrument’s type, usage frequency, and environmental conditions.

Q 13. What are the different types of data acquisition systems?

Data acquisition systems (DAS) collect, convert, and store data from various sources. Types include:

- Standalone DAS: These are self-contained units with built-in signal conditioning, analog-to-digital conversion (ADC), and storage capabilities. They are typically used for smaller applications.

- PC-based DAS: These systems use a computer as the central processing unit. They offer greater flexibility and processing power, ideal for complex applications with large datasets.

- Modular DAS: These use interchangeable modules for different signal types, allowing for customization based on the specific needs of the application. They offer greater scalability and versatility.

- Wireless DAS: These use wireless communication to transmit data, offering increased flexibility in data collection from remote locations. They are increasingly used for remote monitoring and control.

The choice of a DAS depends on factors like the number of channels, required sampling rate, data storage requirements, and the complexity of the application.

Q 14. How do you ensure the safety and integrity of a communication network?

Ensuring the safety and integrity of a communication network requires a multi-layered approach. Key aspects include:

- Network Security: Implementing firewalls, intrusion detection systems, and access control measures to prevent unauthorized access and malicious attacks.

- Data Encryption: Encrypting data transmitted over the network to protect it from eavesdropping and unauthorized access. Protocols like TLS/SSL are crucial.

- Redundancy and Failover: Employing redundant network components (routers, switches) and failover mechanisms to ensure continuous operation in case of component failure. This maintains the system’s availability.

- Network Monitoring: Continuously monitoring network performance and security using tools that detect anomalies and potential problems. Early detection is crucial for timely intervention.

- Regular Updates and Patches: Keeping network software and firmware up-to-date to address security vulnerabilities and improve stability. This minimizes the risks of exploits.

- Physical Security: Protecting network infrastructure from physical damage or unauthorized access through measures like locked server rooms and physical security systems.

A robust security plan requires collaboration between IT, engineering, and operations teams to ensure comprehensive protection of the communication network.

Q 15. Explain the concept of redundancy in instrumentation and control systems.

Redundancy in instrumentation and control systems is the practice of incorporating backup components or systems to ensure continued operation even if one part fails. Think of it like having a spare tire in your car – you don’t need it until you get a flat, but when you do, it’s invaluable. In industrial settings, this is crucial for safety, reliability, and preventing costly downtime.

Redundancy can be implemented in various ways:

- Hardware Redundancy: Having duplicate sensors, actuators, or controllers. If one fails, the other takes over seamlessly.

- Software Redundancy: Using multiple software programs or algorithms to perform the same function. If one fails, the other ensures continuous operation.

- System-Level Redundancy: Employing entirely separate control systems that monitor each other. One system acts as a backup for the other.

Example: In a chemical plant, redundant pressure sensors might be used to monitor a critical vessel. If one sensor fails, the other continues to provide accurate pressure readings, preventing potential hazards. This ensures safety and allows for continued operation while the failed sensor is repaired or replaced.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of noise in instrumentation systems and how to mitigate them?

Noise in instrumentation systems refers to unwanted signals that interfere with the accurate measurement or transmission of data. These signals can originate from various sources, degrading the quality and reliability of the measurements.

- Electromagnetic Interference (EMI): This is a common culprit, often stemming from nearby electrical equipment, power lines, or even radio waves. EMI can induce unwanted voltages or currents in the signal wires, distorting the measured data.

- Ground Loops: Differences in ground potential between different parts of the system can create circulating currents, which appear as noise.

- Thermal Noise: This is a random fluctuation of electrons in conductors due to their thermal energy. It’s an inherent characteristic of electronic components and is amplified at higher temperatures.

- Environmental Noise: Physical vibrations, temperature fluctuations, or pressure changes can directly affect sensors and introduce noise into measurements.

Mitigation Techniques:

- Shielding: Using conductive enclosures or shielding cables to minimize the impact of EMI.

- Grounding: Establishing a common ground point for all components to eliminate ground loops.

- Filtering: Employing electronic filters to remove unwanted frequency components from the signal.

- Signal Conditioning: Amplifying or attenuating the signal to improve the signal-to-noise ratio.

- Signal Averaging: Taking multiple measurements and averaging them to reduce the effect of random noise.

Example: In a temperature measurement application, a shielded thermocouple with proper grounding would help mitigate noise from nearby motors or power supplies. Using a low-pass filter can further reduce high-frequency noise components.

Q 17. Explain the role of a Human-Machine Interface (HMI) in process control.

A Human-Machine Interface (HMI) is the bridge between human operators and the automated control system. It’s essentially the control panel or graphical display that allows operators to monitor and control industrial processes. It’s vital for efficient and safe operation.

Role in Process Control:

- Monitoring: HMIs display real-time data from sensors and other instruments, providing operators with a clear overview of the process. This includes variables like temperature, pressure, flow rate, and level.

- Control: Operators can use the HMI to adjust setpoints, start or stop processes, and make adjustments to control parameters.

- Alarm Management: HMIs alert operators to critical events, deviations from normal operating conditions, or potential safety hazards.

- Data Logging and Reporting: They can record process data for analysis, troubleshooting, and compliance purposes.

- Troubleshooting and Diagnostics: HMIs often provide tools to aid in diagnosing system problems.

Example: In a power plant, the HMI might display the temperature and pressure of various components, allowing operators to monitor the efficiency of turbines and generators. If the temperature exceeds a predefined threshold, the HMI will issue an alarm, allowing the operator to take corrective action.

Q 18. What are the different types of loop controllers and their functionalities?

Loop controllers are the core of many automated control systems. They automatically adjust control elements to maintain a desired process variable (e.g., temperature, pressure, flow) at a setpoint.

- Proportional (P) Controller: The controller output is proportional to the error (difference between the setpoint and the measured value). A larger error results in a larger corrective action. Simple to implement but can suffer from offset (steady-state error).

- Integral (I) Controller: The controller output is proportional to the integral of the error over time. This eliminates offset by continuously adjusting the output until the error is zero. Can be slow to respond to sudden changes.

- Derivative (D) Controller: The controller output is proportional to the rate of change of the error. This anticipates future errors and improves stability and responsiveness. Can amplify high-frequency noise.

- Proportional-Integral (PI) Controller: Combines the advantages of P and I controllers. Offers good stability and eliminates offset.

- Proportional-Integral-Derivative (PID) Controller: The most common type, combines P, I, and D control actions for optimal performance. Offers precise control and handles a wide range of disturbances effectively.

Functionalities: Each type adjusts the control element (e.g., valve, heater) to minimize the error between the measured process variable and the desired setpoint. The choice of controller type depends on the specific application and its characteristics (response time, stability requirements, etc.).

Q 19. Describe your experience with different types of fieldbuses.

My experience encompasses several fieldbus technologies, each with its own strengths and weaknesses. Fieldbuses are digital communication networks used to connect field instruments (sensors, actuators) to the control system.

- Profibus: A widely used fieldbus for industrial automation. It offers high speed and reliability, often found in process automation and factory automation.

- Profinet: An Ethernet-based fieldbus, providing high bandwidth and excellent performance for demanding applications. Suitable for real-time communication and complex systems.

- Modbus: A simple, widely adopted serial communication protocol. Cost-effective but may have limitations in speed and complexity compared to other fieldbuses.

- Foundation Fieldbus: A high-level fieldbus suitable for complex process control applications. Provides features like digital control algorithms and advanced diagnostics in the field devices.

- EtherCAT: An Ethernet-based fieldbus known for its high speed and deterministic communication. Ideal for applications requiring fast response times, like robotics and machine control.

In my projects, I’ve used these fieldbuses to integrate various sensors, actuators, and controllers into centralized control systems. Selecting the appropriate fieldbus depends on factors like the application’s communication speed, network size, and budget. Experience in troubleshooting and configuring these different technologies is crucial for ensuring efficient system operation.

Q 20. Explain the concept of PID control and its tuning methods.

PID control is a widely used feedback control algorithm that adjusts a control element to maintain a desired process variable at a setpoint. It’s a cornerstone of industrial automation.

Concept: The PID controller calculates an error signal which is the difference between the setpoint and the actual measured value. This error signal is then used to calculate three control actions: Proportional, Integral, and Derivative.

- Proportional (P): The output is proportional to the error. A larger error results in a larger corrective action. Simple, but can have offset.

- Integral (I): The output is proportional to the integral of the error over time. Eliminates the offset present in P controllers.

- Derivative (D): The output is proportional to the rate of change of the error. Anticipates future errors, improves stability and reduces overshoot.

Tuning Methods: Proper tuning is vital for optimal PID controller performance. Methods include:

- Ziegler-Nichols Method: A simple tuning method that involves pushing the system to its limits to determine controller parameters. It’s quick but can be less precise.

- Cohen-Coon Method: Another empirical method that provides stable controller settings but requires process knowledge.

- Auto-tuning: Some controllers have built-in auto-tuning features that automatically determine optimal parameters based on the process response.

- Manual Tuning: Involves systematically adjusting the PID gains (Kp, Ki, Kd) to observe the system’s response and fine-tune the controller. Requires knowledge and experience.

Effective PID tuning minimizes overshoot, settling time, and steady-state error, leading to efficient and stable process control.

Q 21. How do you handle data from various sources and integrate them into a control system?

Integrating data from diverse sources into a control system requires a structured approach that handles various communication protocols and data formats.

Steps Involved:

- Data Acquisition: This involves using appropriate hardware and software to collect data from different sources. This may include using various fieldbuses (as discussed earlier), OPC servers (for accessing PLCs and other devices), or custom interfaces for specialized equipment.

- Data Conversion: Data often arrives in different formats (analog, digital, various units). Data conversion is necessary to ensure consistency and compatibility within the system. This may involve scaling, unit conversion, filtering, and error handling.

- Data Aggregation: Centralizing data from multiple sources requires a robust data historian or database. This provides a unified view of the entire system and enables efficient analysis and reporting.

- Data Validation: Verifying the accuracy and reliability of data is essential. This can involve plausibility checks, error detection, and data reconciliation techniques.

- Data Integration: The data is integrated into the control system, which may be a supervisory control and data acquisition (SCADA) system, distributed control system (DCS), or programmable logic controller (PLC). This allows for real-time monitoring, control, and decision-making.

Example: In a smart manufacturing facility, data might be collected from robots, PLCs, sensors, and ERP systems. A data historian would aggregate this data, providing a unified view of the production process. The integrated data can be used for real-time monitoring, predictive maintenance, and optimizing production efficiency. This integration requires knowledge of various communication protocols, databases, and data analysis techniques.

Q 22. What is your experience with different types of industrial communication protocols (e.g., Modbus, OPC UA)?

My experience encompasses a wide range of industrial communication protocols, crucial for seamless data exchange in automation systems. I’ve extensively worked with Modbus, a widely adopted serial communication protocol known for its simplicity and robustness, primarily used for supervisory control and data acquisition (SCADA) systems in applications like monitoring and controlling temperature and pressure in a manufacturing process. I’ve used Modbus RTU and Modbus TCP, understanding the differences between them, especially the impact on network architecture and data transmission speed.

Furthermore, I possess significant experience with OPC UA (Unified Architecture), a modern, platform-independent protocol offering enhanced security and interoperability. I’ve used OPC UA in complex systems integrating diverse equipment from different vendors, leveraging its ability to handle large amounts of data efficiently and securely. This often involved configuring OPC UA servers and clients, setting up secure communication channels, and troubleshooting connectivity issues. For example, I recently implemented OPC UA in a project involving a robotic arm, a programmable logic controller (PLC), and a historian, ensuring smooth data flow between these disparate systems.

My experience also includes exposure to other protocols such as Profibus, Profinet, and EtherCAT, each with its own strengths and weaknesses depending on the specific application and requirements. I understand the tradeoffs involved in selecting the appropriate protocol for a given project, considering factors like speed, reliability, cost, and security.

Q 23. Explain your experience with cybersecurity in industrial automation systems.

Cybersecurity is paramount in industrial automation, given the potential consequences of a successful attack. My approach involves a multi-layered defense strategy. This begins with network segmentation, isolating critical systems from less sensitive ones to limit the impact of a breach. I utilize firewalls and intrusion detection systems (IDS) to monitor network traffic and detect suspicious activity.

Furthermore, I am experienced in implementing robust authentication and access control mechanisms, ensuring only authorized personnel can access critical systems. This includes implementing strong passwords, multi-factor authentication, and role-based access control (RBAC). Regular security audits and vulnerability assessments are crucial, and I actively participate in such efforts. My experience also includes working with industrial control system (ICS) specific security standards like ISA/IEC 62443, which provides a framework for securing industrial control systems.

Finally, I emphasize employee training as a fundamental aspect of cybersecurity. Raising awareness of phishing attacks and other social engineering techniques is essential to prevent vulnerabilities from being exploited. For instance, in a previous project, we experienced a near-miss phishing attack that targeted the engineering team. We quickly implemented additional security awareness training, and subsequently, implemented phishing simulations to further strengthen our defenses.

Q 24. Describe your experience with commissioning and testing of instrumentation and control systems.

Commissioning and testing are critical phases, ensuring the instrumentation and control systems function as designed. My approach is systematic and follows a well-defined process. It begins with a thorough review of the design documents, ensuring a clear understanding of the system’s architecture and functionality. This is followed by a detailed inspection of the installed equipment, verifying its proper configuration and wiring.

Loop testing is a key part of the process, systematically verifying each control loop’s functionality. This often involves using dedicated test equipment to simulate process variables and monitor the controller’s response. Functional testing involves validating the system’s overall performance against the defined specifications. This might include running simulations or performing real-world tests under various operating conditions. Documentation is critical throughout the entire commissioning process, ensuring that all tests and results are properly recorded.

For example, in a recent project involving a water treatment plant, I meticulously tested each level sensor, flow meter, and valve actuator, ensuring their accuracy and responsiveness. The functional testing involved running the system under various scenarios, simulating different water flow rates and quality levels to validate its performance and reliability. Any issues discovered during commissioning were thoroughly documented and resolved before system handover.

Q 25. How do you ensure data integrity and reliability in a real-time control environment?

Data integrity and reliability are crucial in real-time control environments, directly impacting operational efficiency and safety. My approach involves implementing several strategies. Firstly, redundancy is critical. This might involve using dual sensors, controllers, or communication networks, ensuring that if one component fails, there’s a backup to maintain continuous operation.

Data validation is crucial; input values should be checked for plausibility and consistency before being used in control algorithms. This involves implementing limit checks, range checks, and consistency checks to detect and filter out erroneous data. Data logging and archiving are also vital, maintaining a comprehensive record of all process data. This allows for data analysis, trend identification, and troubleshooting in case of issues.

Regular system calibration is essential to ensure the accuracy of measurement instruments. A well-defined calibration schedule should be established, and the calibration results meticulously documented. Using secure communication protocols like OPC UA with robust digital signatures also ensures data integrity during transmission.

Q 26. Explain your problem-solving approach in a complex instrumentation and control scenario.

My problem-solving approach in complex instrumentation and control scenarios is systematic and data-driven. I begin by clearly defining the problem, gathering all relevant information, including process data, alarm logs, and equipment documentation.

Next, I develop a hypothesis based on the gathered information. This may involve analyzing trends in process data, examining alarm history, or consulting with other engineers. Testing the hypothesis is the next step. This may involve modifying system parameters, performing simulations, or implementing temporary workarounds. The results of the tests are carefully analyzed and documented.

Finally, I implement the solution, carefully documenting all changes and performing thorough testing to ensure the problem is resolved and does not introduce new issues. For example, during a recent project, we experienced inconsistent readings from a flow meter. By systematically analyzing data, conducting on-site tests and using specialized tools, I identified the problem as a faulty calibration and replaced it.

Q 27. What are your experiences with different programming languages used in industrial automation?

My experience includes several programming languages commonly used in industrial automation. I’m proficient in ladder logic (used extensively in PLCs), often using Rockwell Automation’s RSLogix 5000 or Siemens TIA Portal. I am also skilled in Structured Text, a high-level language used for more complex control algorithms within PLCs.

I’ve also worked with C# and C++, especially in developing SCADA applications and custom interfaces. Python’s versatility is also valuable in automating tasks, analyzing data, and creating custom scripts for data processing and visualization. My experience with these languages allows me to adapt to different project requirements and utilize the most appropriate language for the task at hand.

For instance, I recently used Python to develop a script for automatically generating reports based on data from a PLC. This automated task that previously required manual effort and minimized the risk of human error. The ability to seamlessly transition between these programming languages greatly enhances my problem-solving capability and project delivery.

Q 28. Explain your experience with preventative maintenance of instrumentation and control systems.

Preventative maintenance is crucial for maximizing the lifespan and reliability of instrumentation and control systems. My approach is proactive and risk-based. It starts with developing a comprehensive maintenance plan that outlines the schedule for routine inspections, calibrations, and repairs for all equipment. This plan considers the criticality of each instrument and the potential impact of its failure.

Regular inspections involve visually checking equipment for signs of wear and tear, ensuring proper functionality and identifying potential problems early. Calibration procedures are carefully followed to ensure the accuracy of measurement instruments. This usually involves using certified calibration equipment and following established procedures.

Predictive maintenance techniques, such as vibration analysis and thermal imaging, can be utilized to identify potential problems before they lead to failures. All maintenance activities are carefully documented, providing a history of maintenance performed and assisting in predicting future needs. A well-structured preventative maintenance program is fundamental to a stable and reliable operation, minimizing downtime and extending the life cycle of equipment.

Key Topics to Learn for Communication and Instrumentation Systems Interview

- Data Acquisition and Signal Conditioning: Understanding sensor technologies, signal processing techniques (filtering, amplification), and analog-to-digital conversion (ADC) is crucial. Consider practical applications like designing a system to measure temperature and pressure in a remote environment.

- Industrial Communication Protocols: Mastering protocols like Modbus, Profibus, Ethernet/IP, and others is essential for understanding how various instruments communicate within a system. Explore real-world examples of integrating different instruments in a manufacturing setting.

- Network Topologies and Architectures: Familiarize yourself with different network structures (bus, star, ring) and their implications for reliability and efficiency in instrumentation systems. Consider the challenges and benefits of each topology in a large-scale industrial control system.

- Control System Design and Implementation: Understand basic control theory concepts (PID control, feedback loops), and how they apply to real-world systems. Analyze examples of designing and implementing control systems for automated processes.

- Troubleshooting and Diagnostics: Develop your skills in identifying and resolving issues in communication and instrumentation systems. Practice diagnosing faults using diagnostic tools and techniques.

- Safety and Reliability: Understand the importance of safety standards and best practices in the design and operation of instrumentation systems. Explore examples of safety protocols and their applications in hazardous environments.

- Cybersecurity in Industrial Control Systems (ICS): Become familiar with common vulnerabilities and security measures in ICS environments. Discuss potential threats and mitigation strategies.

Next Steps

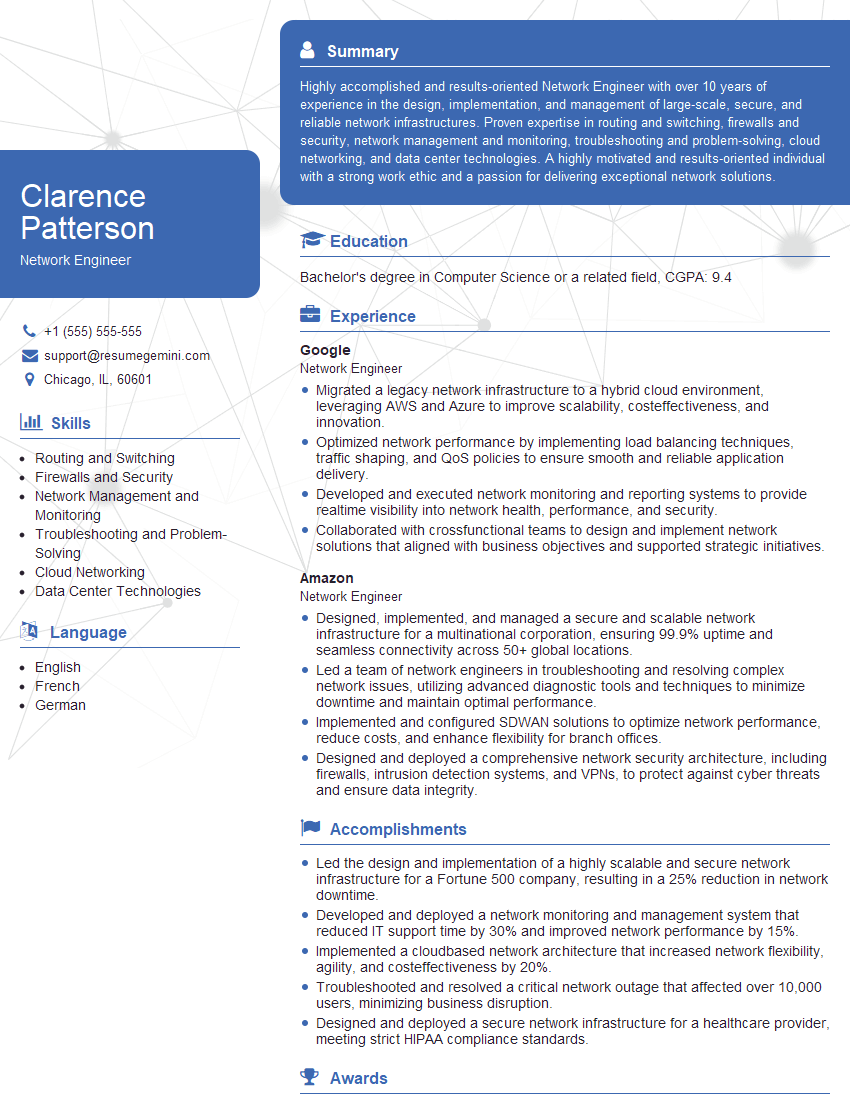

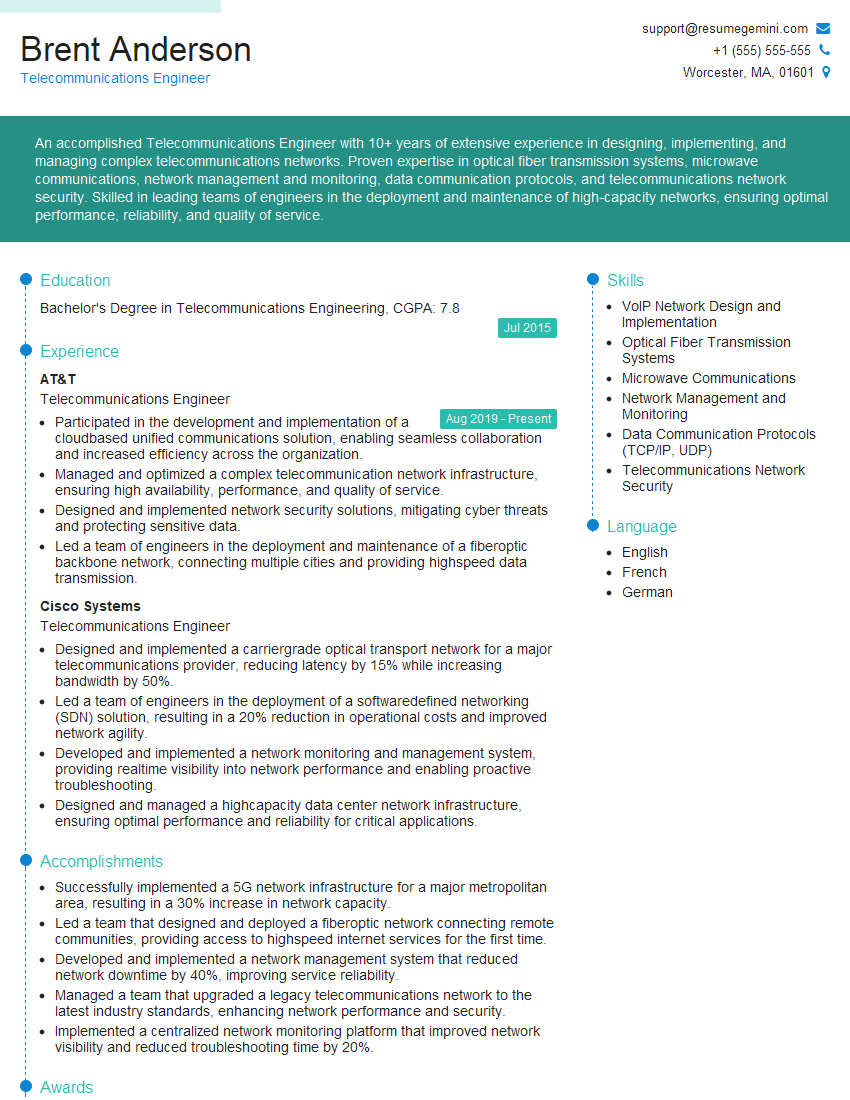

Mastering Communication and Instrumentation Systems opens doors to exciting careers in diverse industries, offering opportunities for innovation and problem-solving. A strong foundation in these areas will significantly enhance your career prospects and allow you to contribute meaningfully to advanced technological projects. To maximize your chances, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out. Examples of resumes tailored to Communication and Instrumentation Systems are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.