Unlock your full potential by mastering the most common Maintenance Coordination and Supervision interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Maintenance Coordination and Supervision Interview

Q 1. Describe your experience with CMMS software.

My experience with CMMS (Computerized Maintenance Management System) software spans over eight years, encompassing various systems like IBM Maximo, SAP PM, and UpKeep. I’m proficient in utilizing these platforms for work order management, preventive maintenance scheduling, inventory control, and generating insightful reports. For instance, in my previous role at a manufacturing plant, I implemented UpKeep to streamline our maintenance processes. This resulted in a 15% reduction in downtime by efficiently tracking and managing work orders, ensuring timely completion of preventative maintenance, and providing real-time visibility into equipment status.

Beyond basic functionalities, I’m skilled in customizing CMMS systems to meet specific organizational needs. This includes configuring workflows, creating custom reports, and integrating the system with other enterprise software. For example, at another company, I integrated our CMMS with our ERP system, enabling seamless data flow between maintenance and production, leading to improved resource allocation and enhanced operational efficiency.

Q 2. How do you prioritize maintenance tasks?

Prioritizing maintenance tasks requires a structured approach balancing urgency and impact. I use a system combining several factors: Criticality (how vital is the equipment to operations?), Urgency (how imminent is the failure?), and Cost (repair vs. replacement costs). I often employ a matrix that visually represents these factors, allowing for quick assessment and prioritization. For instance, a critical piece of equipment showing signs of imminent failure (high criticality and urgency) would naturally take precedence over a less critical piece requiring routine maintenance.

Furthermore, I consider factors like safety, regulatory compliance, and production schedules. A task posing a safety risk will always be prioritized, even if its impact on production is seemingly lower. I regularly review and adjust priorities based on changing operational needs and unforeseen circumstances. For example, a sudden power outage might require immediate attention to a backup generator, shifting the priorities temporarily.

Q 3. Explain your approach to preventive maintenance scheduling.

My approach to preventive maintenance scheduling centers around risk mitigation and maximizing equipment lifespan. I start by analyzing equipment failure history, manufacturer recommendations, and industry best practices to determine optimal maintenance intervals. This involves creating a detailed preventive maintenance schedule encompassing routine inspections, lubrication, and part replacements. We use both time-based and condition-based monitoring methods. Time-based involves scheduled maintenance at predetermined intervals (e.g., oil changes every 3 months). Condition-based involves monitoring equipment performance parameters (e.g., vibration analysis) to trigger maintenance only when needed, optimizing maintenance costs and minimizing disruption.

I leverage the CMMS system to automate scheduling, send reminders, and track completed tasks. The schedule is dynamically updated based on actual performance and identified issues during inspections. Regular review and refinement of the schedule are key, ensuring it remains effective and aligned with evolving operational needs. For example, we might adjust the frequency of inspections for a piece of equipment that has shown a higher-than-average failure rate in the past.

Q 4. How do you manage a team of maintenance technicians?

Managing a team of maintenance technicians requires strong leadership, clear communication, and a focus on teamwork. I foster a collaborative environment where technicians feel valued and empowered. This involves regular team meetings to discuss challenges, share best practices, and address concerns. I delegate tasks based on individual skills and experience, ensuring everyone has opportunities for growth and development. I provide ongoing training and mentorship to enhance their technical skills and problem-solving abilities. This might involve sponsoring them for specialized certifications or sending them to workshops.

Performance monitoring is crucial. I regularly track individual performance metrics (e.g., completion rates, adherence to safety protocols) and provide constructive feedback. Regular performance reviews are conducted, recognizing achievements and addressing areas for improvement. Open communication channels ensure that any issues or concerns are promptly addressed. For example, I encourage technicians to report any safety hazards or equipment malfunctions immediately.

Q 5. What metrics do you use to measure maintenance performance?

Measuring maintenance performance requires a multifaceted approach, using key performance indicators (KPIs) tailored to specific organizational goals. Some crucial metrics include Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR), equipment uptime, maintenance costs per unit produced, and safety incident rates. MTBF measures the average time between equipment failures; a higher MTBF indicates improved reliability. MTTR measures the average time taken to restore equipment to operational status; a lower MTTR indicates faster repair times. Equipment uptime is the percentage of time equipment is operational, reflecting overall maintenance efficiency.

These KPIs, tracked through the CMMS system, provide insights into maintenance effectiveness and highlight areas for improvement. For instance, consistently high MTTR might indicate a need for additional training or improved parts management. Regular analysis of these metrics allows for data-driven decision-making and continuous improvement in maintenance strategies. We use these metrics not only for evaluation but also to set targets for future performance and to justify budget allocations.

Q 6. How do you handle emergency maintenance requests?

Handling emergency maintenance requests requires a swift and effective response mechanism. We have established a prioritized escalation process to ensure immediate attention to critical situations. This process involves a dedicated emergency contact line, a rapid response team, and a well-defined procedure for assessment and repair. The CMMS system plays a crucial role in tracking emergency work orders, allocating resources, and documenting the repair process. Our system sends out immediate notifications to the relevant technicians, outlining the situation and required actions.

After the immediate crisis is handled, a thorough root cause analysis is conducted to prevent similar occurrences in the future. This involves examining the circumstances that led to the emergency and implementing preventive measures to avoid recurrence. For example, if an emergency was caused by equipment wear and tear, we might adjust the preventive maintenance schedule for that equipment. We maintain a detailed log of all emergency requests, analyzing patterns to improve the overall robustness of the maintenance program.

Q 7. Describe your experience with budgeting and cost control in maintenance.

Budgeting and cost control in maintenance are paramount for efficient operation. My experience includes developing annual maintenance budgets, forecasting costs based on historical data, equipment condition assessments, and planned maintenance activities. I utilize the CMMS system to track actual spending against the budget, identifying any variances and implementing corrective actions. Cost control measures involve optimizing parts procurement through strategic sourcing, negotiating favorable contracts with suppliers, and implementing inventory management strategies to minimize waste.

Regular budget reviews are conducted to assess performance against targets and identify potential cost-saving opportunities. This might involve exploring alternative repair strategies, adopting more efficient maintenance techniques, or investing in newer technologies to reduce downtime and maintenance costs. For example, predictive maintenance technologies can help us avoid costly emergency repairs by predicting potential failures in advance. Effective cost control ensures that the maintenance budget is optimized while maintaining high levels of equipment reliability and operational efficiency.

Q 8. How do you ensure compliance with safety regulations in maintenance?

Ensuring safety compliance in maintenance is paramount. It’s not just about ticking boxes; it’s about fostering a safety-first culture. My approach is multifaceted and begins with thorough risk assessments for every task. This involves identifying potential hazards, evaluating their severity and likelihood, and implementing control measures. We use a system of Permit-to-Work (PTW) for high-risk activities, ensuring all personnel involved understand the risks and procedures. Regular safety training, including refresher courses on lockout/tagout procedures, hazard communication, and personal protective equipment (PPE) use, is mandatory. We also conduct frequent safety audits and toolbox talks to address immediate concerns and reinforce best practices. Beyond the formal processes, I encourage open communication; team members are empowered to report any unsafe conditions or practices without fear of reprisal. Finally, we meticulously document all safety incidents, analyzing root causes to prevent recurrence. For instance, a recent near-miss involving a faulty electrical panel led us to implement a more robust inspection schedule and additional training on electrical safety.

Q 9. Explain your process for identifying and addressing maintenance backlog.

Tackling maintenance backlog requires a systematic approach. Firstly, we prioritize tasks based on their criticality and impact on operations. We use a computerized maintenance management system (CMMS) to track all work orders, their status, and associated assets. This allows us to identify recurring problems, pinpoint equipment with high maintenance needs, and accurately estimate the resources required. We categorize the backlog – for example, emergency repairs, routine maintenance, and planned upgrades – and allocate resources accordingly. We also implement a robust preventive maintenance (PM) program, which significantly reduces the backlog by preventing equipment failures before they occur. We analyze historical data to predict potential failures and proactively schedule maintenance, preventing them from becoming urgent repairs. Visual management tools, like Kanban boards, help visualize the workflow, identify bottlenecks, and ensure efficient task assignment. For instance, we recently tackled a significant backlog in our HVAC system by prioritizing critical repairs first, then implementing a PM program to significantly reduce future failures.

Q 10. How do you train and develop your maintenance team?

Developing my maintenance team is an ongoing investment. We provide a blend of on-the-job training, formal courses, and mentorship programs. New hires receive comprehensive training on our CMMS, safety procedures, and specific equipment. Experienced technicians mentor junior staff, fostering knowledge transfer and skill development. We encourage participation in relevant industry certifications and offer reimbursement for training courses to enhance their technical expertise. We also focus on soft skills – communication, teamwork, and problem-solving – through workshops and team-building activities. Regular performance reviews provide feedback and identify areas for improvement. Recently, we invested in a virtual reality (VR) training program to simulate complex maintenance procedures in a safe and controlled environment, resulting in improved efficiency and reduced risk during real-world tasks.

Q 11. What is your experience with root cause analysis in maintenance?

Root cause analysis (RCA) is crucial for preventing recurring maintenance issues. I utilize various techniques, including the ‘5 Whys’ method, fault tree analysis, and fishbone diagrams. The process typically begins with clearly defining the problem. Then, we gather data from multiple sources – maintenance logs, operator reports, and even direct observation – to identify potential causes. We systematically analyze these causes to pinpoint the root cause, which often lies beyond the immediate symptoms. For instance, a recurring pump failure wasn’t due to the pump itself but rather to inadequate lubrication, stemming from a faulty lubrication system. By addressing the root cause (the lubrication system), we eliminated the recurring pump failures, saving significant time and cost. We document the RCA process and its findings, sharing them with the team to prevent similar issues in the future.

Q 12. How do you communicate effectively with stakeholders regarding maintenance issues?

Effective communication is key to managing maintenance issues. I utilize various methods to ensure all stakeholders are informed and involved. Regular status reports, both written and verbal, keep management updated on project progress and any challenges encountered. We use the CMMS to track work orders and provide real-time visibility into maintenance activities. For complex issues or emergencies, I hold meetings involving all relevant parties to collaborate on solutions. We use clear and concise language, avoiding technical jargon whenever possible, to ensure effective communication across different departments. For instance, during a recent major equipment failure, I used a combination of email updates, a detailed incident report, and a presentation to keep management, operations, and the maintenance team informed and coordinated.

Q 13. Describe a time you had to deal with a challenging maintenance situation.

One challenging situation involved a critical compressor failure during peak production. The repair required specialized parts with a long lead time, creating a significant operational risk. My first step was to conduct a thorough assessment of the damage to determine the extent of the repairs needed. Simultaneously, I worked with the procurement team to expedite the delivery of the necessary parts. I also explored temporary solutions to maintain partial production capacity. We implemented a modified operational procedure to reduce the load on other equipment and prevent further damage. The situation required constant communication and collaboration with all stakeholders to minimize downtime and its impact on production targets. Through effective communication, resource allocation, and problem-solving, we minimized the downtime and averted a major production crisis, eventually restoring full functionality within a week.

Q 14. How do you manage conflicts within your maintenance team?

Conflict resolution within the maintenance team is addressed proactively. I foster a culture of open communication and respect where team members feel comfortable expressing their concerns. When conflicts arise, I facilitate constructive dialogue, encouraging each party to express their perspective. I focus on understanding the underlying issues rather than placing blame. If necessary, I mediate discussions, helping team members find common ground and mutually acceptable solutions. We utilize team-building activities and workshops on conflict resolution techniques to strengthen interpersonal skills and prevent future conflicts. For example, a recent disagreement between two technicians regarding a repair procedure was resolved through a collaborative problem-solving session, resulting in a more efficient and safer method. The focus is always on finding solutions that improve team performance and overall efficiency.

Q 15. What is your experience with spare parts inventory management?

Effective spare parts inventory management is crucial for minimizing downtime and optimizing maintenance costs. My experience encompasses developing and implementing inventory control systems using both manual and computerized methods. This includes forecasting demand based on historical data, equipment criticality, and planned maintenance schedules. I’ve utilized various inventory management techniques, such as ABC analysis (classifying parts based on consumption value) and just-in-time (JIT) inventory, to optimize stock levels and reduce storage costs. For example, in a previous role, I implemented an ABC analysis that identified 20% of our parts accounted for 80% of our total usage. This allowed us to focus our efforts on optimizing the inventory levels of those critical parts, reducing our overall inventory holding costs by 15% while maintaining sufficient stock to avoid delays.

I’m proficient in using software solutions like ERP systems to manage inventory, track parts usage, and generate reports on stock levels and consumption trends. This allows for proactive identification of low-stock items and timely procurement to prevent delays in maintenance activities. I also have experience implementing barcode scanning and RFID tracking systems to enhance inventory accuracy and reduce manual errors.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy of maintenance records?

Ensuring the accuracy of maintenance records is paramount for effective maintenance planning and decision-making. My approach focuses on establishing a robust system that includes both digital and physical record-keeping. This begins with clear and standardized documentation procedures. Every maintenance task, from preventative maintenance to corrective repairs, should be meticulously documented. I typically use a computerized maintenance management system (CMMS) to track work orders, maintenance schedules, and parts usage. This system allows for easy retrieval of information, reducing the time spent searching for records and improving data accuracy.

Regular audits of maintenance records are crucial. These audits should compare the planned maintenance activities to the actual tasks performed, verifying that all work is correctly recorded and signed off. This also helps identify any discrepancies and implement corrective actions. Furthermore, I strongly emphasize training for maintenance personnel on proper record-keeping procedures, emphasizing the importance of detailed descriptions, accurate dates and times, and the use of standardized codes and terminology. Think of it as a rigorous scientific method: clear documentation allows for effective analysis, review, and improvement.

Q 17. How do you utilize data analytics to improve maintenance efficiency?

Data analytics plays a critical role in optimizing maintenance efficiency. By analyzing historical maintenance data, we can identify patterns, predict potential failures, and optimize maintenance strategies. I use data analytics tools to identify recurring problems, understand equipment failure rates, and assess the effectiveness of different maintenance techniques. For example, by analyzing historical data on equipment breakdowns, we can identify common failure points and implement preventative maintenance tasks to address these issues before they cause major disruptions. This proactive approach reduces downtime and improves overall equipment effectiveness (OEE).

Specific analytical techniques I utilize include:

- Predictive maintenance: Analyzing sensor data and historical trends to predict equipment failures and schedule maintenance proactively.

- Root cause analysis (RCA): Investigating the underlying causes of equipment failures to identify and implement corrective actions.

- Performance monitoring: Tracking key performance indicators (KPIs) such as Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) to assess maintenance performance and identify areas for improvement.

Q 18. What is your experience with contract management for maintenance services?

Effective contract management for maintenance services is crucial for ensuring quality, compliance, and cost control. My experience encompasses the entire contract lifecycle, from developing clear and comprehensive service level agreements (SLAs) to monitoring contractor performance and managing disputes. I focus on developing detailed SLAs that clearly define scope of work, performance metrics, payment terms, and dispute resolution mechanisms. These agreements should clearly outline the responsibilities of both the contractor and the client, minimizing ambiguity and potential conflicts.

Regular monitoring of contractor performance is crucial. This involves tracking key performance indicators (KPIs) defined in the SLA, conducting regular site visits to assess the quality of work, and reviewing contractor reports. I use a structured system for tracking compliance against the SLA, highlighting any areas where improvements are needed. Strong communication with contractors is essential to ensure alignment on project goals and to promptly address any issues that arise. For example, a weekly progress report from the contractor accompanied by site visits and detailed reviews ensures the project stays on track and that quality standards are met.

Q 19. Describe your process for developing and implementing maintenance procedures.

Developing and implementing maintenance procedures involves a structured approach that starts with a thorough understanding of the equipment and its operational needs. This includes analyzing equipment documentation, conducting site surveys, and interviewing operators to identify potential failure points and maintenance requirements. Once this information is gathered, a detailed maintenance plan is developed, outlining preventative maintenance tasks, corrective maintenance procedures, and safety protocols. This plan should clearly define the tasks, required tools, materials, and responsible personnel.

The procedures are then documented in a clear, concise, and easy-to-understand format. This may involve using visual aids like diagrams and flowcharts. Crucially, the procedures are tested and refined through pilot implementation before full rollout. Feedback from maintenance personnel is crucial in identifying areas for improvement and ensuring the procedures are practical and effective. Once finalized, the procedures are distributed to relevant personnel, and training is provided to ensure understanding and adherence. A system for tracking the effectiveness of the procedures and making updates as needed is also essential. This iterative process ensures the maintenance procedures remain accurate, efficient, and effective over time.

Q 20. How do you handle vendor relationships related to maintenance?

Managing vendor relationships for maintenance requires a collaborative and strategic approach. I focus on building strong, mutually beneficial relationships with vendors based on trust, transparency, and clear communication. This starts with a thorough vendor selection process that considers factors such as experience, qualifications, pricing, and reliability. Once a vendor is selected, a clear contract outlining scope of work, payment terms, and performance expectations is established.

Regular communication and performance monitoring are key. This involves regular meetings to review progress, address concerns, and discuss potential improvements. Performance is tracked against KPIs defined in the contract, and regular feedback is provided to vendors. Addressing issues promptly and constructively is essential for maintaining strong vendor relationships. A system for evaluating vendor performance and providing feedback allows for continuous improvement and the selection of high-performing vendors in the future. Think of it as a partnership – a strong vendor relationship helps ensure reliable maintenance services and helps drive down costs in the long term.

Q 21. Explain your experience with different maintenance strategies (e.g., RCM, TPM).

My experience encompasses various maintenance strategies, including Reliability-Centered Maintenance (RCM) and Total Productive Maintenance (TPM). RCM is a proactive approach that focuses on identifying critical equipment and implementing maintenance strategies to optimize equipment reliability and minimize downtime. This involves analyzing equipment functions, failure modes, and consequences to determine the most effective maintenance tasks. For example, using RCM, we might identify that a specific component failure on a critical piece of equipment would lead to significant production losses. Therefore, we would prioritize preventative maintenance on that component to avoid such a failure.

TPM, on the other hand, is a holistic approach that involves all employees in maintaining equipment and improving overall equipment effectiveness. This includes implementing preventative maintenance procedures, training personnel on equipment operation and maintenance, and fostering a culture of continuous improvement. For instance, implementing TPM could include regular equipment inspections by operators, empowering them to identify minor issues before they escalate into major problems. This collaborative approach reduces downtime, improves product quality, and enhances the overall efficiency of the operation. I’ve successfully implemented both strategies in various settings, adapting them to suit the specific needs and characteristics of the equipment and the organization. The key is to understand the strengths and weaknesses of each strategy and to tailor its application to maximize its impact.

Q 22. How do you measure the effectiveness of maintenance programs?

Measuring the effectiveness of a maintenance program goes beyond simply tracking completed tasks. It requires a holistic approach focusing on key performance indicators (KPIs) that reflect both efficiency and effectiveness. We need to look at the impact on overall equipment effectiveness (OEE), reduction in downtime, and improved safety.

- Mean Time Between Failures (MTBF): This metric indicates the average time a piece of equipment operates before it fails. A higher MTBF suggests effective preventative maintenance.

- Mean Time To Repair (MTTR): This measures the average time taken to repair a piece of equipment after a failure. A lower MTTR indicates efficient corrective maintenance procedures and well-trained technicians.

- Overall Equipment Effectiveness (OEE): This is a comprehensive metric combining availability, performance, and quality rate. It gives a clear picture of how efficiently the equipment is being utilized, reflecting the effectiveness of the entire maintenance strategy.

- Maintenance Cost per Unit Produced: This KPI helps to gauge the cost-effectiveness of the maintenance program by relating maintenance expenses to production output. A reduction shows an improvement.

- Safety Incident Rate: A well-maintained facility reduces the likelihood of accidents. Tracking safety incidents directly reflects the effectiveness of the safety aspects of the maintenance program.

For example, in my previous role at a manufacturing plant, we implemented a new preventative maintenance schedule. By tracking MTBF and MTTR, we saw a 20% increase in MTBF and a 15% decrease in MTTR within six months, directly impacting the plant’s OEE.

Q 23. What is your experience with maintenance planning and scheduling software?

I have extensive experience utilizing various Computerized Maintenance Management Systems (CMMS) software, including SAP PM, Maximo, and UpKeep. My experience ranges from implementing and configuring the software to training personnel and generating reports. I’m proficient in using these systems to schedule preventative maintenance, track work orders, manage inventory, and analyze maintenance data.

For instance, at my previous company, we migrated from a paper-based system to Maximo. This transition involved data migration, user training, and the customization of the system to meet our specific requirements. The result was improved efficiency in scheduling and tracking maintenance activities, leading to a significant reduction in downtime.

I understand the importance of selecting the right CMMS based on the organization’s needs and size. My expertise includes evaluating different software options, configuring the system, and ensuring smooth integration with other enterprise systems.

Q 24. How do you ensure the timely completion of maintenance tasks?

Ensuring timely completion of maintenance tasks requires a proactive approach that combines effective planning, clear communication, and robust monitoring. This involves establishing clear priorities, assigning tasks to qualified personnel, and utilizing appropriate resources.

- Prioritization: Employing a prioritization system (e.g., criticality analysis, risk assessment) ensures that the most important tasks are tackled first.

- Resource Allocation: Matching the right skills and equipment to each task is crucial for efficient completion. This might include outsourcing specialized work.

- Real-time Monitoring: Regular monitoring of task progress allows for identification and resolution of any delays. This could be done through the CMMS or regular status meetings.

- Clear Communication: Open communication channels ensure everyone involved is informed about deadlines, changes, and any potential challenges.

- Contingency Planning: Anticipating potential problems and having backup plans in place helps minimize disruptions.

For example, I once managed a critical repair during a production peak. By quickly assembling a team, prioritizing resources, and communicating transparently, we completed the repair ahead of schedule, avoiding costly production downtime.

Q 25. Describe your experience with performance management of maintenance personnel.

Performance management of maintenance personnel is crucial for maintaining high standards and continuous improvement. My approach is based on a combination of regular performance reviews, targeted training, and constructive feedback.

- Setting Clear Expectations: Establishing clear performance goals and expectations is the foundation of effective performance management. These goals should align with the overall maintenance strategy.

- Regular Feedback: Providing regular, constructive feedback allows for timely course correction and supports continuous improvement. This should include both positive reinforcement and areas for development.

- Performance Reviews: Formal performance reviews offer a structured platform to evaluate performance against set goals, identify strengths and weaknesses, and plan for future development.

- Training and Development: Investing in training and development opportunities allows personnel to enhance their skills and stay current with the latest technologies and best practices.

- Recognition and Rewards: Acknowledging and rewarding excellent performance motivates employees and encourages continued high performance.

In a previous role, I implemented a mentorship program that paired experienced technicians with newer ones. This improved knowledge transfer, enhanced skill development, and boosted overall team performance.

Q 26. How do you identify and mitigate potential maintenance risks?

Identifying and mitigating potential maintenance risks involves a systematic approach that includes risk assessment, preventative measures, and contingency planning. This requires a thorough understanding of the equipment, processes, and potential hazards.

- Risk Assessment: Regularly assessing potential risks, considering factors such as equipment age, operating conditions, and environmental factors.

- Preventative Measures: Implementing preventative maintenance schedules, using appropriate safety equipment, and adhering to safety protocols.

- Contingency Planning: Developing plans to handle potential disruptions or failures, including identifying backup equipment or resources.

- Root Cause Analysis: When incidents occur, conducting thorough root cause analyses to identify the underlying issues and prevent recurrence.

- Regular Inspections: Implementing a regular inspection program to identify and address potential problems before they escalate.

For example, during a hurricane season, I developed a detailed contingency plan for our critical equipment. This plan included securing vulnerable equipment, identifying backup power sources, and arranging for emergency repairs. The plan ensured smooth operations despite the severe weather.

Q 27. What is your experience with developing maintenance budgets?

Developing maintenance budgets requires careful planning and a thorough understanding of the organization’s financial position and maintenance needs. It’s a process that requires collaboration with various stakeholders.

- Forecasting Maintenance Costs: Accurately estimating future maintenance costs based on historical data, equipment condition, and planned maintenance activities. This includes both preventative and corrective maintenance.

- Prioritization of Projects: Prioritizing maintenance projects based on their impact on production, safety, and overall operational efficiency.

- Resource Allocation: Allocating resources effectively to ensure that the budget adequately supports the planned maintenance activities.

- Tracking and Monitoring: Closely monitoring actual spending against the budget to identify any variances and take corrective action.

- Cost-Benefit Analysis: Evaluating the cost-effectiveness of different maintenance strategies and selecting the most efficient approach.

In one instance, I successfully negotiated a lower contract price with a vendor by leveraging competitive bidding and demonstrating a clear understanding of our needs. This saved a significant portion of the budget while maintaining a high standard of service.

Q 28. How do you stay up-to-date with the latest maintenance technologies and best practices?

Staying up-to-date with the latest maintenance technologies and best practices is crucial for maintaining a competitive edge. I employ several strategies to ensure continuous learning and development.

- Professional Organizations: Active participation in professional organizations like the Society for Maintenance & Reliability Professionals (SMRP) provides access to resources, networking opportunities, and industry insights.

- Industry Publications and Conferences: Staying current with the latest industry publications, attending conferences, and webinars helps to stay abreast of emerging trends and best practices.

- Online Courses and Webinars: Utilizing online learning platforms to enhance skills in areas such as predictive maintenance, CMMS software, and advanced analytics.

- Vendor Training: Attending vendor training programs to deepen understanding of the specific equipment and software used in the organization.

- Mentorship and Collaboration: Engaging in knowledge sharing with colleagues, mentors, and peers, fostering a collaborative learning environment.

Recently, I completed a course on predictive maintenance using vibration analysis, a technique that helps anticipate equipment failure and optimize maintenance schedules, directly improving our maintenance efficiency.

Key Topics to Learn for Maintenance Coordination and Supervision Interview

- Preventive Maintenance Strategies: Understanding and implementing various preventive maintenance schedules, including their impact on equipment lifespan and operational costs. Practical application: Developing and managing a PM schedule for a specific facility or equipment set.

- Corrective Maintenance Procedures: Troubleshooting equipment malfunctions, prioritizing repairs, and managing emergency situations effectively. Practical application: Describing your approach to diagnosing a critical equipment failure and coordinating a timely repair.

- Resource Allocation and Budget Management: Optimizing the allocation of personnel, materials, and budget resources to maximize efficiency and minimize downtime. Practical application: Presenting a plan for managing a maintenance budget and justifying resource requests.

- Team Management and Leadership: Motivating and supervising maintenance teams, delegating tasks, and fostering a collaborative work environment. Practical application: Describing a situation where you successfully led a team to overcome a challenging maintenance project.

- Safety Regulations and Compliance: Adhering to all relevant safety regulations, implementing safety procedures, and ensuring a safe working environment for your team. Practical application: Explaining your experience with implementing and enforcing safety protocols in a maintenance setting.

- Inventory Management and Procurement: Maintaining accurate inventory records, managing spare parts, and coordinating the procurement of necessary materials. Practical application: Describing your system for tracking inventory and ensuring timely procurement of needed supplies.

- Performance Monitoring and Reporting: Tracking key performance indicators (KPIs), generating reports on maintenance activities, and identifying areas for improvement. Practical application: Illustrating how you use data to measure maintenance efficiency and identify opportunities for optimization.

- Communication and Collaboration: Effectively communicating with various stakeholders, including management, technicians, and other departments. Practical application: Describing a successful instance of collaborating with other departments to resolve a maintenance-related issue.

Next Steps

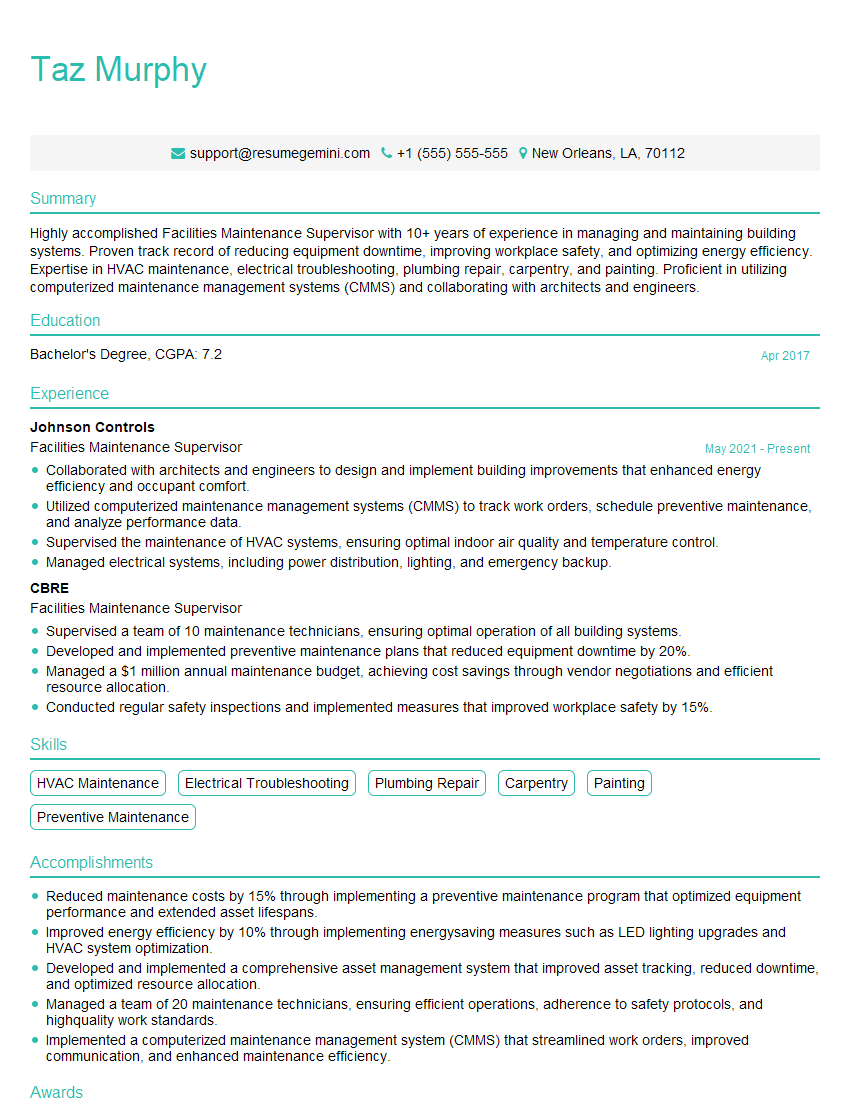

Mastering Maintenance Coordination and Supervision is crucial for career advancement, opening doors to leadership roles and increased responsibilities within your field. A strong, ATS-friendly resume is essential to showcasing your skills and experience effectively to potential employers. We strongly encourage you to utilize ResumeGemini to build a professional and impactful resume that highlights your achievements and qualifications. ResumeGemini offers helpful tools and resources, including examples of resumes tailored specifically to Maintenance Coordination and Supervision positions, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.