Preparation is the key to success in any interview. In this post, we’ll explore crucial Material and Supply Sourcing interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Material and Supply Sourcing Interview

Q 1. Explain the difference between strategic sourcing and tactical purchasing.

Strategic sourcing and tactical purchasing, while both focused on acquiring materials and supplies, differ significantly in their scope and approach. Think of it like this: tactical purchasing is putting out fires, while strategic sourcing is preventing them.

Tactical Purchasing: This is a short-term, transactional approach focused on immediate needs. It’s reactive, addressing immediate demands with a primary focus on price and availability. An example would be quickly ordering office supplies when they run low. The emphasis is on speed and efficiency in fulfilling current requirements.

Strategic Sourcing: This is a long-term, proactive approach that analyzes the entire supply chain to identify opportunities for cost reduction, risk mitigation, and value improvement. It considers factors beyond price, such as quality, supplier reliability, and innovation. A strategic sourcing project might involve a complete overhaul of a company’s sourcing strategy for a critical component, potentially involving global supplier selection and long-term contracts. The emphasis is on long-term value and competitive advantage.

In essence, tactical purchasing is about getting the right goods at the right time, while strategic sourcing is about getting the right goods at the right price, from the right supplier, with the right quality, over the long term.

Q 2. Describe your experience with supplier relationship management (SRM).

My experience with Supplier Relationship Management (SRM) spans over ten years, encompassing both collaborative and transactional relationships. I’ve implemented SRM systems that leverage technology to track supplier performance, manage contracts, and facilitate communication. This includes establishing key performance indicators (KPIs) to measure supplier performance against agreed-upon targets, such as on-time delivery, quality, and cost.

For example, in my previous role at XYZ Corporation, we faced consistent quality issues with a key supplier of electronic components. Through improved communication and collaborative problem-solving (a core component of SRM), we identified the root cause – inconsistent manufacturing processes at the supplier’s facility. We worked closely with the supplier, providing technical expertise and implementing a joint improvement plan. This resulted in a significant improvement in quality, reducing our defect rates by 40% within six months. This demonstrates the value of building strong, mutually beneficial relationships with suppliers beyond simply focusing on price.

Beyond performance monitoring, I have experience in developing and negotiating long-term contracts that incorporate incentives for superior performance and penalties for non-compliance. This ensures alignment between our needs and the supplier’s capabilities.

Q 3. How do you identify and mitigate supply chain risks?

Identifying and mitigating supply chain risks requires a proactive and multi-faceted approach. I utilize a risk assessment framework that considers various factors, including geopolitical instability, natural disasters, supplier financial health, and technological disruptions.

Risk Identification: This involves regularly monitoring global events, analyzing supplier performance data, and conducting regular supplier audits. Tools like scenario planning help us anticipate potential disruptions.

Risk Mitigation: Strategies include diversifying suppliers (reducing reliance on single sources), building strong supplier relationships, holding safety stock for critical components, developing contingency plans, and implementing robust supply chain visibility systems. For example, during the recent semiconductor shortage, our risk mitigation strategies – including securing alternative sources and working collaboratively with suppliers to prioritize our needs – allowed us to minimize the impact on our production schedules.

A key aspect is understanding the potential impact of each risk and prioritizing mitigation efforts based on their severity and likelihood. Regular reviews of our risk assessments allow us to adapt our strategies as the supply chain landscape evolves.

Q 4. What are your preferred negotiation strategies for securing favorable pricing?

My negotiation strategies focus on building strong relationships and creating win-win scenarios. I avoid adversarial tactics; instead, I prefer collaborative approaches that foster mutual trust and understanding. This involves thorough preparation, including a deep understanding of market prices, competitor offerings, and the supplier’s cost structure.

Value-Based Negotiation: This approach centers on demonstrating the value we bring to the supplier, highlighting the long-term potential of the relationship. For example, securing large, consistent orders can provide a supplier with economies of scale, which they are often willing to share through price concessions.

Total Cost of Ownership (TCO) Analysis: This focuses on the overall cost of the product or service over its entire lifecycle, not just the initial purchase price. By highlighting the cost savings achieved through improved quality, reduced lead times, or better service, we can often justify higher upfront costs.

Leveraging Market Intelligence: Knowing competitor pricing and market trends allows us to negotiate from a position of strength.

The ultimate goal is to establish a fair and sustainable pricing model that benefits both parties and lays the groundwork for a long-term, mutually beneficial relationship.

Q 5. Explain your experience with different sourcing methodologies (e.g., RFQ, RFP, Reverse Auction).

My experience encompasses a range of sourcing methodologies, each suited to different situations:

Request for Quotation (RFQ): Used for simpler purchases with clearly defined specifications where price is the primary decision criterion. I often use RFQs for standard components with numerous readily available suppliers.

Request for Proposal (RFP): Employed for more complex purchases requiring detailed solutions and potentially involving significant customization. RFPs are essential for projects demanding specialized expertise and creative solutions.

Reverse Auction: A competitive bidding process that allows multiple suppliers to bid in real-time, often resulting in aggressive price reductions. This methodology works well for commodity items with a high degree of standardization.

The choice of methodology depends on the complexity of the procurement, the level of customization required, and the desired level of supplier competition. I frequently combine these methods, using an RFP to gather detailed proposals, followed by an RFQ to refine pricing for preferred suppliers. In some cases, a reverse auction can be used as a final step to secure the best possible price.

Q 6. How do you manage supplier performance and ensure quality control?

Managing supplier performance and ensuring quality control involves a combination of proactive monitoring and reactive intervention. Key elements include:

Establishing Key Performance Indicators (KPIs): Defining metrics such as on-time delivery, defect rate, and lead time allows for objective performance measurement. These KPIs are included in supplier contracts and regularly monitored.

Regular Performance Reviews: Conducting periodic reviews with suppliers to discuss performance, identify areas for improvement, and address any concerns. These reviews provide a platform for open communication and collaboration.

Supplier Audits: Regularly auditing suppliers to assess their capabilities, quality systems, and compliance with our standards. This ensures that suppliers adhere to required processes and maintain consistent quality.

Quality Control Inspections: Implementing quality control checks at various stages of the supply chain, including incoming inspection of materials and regular testing of finished goods. This helps detect and prevent defects early on.

In cases of performance shortfalls, corrective actions are developed and implemented collaboratively with the supplier. This might include providing technical assistance, training, or implementing process improvements. Ultimately, the goal is to foster a culture of continuous improvement and mutual accountability.

Q 7. Describe your experience with contract negotiation and management.

Contract negotiation and management are critical to successful sourcing. My approach emphasizes creating mutually beneficial agreements that clearly define expectations, responsibilities, and performance metrics.

Contract Negotiation: I focus on building rapport with the supplier and creating a collaborative environment. This includes thorough preparation, understanding the supplier’s needs, and exploring various contract structures to achieve optimal outcomes for both parties.

Contract Management: After securing an agreement, I implement a robust system for tracking performance, managing changes, and resolving disputes. This often involves a dedicated contract management system to monitor key terms, milestones, and performance against contractual obligations. Regular communication with suppliers is crucial to address potential issues proactively.

Risk Allocation: Contracts should clearly define risk allocation between the buyer and the supplier, including provisions for liability in case of delays, defects, or other unforeseen events.

Effective contract management ensures compliance, minimizes disputes, and protects the interests of both parties, leading to a sustainable and productive long-term relationship.

Q 8. How do you analyze market trends and forecast future demand?

Analyzing market trends and forecasting future demand involves a multi-faceted approach combining qualitative and quantitative methods. We start by monitoring industry publications, attending trade shows, and networking with key players to understand emerging technologies and shifts in consumer preferences. This qualitative data gives us a sense of the bigger picture. Then, we delve into quantitative analysis using historical sales data, economic indicators (like GDP growth and inflation), and predictive analytics tools. For example, if we see a consistent upward trend in sales of a particular material alongside a predicted increase in construction activity, we can confidently project increased demand. We also use regression analysis and time series forecasting models to refine our predictions, factoring in seasonality and other relevant variables. The key is to continuously iterate, refining our forecasts based on new data and market feedback.

Imagine predicting the demand for solar panels. We wouldn’t just look at past sales; we’d also consider government policies promoting renewable energy, technological advancements making panels more efficient and affordable, and general awareness of climate change. All these factors feed into a more accurate demand forecast.

Q 9. What metrics do you use to measure the success of your sourcing efforts?

Measuring the success of sourcing efforts requires a balanced scorecard approach, encompassing cost, quality, delivery, and supplier relationship metrics. Key metrics include:

- Cost Savings: Percentage reduction in material costs compared to previous periods or benchmarks.

- Total Cost of Ownership (TCO): This considers not just the purchase price but also transportation, storage, quality control, and other associated costs.

- Supplier Performance: On-time delivery rate, defect rate, and lead time. We use KPIs (Key Performance Indicators) to track these regularly.

- Supplier Relationship Management (SRM): We assess collaboration effectiveness and conflict resolution through surveys and regular reviews.

- Inventory Turnover: Measures how efficiently we manage inventory and optimize stock levels.

For instance, a successful sourcing initiative might show a 15% reduction in TCO, a 98% on-time delivery rate from our key suppliers, and improved collaboration leading to faster problem-solving.

Q 10. How do you manage inventory levels to optimize costs and minimize stockouts?

Managing inventory levels is a delicate balancing act between minimizing costs and preventing stockouts. We employ various techniques including:

- Just-in-Time (JIT) inventory: This minimizes storage costs by receiving materials only when needed. It requires close collaboration with suppliers and accurate demand forecasting.

- Economic Order Quantity (EOQ): A mathematical model that calculates the optimal order quantity to minimize the total cost of inventory. It considers factors like ordering costs, holding costs, and demand.

- Safety Stock: Maintaining a buffer stock to account for unexpected demand fluctuations or supplier delays. The level of safety stock is determined by demand variability and lead time.

- Inventory Management Software: Using software to track inventory levels in real-time, predict demand, and automate ordering processes.

For example, we might use EOQ to determine the optimal number of units to order for a particular component. We also use safety stock to prevent a production line shutdown if a supplier experiences a delay. A sophisticated inventory management system integrates all these elements for efficient stock control.

Q 11. Explain your experience with various sourcing tools and technologies.

My experience encompasses a range of sourcing tools and technologies, including:

- Enterprise Resource Planning (ERP) systems: Such as SAP or Oracle, for integrated management of procurement, inventory, and supply chain processes.

- Supplier Relationship Management (SRM) software: For managing supplier information, performance, and communication.

- e-Procurement platforms: For online sourcing, bidding, and purchase order management.

- Demand forecasting and planning tools: For statistical modeling and predictive analytics to anticipate future demand.

- Blockchain technology: For enhanced transparency and traceability in the supply chain, especially beneficial for ethical and sustainable sourcing.

I’m proficient in using these tools to streamline sourcing processes, improve data visibility, and enhance collaboration with suppliers. For instance, I’ve used an ERP system to automate purchase order generation, reducing manual errors and processing time.

Q 12. Describe your process for evaluating and selecting new suppliers.

Evaluating and selecting new suppliers is a rigorous process. We typically follow these steps:

- Supplier Identification: Identifying potential suppliers through online directories, industry events, and referrals.

- Pre-qualification: Screening potential suppliers based on financial stability, capacity, and quality certifications (ISO 9001, for example).

- Supplier Audits: Conducting on-site audits to assess their facilities, processes, and quality control systems.

- Sample Testing: Testing samples of the material to ensure it meets our specifications and quality standards.

- Negotiation and Contractual Agreement: Negotiating pricing, terms, and conditions, and finalizing a formal contract.

- Performance Monitoring: Continuously monitoring the supplier’s performance after onboarding.

Think of it like hiring a new employee: we wouldn’t just take anyone; we’d perform background checks, interviews, and probationary periods. Similarly, we meticulously evaluate suppliers before establishing a long-term relationship.

Q 13. How do you handle supplier disruptions or delays?

Handling supplier disruptions requires a proactive and multi-pronged approach. We have contingency plans in place to mitigate the impact of potential delays or shortages. These include:

- Diversification of Suppliers: We avoid relying on a single source for critical materials, reducing dependence on any one supplier.

- Early Warning Systems: Establishing communication channels to receive timely alerts about potential disruptions.

- Alternative Sourcing Strategies: Identifying backup suppliers or exploring alternative materials if necessary.

- Negotiation and Collaboration: Working closely with the affected supplier to address the root cause of the disruption and find solutions.

- Risk Assessment and Mitigation: Regularly analyzing potential risks in the supply chain and developing mitigation strategies.

For instance, during a global pandemic, we proactively engaged with our suppliers to understand their operational challenges and worked collaboratively to ensure continued supply. We also leveraged our diversified supplier base to secure alternative sources of critical materials.

Q 14. How do you ensure compliance with ethical sourcing and sustainability initiatives?

Ethical sourcing and sustainability are paramount. We ensure compliance through a comprehensive approach:

- Supplier Code of Conduct: Establishing a code of conduct that outlines our expectations regarding labor practices, environmental protection, and ethical business practices. Suppliers must adhere to this code.

- Third-Party Audits: Using independent auditors to verify supplier compliance with our code of conduct and relevant industry standards.

- Traceability and Transparency: Tracking the origin of materials and ensuring transparency throughout the supply chain.

- Sustainable Procurement Practices: Prioritizing suppliers who demonstrate commitment to environmental sustainability and responsible resource management.

- Continuous Improvement: Regularly reviewing and updating our ethical sourcing policies and practices to reflect evolving standards and best practices.

We actively support suppliers in their sustainability efforts, providing guidance and resources where needed. We believe that ethical and sustainable sourcing is not just a compliance issue, but a strategic imperative for long-term success.

Q 15. Describe your experience with cost reduction strategies in procurement.

Cost reduction in procurement isn’t just about slashing prices; it’s a strategic approach that enhances value while minimizing expenses. My experience involves a multi-pronged strategy, focusing on:

- Supplier Relationship Management (SRM): Building strong, collaborative relationships with key suppliers allows for negotiating better pricing and terms. For example, I negotiated a volume discount of 15% with a long-term supplier by guaranteeing a consistent order volume over three years.

- Strategic Sourcing: This involves thoroughly analyzing the market, identifying alternative suppliers, and leveraging competition to secure the best possible price. In one project, we implemented a competitive bidding process, leading to a 10% cost reduction on a critical component.

- Value Engineering: This focuses on identifying opportunities to reduce costs without sacrificing quality or performance. We once redesigned a packaging process, using less material and reducing labor costs by 8%, resulting in significant savings.

- Process Optimization: Streamlining procurement processes, improving efficiency, and minimizing waste can lead to significant savings. Implementing an automated purchasing system reduced our administrative overhead by 20%.

- Demand Management: Accurate forecasting and inventory control play a critical role. Reducing waste through better forecasting saved us approximately 5% on our annual materials budget.

My approach is data-driven, using analytics to identify areas for improvement and measure the success of implemented strategies. Cost reduction isn’t a one-time event; it’s an ongoing process requiring continuous monitoring and improvement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of Total Cost of Ownership (TCO).

Total Cost of Ownership (TCO) encompasses all direct and indirect costs associated with an asset or product throughout its lifecycle. It’s more than just the initial purchase price; it includes costs like operation, maintenance, repairs, upgrades, disposal, and even potential downtime. Thinking about TCO helps avoid the trap of focusing solely on upfront cost savings, which can lead to higher long-term expenses.

Example: Consider two computers. One has a lower initial price but requires frequent repairs and has a shorter lifespan, while another is more expensive initially but is more durable and requires less maintenance. By considering TCO, we might find the more expensive computer is actually more cost-effective in the long run.

I utilize TCO analysis by carefully mapping out all potential costs associated with each sourcing decision. This helps in making informed decisions that align with the organization’s long-term financial goals. A robust TCO model can include factors like:

- Acquisition cost

- Operating costs (energy, maintenance)

- Downtime costs

- Disposal costs

- Training costs

Q 17. How do you build strong relationships with key stakeholders?

Building strong stakeholder relationships is crucial for effective sourcing. I approach this by:

- Open Communication: Regularly engaging stakeholders through meetings, emails, and informal updates, ensuring transparency and proactive communication about challenges and progress.

- Active Listening: Truly understanding their needs and concerns, and incorporating their feedback in the sourcing process. This shows them I value their input.

- Collaboration: Working collaboratively to find mutually beneficial solutions. Sourcing decisions shouldn’t be made in a vacuum; involving stakeholders helps to ensure buy-in and reduces conflict.

- Relationship Building: Investing time in building personal connections through regular interactions, building trust, and demonstrating reliability and accountability.

- Delivering Value: Consistently exceeding expectations and demonstrating the value of my contributions strengthens relationships.

For example, by proactively involving engineering and operations teams early in the sourcing process for a new component, I ensured that their technical requirements were met, leading to a smoother integration and improved stakeholder satisfaction.

Q 18. How do you prioritize sourcing projects based on business needs?

Prioritizing sourcing projects involves a strategic approach that aligns with overall business goals. I typically use a framework that combines urgency, impact, and feasibility.

- Urgency: How quickly does the project need to be completed? This could be due to contractual deadlines, production schedules, or critical supply chain disruptions.

- Impact: What is the potential impact of the project on the business? This could include cost savings, quality improvements, or risk mitigation.

- Feasibility: How feasible is the project given available resources, time constraints, and market conditions?

I often use a matrix to visualize these factors and prioritize projects accordingly. Projects with high urgency, high impact, and high feasibility get prioritized first. For instance, securing a critical raw material facing a potential supply shortage would rank higher than optimizing a low-impact, less urgent component.

Q 19. Explain your experience with different types of contracts (e.g., fixed-price, cost-plus).

My experience encompasses various contract types, each with its own strengths and weaknesses:

- Fixed-Price Contracts: These offer price certainty for the buyer, but the seller bears the risk of cost overruns. They are suitable for projects with well-defined specifications and low risk of changes.

- Cost-Plus Contracts: These reimburse the seller for their actual costs plus a pre-agreed markup or fee. They provide flexibility for projects with uncertain requirements or significant risks, but require careful cost monitoring to avoid overspending. For instance, I used a cost-plus contract for a complex R&D project where the specifications were still being developed.

- Time and Materials Contracts: These charge the buyer for both the time spent and the materials used. They offer flexibility but require meticulous tracking and clear definitions of deliverables to prevent cost escalation.

- Long-Term Agreements (LTAs): These offer greater price stability and supply security over an extended period. They involve greater collaboration with suppliers and often include performance incentives.

The choice of contract type depends on the specific project needs, risk tolerance, and the nature of the relationship with the supplier. I carefully evaluate each option and select the one that best aligns with the overall objectives.

Q 20. How do you utilize data analytics to improve sourcing decisions?

Data analytics is integral to improving sourcing decisions. I leverage data in several ways:

- Spend Analysis: Analyzing historical spending data identifies areas of high expenditure and potential cost-saving opportunities. This helps to prioritize sourcing projects.

- Market Intelligence: Tracking market trends, commodity prices, and supplier performance provides valuable insights for negotiation and strategic planning.

- Supplier Performance Management: Monitoring key supplier metrics such as on-time delivery, quality, and cost helps to identify high-performing and underperforming suppliers, enabling corrective actions or supplier changes.

- Risk Management: Analyzing data related to supplier capacity, geopolitical factors, and natural disasters allows for proactive risk mitigation.

- Predictive Analytics: Utilizing advanced analytics to predict future demand and market trends can improve forecasting accuracy and optimize inventory levels.

Tools like advanced analytics software and dedicated procurement systems enable me to access and analyze this data efficiently. For example, I used data analytics to identify a pattern of late deliveries from a particular supplier, prompting a review of their performance and implementation of corrective actions.

Q 21. Describe a time you had to resolve a conflict with a supplier. What was the outcome?

In one instance, a key supplier experienced significant production delays, jeopardizing our production schedule. This led to a conflict because we faced potential penalties for missed deadlines.

To resolve this, I followed a structured approach:

- Open Communication: I initiated a direct and frank conversation with the supplier’s management to understand the root causes of the delay.

- Collaborative Problem-Solving: We worked together to identify potential solutions, including expediting production, finding alternative sources for some components, and adjusting our production schedule.

- Negotiation: We negotiated a revised delivery schedule and a partial compensation for the anticipated penalties we might face.

- Documentation: All agreements and solutions were documented formally to avoid future misunderstandings.

The outcome was a revised delivery schedule that minimized disruption to our production, though slightly delayed. We maintained a strong relationship with the supplier by working collaboratively to solve the problem, demonstrating trust and commitment.

Q 22. What is your experience with managing global suppliers?

My experience with managing global suppliers spans over 10 years, encompassing various industries including technology, manufacturing, and pharmaceuticals. I’ve led teams responsible for sourcing components, raw materials, and finished goods from suppliers across Asia, Europe, and North America. This involved everything from initial supplier selection and contract negotiation to ongoing performance management and risk mitigation. For example, while sourcing critical components for a medical device manufacturer, I successfully navigated complex regulatory hurdles and geopolitical risks in securing a reliable supply chain from a supplier in Southeast Asia, ensuring consistent quality and timely delivery. This involved developing strong relationships with key stakeholders, conducting thorough due diligence, and implementing robust quality control measures. Another significant accomplishment was establishing a strategic sourcing agreement with a key supplier in China, reducing material costs by 15% while simultaneously improving delivery lead times.

Q 23. How do you ensure the accuracy and integrity of your sourcing data?

Ensuring data accuracy and integrity in sourcing is paramount. My approach is multifaceted. First, we utilize a centralized, cloud-based procurement system that provides a single source of truth for all sourcing data. This system incorporates automated data validation checks to flag inconsistencies and potential errors in real-time. Second, we implement regular audits of supplier data, comparing our records against the supplier’s own documentation. Third, we actively encourage feedback from internal stakeholders and suppliers to identify and correct any inaccuracies. Finally, we leverage data analytics to identify trends and patterns in our sourcing data, which helps in proactively addressing any potential issues. For instance, if we see a consistent discrepancy in reported lead times from a particular supplier, we investigate the root cause and implement corrective actions.

Q 24. Explain your understanding of different procurement processes (e.g., Purchase-to-Pay).

My understanding of procurement processes is extensive, particularly the Purchase-to-Pay (P2P) cycle. P2P encompasses all stages from identifying a need to receiving payment. It includes:

- Requisitioning: Internal departments submit requests for goods or services.

- Supplier Selection: Identifying and evaluating potential suppliers.

- Negotiation and Contract Management: Negotiating favorable terms and conditions.

- Purchase Order (PO) Creation: Issuing formal purchase orders to selected suppliers.

- Goods Receipt and Invoice Verification: Receiving goods and verifying invoices against purchase orders.

- Payment Processing: Processing payments to suppliers.

Q 25. How do you adapt your sourcing strategies to changing market conditions?

Adapting sourcing strategies to changing market conditions is crucial for maintaining a competitive edge. My approach involves continuous monitoring of market trends, including commodity prices, geopolitical events, and technological advancements. We employ scenario planning to anticipate potential disruptions and develop contingency plans. For example, during the recent semiconductor shortage, we diversified our supplier base, secured long-term contracts with key suppliers, and invested in alternative technologies to mitigate supply chain risks. Furthermore, we leverage advanced analytics and market intelligence tools to identify emerging trends and opportunities, enabling us to make data-driven decisions that enhance our sourcing strategies’ resilience.

Q 26. How do you measure the effectiveness of your sourcing strategies?

Measuring the effectiveness of sourcing strategies requires a robust Key Performance Indicator (KPI) framework. Key metrics include:

- Cost Savings: Tracking reductions in material costs.

- Supplier Performance: Evaluating on-time delivery, quality, and responsiveness.

- Lead Times: Measuring the time from order placement to goods receipt.

- Inventory Levels: Optimizing inventory levels to minimize storage costs and waste.

- Risk Management: Assessing and mitigating supply chain risks.

Q 27. What is your experience with implementing and managing e-procurement systems?

I have extensive experience implementing and managing e-procurement systems. I’ve led projects involving the selection, implementation, and integration of various e-procurement platforms, including Ariba and Coupa. These systems streamline the entire procurement process, from requisition to payment, automating tasks, improving transparency, and reducing administrative overhead. My experience includes managing user training, system configuration, and ongoing maintenance. A successful implementation I oversaw resulted in a 20% reduction in procurement cycle time and a 10% reduction in processing errors. This involved careful planning, stakeholder engagement, and change management processes to ensure a smooth transition and user adoption.

Q 28. Describe a time you had to make a difficult sourcing decision under pressure.

One challenging situation involved securing a critical raw material during a sudden global shortage. Our primary supplier faced unexpected production issues, jeopardizing the timely completion of a major project. Under immense pressure, I had to quickly identify and vet alternative suppliers, negotiating favorable terms while ensuring quality and delivery deadlines were met. This involved extensive research, supplier qualification, and negotiations under tight deadlines. Ultimately, I secured a contract with a new supplier, minimizing disruption and ensuring project success. This experience highlighted the importance of proactive risk management, having backup suppliers, and strong negotiation skills in managing unexpected supply chain disruptions.

Key Topics to Learn for Material and Supply Sourcing Interview

- Supplier Relationship Management (SRM): Understanding the strategies and techniques for building and maintaining strong relationships with key suppliers, including negotiation and performance management. Practical application: Describe a scenario where you successfully resolved a conflict with a supplier.

- Sourcing Strategies: Familiarize yourself with various sourcing approaches (e.g., global sourcing, single sourcing, multiple sourcing) and their implications on cost, risk, and quality. Practical application: Analyze the pros and cons of different sourcing strategies for a specific product or service.

- Supply Chain Risk Management: Develop a strong understanding of potential disruptions and develop mitigation strategies. Practical application: Discuss how you would address a potential supply chain disruption, such as a natural disaster or geopolitical event.

- Negotiation and Contract Management: Master the art of effective negotiation, contract drafting, and management to secure favorable terms and conditions with suppliers. Practical application: Describe your experience negotiating contracts and managing supplier performance.

- Cost Optimization and Savings Initiatives: Explore strategies for identifying and implementing cost-saving measures throughout the sourcing process. Practical application: Present a case study where you successfully reduced procurement costs.

- Technology and Data Analytics in Sourcing: Understand how technology and data analytics are used to improve efficiency and decision-making in material and supply sourcing. Practical application: Discuss your experience using sourcing software or data analysis tools.

- Sustainability and Ethical Sourcing: Learn about the growing importance of incorporating sustainability and ethical considerations into sourcing decisions. Practical application: Describe how you would ensure ethical and sustainable practices within your sourcing strategy.

Next Steps

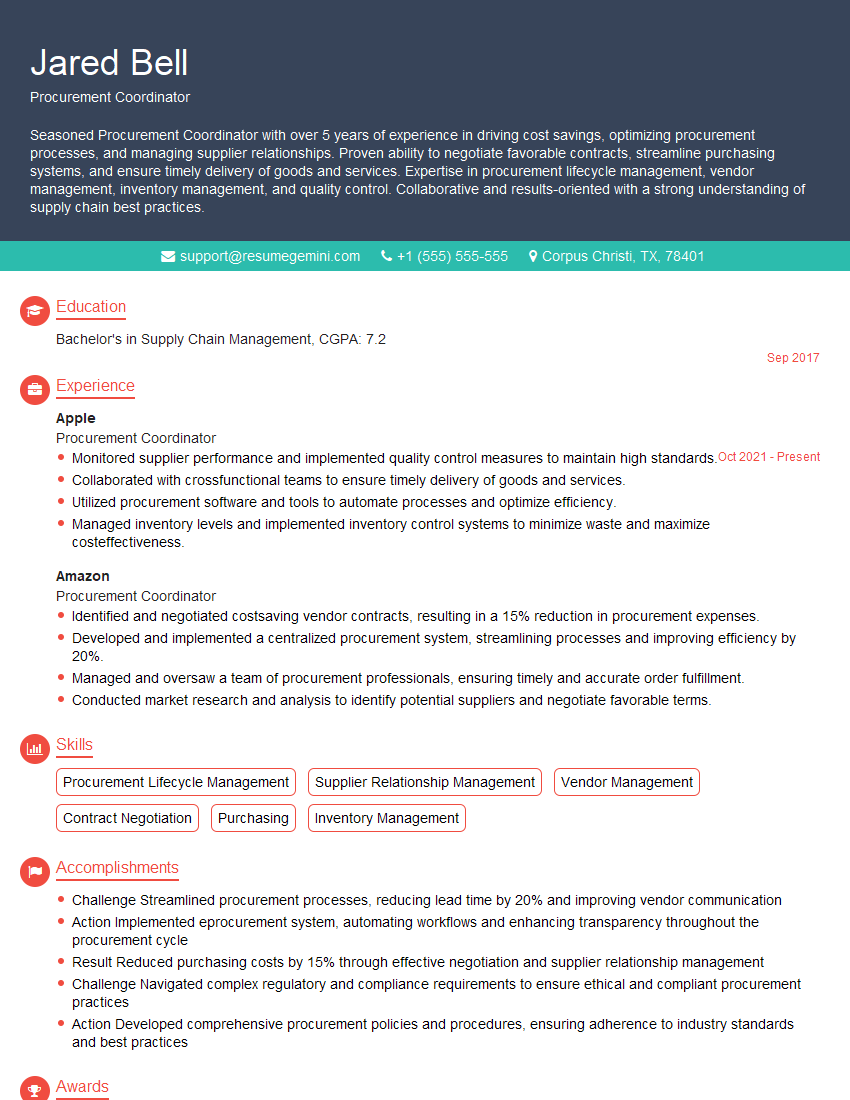

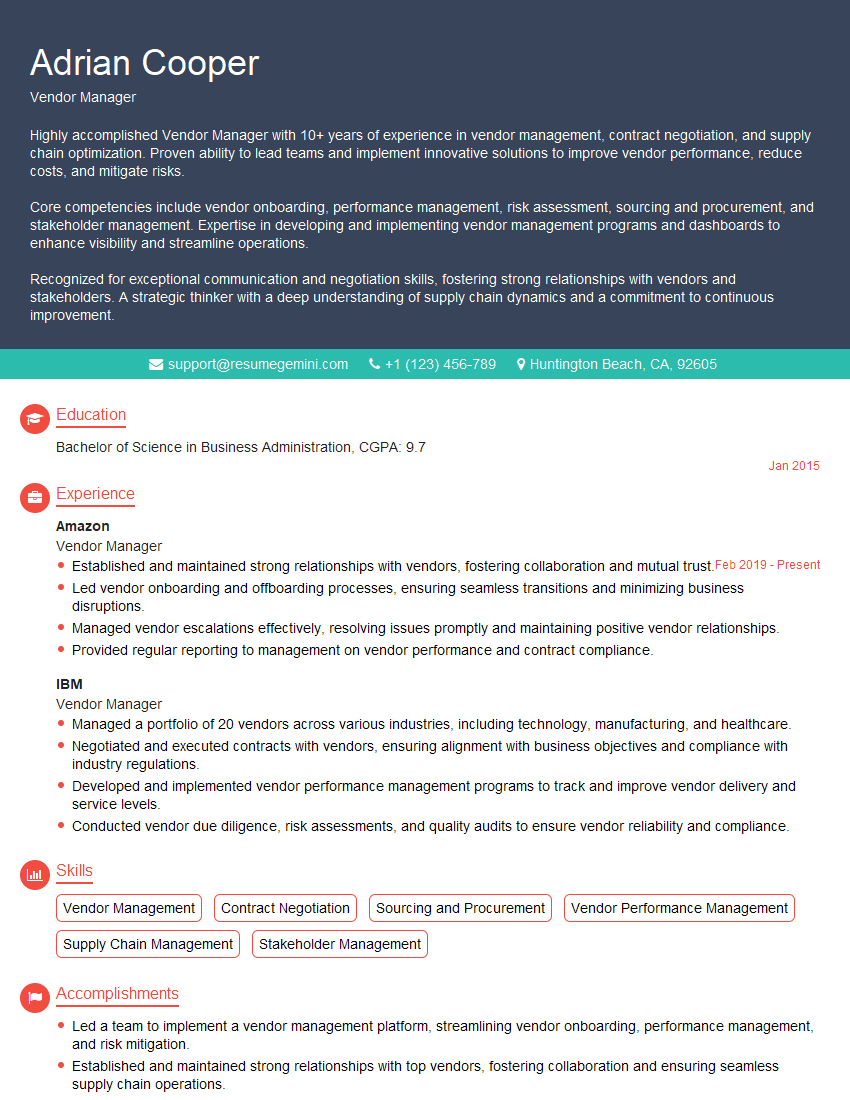

Mastering Material and Supply Sourcing is crucial for a successful and rewarding career. It opens doors to leadership roles and positions with significant impact on organizational profitability and efficiency. To maximize your job prospects, it’s vital to create an ATS-friendly resume that highlights your skills and experience effectively. We strongly recommend using ResumeGemini to build a professional and compelling resume. ResumeGemini offers a user-friendly interface and provides examples of resumes tailored to the Material and Supply Sourcing field, helping you present your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.