Preparation is the key to success in any interview. In this post, we’ll explore crucial Welding Quality interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Welding Quality Interview

Q 1. What are the common welding defects and their causes?

Welding defects are imperfections that compromise the integrity and performance of a weld. Understanding their causes is crucial for preventing them. Common defects include:

- Porosity: Small holes or voids in the weld metal, often caused by trapped gases (hydrogen, nitrogen, oxygen) during solidification. Think of it like bubbles in a cake – improper cleaning or shielding gas flow can cause this.

- Incomplete Fusion: Failure of the weld metal to completely fuse with the base metal, creating a weak point. This happens when insufficient heat is applied or the weld joint isn’t properly prepared.

- Lack of Penetration: The weld metal doesn’t extend fully through the thickness of the joint, leaving a thinner, weaker area. This is often due to insufficient current or improper welding technique.

- Undercutting: A groove melted into the base material adjacent to the weld toe. This weakens the weld and indicates excessive heat input or improper travel speed.

- Cracks: Breaks in the weld metal, which can be caused by rapid cooling, residual stresses, or the presence of impurities. These are particularly dangerous as they can propagate and lead to catastrophic failure.

- Slag Inclusions: Non-metallic materials trapped within the weld. This often occurs when not properly removing slag from previous weld passes.

- Spatter: Small droplets of molten metal ejected from the weld pool, resulting in an uneven surface. This is often due to excessive current or incorrect welding parameters.

Identifying the root cause of a defect requires careful analysis of the welding process, including parameters like current, voltage, travel speed, and shielding gas flow, alongside the material properties and joint design.

Q 2. Explain the different types of welding processes and their applications.

Numerous welding processes exist, each with specific advantages and disadvantages. Here are a few examples:

- Shielded Metal Arc Welding (SMAW): A relatively simple and versatile process using a consumable electrode coated with flux to protect the weld from atmospheric contamination. Widely used in construction and maintenance due to its portability and low cost. Think of it as the workhorse of welding.

- Gas Metal Arc Welding (GMAW): (MIG welding) Uses a continuously fed consumable wire electrode and a shielding gas (usually Argon or CO2) to protect the weld. Known for its high deposition rate and good quality, it’s extensively used in automotive manufacturing and industrial fabrication.

- Gas Tungsten Arc Welding (GTAW): (TIG welding) Employs a non-consumable tungsten electrode and a shielding gas to produce high-quality welds. Ideal for applications requiring precision and cleanliness, such as aerospace and nuclear industries.

- Submerged Arc Welding (SAW): Uses a consumable electrode and a blanket of granular flux to shield the weld. Known for its high deposition rate and deep penetration, often used for large-scale projects such as pipelines.

The choice of welding process depends heavily on factors like material type, thickness, joint design, required weld quality, and accessibility.

Q 3. Describe your experience with Nondestructive Testing (NDT) methods for weld inspection.

My experience with Nondestructive Testing (NDT) for weld inspection includes extensive use of several key methods:

- Visual Inspection (VI): A fundamental initial step, visually assessing the weld for surface defects like cracks, porosity, or undercutting. It’s crucial for identifying obvious problems and guiding further inspection.

- Radiographic Testing (RT): Uses X-rays or gamma rays to detect internal defects such as porosity, inclusions, and cracks. It’s effective for thick welds but requires specialized equipment and expertise in film interpretation or digital imaging.

- Ultrasonic Testing (UT): Employs high-frequency sound waves to detect internal flaws. It’s particularly useful for locating discontinuities in various weld orientations and materials, and providing depth information.

- Magnetic Particle Testing (MT): Uses magnetic fields and ferromagnetic particles to detect surface and near-surface flaws in ferromagnetic materials. Ideal for identifying cracks in welds that are difficult to see with the naked eye.

- Liquid Penetrant Testing (PT): Uses a dye penetrant to reveal surface-breaking defects. It’s a simple and cost-effective method for detecting cracks and other surface discontinuities.

In my previous role, I was responsible for selecting appropriate NDT methods based on the weld type and application, interpreting results, and documenting findings, ensuring the integrity and safety of welded structures.

Q 4. How do you interpret welding symbols?

Welding symbols provide a standardized way to communicate weld specifications on engineering drawings. They contain a wealth of information in a concise format. A typical symbol includes:

- Reference Line: The horizontal line connecting the symbol to the drawing.

- Arrow Side: The side of the joint to which the symbol applies.

- Other Side: The opposite side of the joint, which may have different specifications.

- Basic Weld Symbols: Represent the type of weld (e.g., fillet, groove, plug).

- Dimension Symbols: Specify weld size, length, and other geometrical details.

- Process Symbols: Indicate the welding process to be used.

- Supplementary Symbols: Provide additional information such as weld contour, root opening, and finishing requirements.

For example, a symbol with a triangular basic weld symbol on the arrow side and a length dimension indicates a fillet weld of a specified size on that side of the joint. Interpreting these symbols accurately is crucial to ensure that the weld is executed according to the design specifications.

Q 5. What are the key requirements of AWS D1.1?

AWS D1.1, “Structural Welding Code – Steel,” is a widely used standard for structural welding in the United States. Its key requirements include:

- Qualified Welders and Welding Procedures: Requires welders to be qualified through testing and the use of approved Welding Procedure Specifications (WPS).

- Material Specifications: Specifies acceptable base materials and filler metals for different applications.

- Weld Joint Design: Provides guidelines for designing weld joints to ensure adequate strength and stability.

- Welding Process Qualification: Outlines the procedures for qualifying welding processes for specific materials and applications.

- Inspection and Testing: Prescribes inspection and testing methods, including NDT, to verify weld quality.

- Acceptance Criteria: Defines acceptable levels of weld defects and imperfections.

Compliance with AWS D1.1 is essential for ensuring the structural integrity and safety of welded steel structures.

Q 6. Explain the importance of a Welding Procedure Specification (WPS).

A Welding Procedure Specification (WPS) is a documented procedure that outlines the parameters for performing a specific weld. It acts as a recipe for producing consistent, high-quality welds. Its importance lies in:

- Ensuring Weld Quality and Repeatability: By standardizing welding parameters, WPSs minimize variability and defects, leading to consistently reliable welds.

- Meeting Code Requirements: WPSs are often required for compliance with codes and standards like AWS D1.1, demonstrating that the welding process has been qualified.

- Facilitating Qualification of Welders: Welders use WPSs during their qualification tests, proving their ability to produce acceptable welds under specified conditions.

- Improving Efficiency and Productivity: Standardized procedures streamline the welding process and reduce rework, saving time and resources.

Imagine baking a cake: a WPS is like the recipe that guarantees a consistently good result. Without it, the results can vary widely, potentially leading to an inedible cake (or a failed weld).

Q 7. How do you ensure the traceability of welding materials?

Traceability of welding materials is crucial for ensuring quality and safety. It involves maintaining a complete record of the material’s origin, handling, and processing. Methods to ensure this include:

- Material Certification: Requires manufacturers to provide certificates of compliance verifying that the materials meet specified standards. These certificates usually include chemical composition, mechanical properties, and heat treatment information.

- Heat Number Tracking: Assigning a unique heat number to each batch of material allows for tracking its entire history. This is especially important for identifying the source of any problems.

- Proper Storage and Handling: Materials should be stored and handled appropriately to prevent damage or contamination.

- Documentation: Maintaining detailed records of material usage, including lot numbers, quantities, and dates. This aids in identifying the specific material used in a particular weld.

- Barcode or RFID Tracking: Advanced systems utilize barcodes or RFID tags to track materials throughout the entire process, ensuring complete traceability.

In case of a weld failure, traceability allows for quick identification of the potential cause, whether it be a faulty material or a procedural issue, allowing for prompt corrective actions.

Q 8. What is the difference between destructive and non-destructive testing?

The key difference between destructive and non-destructive testing (NDT) lies in whether the test sample is damaged during the process. Destructive testing involves sacrificing the test piece to determine its properties. This is done through methods like tensile testing, where a weld sample is pulled apart until failure to measure its strength. In contrast, non-destructive testing methods evaluate the weld’s integrity without damaging it. Examples include visual inspection, radiographic testing (RT), ultrasonic testing (UT), and magnetic particle testing (MT). Choosing between the two depends on the criticality of the weld, the availability of material, and the information needed.

Think of it like this: destructive testing is like breaking open a toy to see how it works, while NDT is like examining the toy’s exterior and internal structure using tools without breaking it. Destructive testing provides definitive data on strength and material properties, while NDT provides a broader view of the weld’s overall integrity, helping identify potential defects early.

Q 9. Describe your experience with visual inspection of welds.

Visual inspection is the cornerstone of weld quality assessment. My experience encompasses years of performing visual inspections on a wide range of welds, from simple fillet welds in sheet metal to complex butt welds in heavy structural steel. I’m proficient in identifying surface defects such as cracks, porosity, undercuts, overlaps, and lack of fusion. I utilize magnification tools like magnifying glasses and borescopes for close examination, and consistently document my findings with detailed reports, including photographs and sketches. A crucial aspect of visual inspection is understanding the weld process used – knowing the welding procedure helps anticipate potential defects and guide my inspection.

For example, I once identified a series of overlapping welds in a pressure vessel construction, which, although seemingly minor, could have led to significant stress concentration and potential failure under pressure. Early detection through visual inspection prevented a costly and dangerous incident.

Q 10. What are the safety precautions you take during welding inspection?

Safety is paramount during any welding inspection. My safety practices include, but are not limited to:

- Personal Protective Equipment (PPE): Always wearing safety glasses, gloves, and appropriate clothing to protect against sparks, spatter, and UV radiation.

- Respiratory Protection: Utilizing respirators when working in confined spaces or when there’s potential exposure to fumes.

- Fall Protection: Employing fall protection equipment when inspecting welds at heights.

- Awareness of Hot Surfaces: Exercising caution around hot metal and equipment, allowing ample time for cooling before handling.

- Environmental Considerations: Being aware of and complying with all site-specific safety regulations and permits.

- Emergency Preparedness: Knowing the location of emergency exits and emergency response procedures.

I always prioritize a thorough risk assessment before commencing any inspection and adapt my safety procedures accordingly.

Q 11. How do you handle non-conforming welds?

Handling non-conforming welds requires a systematic approach. The first step is to thoroughly document the defect type, location, and severity, using detailed records, photographs, and sketches. Next, I collaborate with the welding team and engineering staff to assess the severity of the non-conformity and its impact on the structural integrity. Depending on the severity and the application, several options are considered:

- Repair: Minor defects can often be repaired by grinding and re-welding, subject to approval from quality control and engineering.

- Removal and Replacement: Severe defects necessitate complete removal of the defective weld and replacement with a new weld, ensuring compliance with the welding procedure specification.

- Acceptance Criteria: Sometimes, depending on the application and relevant codes and standards, minor imperfections might be acceptable provided they fall within predefined acceptance criteria. This requires careful evaluation and justification.

- Rejection: In cases where repair is impractical or the defect poses an unacceptable risk, the entire welded component may be rejected.

Throughout the process, clear communication and thorough documentation are crucial to ensuring a safe and compliant outcome.

Q 12. Explain the concept of weld penetration and its importance.

Weld penetration refers to the depth of the weld into the base material. It’s crucial because inadequate penetration results in a weak weld joint susceptible to failure. Complete penetration, on the other hand, ensures that the weld metal fully fuses with the base material, creating a strong and reliable joint. The required degree of penetration depends greatly on the application and relevant codes and standards; for example, a pressure vessel weld requires full penetration for safety.

Imagine trying to connect two pieces of wood with glue. If the glue only covers a small surface area, the connection will be weak. Complete penetration is akin to the glue effectively bonding the entire surface area, providing maximum strength.

Factors influencing penetration include welding parameters (current, voltage, travel speed), electrode type, joint design, and base metal properties. Inspection methods like radiographic testing (RT) and ultrasonic testing (UT) are often employed to verify the extent of penetration.

Q 13. How do you determine the appropriate type of filler metal for a specific application?

Selecting the appropriate filler metal is paramount for achieving a high-quality weld. This selection depends on several factors:

- Base Material: The chemical composition of the base metal dictates the compatibility of the filler metal. Using an incompatible filler can lead to porosity, cracking, and reduced strength.

- Welding Process: Different welding processes (e.g., SMAW, GMAW, GTAW) necessitate specific filler metal types and forms (e.g., solid wire, flux-cored wire, rods).

- Application Requirements: The intended application determines the required mechanical properties (strength, ductility, toughness) of the weld. For high-strength applications, a higher tensile strength filler is needed.

- Environmental Conditions: The weld’s operating environment (temperature, corrosion, etc.) influences the choice of filler metal. For example, a weld operating in a corrosive environment might require a corrosion-resistant filler.

Consult welding procedure specifications (WPS) and relevant codes (e.g., AWS D1.1) to determine the appropriate filler metal for a given application. These specifications outline the required chemical composition, mechanical properties, and other critical parameters of the filler metal.

Q 14. Describe your experience with different types of weld joints.

My experience covers a wide range of weld joints, including:

- Butt Joints: These are used to join two pieces of metal end-to-end. They can be single-V, double-V, or other configurations, depending on thickness and material.

- Fillet Joints: These form a triangular weld between two intersecting pieces of metal. They are commonly used in lighter-gauge materials.

- Lap Joints: These involve overlapping two pieces of metal and welding the overlap. Simple but effective for joining thinner materials.

- T-Joints: These join a vertical member to a horizontal one, offering significant strength for structural applications.

- Corner Joints: Used to join two pieces of metal at a 90-degree angle.

Each joint type has its own advantages and disadvantages, and the choice depends on factors like material thickness, strength requirements, and ease of welding. Understanding the characteristics of each joint type is critical for selecting the optimal joint design and welding procedure for a specific application.

Q 15. What are the common causes of weld porosity?

Weld porosity, the presence of small gas pockets within a weld, significantly weakens the joint and compromises its integrity. Think of it like tiny holes in a sponge – it’s not as strong as a solid piece. Several factors contribute to this issue.

- Trapped Gases: This is the most common cause. Gases like hydrogen, nitrogen, and oxygen can become trapped during the welding process due to improper cleaning of the base metal, insufficient shielding gas coverage (in GMAW or GTAW), or moisture in the filler material. Imagine trying to bake a cake with flour that’s damp – the steam will create pockets.

- Rapid Cooling: Too-fast cooling rates can prevent dissolved gases from escaping the weld pool, leading to porosity. It’s like shaking a soda bottle vigorously before opening it – the pressure release causes fizz.

- Poor Joint Design: A poorly designed joint, with gaps or insufficient root opening, can trap gases. Consider trying to weld two pieces of metal together with a large gap in between – the gas won’t be able to escape easily.

- Contaminated Materials: Rust, oil, paint, or other contaminants on the base metal will release gases during welding, creating porosity. It’s similar to trying to bake a cake with a dirty pan – the result will be compromised.

- Incorrect Welding Parameters: Using the wrong welding current, voltage, or travel speed can also lead to porosity. It’s like trying to bake a cake in an oven that’s not at the right temperature – the result won’t be optimal.

Addressing these root causes, through proper cleaning, shielding, joint preparation, and parameter optimization, is crucial for preventing weld porosity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your experiences with different codes and standards (e.g., ASME, API)?

My experience spans a wide range of codes and standards, including ASME Section IX for boilers and pressure vessels, and API standards for the oil and gas industry. I’m proficient in interpreting their requirements for welding procedures, welder qualification, and inspection.

For instance, in ASME Section IX, I’m intimately familiar with the qualification requirements for welders and welding procedures, including the different types of weld tests (e.g., bend tests, tensile tests, radiographic tests) and their acceptance criteria. Understanding the nuances of these codes is crucial for ensuring the structural integrity and safety of the welded components.

Working with API standards requires a deep understanding of the specific requirements for pipelines and pressure vessels within the oil and gas sector. This often involves specialized welding processes and stringent quality control measures to withstand harsh environmental conditions and prevent potential hazards. I’ve applied my knowledge of these standards in several projects, ensuring compliance and minimizing risk.

I’m also familiar with other relevant standards like AWS D1.1 for structural welding and ISO standards, allowing me to adapt to diverse project requirements.

Q 17. Explain the importance of pre-weld and post-weld heat treatments.

Pre-weld and post-weld heat treatments (PWHT and PWHT) are critical steps in many welding projects, influencing the microstructure and mechanical properties of the weld and the surrounding base metal.

Pre-weld heat treatment, while less common, can be used to relieve stresses in the base metal before welding, preventing cracking and improving weldability. Think of it as preparing the canvas before painting a masterpiece – you want a smooth and even surface to work with.

Post-weld heat treatment is far more common and serves several vital purposes:

- Stress Relief: Welding introduces residual stresses which can lead to cracking over time. PWHT helps to alleviate these stresses, promoting long-term structural integrity. Imagine a tightly wound spring – PWHT is like gently releasing the tension.

- Improved Toughness and Ductility: PWHT can refine the weld’s microstructure, enhancing its toughness and ductility (ability to deform without breaking). This is particularly important in applications where impact loads are expected.

- Reduced Hydrogen Embrittlement: PWHT helps to diffuse hydrogen from the weld metal, preventing hydrogen embrittlement, a form of cracking that can occur due to trapped hydrogen. It’s like removing a hidden contaminant that would otherwise cause damage.

The specific parameters of PWHT (temperature and time) are determined by the material, weld configuration, and relevant codes and standards. Incorrect PWHT can be detrimental, so careful planning and execution are essential.

Q 18. How do you manage welding documentation and records?

Effective welding documentation is the cornerstone of traceability and quality control. My approach involves a comprehensive system incorporating both physical and digital records.

Physical Records: This includes completed Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), welder performance qualification records, and inspection reports (visual inspection, NDT reports). These are kept securely in a designated area, organized chronologically and by project.

Digital Records: I utilize specialized welding management software to digitally store all documentation. This allows for easy retrieval, searching, and analysis of data. The software also facilitates reporting and helps ensure compliance with relevant codes and standards. This digital system provides a central repository, easily accessible to all stakeholders.

Each weld is assigned a unique identifier linked to its associated documentation, providing full traceability throughout the entire process. Regular audits of the documentation system ensure its integrity and accuracy. This meticulously organized approach helps to minimize errors and promotes overall transparency and accountability.

Q 19. How do you ensure the accuracy of your measurements during weld inspection?

Accuracy in weld measurements during inspection is paramount to ensuring the quality and safety of the welded joint. I employ various techniques and tools to maintain high accuracy:

- Calibrated Measuring Equipment: I only use calibrated instruments like vernier calipers, micrometers, and rulers, ensuring their accuracy is regularly verified. Imagine trying to build a house without an accurate measuring tape – the result would be disastrous.

- Proper Measurement Techniques: I adhere to established measurement protocols, accounting for factors such as temperature and surface irregularities. This includes multiple measurements taken at different points to obtain an average value and reduce individual errors.

- Digital Measurement Tools: Where feasible, I use digital measuring devices which provide higher precision and automatically record measurements, reducing manual errors and improving traceability.

- Visual Aids: In some cases, using magnification tools or visual aids like comparison charts can enhance accuracy, especially when dealing with small details or intricate weld geometries.

- Documentation: All measurements are carefully documented, including date, time, location, equipment used, and the person performing the measurement. This rigorous documentation trail is essential for traceability and quality assurance.

By combining calibrated equipment, precise techniques, and thorough documentation, I consistently maintain accuracy and reliability in all my weld measurements.

Q 20. What are your experiences with different types of NDT equipment?

My experience encompasses a wide range of NDT (Non-Destructive Testing) equipment, which is crucial for assessing weld quality without damaging the component.

- Radiographic Testing (RT): I’m proficient in interpreting radiographs (X-ray and gamma-ray images) to detect internal flaws like porosity, cracks, and inclusions. This is like using a medical X-ray to see inside the weld without cutting it open.

- Ultrasonic Testing (UT): I use ultrasonic probes to detect internal flaws through sound wave reflections. This is similar to using sonar to detect objects underwater.

- Magnetic Particle Testing (MT): Used for detecting surface and near-surface cracks in ferromagnetic materials, this method relies on applying a magnetic field and observing the patterns of magnetic particles that accumulate at discontinuities.

- Liquid Penetrant Testing (PT): I use this method to detect surface-breaking flaws in a wide range of materials. It involves applying a dye that penetrates the crack, then revealing the flaw by using a developer.

- Visual Inspection (VT): This is the most fundamental NDT method, used to visually assess weld quality for surface imperfections such as undercutting, cracks, and lack of fusion.

My expertise extends to understanding the limitations and applications of each NDT method, ensuring the right technique is chosen for the specific application and material.

Q 21. Describe your troubleshooting skills related to welding problems.

Troubleshooting welding problems requires a systematic approach, combining theoretical knowledge with practical experience. My approach typically involves these steps:

- Identify the Problem: Carefully examine the weld defect, noting its type, location, and extent. Is it porosity, cracking, lack of fusion, or something else? Detailed observation is key.

- Gather Information: Review the welding procedure, parameters (current, voltage, travel speed), materials used, and pre- and post-weld heat treatment details. Speaking to the welder about any unusual occurrences during the welding process is valuable.

- Analyze the Data: Correlate the observed defect with the welding process and material properties. This step often involves applying my knowledge of metallurgy and welding science.

- Develop and Test Hypotheses: Based on the analysis, formulate potential causes for the defect (e.g., inadequate cleaning, incorrect welding parameters, material incompatibility). Testing these hypotheses may involve performing trial welds with adjusted parameters.

- Implement Corrective Actions: Based on the successful hypothesis, implement changes to the welding procedure, parameters, or material selection. This may involve retraining welders, modifying equipment, or changing filler materials.

- Verify the Solution: After implementing the corrective actions, carefully inspect the subsequent welds to confirm that the problem has been resolved. Documentation of the entire troubleshooting process is essential.

For example, if I encounter excessive porosity, I might first check for moisture contamination on the base metal, then adjust the shielding gas flow rate or even the welding parameters to address the issue. A systematic, data-driven approach ensures effective and efficient troubleshooting.

Q 22. How do you interpret radiographic images of welds?

Interpreting radiographic images of welds involves carefully examining the film or digital image for any discontinuities within the weld or the Heat Affected Zone (HAZ). We’re looking for indications of flaws like cracks, porosity (small gas pockets), inclusions (foreign material), lack of fusion (incomplete joining of weld metal to base metal), and lack of penetration (weld metal not reaching the required depth).

The process involves comparing the image to established acceptance criteria defined in relevant codes and standards (like AWS D1.1 for structural welding). This requires a trained eye to differentiate between acceptable variations in weld appearance and actual defects. For example, a small amount of porosity might be acceptable depending on the weld type and application, while a crack, regardless of size, is usually unacceptable. I typically use magnification tools and standardized interpretation aids to carefully analyze the image, noting the size, shape, location, and type of any detected discontinuities. Documentation is crucial, recording the findings and making recommendations based on the severity of the detected flaws.

Imagine looking at an X-ray of a bone – you’re searching for fractures or abnormalities. Radiography of welds is similar; it gives us a visual representation of the internal structure, allowing us to assess its integrity before it’s put into service.

Q 23. What are your experiences with ultrasonic testing of welds?

Ultrasonic testing (UT) is a valuable NDT method I’ve extensively used to evaluate weld integrity. UT uses high-frequency sound waves to detect internal flaws. A transducer sends ultrasonic pulses into the material; these pulses reflect off discontinuities (like cracks or lack of fusion) and are received by the same or a separate transducer. The time it takes for the sound waves to travel and return, along with the amplitude of the reflected signal, provides information about the flaw’s size, location, and orientation.

My experience includes using both pulse-echo and through-transmission techniques. Pulse-echo is common for detecting flaws within the weld, while through-transmission verifies the overall soundness of the weld. I’ve worked on various weld types and materials, from stainless steel pressure vessels to pipeline welds. The choice of UT technique and transducer depends heavily on the material, weld geometry, and type of defect anticipated. Data interpretation requires understanding the acoustic properties of the material and recognizing the different patterns produced by various types of flaws. I’ve routinely used UT in conjunction with other NDT methods, such as radiography, for a comprehensive assessment of weld quality.

For instance, during an inspection of a pipeline weld, UT detected a small area of lack of fusion that was not readily apparent visually or through radiography. This early detection prevented a potential catastrophic failure.

Q 24. How do you maintain calibration of NDT equipment?

Maintaining the calibration of NDT equipment is critical for ensuring accurate and reliable test results. This involves a rigorous process of periodic checks against known standards. For example, for ultrasonic testing, we use calibration blocks with artificial flaws of known size and location. The equipment is adjusted until it accurately measures the size and position of these flaws. This calibration process is documented, including the date, time, and results of the calibration checks. Calibration blocks should be traceable to national or international standards.

Similar procedures are followed for other NDT equipment like radiographic systems (using calibrated penetrameters) and magnetic particle inspection equipment (using standard test blocks with known artificial discontinuities). Calibration is not a one-time event; it’s a continuous process performed according to a pre-defined schedule, typically annually or more frequently depending on usage and equipment type. Equipment is also checked before each use to verify it is functioning correctly. Any deviations from established standards trigger recalibration or equipment maintenance. This ensures test results are consistent and reliable, leading to accurate assessment of weld quality and increased safety.

Failing to maintain proper calibration can lead to inaccurate readings, potentially missing critical flaws or falsely rejecting sound welds – both situations can be incredibly costly and dangerous.

Q 25. Explain the importance of root pass control in welding.

Root pass control in welding is paramount because it forms the foundation of the entire weld. Any defects in the root pass will propagate through subsequent weld passes, compromising the overall weld integrity. A properly executed root pass ensures complete penetration, avoids undercut or other imperfections, and provides a stable base for subsequent weld beads.

Techniques for root pass control vary depending on the joint design, material, and welding process used. Common methods include using backing strips (to support the weld metal and prevent burn-through), proper electrode manipulation (ensuring complete penetration), pre-heating (to control thermal gradients and reduce cracking), and using appropriate welding parameters (such as current, voltage, and travel speed). Visual inspection of the root pass after completion is crucial to ensure its quality before proceeding to subsequent passes. Advanced techniques like hot pass control further minimize potential defects.

Think of building a house: if the foundation (root pass) is weak or flawed, the entire structure is at risk. Similarly, a defective root pass can lead to weld failure, potentially with catastrophic consequences.

Q 26. What are your experiences with magnetic particle testing?

Magnetic particle testing (MT) is a widely used NDT method I’ve employed for detecting surface and near-surface flaws in ferromagnetic materials (those that can be magnetized, like steel). The method involves magnetizing the weld, then applying magnetic particles (usually a fine powder) to the surface. Flaws disrupt the magnetic field, causing the particles to accumulate over the defect, making it visible. The inspection can be done using either wet or dry particles.

My experience with MT includes performing both longitudinal and circular magnetization techniques, depending on the geometry of the weld and the orientation of potential defects. I’ve utilized this method extensively for detecting surface cracks, lack of fusion, and other discontinuities in welds. MT is especially valuable because it’s relatively quick, portable, and cost-effective. However, it’s limited to detecting surface or near-surface defects and only works on ferromagnetic materials. Data interpretation relies on recognizing the patterns and distributions of the magnetic particles over the weld surface. Proper demagnetization after testing is also essential to avoid affecting the material’s subsequent handling or processing.

In a recent project, MT successfully identified a small surface crack in a weld that could have potentially led to fatigue failure if left undetected. This prevented a costly and potentially dangerous failure.

Q 27. Describe your understanding of weldability of different metals.

Weldability refers to a material’s ability to be joined by welding processes without producing unacceptable weld defects or compromising the integrity of the joint. Different metals exhibit varying weldability characteristics. Some metals are easily weldable, while others require specific procedures and pre- and post-weld treatments. For example, mild steel is relatively easy to weld, while stainless steels require more careful control of heat input to avoid sensitization (reducing corrosion resistance).

Factors affecting weldability include the material’s chemical composition, microstructure, melting point, and susceptibility to hot cracking, cold cracking, or other weld defects. For example, high carbon steels are more prone to cracking during welding than low carbon steels. Aluminum, although widely used, has its own welding challenges, requiring specialized procedures and filler metals. Understanding the material’s weldability is critical in selecting the appropriate welding process, filler metal, and parameters to ensure a sound and defect-free weld. Material specifications (like those provided in ASME Section IX) often include information on the recommended welding procedures and pre/post-weld heat treatments to ensure satisfactory weldability.

Choosing the wrong welding process or parameters for a particular material can lead to defects like porosity, cracking, or lack of fusion, rendering the weld unusable. Therefore, a comprehensive understanding of the weldability of different metals is vital for producing high-quality welds.

Q 28. How do you communicate effectively with welders and other stakeholders about weld quality?

Effective communication is essential in ensuring weld quality. It involves clear and concise communication with welders, inspectors, engineers, and other stakeholders. With welders, I emphasize the importance of following correct procedures, using proper techniques, and adhering to the specifications. Feedback is crucial, providing constructive criticism when necessary and recognizing excellent work.

With inspectors and engineers, I communicate technical findings clearly and objectively, using standardized reports and visual aids like photographs and NDT results. My approach involves explaining the implications of any defects identified, focusing on the severity and potential impact on the weld’s performance. This also includes proposing corrective actions and recommendations to prevent similar issues in the future. For broader stakeholders, I tailor my communication style to match their technical knowledge, providing understandable summaries without unnecessary jargon. Strong documentation (reports, photos, drawings) serves as a central point of reference to ensure everyone is aligned.

Building trust and rapport with all parties through open communication and a collaborative approach is crucial. A collaborative environment encourages prompt issue resolution and promotes continuous improvement in weld quality.

Key Topics to Learn for a Welding Quality Interview

- Welding Processes: Understanding the nuances of various welding processes (e.g., GMAW, SMAW, GTAW) and their suitability for different materials and applications. Consider the impact of process parameters on weld quality.

- Weld Defects and their Causes: Develop a strong understanding of common weld defects (porosity, cracks, inclusions, etc.), their root causes, and how to prevent them through proper welding techniques and procedures. Be prepared to discuss non-destructive testing (NDT) methods used to identify these defects.

- Weld Metallurgy: Familiarize yourself with the metallurgical changes that occur during welding and how these changes affect the mechanical properties of the weld. Understand the importance of proper heat input and cooling rates.

- Welding Codes and Standards: Demonstrate your knowledge of relevant welding codes and standards (e.g., AWS D1.1, ASME Section IX) and their application in ensuring weld quality and compliance. Be able to discuss specific code requirements related to various welding processes and materials.

- Quality Control and Assurance: Understand the role of quality control and assurance in the welding process, including inspection techniques, documentation, and corrective actions. Discuss your experience with implementing quality control procedures and maintaining detailed records.

- Practical Application: Be ready to discuss real-world examples from your experience where you had to troubleshoot weld defects, implement quality control measures, or resolve issues related to welding procedures. Quantify your achievements whenever possible.

- Problem-Solving and Analytical Skills: Interviewers will assess your ability to identify and solve problems related to weld quality. Practice using a structured approach to problem-solving, outlining your thought process clearly.

Next Steps

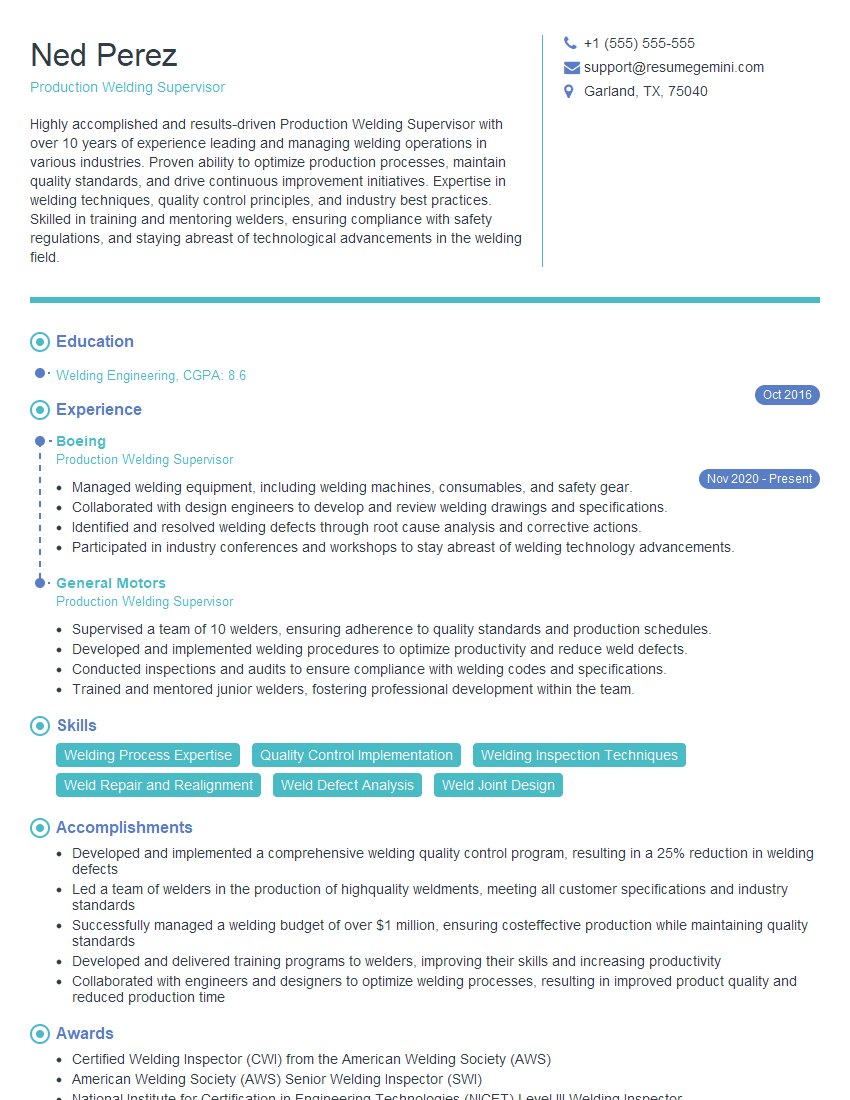

Mastering Welding Quality is crucial for career advancement in this field. Demonstrating a deep understanding of welding processes, defect identification, and quality control practices will significantly increase your job prospects. To enhance your chances of landing your dream role, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to the Welding Quality field to help you get started. Invest the time to create a compelling resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.