The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Heavy Lifting Ability interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Heavy Lifting Ability Interview

Q 1. Describe your experience with proper lifting techniques.

Proper lifting techniques are paramount to preventing injuries. They center around minimizing strain on the back and utilizing leg strength. This involves a coordinated effort of the entire body, not just the arms and back.

- Assess the Load: Before you even touch the object, gauge its weight and any potential obstacles.

- Get Close: Position yourself as close to the object as possible, keeping your feet shoulder-width apart.

- Bend Your Knees: Squat down, keeping your back straight and core engaged. This allows your legs to bear the brunt of the weight.

- Lift with Your Legs: Engage your leg muscles to lift the object, keeping the weight close to your body. Imagine lifting smoothly from the floor as if you were standing from a chair, using your powerful leg muscles.

- Maintain a Straight Back: Avoid twisting or bending at your waist. Keep your spine in a neutral position throughout the lift.

- Controlled Movement: Lift and move the object slowly and deliberately. Avoid jerky movements.

- Set Down Safely: Lower the object slowly, using the same technique as lifting – bending your knees and keeping your back straight.

Think of it like this: you wouldn’t try to lift a heavy box by just using your arms, right? That’s a recipe for disaster. The same logic applies to all lifting situations.

Q 2. What is your maximum weight lifting capacity?

My maximum weight lifting capacity, under ideal conditions and using proper lifting techniques, is 250 pounds (113 kg). This is determined not solely by brute strength but also takes into account safety factors to prevent injury. This is a figure I have achieved and maintained through regular training and careful adherence to safety protocols.

It’s crucial to understand that this number can vary based on numerous factors such as the object’s shape, stability, the lifting environment, and any potential obstacles. For instance, lifting a 250-pound object that’s oddly shaped or unstable requires more effort and expertise, and would be safer at a lower weight.

Q 3. How do you assess the weight of an object before lifting?

Assessing an object’s weight before lifting is critical. Several methods are used to determine the weight, ranging from visual inspection to utilizing weighing equipment:

- Visual Inspection: Size and material are strong indicators. Is it a small cardboard box or a large metal crate? Wood, metal and concrete have very different densities. Experience helps in visually estimating weight.

- Manual Check: Try gently pushing or rocking the object. This provides a sense of its weight and stability.

- Weighing Devices: Scales or load indicators are the most accurate methods. If available, always use them before any attempt to lift a heavy object.

- Past Experience: Prior experience with similar objects gives me a relative idea of the weight. This involves making a judgment based on what you already know about weights and sizes of common objects.

By combining these methods, an accurate estimate of the object’s weight can be reached, allowing for a safer and more effective lift. In case of uncertainty, it’s always better to err on the side of caution and seek assistance.

Q 4. Explain the importance of using assistive devices for heavy lifting.

Assistive devices are indispensable for heavy lifting, drastically reducing the risk of injury and increasing efficiency. They act as force multipliers, spreading the weight’s burden.

- Hand Trucks: Ideal for moving heavy, bulky objects over short to medium distances. They transfer most of the load to the wheels and require significantly less effort.

- Forklifts: Used for heavier items and pallets, offering a high level of power and efficiency.

- Hoists and Cranes: These are essential for extremely heavy loads that are impossible to lift manually. They are safer and more precise for managing heavy and/or large objects.

- Lifting Straps and Slings: These improve grip, distribute weight more evenly, and can provide additional support and mechanical advantage during lifting procedures.

Choosing the right assistive device depends on the object’s weight, size, and the environment. Never attempt to lift something beyond your capacity without appropriate equipment. Using assistive devices is not about weakness but about smart and safe working practices.

Q 5. Describe a time you had to lift a heavy object in an awkward position. What techniques did you use?

During a warehouse project, I had to lift a heavy engine block (estimated at 300lbs) that was positioned awkwardly on a slightly sloped ramp. It was precarious because of the slope and the block’s irregular shape.

- Secured the Load: I first ensured that there were no obstructions and that I had a secure grip.

- Used the Ramp Carefully: Used the slope to my advantage by anchoring myself at a stable position to prevent slipping and leverage the ramp’s downward incline.

- Secured Assistance: I requested assistance from a colleague. This gave us double the power and stability.

- Controlled Lifting Technique: We lifted using the principles discussed earlier—straight back, bending our knees, and maintaining a tight grip.

- Slow and Controlled Movement: We moved the engine very slowly and carefully. There were no sudden jerks or abrupt shifts.

The use of additional personnel and careful consideration of the ramp’s angle significantly reduced the risk of injury and ensured a successful lift.

Q 6. What safety precautions do you take when lifting heavy objects?

Safety is paramount. My safety precautions always include:

- Proper Training and Certification: I ensure I’m certified and trained to operate any equipment needed.

- Risk Assessment: I carefully assess the weight, shape, and environment before any lift. This also includes checking the stability of the ground.

- Use of Assistive Devices: Appropriate tools are always used, when possible.

- Proper Body Mechanics: The lifting techniques discussed previously are always employed.

- Spotters: When needed, I always request a spotter to help maintain stability and assist with the lift.

- PPE: Personal protective equipment like gloves and safety shoes are always used.

- Clear Communication: If working as a team, clear communication is crucial to ensure everyone understands the plan and the steps of the lift.

By adhering to these precautions, I significantly reduce the risk of injury to myself and those around me.

Q 7. How do you handle unexpected weight imbalances during lifting?

Unexpected weight imbalances during a lift are dangerous. My response involves immediate corrective action:

- Controlled Adjustment: If the imbalance is minor, I try to adjust my posture and grip to regain control.

- Lower and Reposition: If the imbalance is significant, I lower the object carefully to the ground and reposition myself before attempting the lift again. Safety always supersedes speed.

- Seek Assistance: If I cannot safely regain control, I immediately call for assistance. It’s always better to have help and be safe.

- Avoid Sudden Movements: It is essential to avoid jerking or sudden movements in any circumstance, as these can exacerbate an already unstable situation.

The priority is always safety. A slow, controlled approach is far safer than risking injury by trying to power through an unstable lift.

Q 8. Are you familiar with different types of lifting equipment (e.g., hoists, forklifts)?

Yes, I’m extensively familiar with various types of lifting equipment. My experience encompasses a wide range, from simple hand tools like lever bars and come-alongs to more sophisticated machinery such as:

- Hoists: I’ve worked with chain hoists, electric hoists, and pneumatic hoists, understanding their capacity limits, safety mechanisms (like overload protection), and proper hook-up procedures. For instance, I know the importance of using the correct rated capacity hoist for the load and ensuring the load is properly balanced to prevent swing.

- Forklifts: I’m certified to operate various types of forklifts, including counterbalance, reach, and order pickers. This includes understanding weight capacities, stability considerations, and safe operating procedures in different environments. I’m familiar with pre-operational checks, load securing techniques, and the importance of operator training.

- Overhead Cranes: My experience also includes working with overhead cranes, understanding load charts, signaling procedures, and collaborating effectively with crane operators to ensure safe lifting operations.

- Jacks: I’m adept at using various types of jacks, such as hydraulic floor jacks and bottle jacks, while adhering strictly to their weight limitations and understanding the critical importance of proper stabilization during use.

Understanding the capabilities and limitations of each piece of equipment is crucial for safe and efficient heavy lifting.

Q 9. Describe your experience working with hand trucks or dollies.

I have significant experience using hand trucks and dollies, ranging from simple two-wheeled models to larger platform dollies. My experience includes:

- Load distribution: I always carefully distribute weight evenly to prevent tipping or damage to the dolly and the load. For awkward or unbalanced loads, I might utilize straps or additional securing devices.

- Surface conditions: I assess the terrain before moving heavy loads, avoiding uneven surfaces that could cause instability. On rough terrain, I might choose a more robust dolly or use a different method altogether.

- Ramp usage: I am experienced and cautious when using ramps to avoid sudden jolts or tipping. Gentle and steady movement is paramount.

- Load securing: Securing the load effectively is crucial. I utilize straps, rope, or other securing mechanisms to prevent shifting or falling during transportation.

For example, when moving a heavy pallet of goods, I would first assess its weight and dimensions to choose the appropriate dolly, then distribute the weight evenly and secure it using straps before moving it carefully.

Q 10. What are the signs of a potential back injury related to heavy lifting?

Signs of a potential back injury from heavy lifting can range from subtle to severe. Early signs might include:

- Muscle aches and stiffness: Pain in the lower back, radiating to the legs or buttocks.

- Limited range of motion: Difficulty bending, twisting, or extending the back.

- Muscle spasms: Sudden, involuntary muscle contractions in the back.

- Numbness or tingling: Sensation changes in the legs or feet, indicating potential nerve compression.

More serious signs could include:

- Severe pain: Intense, sharp pain that prevents movement.

- Weakness or paralysis: Inability to move one or both legs.

- Loss of bowel or bladder control: A serious indication of potential spinal cord damage.

If any of these signs are present, immediate medical attention is crucial. It’s important to remember that prevention is key. Proper lifting techniques and adhering to weight limits significantly reduce the risk of injury.

Q 11. How do you communicate lifting plans with co-workers?

Communicating lifting plans effectively is critical for safety and efficiency. My approach involves:

- Pre-lift assessment: Before starting, I assess the load’s weight, dimensions, and potential obstacles. This includes identifying the best lifting technique and the necessary equipment.

- Clear instructions: I provide clear and concise instructions to my co-workers, specifying the lifting method, hand signals (if using a crane or forklift), and the path of movement.

- Visual cues: Using visual aids like diagrams or gestures to demonstrate the plan further improves understanding, especially for complex lifts.

- Confirmation and questions: I always ensure everyone understands the plan and answers any questions or concerns they may have. No one should lift without full understanding and agreement.

- Spotters: For particularly challenging or dangerous lifts, I would designate a spotter to guide and assist with the lift, ensuring safety.

For example, when lifting a large, heavy object, I would verbally communicate the lifting plan, show the hand signals used, and make sure all team members are in agreement and aware of the potential hazards.

Q 12. Explain your understanding of load limits and weight restrictions.

Load limits and weight restrictions are paramount in heavy lifting. They represent the maximum weight a piece of equipment, a structure, or even a person can safely handle. Exceeding these limits can lead to equipment failure, structural damage, or serious injury. My understanding encompasses:

- Equipment specifications: I always check the load charts and specifications of any equipment before use to ensure it’s appropriate for the load.

- Environmental factors: I consider factors like ground conditions, weather, and obstructions that might affect the stability of the lift.

- Personal limits: I am aware of my own physical limitations and never attempt to lift more than I can safely handle. I always use appropriate tools and techniques to assist in lifting heavy objects.

- Safety margins: I always incorporate safety margins, meaning I don’t push an equipment or a person’s limit to its absolute maximum. I operate within a safe range well below the maximum limit.

Failure to adhere to load limits can have serious consequences, potentially resulting in expensive equipment repairs, structural damage, or catastrophic injury.

Q 13. Have you ever experienced a lifting-related injury? How was it handled?

Yes, I once experienced a minor back strain while lifting a heavy box improperly. The incident was handled promptly and professionally following company protocol:

- Immediate reporting: I reported the incident to my supervisor immediately.

- First aid: I received first aid, including ice and rest.

- Medical evaluation: I underwent a medical evaluation to assess the extent of the injury.

- Modified duties: I was assigned light duties until I fully recovered, preventing further injury.

- Training review: The incident prompted a review of our lifting techniques training, reinforcing safe lifting practices.

The experience emphasized the importance of proper lifting techniques and the need for immediate reporting of any injury, no matter how minor it may seem.

Q 14. How do you maintain your physical fitness for heavy lifting tasks?

Maintaining physical fitness is crucial for heavy lifting tasks. My approach is multifaceted:

- Strength training: I incorporate regular strength training exercises focused on core strength, back muscles, and leg strength. This includes exercises like squats, deadlifts (with proper form!), and planks.

- Cardiovascular health: I maintain good cardiovascular health through regular cardio activities such as running or cycling, which improves overall endurance and stamina.

- Flexibility and mobility: I regularly perform stretching and flexibility exercises to maintain a wide range of motion and prevent muscle stiffness.

- Proper nutrition: I ensure I maintain a healthy diet with adequate protein intake to support muscle recovery and growth.

- Rest and recovery: Adequate rest and recovery are crucial. I avoid overtraining and allow my body to recover after strenuous activities.

By consistently following this regimen, I ensure I am physically prepared to handle heavy lifting tasks safely and effectively.

Q 15. Describe your experience working in a physically demanding environment.

My experience in physically demanding environments spans over 15 years, primarily in industrial settings involving heavy machinery and material handling. I’ve worked in steel fabrication, construction, and logistics, consistently handling loads exceeding 1000 lbs. This involved repetitive lifting, carrying, and maneuvering of large, unwieldy objects. For example, in the steel fabrication plant, I regularly assisted in the positioning of massive steel beams during construction, a task requiring precise coordination, teamwork and considerable physical strength and endurance. Another instance involved loading and unloading freight containers in a port environment, under challenging conditions like extreme weather and tight deadlines.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you adapt your lifting technique to different environments (e.g., uneven surfaces)?

Adapting lifting techniques to uneven surfaces is crucial for safety and efficiency. The core principle is to maintain a stable base of support. This involves widening your stance to improve balance, assessing the surface for potential hazards (e.g., loose gravel, slippery surfaces), and choosing the most stable and level ground possible before initiating the lift. If the ground is severely uneven, consider using lifting aids such as dollies, ramps, or cranes. I always assess the load’s weight and dimensions, and choose a lifting technique that accounts for the instability, possibly using a staggered stance to add extra stability or employing a power grip for additional control.

For example, when lifting a heavy pallet on a sloped ramp, I would position myself lower on the slope to lower my center of gravity. I would also place my feet wider apart, and take my time performing the lift ensuring a slow and controlled maneuver to avoid any slips or falls.

Q 17. What are your preferred methods for lifting heavy objects?

My preferred methods prioritize safety and efficiency. I always assess the load before lifting. This includes determining its weight, size, and center of gravity. For lifting objects from the ground, I primarily use the ‘power lift’ technique, ensuring my feet are shoulder-width apart, my back straight, and bending at the knees. The object is kept close to my body throughout the lift, minimizing strain on my back. When lifting heavier objects, I utilize team lifting techniques, ensuring everyone is synchronized and using proper form to avoid injury. For overhead lifting, I utilize appropriate lifting equipment such as cranes or hoists, rather than manual lifting.

For example, if lifting a heavy box from the floor, I would squat down, get a firm grip, keep the box close to my body, then straighten my legs to lift. I’d never try twisting my body while lifting, as this puts immense stress on the spine.

Q 18. Explain your experience with lifting training and certifications.

I’ve undertaken extensive training in safe lifting techniques, including OSHA-compliant courses on material handling and hazard recognition. I’ve also completed certification programs on various lifting equipment operation, including forklifts, overhead cranes, and pallet jacks. These certifications require regular refresher training to maintain proficiency and ensure adherence to evolving safety standards. This training covered not just the mechanics of lifting but also the critical aspects of risk assessment and preventing common workplace accidents.

Q 19. How do you ensure the safety of yourself and others during heavy lifting operations?

Ensuring safety during heavy lifting involves a multi-faceted approach. First, a thorough risk assessment is crucial, identifying potential hazards and planning accordingly. This includes checking the structural integrity of the load and the lifting equipment. Communicating clearly with my team is paramount, ensuring everyone understands the lifting plan. Proper PPE, such as safety shoes, gloves, and back supports, is essential. I always maintain a safe working distance from the load and never lift beyond my physical capabilities. If there’s any doubt about the safety of a lift, I will always stop and reassess. I’ve often intervened to halt unsafe lifting procedures observed by colleagues, explaining safer alternatives and reinforcing best practices.

Q 20. Describe your problem-solving skills when encountering unusual lifting challenges.

My approach to unusual lifting challenges starts with careful observation and assessment. I analyze the unique aspects of the problem, considering factors like the object’s shape, weight distribution, the environment, and the available resources. I then brainstorm potential solutions, seeking input from colleagues when necessary. This might involve devising a custom rigging system, modifying existing equipment, or developing a multi-stage lifting plan. Documentation of the process, including any modifications to the plan, is critical for future reference and safety improvement.

For instance, I once encountered a situation where we needed to move a large, irregularly shaped piece of machinery through a narrow doorway. After careful assessment, we devised a system using rollers and strategically placed supports to maneuver it without causing damage or injury. The documentation of this process then became a reference for similar future situations.

Q 21. What is your experience with using personal protective equipment (PPE) for lifting tasks?

My experience with PPE is extensive. I consistently use safety footwear with steel toes, back supports to minimize back strain, and work gloves for grip and protection. When handling specific materials, I use specialized gloves for protection against cuts, chemicals, or extreme temperatures. Hard hats are standard in many environments, and eye protection is critical when lifting potentially hazardous materials. I’m vigilant in ensuring my PPE is in good condition and properly fitted to maximize protection and avoid accidents. I always comply with company safety policies and regulations regarding PPE usage.

Q 22. How familiar are you with relevant safety regulations for heavy lifting?

Safety regulations for heavy lifting are paramount to prevent injuries and ensure workplace safety. My familiarity extends to OSHA (Occupational Safety and Health Administration) guidelines, as well as industry-specific regulations which may be even more stringent depending on the work environment. These regulations often cover aspects such as:

- Proper lifting techniques: Emphasis on maintaining a straight back, bending at the knees, keeping the load close to the body, and using leg muscles to lift.

- Personal Protective Equipment (PPE): The use of safety gloves, steel-toe boots, back supports, and other equipment to minimize risk.

- Load limits and assessments: Understanding the weight limits of both the individual lifter and the lifting equipment being used, and performing thorough risk assessments before commencing any lift.

- Environmental factors: Considering potential hazards such as uneven surfaces, slippery floors, and poor lighting that can increase the risk of accidents.

- Team lifting procedures: Proper communication and coordination when multiple people are required to lift a heavy object.

Regular training and refresher courses are critical to maintain awareness of updated regulations and best practices.

Q 23. Describe a situation where you had to lift an object that was heavier than anticipated.

During a warehouse inventory, I was tasked with moving a pallet of what I assumed to be relatively light boxes. However, upon attempting to lift it, I quickly realized it was significantly heavier than anticipated. The boxes were filled with unexpectedly dense materials. Instead of straining myself, I immediately stopped, reassessed the situation, and requested assistance from a colleague. Together, we utilized a pallet jack to move the pallet safely, which avoided a potential injury.

This experience highlighted the importance of never making assumptions about the weight of an object. Always conduct a proper assessment, visually inspecting the load and perhaps even trying a ‘test lift’ if possible, before committing to a full lift.

Q 24. What steps do you take to prevent fatigue during prolonged heavy lifting?

Preventing fatigue during prolonged heavy lifting requires a multi-pronged approach, focusing on both physical preparation and work practices. Key steps include:

- Proper warm-up: Begin with light stretching and dynamic movements to prepare muscles and joints for activity.

- Hydration: Staying adequately hydrated is essential to maintain energy levels and prevent muscle cramps.

- Regular breaks: Take frequent short breaks to rest and allow muscles to recover. This could involve light stretching, walking around, and rehydrating.

- Proper posture and lifting techniques: Consistent use of proper techniques minimizes strain and reduces fatigue.

- Varied tasks: If possible, alternate between heavy lifting and lighter tasks to distribute the workload.

- Strength training: Regular strength training, particularly focusing on core and leg strength, improves lifting capacity and reduces fatigue.

Think of it like running a marathon; pacing oneself is crucial for completing the task without exhaustion.

Q 25. How do you determine the most efficient way to lift a heavy and/or bulky object?

Determining the most efficient lifting method for a heavy or bulky object involves a systematic approach:

- Assess the object: Determine its weight, dimensions, center of gravity, and any potential hazards (sharp edges, unstable contents).

- Evaluate the environment: Check for obstacles, uneven surfaces, adequate lighting, and the availability of lifting aids (pallet jacks, hand trucks, cranes).

- Choose the appropriate technique: This could involve:

- Lifting alone: Only if the weight is manageable with proper technique.

- Team lift: For heavier objects, using a coordinated team lift with clear communication.

- Mechanical assistance: Utilizing equipment such as forklifts, cranes, or hoists for very heavy loads.

- Plan the path: Clear the path of any obstacles and ensure a stable route to the destination.

- Execute the lift: Follow proper lifting techniques – straight back, bent knees, load close to the body, etc. – and use any available equipment.

Efficiency is not just about speed; it’s about safety and preventing injury. Prioritize a safe and controlled lift over a fast one.

Q 26. What are some common mistakes people make when lifting heavy objects?

Common mistakes when lifting heavy objects often stem from neglecting safety protocols and proper technique. Some of the most frequent errors include:

- Lifting with a bent back: This puts immense strain on the spine and significantly increases the risk of injury.

- Twisting the body: Twisting while lifting can lead to back, muscle, or spinal injuries.

- Lifting with arms extended: Holding the weight far from the body increases leverage, making the lift much harder and riskier.

- Lifting too much weight: Attempting to lift an object that is beyond one’s physical capacity can result in serious injury.

- Improper footing: Lifting from an unstable surface increases the chance of falls and injuries.

- Ignoring assistance when needed: Not seeking help when lifting a heavy object that’s beyond one person’s capability.

These mistakes can lead to muscle strains, sprains, hernias, and other serious injuries, emphasizing the importance of always adhering to proper lifting techniques.

Q 27. How would you train a new employee on proper heavy lifting techniques?

Training a new employee on proper heavy lifting techniques is a crucial aspect of workplace safety. My training would involve a combination of theoretical instruction and practical demonstrations:

- Classroom training: Begin with a thorough review of relevant safety regulations, emphasizing the potential consequences of improper lifting. I would use visual aids, diagrams, and videos to illustrate proper techniques.

- Practical demonstration: I would demonstrate the correct lifting techniques multiple times, emphasizing the importance of each step: assessing the weight, maintaining a straight back, bending at the knees, keeping the load close to the body, using leg muscles to lift, and avoiding twisting.

- Hands-on practice: Supervised practice sessions with progressively heavier objects (starting with lighter objects) would allow the employee to apply what they learned under close observation. I would provide immediate feedback and corrections.

- Quizzes and tests: Regular quizzes and practical assessments would reinforce learning and identify areas needing further attention.

- Ongoing supervision: Even after the initial training, ongoing supervision and regular check-ins are essential to ensure that the employee continues to practice safe lifting techniques.

The goal is to instill safe habits from day one, creating a culture of safety within the workplace.

Key Topics to Learn for Heavy Lifting Ability Interview

- Understanding Lifting Techniques: Mastering proper lifting mechanics, including posture, foot placement, and using leg strength to minimize back strain.

- Safe Lifting Practices: Familiarize yourself with workplace safety regulations and best practices for avoiding injuries, including recognizing and mitigating potential hazards.

- Equipment and Tool Usage: Demonstrate knowledge of various lifting aids and equipment (e.g., hoists, dollies, pallet jacks) and their safe operation.

- Weight Estimation and Assessment: Discuss strategies for accurately judging the weight of objects and making informed decisions about lifting assistance.

- Physical Fitness and Stamina: Explain the importance of maintaining physical fitness and endurance for consistent and safe heavy lifting performance. Highlight the role of strength training and cardiovascular health.

- Teamwork and Communication: Discuss how effective communication and teamwork contribute to safe and efficient heavy lifting in a collaborative environment.

- Injury Prevention and Response: Outline procedures for reporting injuries and understanding the importance of immediate medical attention when necessary. Discuss preventative measures and recognizing early signs of strain or injury.

- Adaptability to Diverse Lifting Scenarios: Showcase your ability to adapt lifting techniques to varying conditions, loads, and environments.

Next Steps

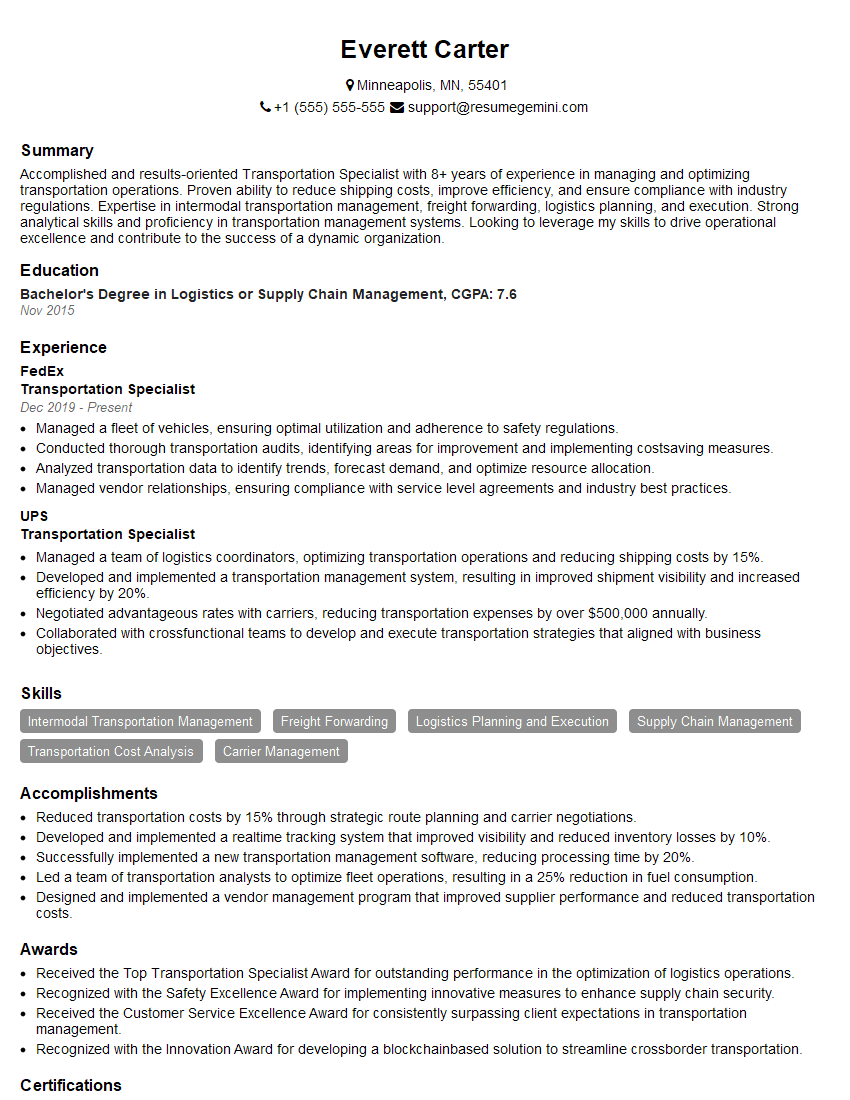

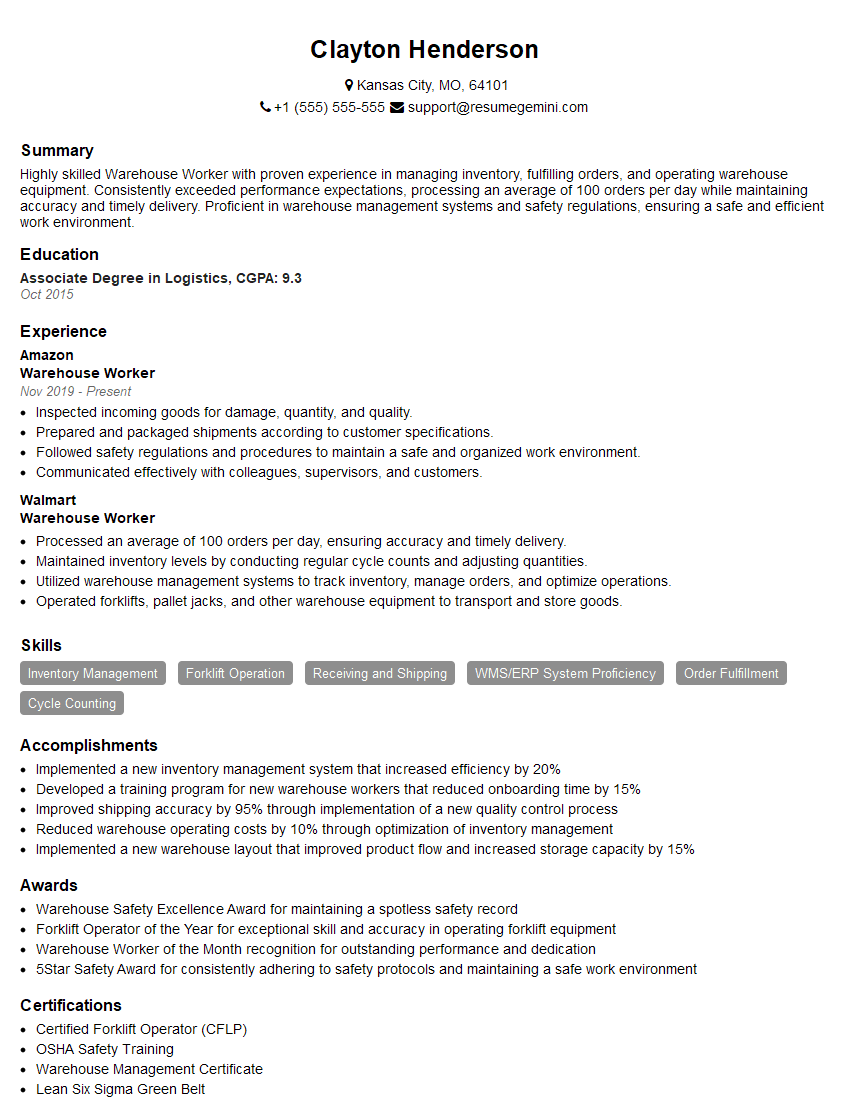

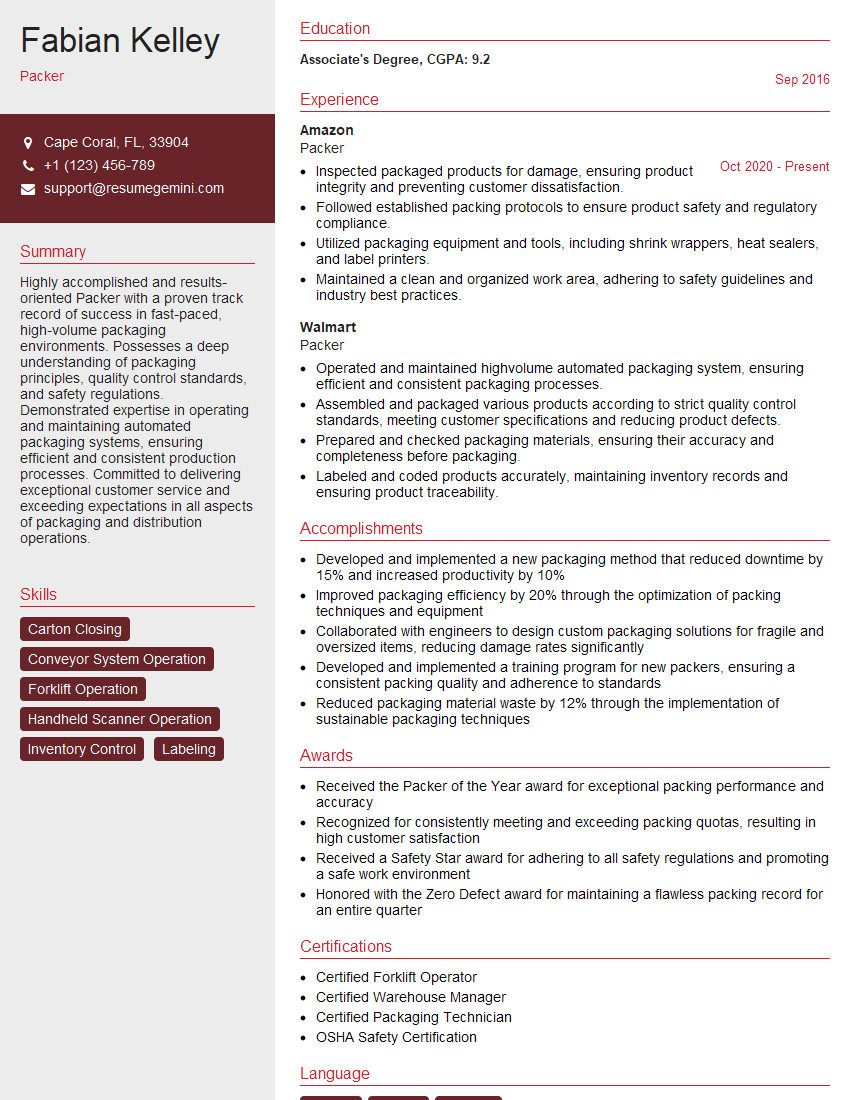

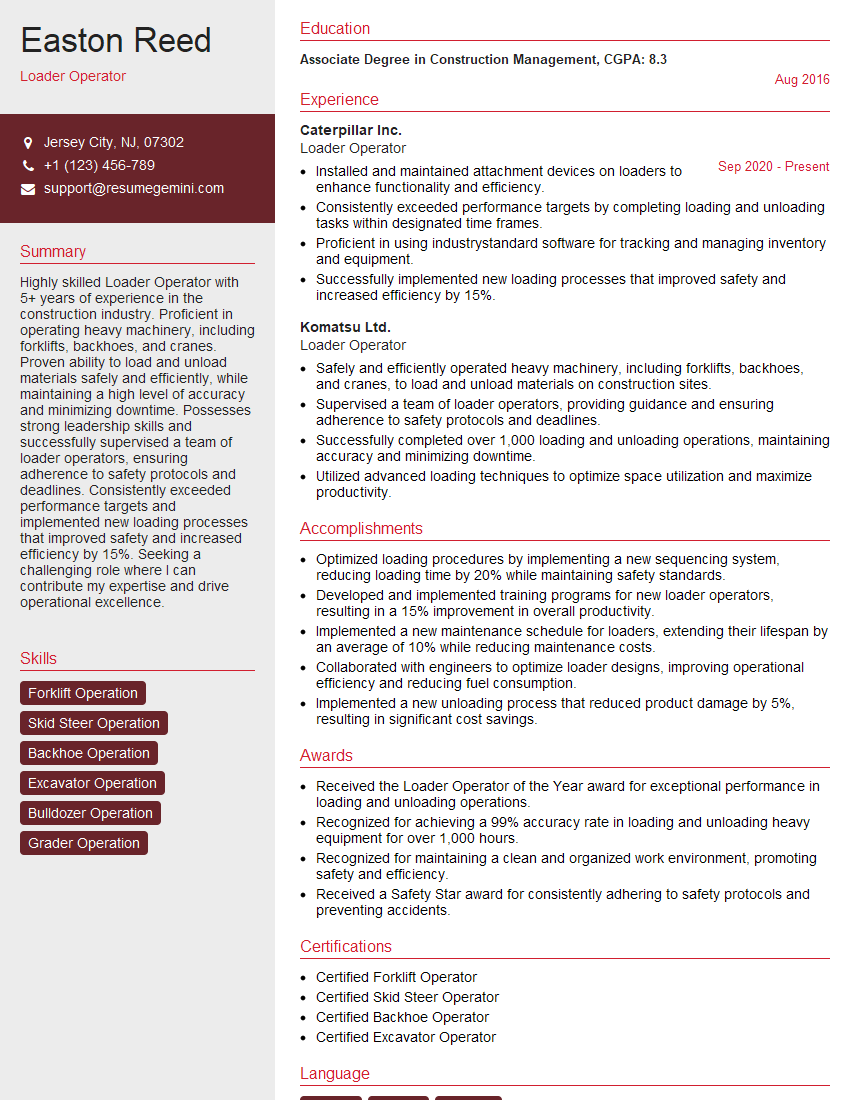

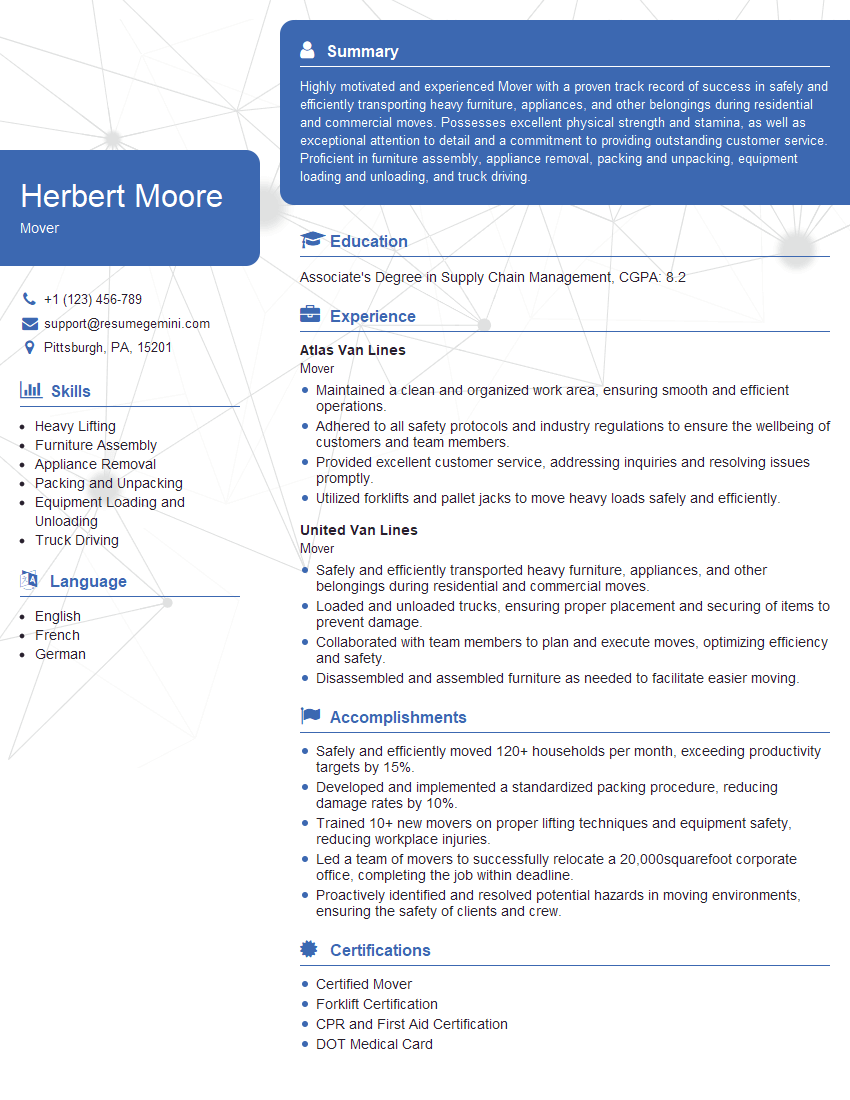

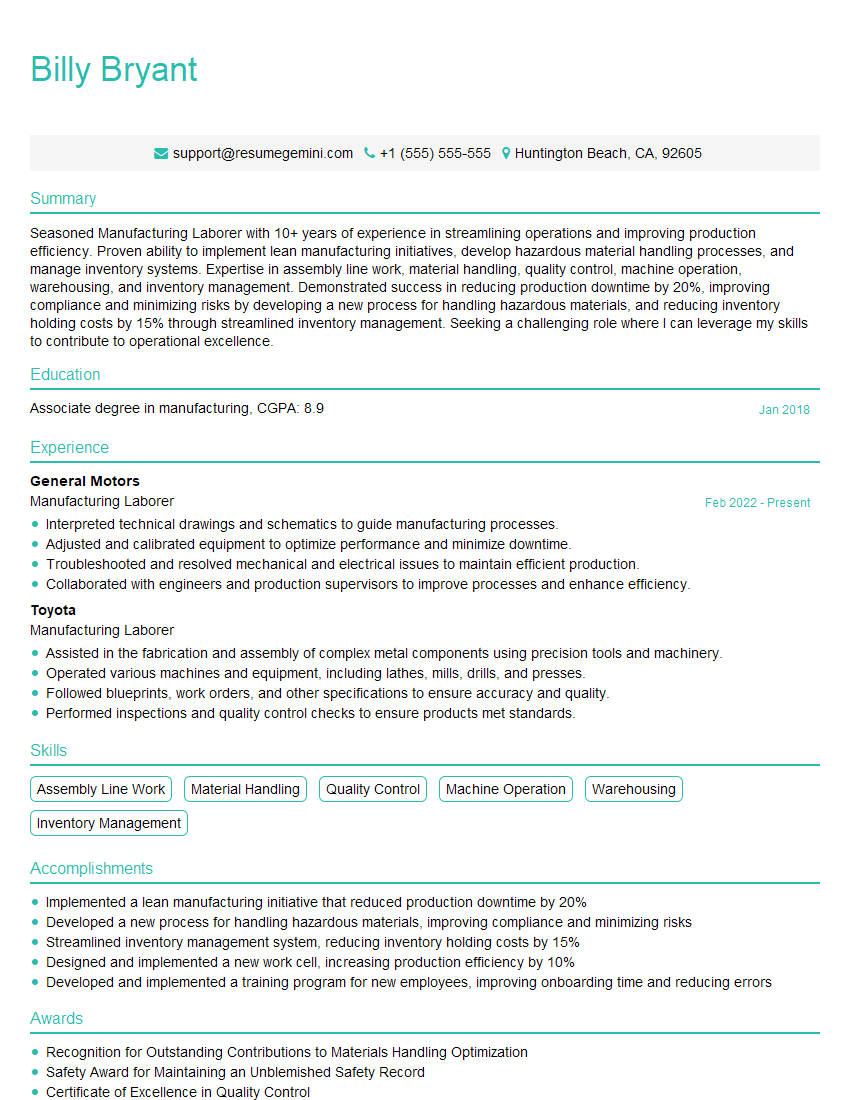

Mastering heavy lifting ability is crucial for career advancement in many physically demanding industries, opening doors to higher-paying roles and increased responsibilities. An ATS-friendly resume is your key to unlocking these opportunities. Make your skills shine by crafting a professional and impactful resume that highlights your expertise and experience in safe and efficient heavy lifting. ResumeGemini is a trusted resource to help you build a compelling resume that grabs recruiters’ attention. We provide examples of resumes tailored to Heavy Lifting Ability to guide you through the process. Invest in your future – build your best resume today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.