The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Lean Six Sigma for Manufacturing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Lean Six Sigma for Manufacturing Interview

Q 1. Define DMAIC and its phases.

DMAIC is a data-driven, five-phase improvement methodology used in Six Sigma to define, measure, analyze, improve, and control a process. Think of it as a structured roadmap to systematically tackle process problems.

- Define: Clearly define the problem, project goals, and customer requirements. This involves identifying the critical-to-quality (CTQ) characteristics and setting measurable targets. For example, in a manufacturing plant, this phase might involve defining the unacceptable defect rate of a product.

- Measure: Collect data to understand the current process performance. This includes identifying key metrics, gathering baseline data, and determining the process capability. For example, measuring the current defect rate, cycle time, and customer satisfaction score.

- Analyze: Analyze the data to identify the root causes of the problem. Tools like Pareto charts, Fishbone diagrams, and process maps are used in this phase. For example, analyzing the data to determine if the defects are due to faulty materials, operator error, or equipment malfunction.

- Improve: Develop and implement solutions to address the root causes identified in the analysis phase. This often involves brainstorming, experimentation, and pilot testing. For example, implementing new training procedures for operators, upgrading equipment, or changing the material supplier.

- Control: Implement controls to sustain the improvements and prevent the problem from recurring. This involves monitoring key metrics, using control charts, and establishing standardized procedures. For example, implementing a regular inspection process, and using control charts to track the defect rate over time.

Q 2. Explain the difference between Lean and Six Sigma.

Lean and Six Sigma are complementary methodologies aimed at improving efficiency and quality, but they focus on different aspects. Lean focuses on eliminating waste and maximizing value from the customer’s perspective, while Six Sigma focuses on reducing variation and improving process capability.

Lean emphasizes speed, efficiency, and waste reduction. Think of it as streamlining a process to remove unnecessary steps, like eliminating bottlenecks and reducing inventory. Its core tools include Value Stream Mapping, 5S, Kanban, and Kaizen.

Six Sigma emphasizes precision, consistency, and minimizing defects. Think of it as fine-tuning a process to ensure consistent output, meeting customer specifications every time. Its core tools include DMAIC, control charts, FMEA (Failure Mode and Effects Analysis), and statistical process control (SPC).

In essence, Lean focuses on ‘doing more with less,’ while Six Sigma focuses on ‘doing it right every time’. Often, they are used together for a synergistic effect.

Q 3. Describe the 5S methodology.

5S is a workplace organization method that uses five Japanese words starting with the letter ‘S’ to create a more efficient and safer work environment. It’s not just about tidiness; it’s about creating a culture of order and efficiency.

- Seiri (Sort): Eliminate unnecessary items from the workspace. Only keep what’s essential for the job. Imagine decluttering your desk—removing unnecessary files and supplies.

- Seiton (Set in Order): Organize the remaining items logically and efficiently. Everything should have a designated place, making it easy to find and use. This is like setting up a filing system for your documents.

- Seiso (Shine): Clean the workspace regularly and thoroughly. This includes cleaning equipment, tools, and the surrounding area. Regular cleaning helps identify potential problems early on.

- Seiketsu (Standardize): Establish standardized procedures for maintaining order, cleanliness, and efficiency. Create checklists and guidelines to ensure consistency. Think of having a cleaning schedule and clear instructions on how to maintain the workspace.

- Shitsuke (Sustain): Maintain the 5S system over time. This requires ongoing commitment and regular review. Regularly audit the workplace to ensure that standards are upheld.

Q 4. What are the key tools used in Lean Six Sigma (e.g., Value Stream Mapping, Pareto Chart, Control Charts)?

Lean Six Sigma utilizes a variety of powerful tools. Here are some key examples:

- Value Stream Mapping (VSM): A visual representation of the entire process, highlighting value-added and non-value-added steps. It’s used to identify bottlenecks and areas for improvement.

- Pareto Chart: A bar graph that ranks the causes of a problem from most to least significant, allowing you to focus on the vital few rather than the trivial many. For example, identifying the top 20% of defects responsible for 80% of the total defects.

- Control Charts: Graphical tools used to monitor process stability and identify variations over time. They help you detect shifts in the process mean or increases in variability.

- Fishbone Diagram (Ishikawa Diagram): A cause-and-effect diagram used for brainstorming and identifying potential root causes of a problem. It helps organize ideas visually.

- FMEA (Failure Mode and Effects Analysis): A systematic approach to identify potential failure modes in a process and assess their impact. It helps prioritize risk mitigation efforts.

- Process Capability Analysis (Cp, Cpk): Statistical methods to determine if a process is capable of meeting specified requirements.

Q 5. How do you calculate the process capability index (Cp and Cpk)?

The process capability indices Cp and Cpk measure how well a process meets the customer’s specifications. They express the relationship between the process variation and the tolerance limits.

Cp (Process Capability Index): Measures the potential capability of a process assuming the process is centered on the target.

Cp = (USL - LSL) / 6σ

Where: USL = Upper Specification Limit, LSL = Lower Specification Limit, σ = standard deviation of the process.

Cpk (Process Capability Index): Measures the actual capability of a process, taking into account the process mean’s distance from the target.

Cpk = min[(USL - μ) / 3σ, (μ - LSL) / 3σ]

Where: μ = process mean.

A Cp or Cpk value greater than 1.33 generally indicates a capable process. Values less than 1 indicate an incapable process needing improvement.

Q 6. Explain the concept of a control chart and its purpose.

A control chart is a time-ordered plot of sample statistics used to monitor process behavior. Its purpose is to detect special cause variation (unexpected shifts or patterns) that indicate a process is out of control and needs attention, distinguishing it from common cause variation (inherent, random fluctuation).

Control charts typically include:

- Center Line: Represents the average process performance.

- Upper Control Limit (UCL): The upper bound beyond which a data point signals a process is out of control.

- Lower Control Limit (LCL): The lower bound beyond which a data point signals a process is out of control.

Different types of control charts are used depending on the type of data (e.g., X-bar and R chart for continuous data, p-chart for proportions).

By regularly monitoring control charts, you can identify problems early, prevent defects, and improve process stability.

Q 7. What is a Fishbone Diagram and how is it used in root cause analysis?

A Fishbone diagram, also known as an Ishikawa diagram or cause-and-effect diagram, is a visual tool used for brainstorming and identifying the potential root causes of a problem. It resembles a fish skeleton, with the ‘head’ representing the problem and the ‘bones’ representing potential causes categorized into different branches.

How it’s used in root cause analysis:

- Define the problem: Clearly state the problem at the head of the fishbone.

- Identify potential cause categories: Brainstorm potential causes and group them into categories (e.g., Materials, Methods, Manpower, Machines, Measurement, Environment). These categories are the main ‘bones’ of the fish.

- Brainstorm specific causes within each category: For each category, brainstorm specific causes that could contribute to the problem. These are the smaller ‘bones’ branching off the main ones.

- Analyze and prioritize causes: Once you have identified potential causes, analyze them to determine which are most likely to be the root causes. This may involve data analysis or further investigation.

- Develop solutions: Based on the identified root causes, develop and implement solutions to address the problem.

The Fishbone diagram facilitates a structured approach to identifying potential root causes, ensuring a thorough investigation and preventing overlooking key factors.

Q 8. Describe your experience with Value Stream Mapping. What improvements did you identify and implement?

Value Stream Mapping (VSM) is a lean manufacturing technique used to visually represent the flow of materials and information required to bring a product or service to the customer. It helps identify waste (Muda) and bottlenecks in the process. In my previous role at Acme Manufacturing, we used VSM to analyze our assembly line for a key product. We mapped the entire process, from raw materials to finished goods, noting the time spent at each step, transportation times, inventory levels, and quality checks.

Through this mapping, we identified several areas for improvement:

- Excessive inventory: We discovered large amounts of work-in-progress (WIP) accumulating between certain workstations due to unbalanced production rates.

- Unnecessary transportation: Raw materials were being moved between storage and workstations inefficiently, adding to lead time.

- Long processing times: One specific workstation had significantly longer processing times than others, causing a bottleneck.

To address these issues, we implemented the following changes:

- Implemented Kanban: We used a Kanban system to manage inventory flow, reducing WIP significantly and improving the pull system.

- Redesigned workstation layout: We reorganized the workstation layout to minimize transportation distances and improve workflow.

- Improved workstation efficiency: We streamlined the processes at the bottleneck workstation by introducing new tools and techniques, reducing processing time.

These changes resulted in a 20% reduction in lead time, a 15% decrease in inventory, and a 10% improvement in overall production efficiency. The VSM process provided a clear visual roadmap to identify and eliminate waste, driving significant improvements in our manufacturing process.

Q 9. How would you identify and prioritize improvement projects using Lean Six Sigma principles?

Identifying and prioritizing improvement projects within a Lean Six Sigma framework involves a structured approach. We typically start with a thorough understanding of the current state, followed by data-driven analysis to pinpoint areas with the highest potential for improvement.

1. Identify Potential Projects: We use various tools, including SIPOC diagrams (Suppliers, Inputs, Process, Outputs, Customers), process maps, and Pareto charts to identify areas with high defect rates, long lead times, high costs, or significant customer complaints.

2. Prioritize Projects: Projects are then prioritized based on their potential impact and feasibility. We often use a matrix that considers factors like:

- Impact: How significant is the potential improvement (cost savings, defect reduction, lead time improvement)?

- Feasibility: How easy is it to implement the improvement (resources, time, support)?

- Urgency: How critical is it to address this issue immediately?

This matrix helps to objectively rank potential projects and focus on those that offer the greatest return on investment (ROI) in the shortest timeframe. The DMAIC (Define, Measure, Analyze, Improve, Control) methodology provides a framework for executing chosen projects.

3. Data-Driven Decision Making: Throughout the process, we rely on statistical analysis to validate our assumptions and measure the effectiveness of implemented improvements. This ensures we are working on the right problems and delivering tangible results. For instance, Control charts are vital for monitoring process stability post-improvement.

Q 10. Explain the concept of Kaizen.

Kaizen, meaning ‘change for the better’ in Japanese, is a philosophy of continuous improvement. It emphasizes small, incremental changes implemented frequently by everyone involved in the process. Instead of relying on large-scale, infrequent improvements, Kaizen encourages a culture of ongoing improvement through daily problem-solving and small-scale adjustments.

Imagine a team constantly tweaking a machine’s settings to optimize performance, or a group brainstorming minor adjustments to a workflow to eliminate a small delay. These actions, though small individually, accumulate to significant improvements over time. Kaizen involves active participation from all employees at all levels, fostering teamwork, engagement, and a sense of ownership in the improvement process. It helps to foster a culture of continuous learning and adaptation.

Effective Kaizen often uses tools like 5S (Sort, Set in Order, Shine, Standardize, Sustain) for workplace organization and Gemba walks (going to the actual place where work is done to observe and understand the process) for firsthand observation and problem-solving.

Q 11. How do you measure the success of a Lean Six Sigma project?

Measuring the success of a Lean Six Sigma project relies on pre-defined metrics aligned with the project’s goals. We use a combination of leading and lagging indicators. Leading indicators track progress during the project, and lagging indicators measure the final impact.

Examples of metrics include:

- Defect rate: Measuring the reduction in defects per unit produced.

- Cycle time: Measuring the time taken to complete a process.

- Cost savings: Quantifying the financial benefits achieved (reduced waste, improved efficiency).

- Customer satisfaction: Assessing the improvement in customer feedback (Surveys, Net Promoter Score).

- Throughput: Tracking an increase in units produced per time period.

Before initiating a project, we establish baseline measurements for these metrics. Then, we track the progress during the improvement phase and compare the final results to the baseline. This quantitative data provides strong evidence of the project’s effectiveness and the achievement of its objectives. We also document the changes implemented and create a control plan to maintain the improvements achieved.

Q 12. What is a Poka-Yoke and provide a manufacturing example.

A Poka-Yoke, meaning ‘mistake-proofing’ in Japanese, is a mechanism or process designed to prevent errors from occurring in the first place. It’s a proactive approach to quality control, aiming to eliminate defects at the source rather than detecting them later.

Example: In a manufacturing plant producing circuit boards, a poka-yoke could be a simple jig that only allows the correct components to be placed in specific slots. If the wrong component is attempted, the jig prevents its insertion. This ensures that the correct components are always used in the right places. Another example is a color-coded system for parts, where different colors indicate different sizes or types, minimizing the chances of incorrect assembly.

Poka-Yoke techniques are valuable because they minimize the possibility of human error, ensuring higher quality and consistency in the output. They are more cost-effective in the long run than dealing with defects downstream.

Q 13. Explain the concept of Standard Work.

Standard Work defines the best-known method for performing a specific task or process. It’s a documented, standardized procedure that ensures consistency, efficiency, and quality across all repetitions of that task. Think of it as a recipe for a perfect product or service.

Components of Standard Work:

- Standard Takt Time: The rate at which the process needs to produce output to meet customer demand.

- Standard Work Sequence: A step-by-step description of the exact steps involved in performing the task.

- Standard Work in Place: A visual representation of the workstation, including the location of tools, materials, and equipment. This ensures that everything is readily available and in its proper place, minimizing waste.

By documenting and standardizing work, companies ensure that employees are trained consistently, leading to reduced errors, improved quality, and better productivity. Standard work also forms the baseline for continuous improvement efforts – identifying areas for further optimization from a well-defined starting point.

Q 14. Describe your experience with Failure Mode and Effects Analysis (FMEA).

Failure Mode and Effects Analysis (FMEA) is a systematic process used to identify potential failures in a system or process, analyze their potential effects, and determine actions to mitigate the risks associated with those failures. It’s a proactive risk assessment tool.

In a manufacturing context, we’ve used FMEA extensively to assess the reliability and safety of new product designs and existing manufacturing processes. The process typically involves a team brainstorming potential failure modes for each component or step in a process. For each failure mode, we assess:

- Severity: How serious would the consequences of this failure be?

- Occurrence: How likely is this failure to occur?

- Detection: How likely is this failure to be detected before it causes problems?

These three factors are multiplied to calculate a Risk Priority Number (RPN). High RPN values indicate areas needing immediate attention. For those high-risk items, the team develops and implements corrective actions to mitigate the risks, such as process improvements, design changes, or additional quality checks. FMEA helps to proactively address potential problems before they impact the product or process, reducing defects and improving quality and safety.

Q 15. What is the difference between a Black Belt and a Green Belt in Lean Six Sigma?

The difference between a Black Belt and a Green Belt in Lean Six Sigma lies primarily in their experience, project scope, and leadership responsibilities. Think of it like a martial arts ranking system. A Green Belt is like a junior belt – they’ve received foundational training and can lead smaller, well-defined projects. A Black Belt is a master – they’ve completed extensive training, possess significant experience leading and mentoring others, and are responsible for larger, more complex projects that impact the entire organization.

- Green Belt: Typically employees who receive several days to a few weeks of training and then apply their knowledge to a specific, often localized, process improvement project. They might focus on a single work cell or a specific department.

- Black Belt: Full-time roles dedicated to leading and mentoring multiple projects simultaneously. They possess deep statistical expertise and are involved in strategic deployment of Lean Six Sigma across the organization. They often train and mentor Green Belts.

In essence, a Green Belt focuses on project execution within a defined scope, while a Black Belt focuses on strategic leadership, project portfolio management, and organizational change management related to Lean Six Sigma.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How would you handle resistance to change during a Lean Six Sigma implementation?

Resistance to change is a common hurdle in any Lean Six Sigma implementation. It’s crucial to address it proactively and empathetically. My approach involves a multi-pronged strategy:

- Communication and Education: Clearly communicate the ‘why’ behind the changes. Explain the benefits to the employees and the organization as a whole, highlighting how the changes will improve their work lives (e.g., less wasted time, more efficient processes). Address concerns and misconceptions directly.

- Involve Employees: Engage employees in the process from the outset. Include them in brainstorming sessions, data gathering, and problem-solving. This fosters a sense of ownership and reduces resistance. Let them feel their input is valued.

- Pilot Projects: Start with smaller, pilot projects to demonstrate the success of the Lean Six Sigma methodology. Success breeds confidence and encourages buy-in from skeptical employees.

- Incentives and Recognition: Acknowledge and reward employees for their contributions and successes. This reinforces positive behaviours and creates a culture of continuous improvement.

- Address Concerns Directly: Identify and address specific concerns raised by employees. Sometimes, resistance is rooted in valid fears about job security or workload. Transparency and open communication are essential.

For example, in a previous project implementing a new inventory management system, we initially faced resistance from warehouse staff who were accustomed to the old, manual system. By involving them in the design and testing of the new system, providing clear training, and addressing their concerns about potential job losses, we successfully overcame resistance and achieved a smooth transition.

Q 17. Describe a time you used data analysis to solve a manufacturing problem.

In a previous role, we experienced a significant increase in defective products from a particular assembly line. Initial assumptions pointed towards operator error. However, I believed a deeper analysis was necessary. Using Minitab, I analyzed several months’ worth of data, including production rates, machine downtime, and environmental factors. The data revealed a strong correlation between temperature fluctuations in the factory and the defect rate.

Specifically, when the factory temperature exceeded a certain threshold, the defect rate surged. Further investigation revealed the adhesive used in the assembly process was highly sensitive to temperature variations. By implementing a climate control system and adjusting the adhesive application process, we significantly reduced the defect rate, resulting in considerable cost savings and improved customer satisfaction.

This experience highlighted the importance of data-driven decision-making. Relying solely on assumptions could have led to ineffective and costly solutions. Using statistical tools allowed us to identify the root cause of the problem, leading to a targeted and effective solution.

Q 18. How familiar are you with statistical software such as Minitab or JMP?

I’m highly proficient in using Minitab and JMP for statistical analysis. My experience encompasses a wide range of statistical techniques including:

- Descriptive statistics and data visualization

- Hypothesis testing (t-tests, ANOVA)

- Regression analysis (linear, multiple)

- Design of Experiments (DOE)

- Control charts (X-bar and R, p-charts, c-charts)

- Capability analysis (Cp, Cpk)

I’ve used these tools extensively in Lean Six Sigma projects to analyze data, identify trends, test hypotheses, and optimize processes. I’m comfortable interpreting statistical output and translating complex findings into actionable insights for non-statistical audiences.

Q 19. What is your experience with different types of process mapping?

My experience with process mapping includes various types, each chosen based on the project’s needs:

- Flowcharts: For visualizing the sequence of steps in a process, highlighting decision points and potential bottlenecks.

- Value Stream Mapping (VSM): A powerful tool for analyzing the entire value stream, identifying waste, and improving efficiency across the entire process. This is particularly useful for large-scale process improvement projects.

- Swimlane Diagrams: To clearly show the responsibilities of different actors or departments within a process.

- SIPOC Diagram: Useful for defining the scope of a project by outlining Suppliers, Inputs, Process, Outputs, and Customers.

I’m proficient in using both manual and software-assisted methods for creating and analyzing process maps. I understand the importance of clear and concise visualization to facilitate communication and collaboration amongst team members.

Q 20. Explain your understanding of the concept of waste in Lean manufacturing (Muda).

In Lean manufacturing, ‘Muda’ refers to waste. It encompasses seven common types of waste, often remembered by the acronym TIMWOOD:

- Transportation: Unnecessary movement of materials or products.

- Inventory: Excess materials, work-in-progress, or finished goods.

- Motion: Unnecessary movement of people or equipment.

- Waiting: Idle time waiting for materials, information, or equipment.

- Overproduction: Producing more than is needed or demanded.

- Over-processing: Performing more work than is necessary.

- Defects: Errors or flaws that require rework or scrap.

Identifying and eliminating Muda is a cornerstone of Lean manufacturing. It leads to reduced costs, improved efficiency, and higher quality. For instance, optimizing the layout of a factory floor to minimize transportation distances or implementing a pull system to reduce inventory are examples of addressing Muda.

Q 21. How do you ensure data integrity in a Lean Six Sigma project?

Data integrity is paramount in any Lean Six Sigma project. Compromised data leads to flawed analysis and potentially incorrect conclusions. My approach to ensuring data integrity includes:

- Data Source Validation: Carefully verify the accuracy and reliability of data sources. This includes assessing data collection methods, verifying data entry procedures, and checking for inconsistencies or errors.

- Data Cleaning and Transformation: Clean and prepare the data by handling missing values, outliers, and inconsistencies. This may involve techniques such as imputation, outlier removal, or data transformation.

- Data Validation Checks: Implement various checks during data collection and analysis to ensure accuracy. This might include range checks, consistency checks, and plausibility checks.

- Documentation: Meticulously document all data sources, cleaning steps, and transformations. This ensures transparency and allows for auditing and verification.

- Data Governance: Establish clear procedures and responsibilities for data management and ensure adherence to quality standards.

For example, in a project involving customer feedback data, we implemented a double-entry system for data entry, ensuring data accuracy before analysis. Regular data checks were also conducted to detect any anomalies and inconsistencies. This rigorous approach to data management ensured reliable results and confidence in the project’s findings.

Q 22. What is your experience with project management methodologies in the context of Lean Six Sigma?

My experience with project management methodologies within the Lean Six Sigma framework is extensive. I’ve successfully utilized various methodologies, including DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify), tailoring my approach based on the specific project needs. For example, in a recent project focused on reducing defect rates in a bottling plant, I employed DMAIC. The Define phase clearly outlined the problem and project goals. Measure involved collecting baseline data on defect rates. Analyze used statistical tools like control charts and Pareto analysis to pinpoint root causes. The Improve phase implemented solutions like process adjustments and operator training. Finally, Control ensured sustained improvements through monitoring and ongoing process control. I also integrate Agile principles, focusing on iterative improvements and frequent stakeholder feedback, ensuring projects stay aligned with evolving business needs and remain flexible. My project management experience extends beyond the technical aspects, encompassing effective team leadership, stakeholder management, and risk mitigation strategies. I’m proficient in using project management software like Microsoft Project and Jira to track progress, manage resources, and ensure timely project completion.

Q 23. Describe your experience with implementing Lean principles in a manufacturing setting.

Implementing Lean principles in manufacturing is all about eliminating waste and maximizing value. In a previous role at a food processing plant, we focused on reducing lead times and improving overall equipment effectiveness (OEE). We started by mapping the entire value stream, using a value stream map to visualize the flow of materials and information. This highlighted areas of waste, such as excessive inventory, unnecessary transportation, and idle time. We then implemented several Lean tools, including 5S (Sort, Set in Order, Shine, Standardize, Sustain) to organize the workspace, Kaizen events (continuous improvement workshops) to address specific bottlenecks, and Kanban to manage work-in-progress. For instance, a Kaizen event focused on optimizing a specific packaging line resulted in a 15% reduction in cycle time. The implementation of Kanban significantly reduced inventory levels, freeing up valuable floor space and improving cash flow. We also incorporated Poka-Yoke (error-proofing) techniques to prevent defects and ensure product quality. These efforts resulted in a significant reduction in lead times, increased OEE, and improved overall plant efficiency. The key to success was active employee engagement, fostering a culture of continuous improvement.

Q 24. How do you ensure the sustainability of Lean Six Sigma improvements?

Ensuring the sustainability of Lean Six Sigma improvements requires a multi-faceted approach. It’s not enough to just implement changes; we need to embed them into the organization’s culture and processes. This involves several key strategies:

- Standardization: Documenting improved processes and creating standard operating procedures (SOPs) ensures consistency and prevents regression to old habits.

- Training and Development: Equipping employees with the necessary skills and knowledge to maintain the improvements is crucial. Ongoing training on Lean principles and relevant tools keeps the improvements relevant and effective.

- Metrics and Monitoring: Regularly tracking key performance indicators (KPIs) allows for early detection of any deviations from the improved state, enabling timely corrective actions.

- Leadership Support: Strong leadership commitment and buy-in are essential. Leaders must champion the Lean Six Sigma initiatives and create a culture of continuous improvement.

- Continuous Improvement Culture: Establish a culture where continuous improvement is valued and actively pursued. This can be achieved through regular Kaizen events, suggestion schemes, and feedback mechanisms.

For instance, in one project, we established a monthly review meeting where the team tracks KPIs, discusses potential issues, and proposes improvements. This ensures that any deviations from the established standards are promptly identified and addressed.

Q 25. How would you approach a situation with conflicting priorities in a Lean Six Sigma project?

Conflicting priorities are common in project management. My approach involves a structured process to resolve them. Firstly, I’d clearly define all project goals and priorities, documenting their relative importance using techniques like a Prioritization Matrix. Then, I’d facilitate a collaborative discussion with stakeholders to understand the root causes of the conflict. This involves open communication and active listening. We would then analyze the impact of each priority on overall project objectives, considering factors like cost, time, and quality. Based on this analysis, we would either negotiate compromises, re-prioritize tasks, or seek additional resources if necessary. Sometimes, this might involve breaking down a large project into smaller, more manageable tasks that can be prioritized independently. A critical path analysis helps identify the most time-sensitive tasks. Transparent communication throughout this process is key to ensure stakeholder buy-in and commitment to the final decisions.

Q 26. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, and are in line with the industry standard for a Lean Six Sigma expert with my qualifications. I am open to discussing a competitive compensation package that reflects the value I bring to your organization.

Q 27. What are your long-term career goals?

My long-term career goals involve becoming a recognized leader in the field of Lean Six Sigma in manufacturing. I aspire to lead and mentor teams, driving continuous improvement across multiple organizations. I also aim to contribute to the advancement of Lean Six Sigma methodologies through research and publication, potentially focusing on the application of advanced analytics and data science to optimize manufacturing processes. My ultimate goal is to make a significant impact on the efficiency and productivity of manufacturing operations globally.

Key Topics to Learn for Lean Six Sigma for Manufacturing Interview

- DMAIC Methodology: Understand the Define, Measure, Analyze, Improve, Control cycle and its application in manufacturing settings. Be prepared to discuss real-world examples of how each phase is implemented.

- Lean Principles: Familiarize yourself with concepts like Value Stream Mapping, 5S, Kaizen, and Poka-Yoke. Be ready to explain how these principles contribute to process efficiency and waste reduction in manufacturing.

- Six Sigma Tools & Techniques: Master the use of statistical tools such as Control Charts, Histograms, Pareto Charts, and Fishbone Diagrams for data analysis and problem solving. Practice applying these tools to solve hypothetical manufacturing scenarios.

- Process Capability Analysis: Understand Cp and Cpk calculations and their significance in determining process performance and meeting customer specifications. Be prepared to discuss how to improve process capability.

- Problem-Solving Methodologies: Demonstrate proficiency in structured problem-solving approaches, such as the 8D report or A3 problem-solving methodology. Be ready to articulate your approach to root cause analysis.

- Measurement Systems Analysis (MSA): Understand the importance of accurate and reliable data. Be able to discuss methods for validating measurement systems and identifying sources of measurement error.

- Design of Experiments (DOE): Familiarize yourself with the basic principles of DOE and how it’s used to optimize processes and improve product quality in manufacturing.

- Lean Six Sigma in specific Manufacturing contexts (e.g., Supply Chain, Production, Quality Control): Demonstrate an understanding of how Lean Six Sigma principles and tools can be applied to different areas within a manufacturing organization.

Next Steps

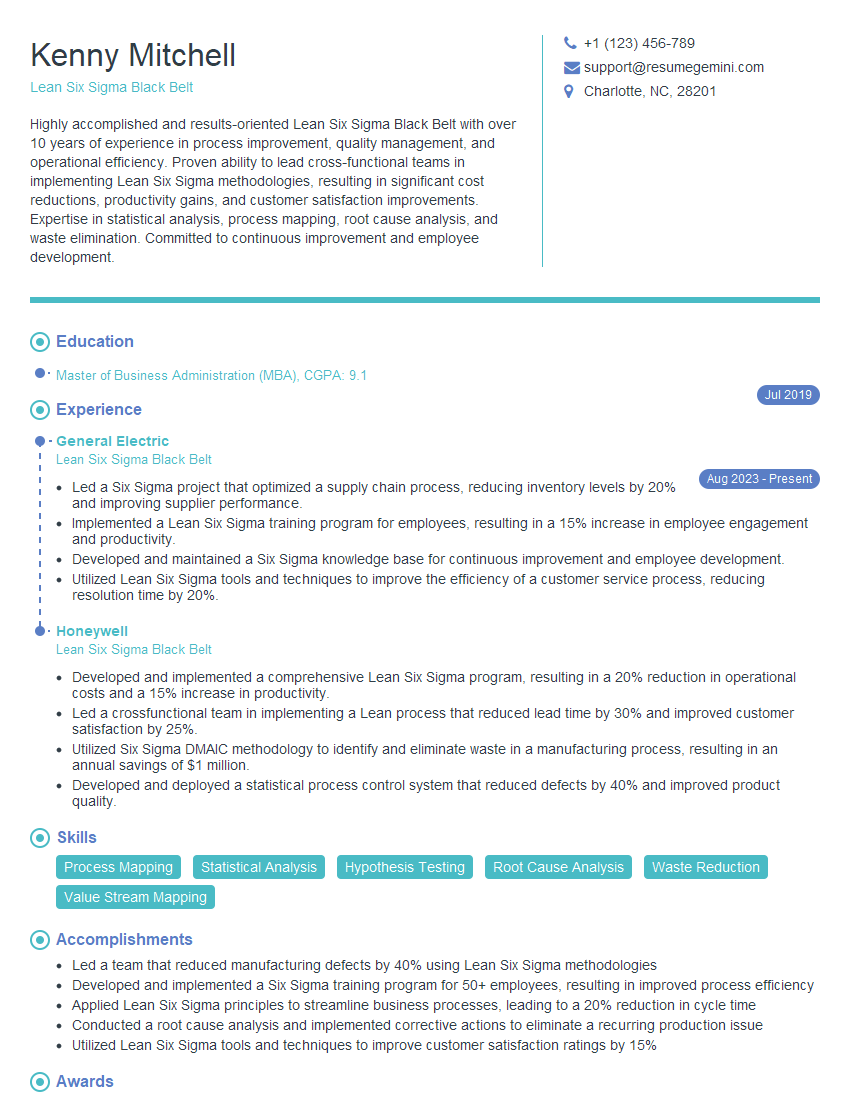

Mastering Lean Six Sigma for Manufacturing significantly enhances your career prospects, opening doors to leadership roles and higher earning potential. A well-crafted resume is crucial for showcasing your skills effectively to prospective employers. An ATS-friendly resume, optimized for Applicant Tracking Systems, is essential to ensure your application gets noticed. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your Lean Six Sigma expertise. ResumeGemini provides examples of resumes tailored to Lean Six Sigma for Manufacturing, guiding you to create a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.