The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Polymer Chemistry and Physics interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Polymer Chemistry and Physics Interview

Q 1. Explain the difference between thermoplastic and thermosetting polymers.

Thermoplastic and thermosetting polymers represent two fundamentally different classes of polymers distinguished by their response to heat. Think of it like this: thermoplastics are like Play-Doh – you can repeatedly heat them, mold them into different shapes, and cool them down without altering their fundamental chemical structure. Thermosets, on the other hand, are like an egg – once you cook them (cure them with heat), they’re permanently set and can’t be easily reshaped without breaking down their chemical structure.

- Thermoplastics: These polymers have linear or branched structures, allowing for chain movement upon heating. They soften upon heating and harden upon cooling, a process that is reversible. Common examples include polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC). These are used extensively in packaging, bottles, and various other applications where recyclability is desirable.

- Thermosets: These polymers have a cross-linked, three-dimensional network structure. Upon heating, they undergo irreversible chemical changes, forming strong covalent bonds between polymer chains. This leads to a rigid, infusible material. Examples include epoxy resins, vulcanized rubber, and phenolic resins. These are often preferred for high-strength applications or when heat resistance is crucial, such as in coatings, adhesives, and composite materials.

Q 2. Describe the glass transition temperature (Tg) and its significance.

The glass transition temperature (Tg) is the temperature at which an amorphous (non-crystalline) solid polymer transitions from a hard, glassy state to a more rubbery or viscous state. Imagine a window – below Tg, it’s hard and brittle; above Tg, it becomes more flexible and less stiff. This transition is not a phase change like melting (Tm), but rather a change in the molecular mobility. The polymer chains gain sufficient kinetic energy to overcome intermolecular forces, allowing for increased segmental motion.

Tg’s significance lies in its impact on polymer properties. Below Tg, the material is brittle and strong; above Tg, it is more flexible and ductile. Knowing the Tg is critical for processing, application, and performance prediction. For example, if you need a material that remains strong at high temperatures, you’d select one with a high Tg. Conversely, a flexible material would require a polymer with a low Tg.

Q 3. What are the different types of polymerizations (e.g., addition, condensation)?

Polymerization is the process of joining small molecules (monomers) together to form larger molecules (polymers). There are several types of polymerization, but the most common are addition and condensation polymerization.

- Addition Polymerization: This involves the sequential addition of monomers to a growing polymer chain without the loss of any atoms. The monomers typically contain unsaturated bonds (like double or triple bonds) that open up during the polymerization process. A classic example is the polymerization of ethylene (CH2=CH2) to form polyethylene (-(CH2-CH2)-)n. This process is often initiated by free radicals, ions, or catalysts.

- Condensation Polymerization: This involves the joining of monomers with the elimination of a small molecule, such as water or methanol. Each monomer must have at least two functional groups capable of reacting. Examples include the formation of polyesters (from dicarboxylic acids and diols with water as a byproduct) and polyamides (nylons, from diamines and diacids with water as a byproduct).

Other types of polymerizations exist, such as ring-opening polymerization and living polymerization, each with its own set of characteristics and applications.

Q 4. Explain the concept of degree of polymerization.

The degree of polymerization (DP) is the number of monomer units in a single polymer chain. For example, if a polyethylene chain consists of 1000 ethylene units, its DP is 1000. This is a crucial parameter in determining the properties of a polymer. A higher DP generally leads to a polymer with a higher molecular weight, increased strength, and improved mechanical properties (such as increased viscosity and tensile strength). However, extremely high DP can lead to processing difficulties due to increased viscosity.

The DP is not always uniform within a polymer sample; there’s often a distribution of chain lengths, typically represented by a molecular weight distribution. Understanding this distribution is vital in quality control and material performance prediction.

Q 5. Describe different techniques for characterizing polymer molecular weight.

Several techniques are used to characterize the molecular weight of polymers, which is often expressed as number-average molecular weight (Mn) or weight-average molecular weight (Mw):

- Gel Permeation Chromatography (GPC) or Size Exclusion Chromatography (SEC): This separates polymers based on their hydrodynamic volume in solution. Larger molecules elute first, followed by smaller molecules. The chromatogram is then used to determine the molecular weight distribution.

- Viscometry: Measures the viscosity of a polymer solution. The viscosity is related to the molecular weight, allowing for an estimation of Mn or Mw.

- Light Scattering: Measures the intensity of light scattered by polymer molecules in solution. This technique provides information on both Mn and Mw, as well as the size and shape of the polymers.

- End-group analysis: This method determines the number of end groups in a polymer chain. Knowing the number of end groups and the total mass allows for the calculation of Mn.

The choice of technique depends on the type of polymer, its molecular weight range, and the required level of detail.

Q 6. How does crystallinity affect the properties of a polymer?

Crystallinity refers to the degree of structural order in a polymer. A perfectly crystalline polymer has a highly ordered, three-dimensional arrangement of its chains, much like a neatly stacked array of pencils. Conversely, an amorphous polymer has a disordered, random arrangement of chains, similar to a pile of tangled spaghetti.

Crystallinity significantly affects polymer properties:

- Mechanical Strength: Crystalline regions contribute to higher strength and stiffness due to strong intermolecular forces and ordered structure. Amorphous regions, on the other hand, are more flexible.

- Density: Crystalline polymers have a higher density than amorphous polymers due to the efficient packing of chains in crystalline regions.

- Melting Point (Tm): Crystalline polymers exhibit a sharp melting point, whereas amorphous polymers have a glass transition temperature (Tg).

- Solubility and Permeability: Crystalline polymers tend to be less soluble and less permeable to gases and liquids than amorphous polymers.

The degree of crystallinity is influenced by factors such as polymer chain structure, processing conditions, and the presence of additives.

Q 7. Explain the concept of viscoelasticity in polymers.

Viscoelasticity describes the behavior of materials that exhibit both viscous (liquid-like) and elastic (solid-like) properties. Think of silly putty – you can stretch it slowly like a liquid, but if you hit it quickly, it bounces back like a solid. Polymers often show viscoelastic behavior because their long chains can undergo both elastic deformation (reversible changes in shape due to chain stretching) and viscous flow (irreversible changes in shape due to chain slippage and rearrangement).

The viscoelastic behavior of a polymer is temperature-dependent. At low temperatures, the polymer behaves more elastically; at high temperatures, it behaves more viscously. This behavior is often described using models such as the Maxwell model (spring and dashpot in series) or the Kelvin-Voigt model (spring and dashpot in parallel). Understanding viscoelasticity is crucial in applications involving time-dependent stress and strain, such as designing polymeric components for shock absorption or vibration damping.

Q 8. What are the different types of polymer degradation mechanisms?

Polymer degradation refers to the breakdown of polymer chains, leading to a decrease in molecular weight and a change in material properties. This can be a desirable process (e.g., controlled degradation of biodegradable plastics) or undesirable (e.g., the weathering of a plastic component). Several mechanisms drive this degradation:

- Chain Scission: The polymer backbone breaks, reducing the average molecular weight. This can be caused by factors like UV radiation, mechanical stress, or hydrolysis (reaction with water).

- Depolymerization: The polymer chain breaks down into its original monomers. This is common in some specific polymers under certain conditions, like the depolymerization of polyethylene terephthalate (PET) at high temperatures.

- Crosslinking: Instead of breaking down, chains link together, increasing molecular weight. While technically not degradation in the sense of molecular weight reduction, it can alter properties negatively, for instance making the polymer brittle.

- Oxidation: Oxygen attacks the polymer chains, leading to chain scission, crosslinking, or the formation of polar groups. This often results in embrittlement and discoloration.

- Hydrolysis: Water reacts with the polymer chains, often causing chain scission, especially in polymers containing ester or amide linkages.

- Thermal Degradation: High temperatures cause random chain scission, depolymerization, or crosslinking, depending on the polymer and the conditions.

Understanding these mechanisms is crucial for designing polymers with enhanced durability and predicting their lifespan in various applications. For example, the addition of UV stabilizers can significantly reduce degradation caused by sunlight exposure in outdoor applications.

Q 9. Describe different methods for polymer synthesis.

Polymer synthesis encompasses a wide range of techniques to create macromolecules from smaller monomers. The choice of method depends on the desired polymer structure, properties, and scale of production. Key methods include:

- Addition Polymerization (Chain-Growth Polymerization): Monomers add to a growing chain one at a time, typically initiated by free radicals, anions, or cations. Examples include polyethylene (PE) made by free-radical polymerization and polystyrene (PS) made using anionic polymerization. This method is efficient for producing high molecular weight polymers.

- Condensation Polymerization (Step-Growth Polymerization): Monomers react to form a larger molecule with the elimination of a small molecule, like water. Examples include polyesters (PET) and nylons. This often leads to polymers with more complex structures.

- Ring-Opening Polymerization: Cyclic monomers open their rings to form linear polymer chains. This allows for the creation of polymers with unique properties, such as polycaprolactone (PCL), a biodegradable polymer.

Each method presents different advantages and disadvantages regarding reaction conditions, control over molecular weight, and the types of polymers that can be synthesized. For example, controlling the temperature and monomer concentration is vital for achieving the desired molecular weight in addition polymerization, whereas controlling the stoichiometry of monomers is crucial in condensation polymerization.

Q 10. Explain the role of plasticizers in polymers.

Plasticizers are low-molecular-weight substances added to polymers to increase their flexibility and workability. They act as internal lubricants, reducing intermolecular forces between polymer chains. Imagine trying to bend a stiff piece of cardboard versus a piece of flexible plastic – the plasticizer acts like the ‘internal lubricant’ allowing the chains to slide past each other more easily.

Common plasticizers include phthalates (though their use is decreasing due to environmental concerns), adipates, and citrates. The choice of plasticizer depends on the polymer type, desired properties, and regulatory requirements. For example, PVC (polyvinyl chloride), a naturally rigid polymer, often requires significant plasticizer to become flexible enough for applications like flooring or clothing.

The effectiveness of a plasticizer depends on its compatibility with the polymer, meaning it needs to interact favorably with the polymer chains without leaching out or causing undesirable changes in properties. Plasticizer migration can be a concern, as it can lead to softening or embrittlement of the polymer over time. Therefore, selection and testing are crucial to ensure long-term product performance.

Q 11. What are the common techniques used for polymer processing (e.g., extrusion, injection molding)?

Polymer processing techniques transform raw polymers into finished products. Many methods exist, but some common ones include:

- Extrusion: A polymer melt is forced through a die to create continuous shapes, such as pipes, films, and fibers. This is a continuous process ideal for large-scale production.

- Injection Molding: Molten polymer is injected into a mold cavity under pressure, allowed to cool and solidify, and then ejected. This is suitable for mass production of complex shapes.

- Compression Molding: A polymer is placed in a heated mold and compressed to form the desired shape. This method is simpler but less precise than injection molding.

- Blow Molding: A heated polymer tube (parison) is inflated in a mold cavity to create hollow shapes, such as bottles.

- Thermoforming: A heated plastic sheet is shaped using vacuum or pressure over a mold. This technique is used to create packaging and other simple shapes.

The selection of processing technique depends on several factors including the polymer’s properties, the complexity of the desired shape, and the required production volume. Each technique involves optimization of parameters like temperature, pressure, and processing time to achieve the desired product quality.

Q 12. How does crosslinking affect polymer properties?

Crosslinking is the formation of covalent bonds between polymer chains. This significantly alters the polymer’s properties:

- Increased Mechanical Strength and Stiffness: Crosslinks act as physical bridges, restricting chain movement and making the polymer harder and more resistant to deformation. Think of a rubber band – uncrosslinked rubber is stretchy, but vulcanized (crosslinked) rubber is more rigid.

- Improved Chemical Resistance: Crosslinking reduces the accessibility of solvents and chemicals to the polymer chains, enhancing its resistance to degradation.

- Reduced Solubility and Swelling: Crosslinked polymers are less likely to dissolve or swell in solvents because the chains are interconnected.

- Enhanced Thermal Stability: Crosslinking increases the polymer’s resistance to thermal degradation, as it restricts chain mobility and reduces the likelihood of chain scission.

However, excessive crosslinking can lead to brittleness and reduce flexibility. The degree of crosslinking, therefore, needs to be carefully controlled to achieve the optimal balance of properties. For example, the crosslinking of rubber through vulcanization is a crucial step in producing durable and resilient tires.

Q 13. Explain the concept of chain entanglement in polymers.

Chain entanglement refers to the physical intermingling of polymer chains without covalent bonding. Imagine a bowl of spaghetti – the strands are not chemically linked but are tangled together. These entanglements are crucial for determining many polymer properties.

Entanglements restrict chain mobility, contributing to the polymer’s viscosity (resistance to flow) in the melt state and its mechanical strength in the solid state. The higher the molecular weight and the higher the chain density, the greater the degree of entanglement. These entanglements play a significant role in determining the viscoelastic behavior of polymers – their ability to exhibit both elastic and viscous properties. For example, high entanglement density leads to higher tensile strength and greater resistance to creep (slow deformation under stress).

Understanding chain entanglement is vital for controlling the rheological properties of polymers during processing and for predicting the mechanical behavior of the final product. Techniques like rheometry are used to characterize entanglement behavior and its influence on processing conditions and product properties.

Q 14. Describe the different types of polymer blends and their properties.

Polymer blends combine two or more different polymers to achieve a combination of properties not found in individual components. The properties of the blend depend on the compatibility of the polymers, their relative proportions, and the interaction between them.

- Miscible Blends: Polymers mix at a molecular level, resulting in homogenous properties. This is relatively rare and usually occurs when the polymers have similar chemical structures and interactions.

- Immiscible Blends: Polymers remain separate phases, creating a heterogeneous structure. This is more common and often leads to blends with improved properties through the combination of different phases. Examples include blends of polypropylene and polyethylene which might combine the impact resistance of PP with the low-cost and stiffness of PE.

- Compatible Blends: Polymers exhibit some degree of interaction but not complete miscibility. This often leads to improved properties compared to immiscible blends, but less than miscible blends.

Blending allows for tailoring of material properties like impact strength, stiffness, flexibility, and processability. For instance, blending a tough but brittle polymer with a flexible, impact-resistant polymer can lead to a material with improved overall toughness. Careful selection of polymers and processing techniques is crucial to achieve the desired properties in the final blend.

Q 15. Explain the role of fillers in polymer composites.

Fillers are inert materials added to polymers to modify their properties. Think of it like adding spices to a dish – they enhance the overall characteristics. They significantly impact the cost, performance, and processability of the resulting polymer composite. The choice of filler depends heavily on the desired outcome. For example, adding calcium carbonate (CaCO3) to polyethylene (PE) reduces the cost and increases stiffness, while adding carbon nanotubes can dramatically enhance strength and electrical conductivity.

- Cost Reduction: Fillers often cost significantly less than the polymer matrix, making the composite more economical.

- Improved Mechanical Properties: Fillers can enhance strength, stiffness, hardness, and impact resistance.

- Modified Thermal Properties: Fillers can improve heat resistance or thermal conductivity.

- Enhanced Processing: Certain fillers improve the flow characteristics of the polymer melt, facilitating easier processing.

- Specialized Properties: Fillers like conductive carbon black can add electrical conductivity, while flame retardants improve fire safety.

For instance, in the automotive industry, glass fibers are commonly used as fillers in polypropylene (PP) to create lightweight and strong car parts. The resulting composite offers a good balance between strength, weight, and cost, making it suitable for various applications.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common methods for analyzing polymer structure (e.g., NMR, FTIR, DSC)?

Analyzing polymer structure is crucial for understanding their properties and behavior. Several techniques are employed, each offering unique insights:

- Nuclear Magnetic Resonance (NMR) Spectroscopy: NMR provides detailed information about the chemical structure of polymers, including the types and arrangement of atoms, as well as molecular weight and chain dynamics. It’s like looking at a highly detailed molecular blueprint. Different types of NMR, such as 1H NMR and 13C NMR, provide information on different nuclei.

- Fourier Transform Infrared (FTIR) Spectroscopy: FTIR identifies functional groups present in the polymer. This helps determine the polymer type and its chemical composition. Think of it as a fingerprint for the polymer’s functional groups.

- Differential Scanning Calorimetry (DSC): DSC measures the heat flow associated with transitions in a polymer as a function of temperature. This technique reveals important information about the glass transition temperature (Tg), melting temperature (Tm), and crystallinity. It helps us understand how the polymer behaves at different temperatures – for example, when it becomes rubbery or melts.

For example, using NMR, we can determine the tacticity of a polypropylene sample (isotactic, syndiotactic, or atactic), which directly affects its crystallinity and mechanical properties. FTIR can help identify the presence of specific additives or contaminants in a polymer sample. DSC helps to determine the processing window for a given polymer – the temperature range where it can be successfully molded or extruded.

Q 17. How do you determine the mechanical properties of a polymer?

Determining the mechanical properties of a polymer involves subjecting it to various stresses and strains and measuring its response. This gives us valuable insights into its strength, elasticity, and durability. Common tests include:

- Tensile Testing: Measures the polymer’s strength and elasticity by pulling it until it breaks. Yield strength, tensile strength, and elongation at break are key parameters obtained.

- Flexural Testing: Evaluates the polymer’s resistance to bending. It provides information about flexural strength and modulus.

- Impact Testing: Assesses the polymer’s resistance to sudden impacts. Izod and Charpy tests are common examples.

- Hardness Testing: Determines the resistance of the polymer to indentation. Shore hardness is a widely used measure.

The specific test chosen depends on the intended application. For instance, a polymer intended for use in a car bumper will undergo rigorous impact testing, while a polymer for a flexible film might be primarily evaluated via tensile testing. Results from these tests are vital in material selection and design processes. The data can be used to predict the polymer’s behavior under service conditions.

Q 18. Explain the concept of polymer rheology.

Polymer rheology studies the flow and deformation of polymers under stress. Imagine trying to pour honey versus water – the honey’s resistance to flow is a rheological property. It’s crucial for understanding how polymers behave during processing (e.g., extrusion, molding) and in their final applications.

Key concepts in polymer rheology include:

- Viscosity: A measure of a polymer’s resistance to flow. Highly viscous polymers flow slowly.

- Elasticity: The ability of a polymer to return to its original shape after deformation.

- Viscoelasticity: Most polymers exhibit both viscous and elastic behavior, a combination called viscoelasticity. This is because polymers consist of long chains that can both flow and entangle.

- Rheometers: Instruments used to measure rheological properties. They apply different types of stress (shear, extensional) to the polymer and measure the resulting strain.

Understanding rheology is essential for controlling the processing conditions of polymers. For example, the viscosity of a polymer melt dictates the pressure required during extrusion. Inappropriate rheological properties can lead to processing defects.

Q 19. Describe the different types of polymer solutions and their behavior.

Polymer solutions involve a polymer dissolved in a solvent. The behavior of these solutions is complex and depends on factors like polymer concentration, molecular weight, and solvent properties. Several types exist:

- Ideal Solutions: These are theoretical solutions where polymer-solvent interactions are similar to polymer-polymer and solvent-solvent interactions. They follow simple laws of thermodynamics.

- Athermal Solutions: These solutions show no heat of mixing, meaning the enthalpy of mixing is zero. The solubility depends solely on entropy.

- Theta Solutions: At a specific temperature (the theta temperature), the polymer behaves ideally in a specific solvent. This temperature is important for understanding polymer properties.

- Concentrated Solutions: High polymer concentration solutions exhibit complex interactions, including chain entanglement and formation of liquid crystalline phases. They behave very differently from dilute solutions.

The behavior of polymer solutions strongly influences their applications. For example, the viscosity of a paint (a polymer solution) determines its flow and application properties. The behavior of a polymer solution in a drug delivery system affects the release kinetics of the drug.

Q 20. How do you design a polymer for a specific application?

Designing a polymer for a specific application is a complex process involving several steps:

- Define the Application Requirements: Clearly specify the necessary mechanical, thermal, chemical, and other properties.

- Select the Polymer Type: Choose a polymer backbone (e.g., polyethylene, polypropylene, polystyrene) that provides a suitable base for the desired properties. This involves considering factors like cost and ease of processing.

- Optimize Polymer Structure: Modify the polymer’s molecular weight, branching, tacticity, and other structural features to fine-tune its properties. This often involves polymerization techniques like controlled radical polymerization or ring-opening polymerization.

- Incorporate Additives: Add fillers, plasticizers, stabilizers, or other additives to tailor the polymer’s performance. This allows you to enhance certain aspects like toughness, flexibility, or UV resistance.

- Test and Iterate: Thoroughly test the polymer’s properties using various techniques. Based on the results, refine the composition and processing parameters to meet the application’s demands.

For instance, designing a polymer for use in medical implants would necessitate biocompatibility, strength, and resistance to degradation in a physiological environment. The design process would involve careful selection of biocompatible materials, thorough testing for cytotoxicity, and optimization for mechanical strength and durability.

Q 21. What are the environmental concerns related to polymer use and disposal?

The widespread use of polymers presents significant environmental concerns:

- Persistence and Accumulation: Many polymers are non-biodegradable or degrade very slowly, leading to accumulation in landfills and the environment.

- Microplastics: The breakdown of larger plastic items into microplastics poses a serious threat to wildlife and potentially human health.

- Greenhouse Gas Emissions: The production and incineration of polymers release greenhouse gases, contributing to climate change.

- Resource Depletion: The production of many polymers relies on finite fossil fuel resources.

- Marine Pollution: Plastics accumulating in oceans harm marine life through entanglement, ingestion, and habitat destruction.

Addressing these concerns requires a multi-pronged approach, including:

- Developing biodegradable and compostable polymers: Exploring alternatives like PLA (polylactic acid) and PHA (polyhydroxyalkanoates).

- Improving recycling infrastructure: Enhancing collection, sorting, and processing capabilities for plastic waste.

- Promoting waste reduction and reuse: Encouraging design for durability, reuse, and recyclability.

- Developing chemical recycling technologies: Exploring ways to break down polymers chemically into their monomers for reuse.

The transition towards a more sustainable future for polymers requires collaborative efforts from researchers, industry, and policymakers to reduce the environmental impact of polymer production and end-of-life management.

Q 22. Explain the principles of polymer recycling.

Polymer recycling aims to recover and reuse polymeric materials, minimizing environmental impact. It’s not a simple process, as polymers are often mixed and contaminated. The process typically involves several stages: collection, where polymers are separated based on type (e.g., PET, HDPE, LDPE); sorting, often using automated systems based on density, color, or infrared spectroscopy; processing, which may involve washing, shredding, melting, and extrusion to create new products; and finally, re-manufacture into new items or raw materials.

For example, PET (polyethylene terephthalate) bottles can be recycled into new bottles or fiber for clothing. However, the quality of the recycled material may degrade with each cycle, limiting the number of times a material can be effectively recycled. This highlights the importance of designing polymers for recyclability from the outset, considering factors like chemical composition and ease of separation.

Mechanical recycling is the most common method, but chemical recycling, which breaks down the polymer chains into their monomers, offers the potential for creating virgin-quality material from waste. This is a rapidly developing area with the potential to revolutionize the polymer recycling landscape.

Q 23. Describe the concept of polymer degradation and its relevance to sustainability.

Polymer degradation refers to the breakdown of polymer chains, either by chemical or physical means. This is crucial for sustainability because it addresses the problem of persistent plastic waste in the environment. Biodegradation, where microorganisms break down polymers into simpler compounds, is a desirable outcome, particularly for environmentally friendly applications. However, many synthetic polymers are highly resistant to biodegradation, leading to environmental pollution.

Photodegradation, where sunlight causes chain scission (breaking of the polymer backbone), is another form of degradation. This can be beneficial in applications where controlled polymer breakdown is required, but it can also lead to material failure in outdoor applications. Similarly, thermal degradation, involving heat-induced breakdown, is used in some recycling processes but can also cause issues with material stability during manufacturing or use. The relevance to sustainability hinges on controlling and managing these degradation processes to promote biodegradability or efficient recycling rather than uncontrolled environmental release.

Understanding the degradation mechanisms of different polymers is key to designing sustainable and biodegradable alternatives to conventional plastics.

Q 24. What are the latest advancements in polymer science and technology?

Recent advancements in polymer science and technology are remarkable and span many areas. One key development is the rise of bio-based and biodegradable polymers derived from renewable resources like corn starch or sugarcane. These materials offer a more sustainable alternative to petroleum-based plastics. Another area of rapid progress is the development of self-healing polymers, which can repair minor damage without human intervention, extending their lifespan and reducing waste.

Significant breakthroughs are also happening in the area of additive manufacturing (3D printing) of polymers, allowing for the production of complex shapes and customized parts with high precision. This technology is transforming various industries, from aerospace to medicine. Furthermore, research into high-performance polymers with enhanced mechanical strength, thermal stability, and chemical resistance continues to drive innovation in fields like aerospace and electronics. Finally, the development of advanced characterization techniques, like advanced microscopy and spectroscopy, allow for a deeper understanding of polymer structure and properties, leading to more targeted material design.

Q 25. How can you improve the adhesion properties of a polymer?

Improving polymer adhesion involves manipulating the surface energy and chemical interactions between the polymer and the substrate. Several strategies can be employed:

- Surface treatment: This involves modifying the polymer surface to increase its wettability and improve interaction with the adhesive. Common methods include plasma treatment, corona discharge, or chemical etching.

- Primer application: A primer layer acts as an intermediary between the polymer and the adhesive, promoting better adhesion by creating strong chemical bonds. The choice of primer depends on the specific polymer and substrate.

- Polymer blending: Incorporating specific additives into the polymer matrix can enhance adhesion. For example, coupling agents can improve interfacial interactions.

- Surface functionalization: Introducing functional groups on the polymer surface that interact strongly with the substrate can significantly improve adhesion. This can be done chemically or through other treatments.

For instance, treating a polyethylene surface with plasma oxidation can introduce polar groups, increasing its surface energy and improving adhesion to a polar adhesive.

Q 26. Describe the different types of polymer networks.

Polymer networks are three-dimensional structures formed by crosslinking polymer chains. The type of network significantly influences the polymer’s properties. Several types exist:

- Linear polymers: These lack crosslinks, resulting in flexible and often melt-processable materials. Think of spaghetti strands.

- Branched polymers: These possess some branching but limited crosslinking, exhibiting moderate flexibility and processability.

- Crosslinked polymers: These have extensive crosslinks forming a three-dimensional network. This results in strong, rigid, and often insoluble materials. Vulcanized rubber is a good example.

- Thermosets: These are irreversibly crosslinked, meaning they cannot be melted or reshaped after curing. Epoxy resins are a typical example.

- Thermoplastics: While they can contain crosslinks, these crosslinks are usually fewer and are less tightly bound. They are reversible, capable of melting and reshaping upon heating.

The degree of crosslinking, the type of crosslinks, and the network density all determine the final properties of the polymer network.

Q 27. Explain how polymer properties are influenced by their chemical structure.

A polymer’s chemical structure profoundly impacts its properties. The type of monomer, the arrangement of monomers (linear, branched, crosslinked), and the presence of functional groups all play crucial roles. For example:

- Monomer type: The chemical structure of the monomer dictates the polymer’s backbone strength, flexibility, and polarity. Polyethylene (PE), with its nonpolar C-C bonds, is flexible, while polyvinyl chloride (PVC), with its polar C-Cl bonds, is more rigid.

- Chain length (molecular weight): Higher molecular weight polymers typically exhibit higher strength, increased viscosity, and higher melting points.

- Branching: Branched polymers are less crystalline and often have lower density and melting points compared to linear polymers.

- Crosslinking: Crosslinks increase a polymer’s strength, stiffness, and resistance to solvents, but can reduce its flexibility and processability.

- Functional groups: The presence of specific functional groups (e.g., hydroxyl, carboxyl, amine) affects the polymer’s polarity, reactivity, and ability to form hydrogen bonds. These can significantly alter properties like solubility and adhesion.

Understanding the relationship between chemical structure and properties is fundamental to designing polymers with tailored characteristics for specific applications.

Q 28. Discuss the challenges and opportunities in the field of polymer science.

Polymer science faces both exciting opportunities and significant challenges. One major challenge is the environmental impact of persistent plastic waste. This necessitates the development of biodegradable and recyclable polymers and more efficient recycling technologies. Another challenge lies in creating high-performance polymers with enhanced properties for demanding applications, such as aerospace and biomedical devices. This requires advanced material design and synthesis techniques.

Opportunities abound in areas like developing sustainable and renewable polymer sources, designing self-healing and responsive materials, and advancing additive manufacturing techniques for polymer processing. The increasing demand for high-performance polymers in various industries, combined with ongoing research into novel polymer architectures and functionalization strategies, promises a bright future for this field. Addressing the environmental concerns while pushing the boundaries of material performance will be key to shaping the future of polymer science.

Key Topics to Learn for Your Polymer Chemistry and Physics Interview

Success in your interview hinges on a strong understanding of both the theoretical foundations and practical applications of Polymer Chemistry and Physics. Prepare yourself by focusing on these key areas:

- Polymer Synthesis and Characterization: Understand different polymerization techniques (addition, condensation, ring-opening), characterization methods (e.g., GPC, NMR, DSC, TGA), and the relationship between synthesis methods and polymer properties.

- Polymer Structure and Properties: Master the connection between polymer microstructure (e.g., tacticity, branching, molecular weight distribution) and macroscopic properties (e.g., mechanical strength, thermal behavior, solubility).

- Polymer Physics: Grasp concepts like viscoelasticity, glass transition temperature (Tg), melting temperature (Tm), and their relationship to polymer structure and application. Be ready to discuss relevant models and theories.

- Polymer Rheology: Familiarize yourself with the flow behavior of polymer melts and solutions. Understand concepts like viscosity, shear thinning, and normal stresses and their importance in processing.

- Polymer Applications and Case Studies: Prepare examples of how polymers are used in various industries (e.g., biomedical, packaging, electronics). Being able to connect theoretical knowledge to real-world applications demonstrates a deeper understanding.

- Problem-Solving and Critical Thinking: Practice approaching problems systematically. Be prepared to explain your thought process and justify your answers, even if you don’t immediately know the solution.

Next Steps: Unlock Your Career Potential

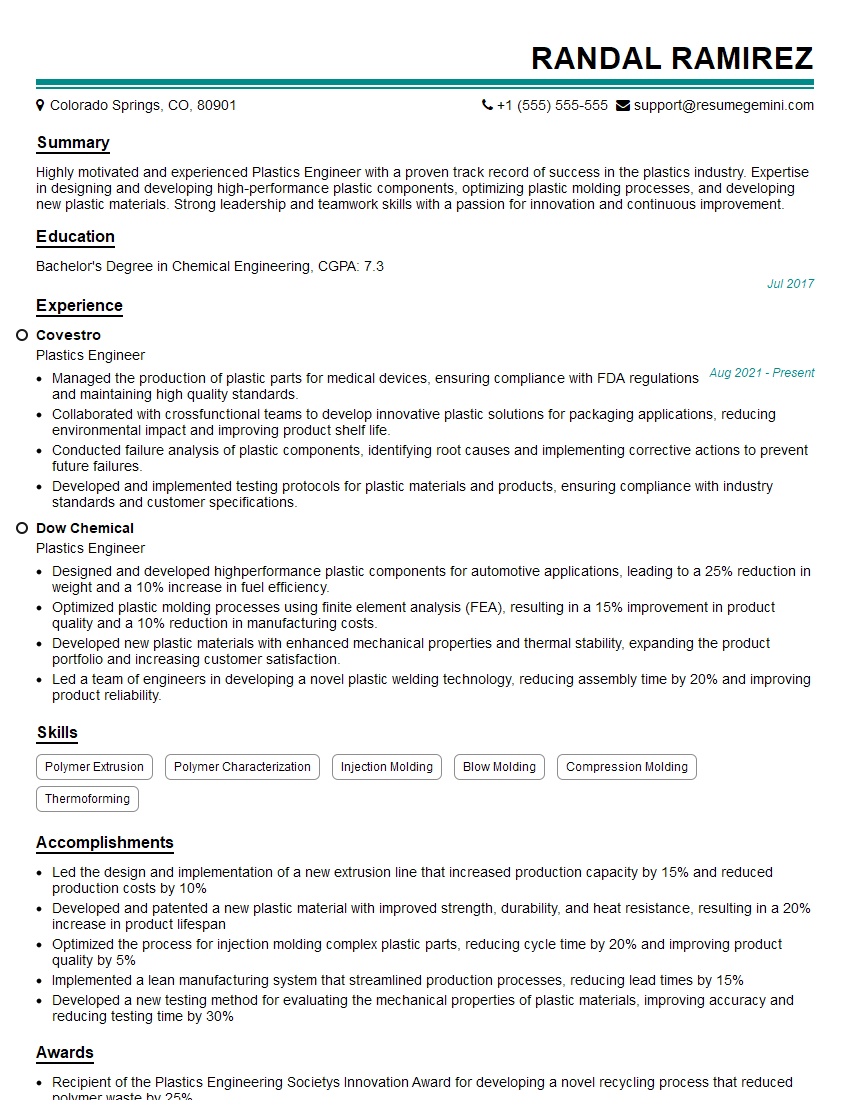

Mastering Polymer Chemistry and Physics opens doors to exciting and rewarding careers in research, development, and manufacturing. To maximize your job prospects, a well-crafted resume is crucial. An ATS-friendly resume ensures your application gets noticed by recruiters and hiring managers.

We strongly recommend using ResumeGemini to build a professional and effective resume tailored to the Polymer Chemistry and Physics field. ResumeGemini provides tools and resources to help you create a compelling narrative that showcases your skills and experience. Examples of resumes specifically designed for Polymer Chemistry and Physics professionals are available to guide you.

Invest time in crafting a strong resume – it’s your first impression and a key step towards landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.