Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Knowledge of Manufacturing Execution Systems (MES) interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Knowledge of Manufacturing Execution Systems (MES) Interview

Q 1. Describe your experience with different MES software platforms.

My experience spans several leading MES platforms, including Siemens Opcenter Execution, Rockwell Automation MES, and AspenTech Manufacturing Execution. I’ve worked with these systems across various industries, from pharmaceuticals and food processing to automotive and electronics manufacturing. This exposure has given me a deep understanding of their strengths, weaknesses, and implementation nuances. For instance, in a pharmaceutical project using Siemens Opcenter Execution, I was instrumental in configuring the system to meet stringent regulatory compliance requirements, including 21 CFR Part 11. In another project with Rockwell Automation MES in the automotive sector, I focused on optimizing the production scheduling and real-time tracking capabilities to enhance efficiency and reduce production downtime. Each system presented unique challenges, but my approach always centered on understanding the client’s specific needs and tailoring the MES solution accordingly.

Q 2. Explain the key functionalities of an MES system.

An MES system’s core functionalities revolve around improving manufacturing operations’ visibility, efficiency, and quality. Key functionalities include:

- Production Scheduling and Execution: This involves creating, managing, and monitoring production schedules in real-time, dynamically adjusting based on events like machine breakdowns or material shortages. Think of it as the central nervous system of the factory floor.

- Quality Management: MES systems enable real-time quality data capture, analysis, and reporting, facilitating proactive identification and resolution of quality issues. Imagine instantly seeing the defect rate for a particular batch and taking corrective actions before it impacts downstream processes.

- Data Acquisition and Reporting: Real-time data capture from shop floor devices (PLCs, sensors, etc.) allows for comprehensive tracking of key performance indicators (KPIs) and generation of reports. This is crucial for identifying areas for improvement and demonstrating compliance.

- Material Management: Managing raw materials, work-in-progress (WIP), and finished goods through the production process, including tracking lot numbers, expiry dates, and batch traceability, is vital, particularly in regulated industries.

- Labor Management: Tracking labor hours, efficiency, and skills, facilitating workforce optimization and improved scheduling.

- Maintenance Management: Integrating with Computerized Maintenance Management Systems (CMMS) to schedule preventive maintenance and manage repairs, minimizing downtime.

These functionalities are tightly integrated to provide a holistic view of the manufacturing process, empowering data-driven decision-making.

Q 3. How do you ensure data integrity within an MES environment?

Data integrity is paramount in an MES environment. We employ several strategies to ensure it:

- Access Control and Security: Implementing robust access controls using role-based permissions ensures only authorized personnel can modify data. Think of it like a secure vault protecting your valuable manufacturing information.

- Data Validation and Error Handling: Implementing checks and balances throughout the system to prevent invalid data entry. This can include data type validation, range checks, and plausibility checks. For example, a system might reject an entry for a negative quantity of material.

- Audit Trails: Maintaining detailed audit trails of all data changes, including who made the change, when it was made, and what the change was. This allows for investigation of any discrepancies or data anomalies. It’s like having a meticulous record of every transaction in a bank.

- Data Backup and Recovery: Implementing regular data backups to protect against data loss due to hardware failure or other unforeseen events. This is the safety net ensuring we can recover data if anything goes wrong.

- Data Reconciliation: Periodic reconciliation of MES data with other systems (like ERP) to identify and resolve any discrepancies. This ensures consistency across the organization.

By diligently implementing these measures, we build trust and confidence in the accuracy and reliability of the MES data.

Q 4. What are the common challenges in MES implementation?

MES implementations often face several challenges:

- Integration Complexity: Integrating the MES with existing ERP, SCADA, and other systems can be complex and time-consuming. Different systems might use different data formats or communication protocols, requiring careful planning and expertise.

- Data Migration: Migrating legacy data from older systems to the new MES can be a substantial undertaking, requiring careful planning and validation to ensure data accuracy and consistency.

- Change Management: Implementing an MES often requires significant changes to existing workflows and processes. Effective change management strategies are crucial for user adoption and success.

- Lack of User Training: Insufficient training for users can hinder adoption and effectiveness. Thorough training programs are essential to ensure users understand the system’s capabilities and how to use them efficiently.

- Cost and Return on Investment (ROI): MES implementations can be expensive, and demonstrating a clear ROI requires careful planning, monitoring, and reporting. A well-defined business case is vital.

Successfully navigating these challenges requires a structured approach, experienced implementation teams, and strong stakeholder engagement.

Q 5. How do you handle data discrepancies between MES and ERP systems?

Data discrepancies between MES and ERP systems are common and require a systematic approach to resolve. Techniques include:

- Data Synchronization: Implementing real-time or near real-time data synchronization mechanisms to minimize discrepancies. This can involve using middleware or integration platforms.

- Data Reconciliation Processes: Establishing regular processes to identify and resolve discrepancies. This could involve manual reconciliation for smaller discrepancies or automated reconciliation for larger volumes of data.

- Data Mapping and Transformation: Carefully mapping data fields between the MES and ERP systems to ensure consistency. Data transformation might be needed if the systems use different data formats.

- Data Governance: Establishing clear data ownership, responsibilities, and processes to ensure data quality and consistency across systems.

The solution often depends on the nature and volume of the discrepancies, and the chosen approach needs to be documented and regularly monitored for effectiveness.

Q 6. Describe your experience with MES system validation and qualification.

My experience with MES validation and qualification includes performing and overseeing activities in accordance with industry standards such as GAMP 5 (Good Automated Manufacturing Practice) and 21 CFR Part 11 for regulated industries. This involves:

- Defining Validation Scope: Clearly defining the scope of the validation activities, including the specific MES functionalities to be validated.

- Risk Assessment: Conducting a thorough risk assessment to identify critical MES functions and processes that need to be validated.

- Test Plan Development: Developing a comprehensive test plan outlining the validation tests to be performed.

- Test Execution and Documentation: Executing the validation tests and meticulously documenting the results.

- Deviation Management: Establishing a process for handling deviations from test plans and investigating any unexpected results.

- Qualification Protocols: Developing and executing qualification protocols for hardware and software components to verify their performance and compliance with specifications. This ensures the MES system meets requirements before deployment.

The goal is to ensure the MES system performs as intended, accurately, and reliably, and meets regulatory requirements. This is often an iterative process requiring rigorous documentation.

Q 7. Explain your understanding of real-time data acquisition in MES.

Real-time data acquisition in MES is the process of collecting data from various sources on the shop floor, such as machines, sensors, and PLCs, as it is generated. This differs from batch data collection, which gathers data at intervals. The key is speed and immediacy.

This is achieved through various technologies and protocols, including:

- OPC UA: A widely adopted standard for industrial communication, facilitating seamless data exchange between different devices and systems.

- MQTT: A lightweight messaging protocol ideal for real-time data transmission in industrial environments.

- Databases: High-performance databases (e.g., time-series databases) are used to store and manage the massive amounts of real-time data generated by the MES.

The real-time data provides insights into the current state of production, enabling timely interventions, optimized resource allocation, and proactive issue resolution. For instance, real-time monitoring of machine speeds and efficiency can help to identify bottlenecks and optimize production schedules in response to sudden changes.

Q 8. How do you troubleshoot issues within an MES system?

Troubleshooting an MES system requires a systematic approach. Think of it like diagnosing a car problem – you need to isolate the issue before you can fix it. I typically begin with the symptom: what exactly isn’t working? Is it a specific machine reporting errors? Are production reports inaccurate? Then, I move to data analysis. I’ll check the MES logs for error messages, examine the data flow to identify bottlenecks, and review user activity logs to rule out human error.

My troubleshooting methodology usually involves:

- Reviewing MES Logs: These logs are invaluable. They provide a timestamped record of events, including errors and warnings. For example, a recurring ‘communication error’ might point to a network problem or a faulty sensor connection.

- Checking System Configuration: Incorrectly configured parameters or rules can lead to MES malfunctions. I’ll verify settings related to data acquisition, production scheduling, and reporting.

- Validating Data Integrity: I’ll cross-reference MES data with data from other systems (like SCADA or ERP) to ensure consistency. Discrepancies might indicate data corruption or integration issues.

- Testing and Verification: After making changes or corrections, thorough testing is crucial to ensure the issue is resolved and doesn’t create new problems. I’ll use both automated and manual testing methods.

For instance, in one project, a production line was consistently halting due to ‘sensor failure’ messages in the MES. By analyzing the logs and examining the sensor data, we found that the issue wasn’t the sensors themselves, but a faulty power supply affecting multiple sensors. Replacing the power supply resolved the problem across the whole line.

Q 9. What are your preferred methods for MES data analysis and reporting?

My preferred methods for MES data analysis and reporting leverage a combination of tools and techniques. I rely heavily on the built-in reporting capabilities of the MES, but also utilize external business intelligence (BI) tools for more advanced analysis.

Within the MES: Most systems offer pre-built reports for key metrics like Overall Equipment Effectiveness (OEE), production output, and downtime. I customize these reports to meet specific needs, using filters and parameters to focus on particular aspects of the manufacturing process. For example, if I want to track yield only for a specific product line during a specific time frame, I’ll tailor the built-in report to show just that information.

External BI tools: For in-depth analysis and visualization, tools like Tableau or Power BI provide powerful capabilities. I can connect these tools to the MES database to create interactive dashboards and custom reports. This allows me to uncover trends, identify root causes of issues, and present findings in a clear and concise manner to stakeholders. For example, creating a dashboard to visualize OEE across all production lines helps spot trends or performance dips immediately.

Additionally, I’m proficient in SQL and other query languages to directly access and manipulate MES data when necessary. This lets me create custom queries to answer specific business questions or extract particular datasets for detailed analysis.

Q 10. How do you ensure MES system security?

MES security is paramount. A compromised MES can lead to production disruptions, data breaches, and even safety hazards. My approach to MES security is multi-layered and encompasses several key areas:

- Access Control: Implementing robust user authentication and authorization is fundamental. This includes strong passwords, multi-factor authentication (MFA), and role-based access control (RBAC) to restrict access to sensitive data and system functionalities based on user roles.

- Network Security: The MES needs to be protected from external threats. This involves firewalls, intrusion detection systems, and regular security audits to identify and mitigate vulnerabilities. Segmenting the MES network from other corporate networks is crucial to limit the impact of a breach.

- Data Encryption: Data at rest and in transit should be encrypted. This safeguards sensitive information from unauthorized access, even if the system is compromised.

- Regular Updates and Patching: Keeping the MES software and its underlying infrastructure updated with the latest security patches is essential to protect against known vulnerabilities. A regular patching schedule is critical.

- Security Awareness Training: Training employees on security best practices, such as recognizing phishing attempts and following secure password protocols, is vital to prevent human error – a significant source of security breaches.

For example, in a recent project, we implemented MFA for all MES users, significantly enhancing its security posture. We also implemented regular penetration testing to identify any weaknesses in the system’s security before malicious actors could exploit them.

Q 11. What are some common metrics used to evaluate MES performance?

MES performance is evaluated using a variety of key performance indicators (KPIs). These metrics provide insights into various aspects of the manufacturing process, enabling continuous improvement. Some common metrics include:

- Overall Equipment Effectiveness (OEE): A comprehensive metric that combines availability, performance, and quality. It’s a key indicator of how effectively equipment is utilized.

- Production Output: Measures the quantity of goods produced within a specific timeframe. This can be expressed in units, weight, or other relevant units.

- Downtime: Tracks the time equipment is not operational. Analyzing downtime reasons helps identify and resolve root causes for improved efficiency.

- Cycle Time: Measures the time taken to complete a single production cycle. Reducing cycle time improves productivity.

- Yield: Represents the percentage of good units produced relative to the total number of units started. High yield indicates efficient and effective processes.

- Work-in-Progress (WIP): Tracks the amount of material currently undergoing processing. High WIP may signal bottlenecks or inefficiencies.

- First Pass Yield (FPY): Measures the percentage of units that pass inspection on the first attempt. High FPY points to improved process quality and reduced rework.

- Mean Time Between Failures (MTBF): Measures the average time between equipment failures, providing insights into equipment reliability.

By monitoring these metrics, we can identify areas for improvement and make data-driven decisions to optimize production processes. For example, consistently low OEE for a specific machine might indicate a need for preventative maintenance or process optimization.

Q 12. Explain your experience with MES integration with other manufacturing systems.

I have extensive experience integrating MES systems with other manufacturing systems, such as ERP (Enterprise Resource Planning), SCADA (Supervisory Control and Data Acquisition), and PLCs (Programmable Logic Controllers). These integrations are crucial for a seamless flow of information across the entire manufacturing value chain.

ERP Integration: Connecting the MES to the ERP system provides crucial information exchange. The MES feeds production data (e.g., actual output, material consumption) to the ERP, which in turn provides production orders, bills of materials, and other relevant information to the MES. This bidirectional flow of information ensures accurate inventory management, efficient scheduling, and timely reporting.

SCADA Integration: Integrating the MES with SCADA allows for real-time monitoring and control of equipment. The MES can receive real-time data from SCADA (e.g., machine status, sensor readings) to provide precise insights into production performance and identify potential issues. For example, sudden drops in pressure readings from a SCADA system can be immediately flagged in the MES as a potential problem.

PLC Integration: PLCs directly control machines and equipment. Integrating the MES with PLCs enables automated data capture and control. The MES can receive machine data (e.g., cycle times, production counts) directly from the PLC, reducing manual data entry and improving data accuracy.

The integration methods vary, depending on the specific systems and technologies involved. Common methods include using APIs (Application Programming Interfaces), middleware, and database connections. Careful planning and testing are essential to ensure a smooth and reliable integration.

Q 13. Describe your experience with MES system upgrades and maintenance.

MES system upgrades and maintenance are ongoing processes vital for ensuring system performance, security, and compliance. My approach to these activities is methodical and involves careful planning, testing, and communication.

Upgrades: Upgrades can range from minor bug fixes and security patches to major releases with new features. I follow a structured approach:

- Planning and Assessment: Thoroughly evaluating the need for an upgrade, assessing its impact, and defining the scope of the project.

- Testing: Rigorous testing in a development or staging environment before deploying the upgrade to the production system. This includes unit testing, integration testing, and user acceptance testing.

- Phased Rollout: Implementing the upgrade in phases to minimize disruption and allow for adjustments if needed.

- Training: Providing training to users on new functionalities and procedures.

Maintenance: Regular maintenance is essential for preventing problems and ensuring system stability. This includes:

- System Monitoring: Continuously monitoring the system’s performance and identifying potential issues early.

- Performance Tuning: Optimizing system settings and configurations to improve response times and efficiency.

- Data Backups: Regularly backing up the MES database to protect against data loss.

- Security Updates: Applying security patches and updates to address vulnerabilities.

For example, during a recent upgrade, we used a phased rollout approach, updating one production line at a time to minimize the impact on production. This allowed us to address any unforeseen issues before rolling out the upgrade across the entire facility.

Q 14. How do you manage user access and permissions in an MES system?

Managing user access and permissions in an MES system is critical for security and data integrity. My approach involves implementing a robust role-based access control (RBAC) system. This system allows granular control over user permissions, ensuring that only authorized personnel have access to specific data and functionalities.

Role Definition: We define roles based on job functions and responsibilities. For example, a production supervisor might have access to real-time production data and the ability to adjust production schedules, while an operator might only have access to data related to their specific machine.

Permission Assignment: Each role is assigned specific permissions, restricting access to certain data or functions. This ensures that users only see the information relevant to their tasks. For instance, a quality control manager would have access to data related to quality inspection, but not necessarily access to financial data.

User Management: The MES system provides tools for managing user accounts and permissions. This includes adding new users, modifying existing user roles, and disabling accounts when needed. This often requires a change management system to properly track access changes and audit compliance.

Auditing: Maintaining audit trails is crucial to track user activity and ensure compliance. This helps identify potential security breaches or unauthorized actions.

For example, I’ve implemented an RBAC system where different roles like ‘Operator’, ‘Supervisor’, ‘Engineer’, and ‘Administrator’ each have distinct permissions. The system also automatically logs all user actions, enabling easy review for audits or troubleshooting.

Q 15. How do you contribute to continuous improvement within an MES environment?

Continuous improvement in an MES environment is a journey, not a destination. It involves systematically identifying areas for optimization, implementing changes, and measuring the impact. My approach focuses on data-driven decision-making and a collaborative spirit.

- Data Analysis: I leverage MES reporting capabilities to identify bottlenecks, inefficiencies, and areas with high error rates. For instance, analyzing production downtime reports might reveal recurring issues with a specific machine, prompting preventative maintenance strategies.

- Kaizen Events/Workshops: I facilitate workshops involving operators, supervisors, and engineers to brainstorm improvements. These events provide a platform for diverse perspectives and ensure buy-in from all stakeholders. A recent project involved a Kaizen event that streamlined our batching process, reducing cycle times by 15%.

- Process Standardization: I work on documenting best practices and implementing standardized operating procedures (SOPs) within the MES system. This ensures consistency and reduces variability, leading to improved quality and efficiency. A key example was implementing a standardized material handling process that minimized errors in picking and delivery.

- Technology Upgrades: I stay abreast of the latest MES technologies and explore opportunities to leverage automation and AI to further optimize processes. We recently integrated a predictive maintenance module into our MES, significantly reducing unexpected downtime.

- Performance Monitoring and KPIs: I establish key performance indicators (KPIs) to track the effectiveness of implemented improvements and ensure continuous monitoring of system performance. This allows us to measure return on investment (ROI) of improvement initiatives and justify future projects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your knowledge of different MES architectures (e.g., client-server, cloud-based).

MES architectures vary depending on the size and complexity of the manufacturing operation, as well as the specific needs of the business. I have experience with both client-server and cloud-based architectures.

- Client-Server Architecture: This traditional approach involves a central server hosting the MES application and client workstations accessing the system. It offers strong control and security, especially beneficial for highly regulated industries. However, it can be expensive to maintain and scale.

- Cloud-Based Architecture: Cloud MES solutions offer scalability, flexibility, and cost-effectiveness. They provide accessibility from anywhere with an internet connection, facilitating remote monitoring and collaboration. Security concerns are addressed through robust cloud security measures. The transition to a cloud-based MES can significantly reduce IT infrastructure costs and improve agility.

The choice between these architectures depends on factors like budget, security requirements, IT infrastructure, and the organization’s IT expertise. Understanding the strengths and limitations of each is crucial for selecting the right solution for a specific manufacturing environment.

Q 17. How do you handle MES system downtime?

MES downtime is a critical issue that can significantly impact production. My approach to handling downtime focuses on prevention, mitigation, and recovery.

- Proactive Maintenance: Implementing a robust preventative maintenance program, leveraging data from the MES to predict potential failures and schedule maintenance before they occur, is crucial. We utilize predictive analytics to identify patterns and prevent equipment issues before they escalate into downtime.

- Disaster Recovery Plan: Having a well-defined disaster recovery plan is paramount. This plan includes backups, failover systems, and procedures for restoring functionality quickly in the event of a major failure. We regularly test our disaster recovery plan to ensure its effectiveness. Drills help to identify shortcomings and adjust our plans.

- Root Cause Analysis: When downtime occurs, a thorough root cause analysis is essential to identify the underlying causes and prevent recurrence. We utilize tools such as the 5 Whys to understand the chain of events leading to the failure.

- Communication Protocol: Establishing clear communication protocols is vital, ensuring stakeholders are informed promptly about downtime incidents, and updates are disseminated. Transparent communication helps to minimize confusion and keep everyone aligned.

- Emergency Response Team: A dedicated team should be responsible for addressing downtime incidents, with clear roles and responsibilities defined. This team can effectively handle the situation promptly and effectively.

Q 18. Describe your experience with MES system configuration and customization.

MES configuration and customization are critical for aligning the system with specific manufacturing processes. My experience spans several MES platforms, allowing me to tailor solutions to meet diverse business requirements.

- Requirements Gathering: Thoroughly understanding the manufacturing process and business needs is the cornerstone of successful configuration. This includes documenting workflows, data requirements, and user roles and responsibilities. I use workshops and interviews to gather this information.

- System Design: Based on the requirements, I design the MES system architecture, defining data structures, workflows, and user interfaces. This involves selecting appropriate modules, customizing screens, and creating custom reports.

- Configuration and Testing: I configure the MES system according to the design, setting up parameters, defining rules, and testing functionality thoroughly. This involves both unit testing and integration testing to ensure all components work together seamlessly.

- User Training: Providing comprehensive user training is vital for successful MES implementation. Training materials and hands-on sessions ensure that users can effectively utilize the system. I develop tailored training programs based on the specific features and functionalities of the customized system.

- Ongoing Support: Providing ongoing support and maintenance is crucial for addressing user issues and making necessary adjustments to the configuration. We regularly monitor system performance and address any issues that arise. This ensures the system remains optimized and supports ongoing production needs.

Q 19. How familiar are you with various MES reporting tools?

My experience encompasses a variety of MES reporting tools, ranging from built-in reporting functionalities within the MES to specialized business intelligence (BI) tools. The choice of tool depends on the complexity of the reporting requirements and the technical expertise available.

- Built-in Reporting: Most MES systems offer basic reporting features that allow users to generate standard reports such as production summaries, downtime reports, and quality metrics. These features are usually sufficient for straightforward reporting needs.

- Business Intelligence (BI) Tools: For more complex reporting and analysis, BI tools such as Power BI, Tableau, or Qlik Sense provide advanced visualization and analytical capabilities. These tools can connect to the MES database to extract data and create dashboards, providing real-time visibility into key performance indicators.

- Custom Reporting: In some cases, custom reports may be needed to address specific business requirements. This often involves working with developers to create custom queries and visualizations.

Regardless of the tools used, ensuring data accuracy, completeness, and timely reporting is paramount. Effective reporting is key to making data-driven decisions, optimizing processes, and improving overall manufacturing performance.

Q 20. How do you ensure compliance with regulatory requirements (e.g., FDA 21 CFR Part 11) in an MES environment?

Ensuring compliance with regulatory requirements, such as FDA 21 CFR Part 11, is critical in regulated industries. My experience involves implementing and maintaining MES systems that meet these stringent requirements.

- Audit Trails: Maintaining complete and accurate audit trails is fundamental. The MES system must record all user activities, changes to data, and system events. This ensures traceability and accountability. We regularly review audit trails to ensure their integrity and identify potential issues.

- Electronic Signatures: The system must support electronic signatures that comply with 21 CFR Part 11. This involves implementing secure authentication mechanisms and procedures for validating electronic signatures. All electronic signatures are managed in accordance with the regulatory framework.

- Data Integrity: Ensuring data integrity is crucial. This involves implementing measures to prevent unauthorized access, modification, or deletion of data. Regular data backups and validation procedures are implemented. We use appropriate validation techniques to maintain data accuracy.

- Access Control: Implementing role-based access control (RBAC) restricts user access to only the necessary data and functionalities. This helps to prevent unauthorized access and maintains data security. Access rights are carefully managed based on job responsibilities.

- System Validation: The entire MES system must undergo rigorous validation to demonstrate its compliance with regulatory requirements. This involves creating validation plans, executing tests, and documenting results. Validation activities adhere to GAMP guidelines and regulatory best practices.

Q 21. Explain your understanding of MES and Industry 4.0 concepts.

MES is the backbone of manufacturing operations, providing real-time visibility into production processes. Industry 4.0 builds upon MES by incorporating advanced technologies such as IoT, AI, and cloud computing to create a more intelligent and interconnected manufacturing environment.

- MES in Industry 4.0: The MES plays a crucial role in Industry 4.0, serving as a central platform for collecting and integrating data from various sources. This allows for real-time monitoring, predictive analytics, and improved decision-making.

- Data Integration: In an Industry 4.0 environment, the MES integrates data from various sources, including machines, sensors, and PLCs. This integrated data provides a holistic view of the manufacturing process, enabling better optimization and control.

- Advanced Analytics: Industry 4.0 leverages advanced analytics techniques such as machine learning and AI to analyze MES data and identify patterns, predict potential issues, and optimize processes. Predictive maintenance models can be deployed to enhance equipment reliability.

- Automation: The MES integrates with automation systems to enable real-time control and adjustments to production processes. Automated responses to deviations in production parameters optimize processes, enhancing efficiency.

- Digital Twin: The MES supports the creation of digital twins, virtual representations of physical assets and processes. Digital twins allow for simulation, testing, and optimization of manufacturing operations before implementation in the real world. This approach significantly reduces risks and accelerates improvements.

In essence, Industry 4.0 enhances the capabilities of the MES, transforming it from a simple monitoring system to a powerful engine for driving efficiency, improving quality, and accelerating innovation within manufacturing.

Q 22. How do you utilize MES data to drive operational efficiency?

MES data is a goldmine for improving operational efficiency. It provides a real-time view of your manufacturing process, allowing for data-driven decision-making rather than relying on gut feelings. I utilize this data in several ways:

- Performance Monitoring and Bottleneck Identification: By analyzing metrics like Overall Equipment Effectiveness (OEE), cycle times, and production output, I can quickly pinpoint areas where improvements are needed. For example, if a specific machine consistently has low OEE, I investigate the root cause – is it due to downtime, defects, or reduced speed?

- Predictive Maintenance: MES data can be used to predict equipment failures. By analyzing historical data on machine performance and maintenance records, we can identify patterns and predict when maintenance is needed, preventing costly downtime. This is like getting a check-up for your equipment before it breaks down.

- Inventory Optimization: Tracking raw materials, work-in-progress (WIP), and finished goods in real-time allows for better inventory management. This minimizes storage costs, reduces waste from expired materials, and prevents stockouts. Think of it as having a constantly updated inventory spreadsheet that’s always accurate.

- Quality Control Improvements: MES collects data on defects and rework. By analyzing this information, we can pinpoint the root causes of quality issues and implement corrective actions, improving product quality and reducing scrap.

- Process Optimization: By analyzing production data, we can identify areas where processes can be streamlined. This might involve optimizing workflows, improving material flow, or changing machine parameters to increase efficiency.

Ultimately, the goal is to use MES data to create a continuous improvement cycle, constantly identifying areas for improvement and implementing changes to optimize the manufacturing process.

Q 23. Describe your experience with MES training and knowledge transfer.

My experience with MES training and knowledge transfer is extensive. I’ve been involved in both delivering and receiving training on various MES platforms, including Siemens Opcenter, Rockwell PlantPAx, and Infor M3.

My approach to training emphasizes hands-on experience. I find that simply reading manuals is ineffective. I structure training sessions with a mix of theoretical explanations and practical exercises using real-world scenarios and simulated data. For example, when training on data analysis, we would work through case studies of actual production issues, using the MES system to find solutions.

I also believe in fostering a collaborative learning environment. I encourage trainees to share their experiences and knowledge with each other, and I’m always available to answer questions and provide support after the training is complete. This builds confidence and reduces the knowledge gap between the training and the live environment.

I use a variety of methods for knowledge transfer including:

- Structured training programs: These are carefully designed programs, including manuals and online learning resources, for onboarding new team members.

- On-the-job training: I mentor junior team members and provide guidance as they perform daily tasks within the MES system.

- Workshops and knowledge sharing sessions: Regular workshops keep the team updated on new features and best practices.

- Documentation: I maintain comprehensive documentation covering all aspects of the MES system, from operational procedures to troubleshooting guides.

Q 24. What are some key performance indicators (KPIs) you monitor within an MES system?

The KPIs I monitor within an MES system depend heavily on the specific manufacturing goals and context, but some key examples include:

- Overall Equipment Effectiveness (OEE): This crucial metric combines availability, performance, and quality rate to reflect the overall efficiency of a machine or production line. A low OEE often signals the need for investigation and improvement.

- Production Output: This measures the total quantity of products produced within a specific timeframe. It helps track production progress and identify deviations from plans.

- Cycle Time: The time it takes to complete a single production cycle. Shorter cycle times translate to greater efficiency.

- Downtime: This KPI quantifies the time a machine or line is not producing due to various reasons like maintenance, breakdowns, or material shortages. Minimizing downtime is a major efficiency driver.

- Defect Rate: This measures the percentage of defective products produced. A high defect rate suggests quality control problems that need addressing.

- Work-in-Progress (WIP) Inventory: This reflects the value of partially completed goods. High WIP inventory can tie up capital and indicate bottlenecks in the production process.

- Material Usage Efficiency: This compares actual material consumption to planned consumption, revealing areas where material waste can be reduced.

- Labor Efficiency: This KPI assesses labor productivity and helps identify potential workforce optimization opportunities.

By continuously monitoring these KPIs and analyzing trends, we can identify areas for improvement and drive operational efficiency.

Q 25. How do you identify and resolve MES system bottlenecks?

Identifying and resolving MES system bottlenecks requires a systematic approach. I typically follow these steps:

- Data Analysis: I start by analyzing MES data to pinpoint the areas experiencing delays or inefficiencies. This might involve examining OEE, cycle times, downtime, and queue lengths for various stages of the process.

- Root Cause Analysis: Once a bottleneck is identified, I perform a root cause analysis to understand why it’s occurring. This might involve reviewing machine logs, interviewing operators, and examining process documentation. Tools like the 5 Whys or fishbone diagrams are useful here.

- Solution Development: Based on the root cause analysis, I develop potential solutions. These could range from simple adjustments like machine parameter changes to more complex solutions involving process re-engineering or software updates.

- Implementation and Testing: Once a solution is chosen, I implement it, carefully monitoring its effects to ensure it resolves the bottleneck without causing new issues.

- Monitoring and Optimization: I continuously monitor the system’s performance after the solution is implemented. This ensures that the fix is sustainable and identifies any unintended consequences or new bottlenecks that have emerged.

For example, if a bottleneck was caused by frequent machine jams, the solution might involve improving the material handling process, upgrading the machine, or implementing a predictive maintenance program to prevent jams before they occur.

Q 26. Explain your experience with MES system testing and validation.

MES system testing and validation are crucial to ensure the system functions as intended and meets regulatory requirements. My experience encompasses various testing methodologies, including:

- Unit Testing: Testing individual modules or components of the system to ensure they operate correctly.

- Integration Testing: Verifying the interaction between different modules to ensure seamless data flow and functionality.

- System Testing: Testing the entire MES system as a whole to confirm it meets requirements and performs as expected.

- User Acceptance Testing (UAT): Involving end-users in the testing process to ensure the system is user-friendly and meets their needs. This often involves structured test cases and scenarios developed collaboratively.

- Performance Testing: Evaluating the system’s performance under various load conditions to ensure scalability and responsiveness.

- Security Testing: This crucial step ensures data integrity and prevents unauthorized access. It usually includes penetration testing and vulnerability assessments.

Validation, often driven by regulatory compliance like FDA 21 CFR Part 11 (for pharmaceutical manufacturing), ensures the system performs reliably and produces consistent results. This may involve generating validation documentation to demonstrate compliance and demonstrate that the MES system accurately reflects production reality.

Throughout the testing process, rigorous documentation is maintained, detailing test plans, test results, and any defects discovered. This documentation is vital for auditing purposes and for ongoing system maintenance.

Q 27. How do you ensure effective communication between MES users and IT support?

Effective communication between MES users and IT support is vital for a smoothly running system. I’ve used several strategies to facilitate this:

- Establishing clear communication channels: This includes designated communication methods like a ticketing system, regular meetings, and a dedicated communication platform. A shared communication platform ensures transparency and accessibility for all stakeholders.

- Training and user manuals: Providing comprehensive training to users empowers them to independently troubleshoot many common issues, reducing the burden on IT support. Well-written manuals also serve as readily available resources.

- Regular feedback mechanisms: Collecting regular user feedback allows for early identification of issues and potential improvements to the system or the support process itself. Surveys and feedback sessions are useful here.

- Proactive communication: Keeping users informed about system updates, planned downtime, and new features prevents confusion and reduces the number of unexpected issues. Regular newsletters or announcements can be very effective.

- Escalation process: Defining a clear escalation process helps to ensure that complex issues are handled promptly and effectively by the right personnel.

By implementing these strategies, I’ve successfully fostered a collaborative environment where MES users feel comfortable reporting issues and IT support can quickly address them.

Q 28. Describe a situation where you had to troubleshoot a complex MES issue. What was your approach and outcome?

In one instance, we experienced intermittent data loss within our MES system during peak production hours. This was impacting real-time reporting and creating inconsistencies in production tracking. The initial diagnosis pointed to potential database issues, but the cause was elusive.

My approach involved a structured troubleshooting methodology:

- Data Collection: I first gathered logs from the MES server, the database server, and the network infrastructure. I also interviewed operators to ascertain the precise circumstances under which the data loss occurred.

- Pattern Recognition: Analyzing the collected data, I noticed a pattern: data loss seemed to coincide with high network traffic. This suggested a potential network bandwidth bottleneck.

- Hypothesis Testing: I hypothesized that the network infrastructure wasn’t adequately equipped to handle the peak data volume from the MES system. To verify, we ran simulations under high-traffic conditions.

- Solution Implementation: Based on the simulation results, we upgraded the network infrastructure to increase its bandwidth capacity.

- Verification: After the upgrade, we closely monitored the system for several weeks. The data loss issue was eliminated.

The outcome was a significant improvement in system stability and reliability. This experience highlighted the importance of thorough data analysis, hypothesis testing, and proactive network capacity planning when dealing with complex MES issues.

Key Topics to Learn for Knowledge of Manufacturing Execution Systems (MES) Interview

- MES Architecture and Functionality: Understanding the core components of an MES system (e.g., scheduling, production tracking, quality management, maintenance management) and how they interact.

- Data Management and Integration: Explore how MES systems collect, process, and integrate data from various sources (e.g., shop floor equipment, ERP systems) and the importance of data integrity.

- Production Scheduling and Optimization: Learn about different scheduling methodologies used in MES and how to optimize production plans for efficiency and on-time delivery. Consider discussing practical applications like Finite Capacity Scheduling (FCS).

- Quality Management and Control within MES: Understand how MES systems support quality control processes, including data collection, analysis, and reporting of quality metrics. Explore concepts like SPC (Statistical Process Control).

- Maintenance Management and Integration: Learn how MES systems support preventative and corrective maintenance activities, including work order management and equipment tracking. Discuss the benefits of integrating MES with CMMS (Computerized Maintenance Management Systems).

- Reporting and Analytics: Understand the importance of data analysis within an MES system. Be prepared to discuss key performance indicators (KPIs) and the creation of reports for management decision-making.

- Industry-Specific Applications: Research common MES implementations across various manufacturing sectors (e.g., pharmaceuticals, automotive, food processing) and how the system adapts to specific industry needs.

- Troubleshooting and Problem-Solving: Prepare to discuss how to approach common MES issues, such as data discrepancies, system downtime, and production bottlenecks. Highlight your problem-solving skills and methodical approach.

Next Steps

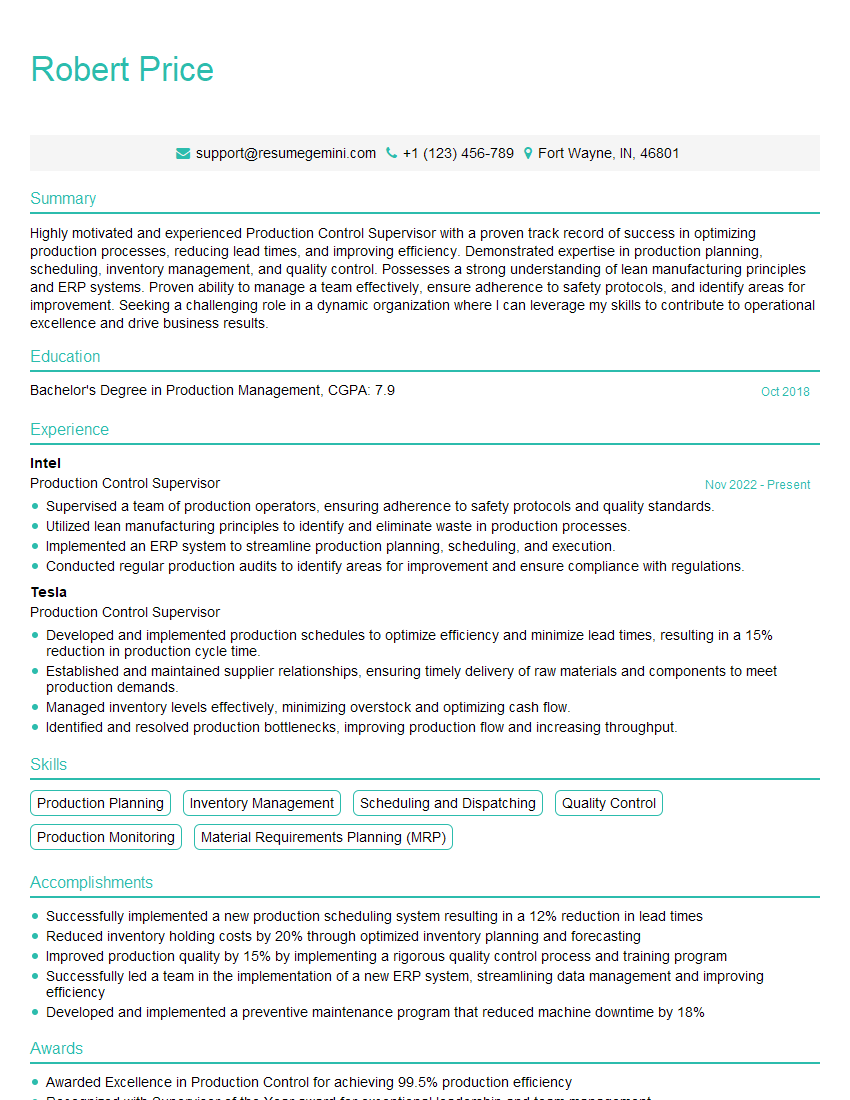

Mastering your knowledge of Manufacturing Execution Systems (MES) is crucial for accelerating your career in manufacturing. A strong understanding of MES principles and applications significantly enhances your value to potential employers. To maximize your job prospects, crafting a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume showcasing your MES expertise. Examples of resumes tailored to MES roles are available within ResumeGemini to help guide your creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.