Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Polymer Injection Molding interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Polymer Injection Molding Interview

Q 1. Explain the injection molding process step-by-step.

Injection molding is a high-volume manufacturing process that creates parts by injecting molten plastic into a mold. Think of it like making plastic cookies with a cookie cutter! Here’s a step-by-step breakdown:

- Clamping: The mold, consisting of two halves, is clamped shut tightly to ensure a leak-proof seal during the injection phase. This prevents the molten plastic from escaping.

- Injection: A precisely measured amount of molten plastic resin is injected into the mold cavity under high pressure. The pressure ensures the resin completely fills the mold and replicates the part’s intricate details.

- Dwelling: Once the mold is full, the injection pressure is maintained for a short period. This dwelling phase allows the resin to fully fill the mold and prevents short shots (incomplete filling).

- Cooling: The molten plastic cools and solidifies within the mold cavity, taking on the exact shape of the mold. Cooling time depends on the resin’s properties and the part’s geometry – thicker sections require longer cooling times.

- Ejection: Once the plastic has solidified sufficiently, the mold opens, and ejection pins push the finished part out of the mold cavity. This process needs to be carefully designed to avoid damage to the molded part.

- Molding Cycle Repeats: The cycle then repeats automatically, producing many identical parts efficiently. The cycle time depends on several factors, including the size and complexity of the part, the type of resin used, and the machine’s capabilities.

For example, consider manufacturing a simple plastic bottle cap. The injection molding process creates thousands of identical caps efficiently and with precise dimensions.

Q 2. What are the different types of injection molding machines?

Injection molding machines vary in size, automation level, and clamping force. They’re broadly classified as:

- Hydraulic Machines: These use hydraulic pressure to generate clamping force and inject the molten plastic. They are robust, offer high clamping forces and are suitable for large parts. They can be less energy efficient than other options.

- Electric Machines: Employ electric motors for both clamping and injection, offering precise control, energy efficiency, and lower noise levels. They are well-suited for high-precision parts and demanding applications.

- Hybrid Machines: Combine hydraulic and electric systems. They leverage the strengths of both types, allowing for high clamping force with precise injection control, often optimized for high-speed operation and reduced energy consumption.

- All-Electric Machines: These are a further development, offering improved precision and energy efficiency. Their control is often fully integrated into the manufacturing process.

The choice of machine depends on factors like part size, production volume, budget, and desired precision. A small company producing low-volume, intricate parts might opt for an electric machine, whereas a large automotive supplier might choose a high-tonnage hydraulic machine for large bumper components.

Q 3. Describe the various types of plastic resins used in injection molding.

A vast range of plastic resins are used in injection molding, each with unique properties. Key types include:

- Thermoplastics: These resins soften when heated and harden when cooled, allowing for repeated melting and molding. Common examples include:

- Polyethylene (PE): Flexible, low-cost, widely used in packaging and films.

- Polypropylene (PP): Tough, resistant to chemicals, used in containers and automotive parts.

- Polyvinyl Chloride (PVC): Rigid or flexible, used in pipes, window frames, and flooring.

- Polystyrene (PS): Brittle, clear, inexpensive, often used in disposable tableware and CD cases.

- Acrylonitrile Butadiene Styrene (ABS): Tough, impact-resistant, used in housings for electronics and appliances.

- Polyethylene Terephthalate (PET): Strong, transparent, used in beverage bottles and food containers.

- Thermosets: Undergo an irreversible chemical change when heated, forming a rigid, cross-linked structure. Once cured, they cannot be re-melted. Examples include epoxy resins and phenolic resins often used for high-strength applications where heat resistance is critical.

The selection of resin significantly impacts the final product’s properties.

Q 4. How do you select the appropriate resin for a specific application?

Resin selection is crucial and involves considering several factors:

- Mechanical Properties: Strength, stiffness, toughness, flexibility – these determine the part’s ability to withstand stress and impact.

- Thermal Properties: Heat resistance, melting point, thermal expansion coefficient – crucial for applications involving temperature extremes.

- Chemical Resistance: Ability to withstand exposure to chemicals, solvents, or other substances.

- Cost: Resins vary significantly in price, influencing the overall product cost.

- Appearance: Color, transparency, surface finish – important for aesthetic considerations.

- Regulatory Compliance: Certain resins may have restrictions depending on the intended use (e.g., food contact applications).

For example, selecting a high-impact polystyrene for a toy requires considering its toughness and ability to withstand accidental drops. In contrast, a heat-resistant resin like PEEK is needed for components in high-temperature environments.

Q 5. Explain the concept of melt flow index (MFI).

Melt Flow Index (MFI) measures the ease with which a thermoplastic resin flows under specified conditions. It’s essentially a measure of the resin’s viscosity. Think of it as how easily the plastic ‘squeezes’ through a small hole under pressure. A higher MFI indicates a lower viscosity – the plastic flows more easily. A lower MFI indicates a higher viscosity – the plastic is more difficult to flow.

MFI is determined by measuring the mass of molten resin that extrudes through a standardized die under specific temperature and pressure conditions. The result is expressed in grams per 10 minutes (g/10min). MFI is critical for selecting the appropriate resin grade and setting processing parameters in injection molding. A resin with an inappropriately high or low MFI can lead to processing issues like short shots or poor surface finish.

Q 6. What are the common causes of short shots in injection molding?

Short shots, where the plastic doesn’t completely fill the mold cavity, are common problems in injection molding. Here are common causes:

- Insufficient Injection Pressure: The pressure may be too low to overcome the resin’s viscosity and completely fill the mold.

- Insufficient Injection Volume: The injection screw might not deliver enough molten plastic.

- High Resin Viscosity: A high viscosity resin requires higher pressure or longer injection times.

- Molding Issues: Restrictions in the mold’s runners or gates might impede flow.

- Cold Mold: If the mold isn’t adequately heated, the resin may cool too quickly and fail to fill completely.

- Air Entrapment: Air trapped in the mold can prevent complete filling.

Troubleshooting involves systematically checking each factor. Increasing injection pressure, adjusting the injection volume, checking gate size and mold temperature are common initial steps. Analyzing the mold’s design for flow restrictions might require adjustments.

Q 7. How do you troubleshoot sink marks in molded parts?

Sink marks are depressions on the surface of a molded part, often caused by internal stresses during cooling. They’re like small divots in the plastic. They can severely compromise part aesthetics and structural integrity.

Troubleshooting involves addressing issues related to the part’s thickness and cooling rate:

- Increase Wall Thickness: If the part is too thin, the surface cools quickly while the interior remains molten. This creates shrinkage and sink marks. Increasing wall thickness provides a more even cooling rate.

- Optimize Mold Design: Improve the mold’s cooling system, especially in thicker sections, ensuring uniform cooling. Adding cooling lines in strategic locations can significantly help.

- Adjust Mold Temperature: A cooler mold will result in more rapid cooling, which exacerbates the problem. Increasing mold temperature can assist.

- Adjust Injection Parameters: Precise control of injection pressure, velocity, and holding pressure may help minimize shrinkage.

- Change Resin: If the resin has a high shrinkage rate, exploring alternative resins with lower shrinkage is necessary.

It’s a systematic approach; you might need to iterate through several adjustments to achieve satisfactory results. Often, it involves fine-tuning various parameters until the sink marks are minimized or eliminated.

Q 8. What are the different types of mold gates?

Mold gates are the crucial pathways through which molten polymer enters the mold cavity. Selecting the right gate type significantly impacts part quality, cycle time, and overall production efficiency. Different gate types offer various advantages and disadvantages, making the choice highly dependent on the specific part geometry and material properties.

- Pin Gate: A small, precisely drilled hole. Simple, inexpensive, and leaves a small, easily removed mark. Ideal for small parts with thin walls.

- Edge Gate: Located at the edge of the part. Easy to locate and remove, minimizes flow distance, suitable for large parts or those with intricate features.

- Submarine Gate: Located beneath the surface of the part. Leaves almost no visible mark, preferred for high-aesthetic parts. However, it’s more complex to manufacture and can be challenging to remove.

- Tab Gate: A small tab of material is created that connects to the main part. Easy to remove post-molding, commonly used for parts where a slight imperfection is acceptable.

- Hot Runner Gate: The molten material is fed directly into the mold cavity through heated nozzles, eliminating the need for sprue and runner systems. This reduces material waste and cycle time. Higher initial investment, but cost-effective for high-volume production.

- Fan Gate: Multiple small gates are used to distribute the flow across a wider area. This helps to reduce weld lines and improve filling in complex geometries.

For example, a delicate cosmetic part would benefit from a submarine gate to maintain its surface quality, while a simple, high-volume component might utilize a pin gate for its cost-effectiveness.

Q 9. Explain the importance of proper mold temperature control.

Precise mold temperature control is paramount for consistent part quality and successful injection molding. Temperature impacts the polymer’s viscosity, flow characteristics, and its ability to fill the mold cavity completely and uniformly. Incorrect temperature can lead to defects like short shots, warping, sink marks, and poor surface finish.

Mold temperature is typically controlled using heating and cooling systems within the mold. Heating ensures the polymer remains fluid enough for proper flow, while cooling rapidly solidifies the part within the cavity, allowing for faster cycle times and dimensional stability. Different polymers require different optimal temperatures. For example, amorphous polymers like polycarbonate usually need higher mold temperatures compared to semi-crystalline polymers like polypropylene.

Imagine baking a cake; the oven temperature directly impacts the cake’s texture and rise. Similarly, in injection molding, accurate temperature control translates to consistent part quality. Monitoring and adjusting temperatures are crucial, often using thermocouples strategically placed within the mold to obtain real-time feedback.

Q 10. What are the common causes of warping in molded parts?

Warpage in molded parts, characterized by unwanted bending or distortion, stems from various factors related to the material, mold design, and processing parameters.

- Uneven Cooling: Different sections of the part cool at different rates, leading to internal stresses that cause warping. Thicker sections cool slower than thinner ones, creating a significant difference in shrinkage.

- Residual Stresses: Internal stresses within the polymer, created during the injection molding process, can be released post-molding, causing warping. This often happens with high-viscosity materials or complex geometries.

- Mold Design Flaws: Asymmetrical mold designs or improper venting can create uneven cooling and warping.

- Material Properties: The polymer’s coefficient of thermal expansion (CTE) plays a crucial role. High CTE materials are more prone to warping.

- High Melt Temperature: Too high a melt temperature can introduce residual stresses and increase the likelihood of warping.

Addressing warping might involve optimizing mold design, adjusting processing parameters like cooling rates and injection pressures, or selecting an alternative polymer with a lower CTE.

Q 11. How do you measure and control clamping force?

Clamping force, the pressure exerted by the mold halves to prevent them from separating during injection, is crucial to prevent flash (excess material escaping the mold) and ensure proper part formation. It’s measured in tons and directly affects the part’s quality.

Clamping force is measured using load cells integrated into the injection molding machine. These cells provide accurate readings of the force applied by the machine’s clamping system. The required clamping force depends on the part size, complexity, and material being molded. A larger, more complex part requires a higher clamping force.

Controlling clamping force involves adjusting the machine settings. Operators typically set the desired clamping force based on prior experience, part design, and material properties. Modern machines offer sophisticated feedback mechanisms, automatically adjusting the clamping force based on real-time conditions. Incorrect clamping force can result in flash, part defects, or even machine damage.

Q 12. Explain the role of injection pressure and velocity.

Injection pressure and velocity are key parameters affecting the filling of the mold cavity. They influence how effectively the molten polymer flows, fills the mold, and the resulting part quality.

Injection Pressure: This force pushes the polymer into the mold cavity, overcoming the resistance posed by the mold’s geometry and viscosity. Higher pressure helps ensure complete filling, especially in complex parts with thin walls. Excessive pressure can cause part defects like jetting or burn marks.

Injection Velocity: This parameter controls the speed at which the molten polymer enters the mold. Faster injection velocities can reduce cycle time but increase the risk of weld lines, air entrapment, and surface defects. Slower velocities offer better control over filling and can improve part quality.

Imagine filling a water balloon. High pressure ensures the balloon fills quickly, but too much pressure might cause it to burst. Similarly, carefully balancing injection pressure and velocity is essential in injection molding to achieve optimal results without compromising part integrity.

Q 13. What are the different types of mold materials?

Mold materials are chosen based on their thermal properties, wear resistance, and compatibility with the polymer being molded. The selection significantly impacts the mold’s lifespan, production efficiency, and the quality of the molded parts.

- Tool Steel: High-strength, heat-resistant steels are the workhorse for many injection molds. They offer excellent wear resistance and durability, suitable for high-volume production runs.

- Aluminum: Lighter and easier to machine than tool steel. Aluminum molds are preferred for prototyping or lower-volume production where wear resistance is less critical.

- BeCu (Beryllium Copper): Offers good thermal conductivity and wear resistance. Often used for molds requiring precise dimensional accuracy.

- Maraging Steel: A high-strength steel alloy with excellent dimensional stability, used for molds producing parts with demanding tolerances.

- Electroformed Nickel: Produced via an electroplating process, suitable for creating intricate mold inserts.

The choice of mold material is a critical decision, and a cost-benefit analysis considering factors like production volume, part complexity, and required surface finish is necessary.

Q 14. How do you maintain and troubleshoot injection molding equipment?

Maintaining and troubleshooting injection molding equipment is vital for uninterrupted production and consistent part quality. Regular preventative maintenance is key.

Maintenance: This includes regular inspections of the machine’s components, lubrication of moving parts, and timely replacement of worn-out components such as seals, heaters, and sensors. Cleaning the mold and the injection unit regularly is also essential to prevent contamination.

Troubleshooting: Common issues include:

- Short shots: Insufficient material filling the mold cavity. Check injection pressure, melt temperature, and mold temperature.

- Flash: Excess material escaping the mold. Check clamping force, mold alignment, and gate design.

- Warpage: Check mold temperature, cooling system, and part design.

- Burn marks: Material degradation due to excessive heat. Check melt temperature and injection speed.

Troubleshooting involves systematically analyzing the problem, examining process parameters, inspecting the mold, and applying knowledge of the material behavior. A well-maintained machine with regular checks will significantly minimize downtime and production issues.

Q 15. What are some common quality control checks performed in injection molding?

Quality control in injection molding is crucial for ensuring consistent part quality and meeting customer specifications. It’s a multi-faceted process encompassing various checks throughout the entire production cycle. We typically perform checks at several stages:

- Visual Inspection: This is the first line of defense, checking for obvious defects like flash (excess material), sink marks (indentations), short shots (incomplete filling), and warping. We use standardized checklists and often employ magnification tools for detailed examination.

- Dimensional Measurement: Using calibrated tools like calipers, micrometers, and coordinate measuring machines (CMMs), we meticulously measure critical dimensions of the molded parts against design specifications. Tolerances are rigorously checked, and any deviations are documented and analyzed.

- Weight Measurement: Consistent part weight indicates consistent material filling. Significant deviations can highlight issues with the injection process or material consistency.

- Material Properties Testing: Depending on the application, we might perform tests like tensile strength, impact resistance, or hardness to ensure the molded part meets the required performance characteristics. We often use specialized equipment for these tests, following established industry standards.

- Functional Testing: For parts with specific functions, we conduct functional tests to ensure they perform as intended. This might involve testing electrical conductivity, air tightness, or mechanical functionality.

A robust quality control system incorporates sampling plans and statistical analysis to monitor process trends and identify potential problems before they escalate.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of cycle time optimization.

Cycle time optimization aims to reduce the time it takes to complete a single injection molding cycle without compromising part quality. This is achieved through a systematic approach focusing on several key areas:

- Mold Design Improvements: Optimizing the mold design itself, for example, incorporating hot runner systems (which eliminate sprues and runners, reducing cycle time significantly), using efficient gate locations, and ensuring balanced filling to minimize cooling time.

- Process Parameter Adjustments: Fine-tuning injection pressure, melt temperature, mold temperature, and holding pressure to achieve optimal filling and cooling without sacrificing part quality. This often involves iterative adjustments and careful monitoring of the results.

- Automation: Implementing automated processes like robotic part removal, automated sprue separation, and automated material handling can dramatically reduce cycle time and labor costs. In a recent project, implementing robotic part removal cut our cycle time by 15%.

- Material Selection: Selecting materials that cool faster can also reduce cycle time. However, this needs careful consideration as it might affect the material properties and part performance.

- Preventive Maintenance: Regularly scheduled maintenance of the injection molding machine and mold minimizes downtime and ensures optimal performance, thereby contributing to reduced cycle times.

Cycle time optimization is a continuous improvement process. Regular monitoring, data analysis, and adjustments are crucial for sustaining gains.

Q 17. Describe your experience with Statistical Process Control (SPC).

I have extensive experience with Statistical Process Control (SPC), utilizing it to monitor and control the injection molding process. SPC involves using statistical methods to identify and address variations in the process. This enables proactive rather than reactive problem-solving, reducing scrap and improving quality consistency.

Specifically, I’ve used control charts (X-bar and R charts, p-charts, c-charts) to track key process parameters like part dimensions, weight, and cycle time. By plotting these data points, we can identify trends, detect shifts in the process mean, and determine whether the process is in statistical control. We use these charts not only for detecting problems but also for demonstrating process capability.

For example, in a recent project, we used X-bar and R charts to monitor the thickness of a critical part dimension. By identifying a shift in the mean thickness before it led to significant out-of-spec parts, we were able to quickly troubleshoot the issue (a slight adjustment to the mold temperature) and prevent a costly batch rejection.

Q 18. How do you interpret a process capability study?

A process capability study determines whether a process can consistently produce parts within specified tolerances. This is vital for ensuring customer requirements are met. The study uses statistical analysis to calculate process capability indices like Cp, Cpk, and Pp, PpK.

Cp (Process Capability): Measures the inherent variability of the process relative to the tolerance spread. A Cp of 1 indicates the process variability is equal to the tolerance, while a Cp greater than 1 indicates the process variability is less than the tolerance. Higher Cp values indicate better process capability.

Cpk (Process Capability Index): Considers both the process variability and the process centering (how close the process mean is to the target). Cpk is always less than or equal to Cp. A Cpk of 1 or greater generally indicates the process is capable of meeting the specifications.

Pp and Ppk: These indices are calculated using the data from the entire sample, including the short-term and long-term process variations. They give you an overall picture of the capability.

Interpreting these indices requires a thorough understanding of the process and the specifications. For example, a high Cp but a low Cpk suggests that although the process has low inherent variability, its mean is significantly offset from the target value, requiring adjustment.

Process capability studies are essential for identifying areas for improvement, justifying process changes, and providing confidence in the ability of the process to consistently meet customer requirements.

Q 19. What are some common safety concerns in injection molding?

Injection molding presents various safety concerns, demanding strict adherence to safety protocols. These include:

- High-Pressure Systems: The injection molding machines operate under very high pressure, potentially causing serious injuries if safety measures are not in place. Regular maintenance and adherence to lockout/tagout procedures are critical.

- High Temperatures: Molten plastic reaches extremely high temperatures, posing a significant burn risk. Proper safety equipment, including heat-resistant gloves and protective clothing, is essential.

- Moving Parts: The machines contain numerous moving parts, presenting a risk of crushing or entanglement injuries. Guards and interlocks are crucial safety features to prevent accidents.

- Ejection Mechanisms: The ejection system can forcefully eject the molded parts, posing a risk to nearby personnel. Safety barriers and proper training are needed.

- Material Hazards: Certain plastics release harmful fumes or dust, necessitating proper ventilation and respiratory protection. Material Safety Data Sheets (MSDS) should be consulted and followed.

- Noise Pollution: The operation of injection molding machines can produce significant noise, necessitating hearing protection.

Implementing comprehensive safety programs, providing regular safety training, and conducting regular machine inspections are essential to mitigate these risks and create a safe work environment.

Q 20. Explain your experience with different types of mold designs (e.g., hot runner, cold runner).

I have extensive experience with various mold designs, including both hot runner and cold runner systems. The choice between these systems significantly impacts the molding process and part quality.

Cold Runner Molds: These molds utilize a runner system that remains at room temperature. Molten plastic flows through the runner system to fill the cavities. After molding, the solidified runner system is separated from the parts and often recycled. Cold runner systems are generally more cost-effective for lower-volume production. They also offer more flexibility in material choices.

Hot Runner Molds: In hot runner molds, the runner system is heated to maintain the molten state of the plastic. This eliminates the waste associated with cold runner systems and significantly improves cycle times. Hot runner systems are more complex and expensive but offer advantages in higher-volume production, reducing material waste and enhancing overall efficiency. Furthermore, I’ve worked with various gate designs within both systems; the selection of gate type (e.g., submarine, edge, tab, etc.) is critical in minimizing defects.

My experience extends to designing and troubleshooting issues in both systems. I have been involved in projects where we switched from cold runner to hot runner to achieve significant cost savings and cycle time reductions in high-volume productions.

Q 21. How do you handle material degradation during the molding process?

Material degradation during molding can lead to significant quality issues, including reduced mechanical properties, discoloration, and increased defects. Addressing this requires a multi-pronged approach.

- Proper Material Handling: Storing and handling the resin correctly prevents degradation. This includes protecting materials from moisture, heat, and contamination.

- Optimal Processing Parameters: Carefully selecting and controlling processing parameters like melt temperature and residence time is crucial. Excessive heat or prolonged residence time in the barrel can lead to degradation. I regularly monitor these parameters and use data analysis to identify potential issues before they affect part quality.

- Regular Maintenance: Cleaning and maintaining the injection molding machine and the mold itself is essential to prevent contamination and build-up of degraded material. This includes regular inspection of the barrel and screw, ensuring they are free from debris and build-up.

- Material Selection: Selecting a resin with inherent stability and high resistance to degradation is essential. This often involves assessing the intended application and environmental factors. We collaborate closely with material suppliers to ensure the correct material is selected for a specific application.

- Degradation Detection: Regular monitoring of the material’s properties, including color, viscosity, and molecular weight, provides early detection of degradation. This often requires using specialized lab testing to identify potential problems.

In one instance, we observed discoloration in a high-volume production run. By meticulously investigating the processing parameters and the resin’s history, we discovered that prolonged exposure to high temperatures had caused degradation. A reduction in melt temperature and improved machine maintenance resolved the issue. This example highlights the importance of continuous monitoring and a well-structured preventative maintenance program.

Q 22. Describe your experience with mold design software.

My experience with mold design software spans over 10 years, encompassing various industry-standard platforms such as Moldflow, Autodesk Inventor, and SolidWorks. I’m proficient in using these tools to create and analyze injection molds, from initial concept design to detailed manufacturing drawings. I’m not just familiar with the user interface; I understand the underlying engineering principles, allowing me to optimize designs for manufacturability, minimize material waste, and predict potential issues before production.

For example, in a recent project involving a complex, multi-cavity mold for a medical device, I used Moldflow to simulate the filling process and identify potential weld lines and air traps. This analysis allowed us to make design modifications that improved part quality and reduced cycle time. This experience also extends to using the software to create detailed mold bases, cooling systems and runner systems, ensuring that the mold functions optimally.

Q 23. How do you minimize material waste during the injection molding process?

Minimizing material waste in injection molding is crucial for both economic and environmental reasons. Strategies I employ include optimizing the runner and gate system design. A well-designed runner system ensures consistent melt flow to each cavity, minimizing excess material in the sprue and runners. Runners can be hot runners (which melt plastic only as needed) or cold runners (where the runner material must be separated from the molded part). Hot runner systems are preferred, but sometimes cold runners are cost effective.

Another key aspect is precise control of the injection molding parameters like injection pressure, melt temperature, and holding pressure. Overfilling the mold leads to significant waste, while underfilling results in defective parts. I leverage process optimization techniques, often using statistical methods like Design of Experiments (DOE), to refine these parameters and find the ‘sweet spot’ for minimal material use while maintaining part quality. Additionally, using recycled materials and carefully considering the part design for efficient mold filling contributes to reduced waste.

Q 24. Explain your experience with different types of automation in injection molding.

My experience with automation in injection molding encompasses a wide range of technologies. I’ve worked extensively with robotic systems for part removal and placement, significantly improving cycle times and reducing labor costs. These robots typically use vision systems to ensure accurate part handling. I’m also familiar with automated material handling systems, where raw material is automatically fed into the machine, minimizing manual intervention and reducing potential errors. Furthermore, I’ve been involved in integrating automated quality control systems, which use vision systems or other sensors to inspect parts for defects in real-time, reducing waste and improving yield.

A specific example involved implementing a fully automated system for a high-volume production line. This involved integrating a robot, vision system, and a quality control station, resulting in a 20% increase in production efficiency and a 15% reduction in defects. The experience encompasses both programming and troubleshooting PLC controlled automation systems.

Q 25. What are the key factors influencing part shrinkage?

Part shrinkage in injection molding is a complex phenomenon influenced by several key factors. The most significant is the material itself – different polymers exhibit different shrinkage rates. The melt temperature during the injection process plays a crucial role; higher temperatures generally lead to increased shrinkage. Mold temperature also affects shrinkage; colder molds result in more shrinkage due to faster cooling. Injection pressure also influences the final dimensions as higher injection pressures can reduce shrinkage.

Furthermore, the part geometry itself plays a critical role; thicker sections cool more slowly, resulting in higher shrinkage than thinner sections. Finally, the mold design, particularly the cooling system, heavily influences shrinkage. A well-designed cooling system ensures consistent cooling across the part, minimizing variations in shrinkage. I always account for these factors during the design process, often using simulation software to predict shrinkage and compensate for it accordingly.

Q 26. Describe your experience with troubleshooting mold leaks.

Troubleshooting mold leaks requires a systematic approach. I typically start by visually inspecting the mold for any obvious signs of damage, such as cracks or wear. Then, I’ll carefully examine the mold’s components, including the cavity, core, and parting lines, for any misalignment or imperfections. Pressure testing can be used to pinpoint the location of the leak.

If the visual inspection and pressure testing don’t identify the source, I’ll move to more advanced techniques. Dye penetrant testing can reveal small cracks or porosity in the mold material. In some cases, I’ve used specialized leak detection equipment to pinpoint the source of the leak precisely. Once the leak is identified, the solution can involve repairing the mold, replacing damaged components, or modifying the mold design to prevent future leaks.

Q 27. How do you ensure dimensional accuracy of molded parts?

Ensuring dimensional accuracy of molded parts requires attention to detail throughout the entire process. Precise mold design is paramount; this includes accurate CAD modeling, considering material shrinkage, and optimizing the cooling system. Proper mold manufacturing and assembly are also crucial. Any deviation from the design specifications here can affect the final dimensions.

Process parameters need careful control. Consistent melt temperature, injection pressure, and holding pressure are vital for consistent part dimensions. Regular monitoring and adjustments are essential to maintain dimensional accuracy. Furthermore, implementing a robust quality control system with regular dimensional measurements ensures that parts meet specifications. Statistical Process Control (SPC) is invaluable in tracking and controlling the process, maintaining consistent production of accurate parts.

Q 28. Explain your experience with root cause analysis and corrective action in injection molding.

My approach to root cause analysis and corrective action in injection molding follows a structured methodology, often using techniques like the 5 Whys or Fishbone diagrams. The first step is to clearly define the problem, gathering data through process monitoring, part inspection, and operator feedback. Then I move to identify potential root causes.

After identifying the root causes, the next step is developing and implementing corrective actions. This might involve adjusting process parameters, modifying the mold design, improving material handling, or implementing operator training. The effectiveness of corrective actions is then carefully monitored using control charts and other statistical tools. The entire process is documented so that similar issues can be avoided in the future and knowledge is shared.

Key Topics to Learn for Polymer Injection Molding Interview

- Polymer Properties & Selection: Understanding the various types of polymers (thermoplastics, thermosets), their properties (viscosity, melt flow index, shrinkage), and how to select the appropriate polymer for a specific application. Consider the impact of additives and fillers.

- Injection Molding Process: Master the steps involved: material feeding, melting, injection, holding, cooling, and ejection. Understand the role of machine parameters (injection pressure, melt temperature, holding time) and their impact on part quality.

- Mold Design & Manufacturing: Familiarize yourself with mold components (cavity, core, runner system, gates), common mold designs (hot runner, cold runner), and manufacturing processes. Understand considerations for draft angles, parting lines, and ejector pin placement.

- Quality Control & Troubleshooting: Learn about common molding defects (short shots, flash, sink marks, weld lines) and their causes. Understand the use of statistical process control (SPC) and root cause analysis techniques for process optimization and defect reduction.

- Process Optimization & Automation: Explore strategies for optimizing cycle time, minimizing material waste, and improving part consistency. Understand the role of automation in injection molding and common automation technologies.

- Safety & Regulations: Become familiar with relevant safety protocols and industry regulations related to machinery operation, material handling, and workplace safety in an injection molding environment.

Next Steps

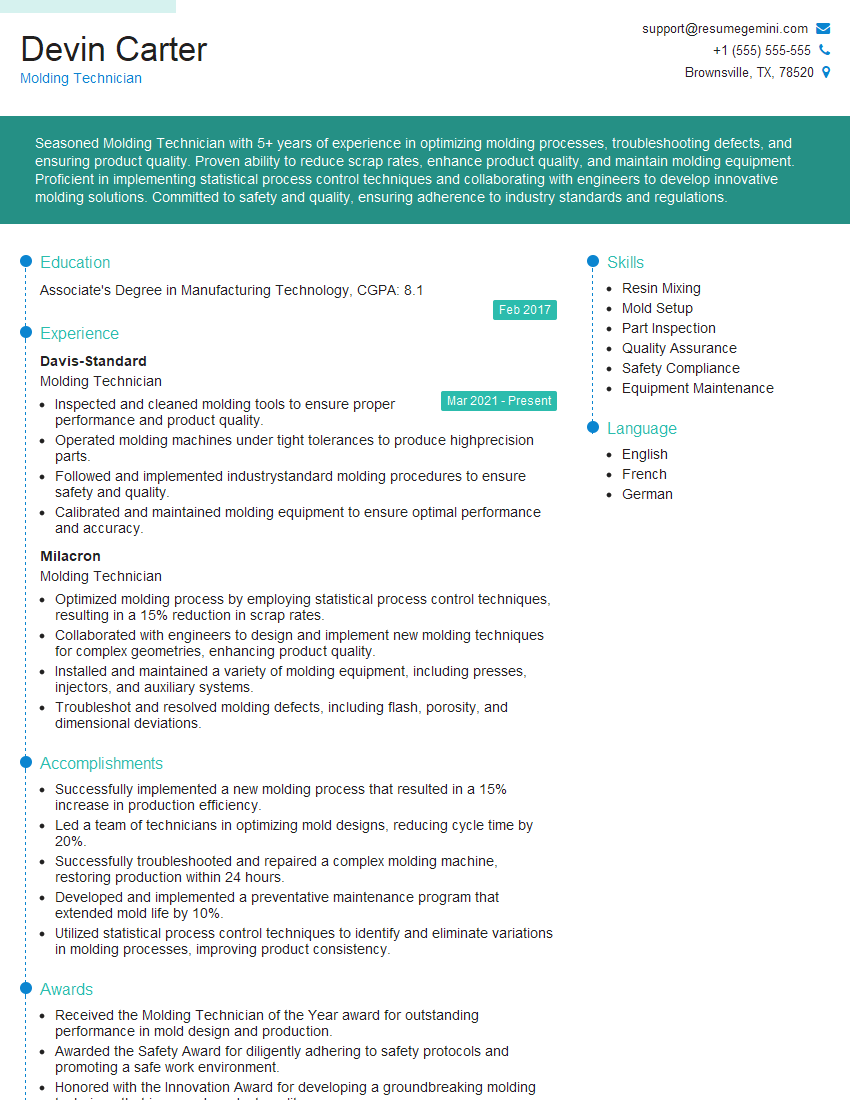

Mastering Polymer Injection Molding opens doors to rewarding careers in manufacturing, engineering, and quality control. A strong understanding of this process is highly valued across many industries. To stand out, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that gets noticed by recruiters. We provide examples of resumes tailored to Polymer Injection Molding to guide you. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.