The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Stacking and Storage interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Stacking and Storage Interview

Q 1. Explain the importance of proper stacking techniques in a warehouse environment.

Proper stacking techniques are crucial in a warehouse for maximizing space utilization, ensuring product safety, and optimizing operational efficiency. Think of it like building a skyscraper – you wouldn’t just randomly pile bricks; you’d follow architectural plans for stability and safety. Improper stacking leads to instability, potentially causing collapses, product damage, and injuries. It also impacts accessibility, making it difficult to retrieve items efficiently.

Effective stacking involves understanding the weight and dimensions of goods, distributing weight evenly, and using appropriate stacking patterns (e.g., interlocking, staggered) to prevent toppling. We also consider factors like the storage environment (temperature, humidity) and the type of packaging to prevent damage. For example, fragile items require careful handling and padding, potentially using specialized racking solutions or less-high stacks.

Q 2. Describe different types of storage systems and their suitability for various products.

Warehouses utilize various storage systems tailored to specific product characteristics and operational needs. Here are a few examples:

- Pallet Racking: The most common system, ideal for storing palletized goods. It allows for easy access to individual pallets, maximizing space utilization and facilitating efficient order picking. Suitable for a wide range of products, from packaged goods to manufactured parts.

- Shelving: Perfect for smaller items or those requiring individual access. Various types exist – heavy-duty, light-duty, cantilever shelving (for long or awkwardly-shaped goods). Suitable for retail stores, archives, or workshops.

- Bulk Storage: Suitable for large quantities of homogenous products like grains or raw materials. This could include silos, bins, or large floor-stacked piles, requiring efficient material handling equipment. Suitable for agricultural products or bulk manufacturing.

- Drive-in/Drive-through Racking: Ideal for high-volume storage of similar products. Forklifts drive into the racking structure, directly accessing the pallets. Suitable for warehouses with high turnover of specific product lines.

- Mobile Racking: Maximizes space by allowing for individual sections of racking to be moved, creating access to the required aisle. Suitable for smaller warehouses or archives where space is premium.

The choice of storage system depends on several factors including warehouse layout, product type, frequency of access, inventory turnover rate and budget.

Q 3. How do you ensure the safety and security of stored goods?

Ensuring safety and security of stored goods is paramount. This involves a multi-pronged approach:

- Physical Security: Implementing measures such as access control systems (e.g., security cameras, keycard access, alarm systems) to prevent theft or unauthorized entry.

- Environmental Control: Maintaining appropriate temperature and humidity levels for temperature-sensitive products. This may involve climate-controlled storage areas.

- Proper Stacking and Racking: Following best practices to prevent collapses and damage from improper stacking. Regular inspections of racking and storage areas are essential.

- Fire Prevention: Implementing fire suppression systems (e.g., sprinklers, fire extinguishers) and maintaining a clean warehouse environment to reduce fire hazards.

- Inventory Management: Accurate inventory tracking reduces the risk of theft, misplacement, and spoilage. Regular stocktaking also ensures products remain in good condition.

- Pest Control: Implementing measures to prevent pest infestations which can lead to product damage and contamination.

In essence, it’s about creating a secure, well-maintained, and climate-controlled environment optimized for the specific needs of the stored goods.

Q 4. What are the common causes of warehouse accidents related to stacking and storage, and how can they be prevented?

Common warehouse accidents related to stacking and storage often stem from negligence or inadequate training. These include:

- Rack collapses: Caused by overloading, improper stacking, damage to racking, or lack of regular maintenance.

- Falling objects: Items falling from shelves or stacks due to improper stacking or damage to packaging.

- Forklift accidents: Collisions between forklifts and racking or personnel, often due to speeding, inadequate training, or poor visibility.

- Injuries from manual handling: Strains, sprains, or other injuries caused by lifting or moving heavy objects improperly.

Prevention strategies include:

- Regular inspections: Inspect racking systems and stored goods for damage or hazards.

- Training: Provide comprehensive training to all personnel on safe stacking, forklift operation, and manual handling techniques.

- Clear procedures: Establish clear procedures for stacking, handling, and retrieving goods.

- Proper equipment: Use appropriate equipment for lifting and moving heavy objects.

- Adequate lighting: Improve lighting to enhance visibility.

- Regular maintenance: Conduct regular maintenance on racking systems and material handling equipment.

By implementing these preventive measures, a significant reduction in warehouse accidents can be achieved.

Q 5. Explain your experience with inventory management software and its role in optimizing stacking and storage.

My experience with inventory management software is extensive. I’ve used several systems, from simple spreadsheet-based solutions to sophisticated warehouse management systems (WMS). These systems play a critical role in optimizing stacking and storage by providing real-time visibility into inventory levels, locations, and movement.

For example, a WMS can optimize picking routes based on the location of goods, reducing travel time and improving efficiency. It can also track product expiration dates, ensuring FIFO (First-In, First-Out) inventory management for perishable goods. Advanced WMS solutions even integrate with warehouse automation systems like automated guided vehicles (AGVs) and robotic picking systems, further enhancing efficiency and accuracy.

In a previous role, we implemented a WMS that reduced picking errors by 20% and increased order fulfillment speed by 15% through optimized storage layouts and automated picking instructions. The data provided by the WMS allowed us to identify slow-moving items and reorganize our storage space, maximizing utilization and streamlining workflows. It’s transformative in terms of efficiency and cost reduction.

Q 6. How do you manage inventory levels to avoid overstocking or stockouts?

Managing inventory levels to avoid both overstocking and stockouts requires a balanced approach that considers several factors:

- Demand forecasting: Accurate forecasting based on historical data, seasonal trends, and market analysis helps predict future demand.

- Lead times: Understanding supplier lead times allows for proactive ordering to avoid stockouts.

- Safety stock: Maintaining a buffer of safety stock to account for unexpected surges in demand or delays in delivery.

- Inventory tracking: Real-time inventory tracking systems provide up-to-date information about stock levels, enabling timely replenishment.

- Regular reviews: Regularly reviewing inventory levels and adjusting ordering quantities based on actual sales data and demand forecasts.

The ABC analysis (classifying inventory items based on their value and consumption rate) can be highly beneficial. This prioritizes the management of high-value items, ensuring optimal stock levels. Using techniques like Just-in-Time (JIT) inventory management can minimize storage costs and reduce waste, but it requires precise demand forecasting and reliable supply chains.

Q 7. Describe your experience with different types of racking systems (e.g., pallet racking, cantilever racking).

My experience encompasses various racking systems, each with its strengths and weaknesses:

- Pallet Racking: I’ve extensively used this system for its versatility and adaptability. It’s ideal for handling a wide variety of pallet sizes and weights. I’ve worked with both selective pallet racking (allowing individual pallet access) and drive-in/drive-through racking (optimized for high-volume, similar products).

- Cantilever Racking: This is excellent for storing long or bulky items like lumber, pipes, or metal sheets that can’t be easily palletized. I’ve been involved in projects where this system significantly improved space utilization and accessibility for long materials.

- Push-Back Racking: I’ve utilized this system in warehouses with high-volume storage needs for a limited number of SKUs. Its efficient use of depth increases storage capacity but requires careful product selection.

- Double-Deep Racking: This offers increased density compared to selective racking. However, it compromises accessibility and requires a more sophisticated materials handling strategy. I’ve utilized this when maximizing storage in a limited footprint was paramount.

The choice of racking system depends on factors such as warehouse layout, product dimensions and weight, storage density requirements, and operational efficiency goals. A thorough assessment of these aspects is crucial before selecting a suitable system.

Q 8. How do you optimize warehouse space utilization for efficient stacking and storage?

Optimizing warehouse space is crucial for efficiency and profitability. It’s like a well-organized Tetris game – maximizing every cubic foot. My approach involves a multi-pronged strategy:

Strategic Slotting: I analyze product velocity (how quickly items move) and dimensions. Fast-moving items get prime, easily accessible locations. For example, best-selling products are placed at eye level and in areas with easy access to loading docks. Less frequently accessed items are stored further back or higher up.

Vertical Space Utilization: Utilizing vertical space is key! We employ high-bay racking systems, mezzanines, and multi-tiered shelving to maximize storage capacity. Think of it like building a vertical city within the warehouse.

Efficient Aisle Planning: Wide enough aisles allow for easy forklift maneuverability, preventing damage and delays. Narrow aisles, however, can significantly increase storage space if handled by appropriate equipment like narrow aisle forklifts. It’s about finding the right balance.

Regular Audits and Adjustments: I conduct regular audits to monitor space utilization. Based on sales data and inventory trends, we adjust the layout, potentially relocating slower-moving items to make space for faster-moving ones. This prevents dead space and increases efficiency.

For instance, in a previous role, we implemented a new slotting strategy based on ABC analysis (classifying items by their value and movement). This resulted in a 15% increase in picking efficiency.

Q 9. What are your strategies for handling oversized or unusually shaped items in a warehouse?

Handling oversized or unusually shaped items requires careful planning and specialized equipment. It’s like solving a 3D jigsaw puzzle!

Designated Storage Areas: We allocate specific areas for these items, often with wider aisles and higher ceilings. This prevents damage to other goods and simplifies retrieval.

Specialized Racking: Custom racking systems are often necessary, such as cantilever racking for long items or specialized shelving for irregularly shaped goods.

Equipment Selection: Appropriate material handling equipment is crucial. This could involve using specialized forklifts, reach trucks, or even overhead cranes, depending on the size and weight of the items.

Protective Packaging: Proper packaging is crucial to prevent damage during transport and storage. This may include custom-designed crates, protective wrapping, and bracing.

In one project, we dealt with a client who manufactured large, oddly shaped industrial components. By implementing a dedicated area with cantilever racking and specialized forklifts, we improved storage efficiency by 30% and reduced damage rates by 10%.

Q 10. How do you prioritize tasks to ensure efficient order fulfillment and product retrieval?

Prioritizing tasks for efficient order fulfillment requires a systematic approach. It’s like running a well-oiled machine.

Order Sequencing: Employing WMS features like order sequencing algorithms – such as prioritizing orders based on due date, customer importance, or product location – helps optimize picking routes and minimizes travel time.

Batch Picking: Group similar orders together to reduce travel time. For example, if multiple orders require the same product, pick all quantities at once.

Zone Picking: Assign different pickers to specific zones within the warehouse to improve efficiency. Each picker focuses on a smaller area, reducing travel time.

Wave Picking: Release orders in waves, grouping orders with similar characteristics to optimize workflow.

I once implemented a wave picking system in a busy e-commerce warehouse which resulted in a 20% increase in order fulfillment speed and a 15% reduction in picking errors.

Q 11. Explain your experience with FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) inventory methods.

FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) are inventory management methods with different applications.

FIFO: Items are used in the order they arrive. Think of a queue. This is ideal for perishable goods (food, pharmaceuticals) to minimize waste due to spoilage. It also helps with managing inventory turnover and preventing obsolete stock.

LIFO: The last items received are used first. This method can be advantageous for non-perishable goods where prices fluctuate frequently. The cost of goods sold reflects current market prices, potentially minimizing tax liability. However, this can make managing inventory turnover more challenging.

In my experience, I’ve used FIFO extensively for food and beverage clients to ensure freshness and minimize loss. For non-perishable items with fluctuating prices, a LIFO approach – or variations of it – could be more suitable.

Q 12. How do you handle damaged or expired goods in a warehouse?

Handling damaged or expired goods requires a clear process to ensure compliance and minimize losses. It’s about damage control and responsible disposal.

Clear Identification and Segregation: Damaged or expired items are clearly marked and separated from sellable inventory to prevent accidental shipment.

Documentation: We maintain detailed records of damaged or expired goods, including the cause of damage, quantity, and disposal method.

Disposal Methods: Disposal methods are chosen depending on the type of goods and local regulations. Options include destruction, donation to charity (if appropriate), or recycling.

Root Cause Analysis: We investigate the cause of damage or expiry to prevent recurrence. This might involve improvements in handling, storage conditions, or inventory management.

In one instance, we identified a recurring issue with damaged packaging due to improper stacking. By implementing new stacking procedures and training staff, we drastically reduced damage rates.

Q 13. Describe your experience with warehouse management systems (WMS).

Warehouse Management Systems (WMS) are the backbone of efficient warehouse operations. They’re like the brain of the warehouse, coordinating all activities.

Inventory Tracking: WMS provides real-time visibility of inventory levels, location, and movement.

Order Management: It facilitates order processing, picking, packing, and shipping. Optimizes order fulfillment by routing pickers efficiently.

Reporting and Analytics: It generates reports on key performance indicators (KPIs) like picking accuracy, order fulfillment times, and storage capacity utilization. This data allows for continuous improvement.

Integration with Other Systems: It integrates seamlessly with other enterprise systems, such as ERP (Enterprise Resource Planning) and transportation management systems (TMS).

I’ve extensive experience implementing and customizing WMS solutions for various clients. In one project, we implemented a new WMS which improved order accuracy by 10%, reduced picking time by 15%, and lowered storage costs by 5%.

Q 14. How do you ensure the accuracy of inventory counts?

Ensuring inventory accuracy is paramount; it’s the foundation of accurate financial reporting and efficient order fulfillment. It’s like a well-calibrated scale.

Cycle Counting: Instead of a full inventory count, we perform cycle counting – regularly checking smaller portions of the inventory. This method is less disruptive to operations and helps identify discrepancies early on.

Barcode and RFID Technology: Utilizing barcode and RFID technology for tracking items ensures accurate real-time data capture. This minimizes manual errors during receiving, put-away, and picking.

Regular Audits and Reconciliation: We conduct regular audits to compare physical inventory counts with system records. Discrepancies are investigated and corrected.

WMS-Based Inventory Management: The WMS system itself plays a vital role. Its accuracy depends on proper data entry and maintenance. Regular system checks and updates are essential.

In a past role, we implemented a cycle counting program that significantly reduced inventory discrepancies, leading to improved financial reporting and reduced stockouts.

Q 15. What are your methods for tracking and managing inventory movements?

Inventory tracking and management is the backbone of efficient warehouse operations. My approach combines manual and automated systems for optimal results. I typically utilize a Warehouse Management System (WMS), which is software that helps manage and optimize the day-to-day operations of a warehouse. This system allows for real-time tracking of inventory movements. For example, every time a product is received, put away, picked, or shipped, the WMS updates the inventory count, location, and status. Alongside the WMS, we employ barcode or RFID scanning at each stage of the process. This creates an audit trail, enabling us to trace the movement of every item from its arrival to its departure. We also regularly conduct physical inventory counts to reconcile the system records with physical stock, identifying and resolving any discrepancies promptly. Finally, thorough documentation is key. This includes packing slips, receiving reports, and transfer orders, all meticulously maintained and readily accessible.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle discrepancies in inventory records?

Inventory discrepancies are inevitable, but their swift resolution is crucial. My approach follows a structured methodology. First, we identify the discrepancy—is it a shortage, surplus, or a mismatch in location? Then, we investigate the potential causes. Common causes include data entry errors, scanning errors, pilferage, or damage. We meticulously review the system logs for any anomalies, checking for discrepancies between receipts, shipments, and internal transfers. Physical verification of the stock location is crucial. We would conduct a thorough recount of the affected items. Depending on the nature and scale of the discrepancy, we may involve a team to expedite the process. If the problem persists, we’ll evaluate our processes and technology, potentially implementing improvements like better training, enhanced quality control measures, or improved inventory management software. Documentation of the entire investigation and corrective actions is critical for future reference and preventing similar issues.

Q 17. Explain your experience with barcode scanning and other inventory tracking technologies.

Barcode and RFID technologies are integral to modern inventory management. I have extensive experience with both. Barcode scanning provides quick and accurate data capture during receiving, putaway, picking, and shipping. For instance, in a previous role, we used barcode scanners integrated with our WMS, significantly reducing errors and speeding up the entire process. RFID (Radio-Frequency Identification) offers superior capabilities for large-scale tracking and management. RFID tags can be read without line-of-sight, allowing for faster inventory counts and tracking of goods even when palletized or in transit. While RFID offers greater accuracy and efficiency for high-volume environments, barcode systems are often more cost-effective for smaller operations. My experience includes implementing and managing both technologies effectively, tailoring the solution to the specific needs and scale of the operation.

Q 18. Describe your experience working with different types of material handling equipment.

My experience with material handling equipment is broad, encompassing forklifts (both sit-down and stand-up), reach trucks, order pickers, conveyor systems, and automated guided vehicles (AGVs). I’m proficient in the safe and efficient operation of these machines and understand their limitations. For example, I’ve optimized warehouse layout to maximize the utilization of reach trucks, improving throughput considerably. I’m also familiar with the necessary maintenance and safety protocols associated with these machines. In one instance, I successfully implemented a new conveyor system which reduced order processing time by 15%. Understanding the capabilities of each piece of equipment is vital in choosing the best solution for specific tasks and optimizing warehouse workflow. Safety training and adherence to strict operational procedures are paramount to preventing accidents.

Q 19. How do you ensure the proper labeling and identification of stored goods?

Proper labeling and identification are essential to avoid confusion and ensure efficient order fulfillment. Our labeling system includes clear and consistent information such as product name, SKU (Stock Keeping Unit), quantity, lot number, and any special handling instructions. We utilize barcode labels that are generated automatically by our WMS to ensure accuracy and eliminate manual data entry errors. These labels are affixed securely to the goods and their packaging. In addition to product labels, we clearly label storage locations to facilitate quick and accurate retrieval. This might involve using color-coded shelves or alphanumeric location codes that are consistently applied and easily understood by all warehouse personnel. For hazardous materials, we follow strict regulatory guidelines ensuring appropriate hazard warnings and safety information are clearly visible.

Q 20. How do you maintain cleanliness and organization in the warehouse?

Maintaining a clean and organized warehouse is crucial for safety, efficiency, and productivity. We establish and enforce a regular cleaning schedule, assigning specific cleaning tasks to personnel. This includes sweeping, mopping, and cleaning up spills immediately. We also have a designated area for waste disposal and recycling. Organized storage is paramount; we use a systematic approach to storing goods, ensuring clear aisleways for safe passage of equipment and personnel. We utilize various storage solutions, including racking systems, shelving units, and pallet racking, to maximize space utilization and streamline retrieval processes. Regular inspections help identify potential hazards, such as damaged racking or blocked aisles, which are addressed promptly. 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) is often employed to maintain a consistently clean and organized environment.

Q 21. What is your experience with warehouse layout and design?

Warehouse layout and design significantly impact efficiency. My experience includes designing and optimizing warehouse layouts to accommodate specific workflow requirements and equipment capabilities. Consideration of factors such as product flow, storage capacity, equipment accessibility, and safety are vital. For example, I’ve designed layouts that optimize the flow of goods, reducing the travel distance for forklifts and increasing overall efficiency. I’ve also utilized slotting optimization techniques to assign optimal storage locations for frequently accessed items. The use of simulation software can be invaluable in designing and testing different layouts before implementation, minimizing disruptions and ensuring the best possible configuration. Ultimately, the goal is a design that optimizes space utilization, improves workflow, and enhances safety.

Q 22. How do you comply with safety regulations related to stacking and storage?

Safety is paramount in stacking and storage. Compliance begins with a thorough understanding of all relevant Occupational Safety and Health Administration (OSHA) regulations and any industry-specific standards. This includes regulations on load capacity, stacking heights, aisle widths, and the proper use of material handling equipment.

- Regular Inspections: I always initiate and oversee regular inspections of the warehouse to identify any potential hazards, such as damaged racking, unstable stacks, or blocked exits. This involves using checklists and documented findings to track progress and ensure corrective actions are taken.

- Training and Education: A comprehensive training program for all warehouse staff is crucial. This program covers safe stacking procedures, proper use of equipment (forklifts, pallet jacks, etc.), hazard recognition, and emergency response protocols. I utilize hands-on training and regularly scheduled refresher courses to reinforce safety practices.

- Personal Protective Equipment (PPE): Ensuring all personnel use appropriate PPE, including safety shoes, gloves, and high-visibility vests, is non-negotiable. Regular checks are conducted to make sure PPE is in good condition and worn correctly.

- Proper Documentation: Maintaining meticulous records of inspections, training, and incidents is vital for demonstrating compliance. This documentation also helps identify trends and areas needing improvement.

For example, in my previous role, we implemented a color-coded system for identifying damaged racking, making it immediately apparent to staff and prompting immediate action. This proactive approach significantly reduced the risk of accidents.

Q 23. Explain your experience with managing warehouse staff and maintaining productivity.

Managing warehouse staff effectively involves a blend of leadership, organization, and communication. My approach focuses on building a positive and productive team environment.

- Clear Expectations and Goals: I start by establishing clear performance expectations and goals, ensuring everyone understands their roles and contributions to the overall warehouse operation. Regular performance reviews and feedback sessions are key to keeping everyone aligned.

- Teamwork and Motivation: I foster a collaborative team spirit by encouraging open communication, mutual respect, and shared responsibility. Recognizing and rewarding employee achievements, both individually and as a team, significantly boosts morale and productivity.

- Efficient Workflow and Scheduling: I optimize workflow processes to ensure tasks are assigned effectively, minimizing downtime and maximizing efficiency. This includes utilizing data analysis to identify bottlenecks and inefficiencies.

- Training and Development: Investing in the professional development of my team members through on-the-job training, cross-training, and external courses is critical. This not only enhances individual skills but also improves team versatility and resilience.

In a previous warehouse, I implemented a system of daily huddles to address immediate concerns, share information, and recognize outstanding performance. This simple change significantly improved communication and team cohesion, leading to a noticeable increase in productivity.

Q 24. How do you address challenges related to seasonal fluctuations in inventory?

Seasonal fluctuations in inventory are a common challenge. Effective management requires a proactive and adaptable approach.

- Demand Forecasting: Accurate demand forecasting is crucial for anticipating seasonal peaks and troughs. This involves analyzing historical sales data, market trends, and economic indicators to create a reliable forecast. I use various forecasting techniques, including moving averages and exponential smoothing, to refine predictions.

- Flexible Storage Solutions: Having flexible storage options, such as adjustable shelving and expandable racking systems, allows for efficient adaptation to changing inventory levels. This minimizes wasted space during slow seasons and provides sufficient capacity during peak periods.

- Inventory Control: Robust inventory control measures, such as the use of a Warehouse Management System (WMS), are essential for tracking inventory levels and minimizing stockouts or overstocking. Real-time inventory visibility aids in making informed decisions about storage and replenishment.

- Strategic Planning: Developing a comprehensive seasonal inventory plan allows for the proactive management of resources, including personnel and equipment. This might involve temporary staffing adjustments during peak seasons or pre-positioning inventory to strategic locations.

For example, during the holiday season, I might employ a combination of temporary staff, overtime, and optimized picking and packing strategies to handle the increased workload while maintaining efficient order fulfillment.

Q 25. How do you implement and maintain a system for receiving, storing, and distributing goods efficiently?

An efficient system for receiving, storing, and distributing goods is fundamental to warehouse operations. It typically involves several key components:

- Receiving: A clearly defined receiving process, including inspection, verification against purchase orders, and proper documentation, is crucial. This minimizes errors and ensures accurate inventory tracking from the start.

- Put-away: Efficient put-away procedures, often guided by a WMS, ensure goods are placed in designated storage locations, optimizing space utilization and facilitating easy retrieval. This might involve zone picking or other strategies to enhance picking efficiency.

- Storage: Optimal storage strategies involve considering factors like product characteristics (size, weight, fragility), turnover rate, and accessibility. Proper labeling and organization are critical for easy identification and retrieval.

- Distribution: Streamlined order picking, packing, and shipping processes are crucial for timely and accurate order fulfillment. This might include the use of barcode scanners, conveyor systems, and automated guided vehicles (AGVs) for enhanced efficiency.

Imagine a system where each incoming pallet is scanned upon arrival, its location in the warehouse is determined by the WMS, and the information is instantly updated in the inventory system. This automated process eliminates manual errors and speeds up the entire receiving and storage process.

Q 26. Describe your experience with implementing and using a WMS (Warehouse Management System).

I have extensive experience implementing and utilizing Warehouse Management Systems (WMS). My experience encompasses the entire lifecycle, from selection and implementation to ongoing maintenance and optimization.

- System Selection: Choosing the right WMS involves careful consideration of the warehouse’s specific needs and operational requirements. This includes evaluating various vendors and selecting a system that integrates seamlessly with existing ERP and other business systems.

- Implementation: Successful WMS implementation requires careful planning, user training, and data migration. This includes defining key performance indicators (KPIs) to track the effectiveness of the system.

- Data Management: Maintaining accurate and up-to-date data within the WMS is crucial. Regular data validation and reconciliation are essential for ensuring the reliability of the system’s outputs.

- Optimization: Continuously monitoring and optimizing the WMS configuration is essential to adapt to changing operational needs and maximize its efficiency. This might involve refining workflows, adjusting parameters, and exploring advanced features.

In one project, I spearheaded the implementation of a new WMS, resulting in a 20% reduction in order fulfillment times and a 15% improvement in inventory accuracy. This was achieved through careful planning, effective training, and ongoing optimization of the system’s parameters.

Q 27. What are your strategies for optimizing the flow of goods within the warehouse?

Optimizing the flow of goods within a warehouse relies on a holistic approach that considers several key factors:

- Layout Design: A well-designed warehouse layout is fundamental. This involves strategically positioning receiving and shipping docks, storage areas, and picking zones to minimize travel distances and maximize efficiency. The use of slotting optimization software can significantly improve layout efficiency.

- Material Handling Equipment: Utilizing appropriate material handling equipment, such as forklifts, conveyors, and automated guided vehicles (AGVs), can dramatically improve the movement of goods. Choosing the right equipment depends on factors like volume, product characteristics, and warehouse layout.

- Workflow Processes: Streamlining workflow processes, such as order picking, packing, and shipping, is crucial. This might involve implementing lean methodologies, such as 5S, to eliminate waste and improve efficiency. Techniques like cross-docking can significantly speed up the flow of goods.

- Technology Integration: Integrating technology, such as WMS, barcode scanners, and RFID, enhances visibility and control over the movement of goods. Real-time tracking and data analysis allow for proactive identification and resolution of bottlenecks.

For example, by implementing a zone picking strategy and utilizing barcode scanners, we were able to reduce the time spent picking orders by 30% in a previous warehouse. This significantly improved order fulfillment speed and customer satisfaction.

Q 28. Describe your experience with dealing with potential warehouse space constraints.

Dealing with warehouse space constraints requires a multi-pronged approach focused on maximizing existing space and optimizing operational efficiency.

- Space Optimization: Careful analysis of current space utilization is the first step. This includes identifying areas with unused or underutilized space. Strategies like vertical storage, high-density racking, and improved slotting can significantly increase storage capacity.

- Inventory Management: Effective inventory management is essential for preventing overstocking and ensuring only necessary inventory is stored. Regular inventory audits and the use of inventory management software helps optimize space utilization.

- Process Improvement: Analyzing and improving warehouse processes can reduce the space needed for operations. This includes streamlining workflows, improving material handling efficiency, and optimizing picking and packing processes.

- Outsourcing: In some cases, outsourcing certain functions, such as storage or distribution, can be a cost-effective solution for addressing space constraints. This frees up valuable space in the main warehouse for core operations.

In one situation, we addressed significant space limitations by implementing a high-density racking system and a more efficient slotting strategy, which increased storage capacity by 25% without expanding the warehouse footprint.

Key Topics to Learn for Stacking and Storage Interview

- Warehouse Layout and Design: Understanding optimal space utilization, aisle configurations, and flow optimization for efficient stacking and retrieval.

- Inventory Management Techniques: Applying FIFO, LIFO, and FEFO methods; understanding the impact of different techniques on storage efficiency and product lifespan.

- Storage Equipment and Technology: Familiarity with various racking systems (pallet racking, cantilever racking, etc.), automated storage and retrieval systems (AS/RS), and warehouse management systems (WMS).

- Safety Regulations and Procedures: Knowledge of OSHA or relevant safety regulations concerning stacking heights, load stability, and safe operating procedures for equipment.

- Material Handling Principles: Understanding the principles of load balancing, weight distribution, and proper handling techniques to prevent damage and ensure safety.

- Space Optimization Strategies: Developing strategies to maximize storage capacity, minimize wasted space, and improve overall warehouse efficiency. This includes considering product dimensions and weight.

- Order Fulfillment Processes: How stacking and storage directly impact order picking, packing, and shipping processes. Understanding the relationship between storage location and order fulfillment speed.

- Problem-Solving and Troubleshooting: Applying analytical skills to identify and solve issues related to inefficient stacking, damaged goods, or equipment malfunctions.

- Cost Optimization in Storage: Analyzing storage costs, identifying areas for improvement, and proposing solutions for reducing expenses while maintaining efficiency.

Next Steps

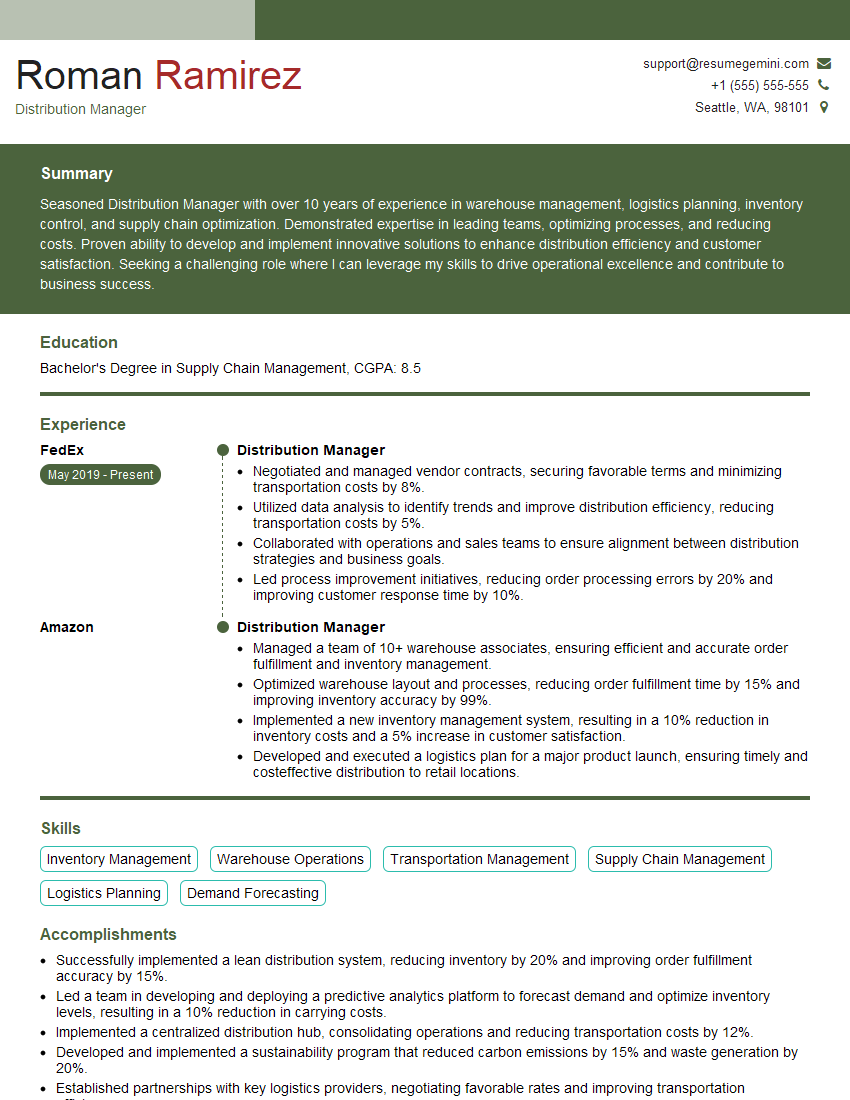

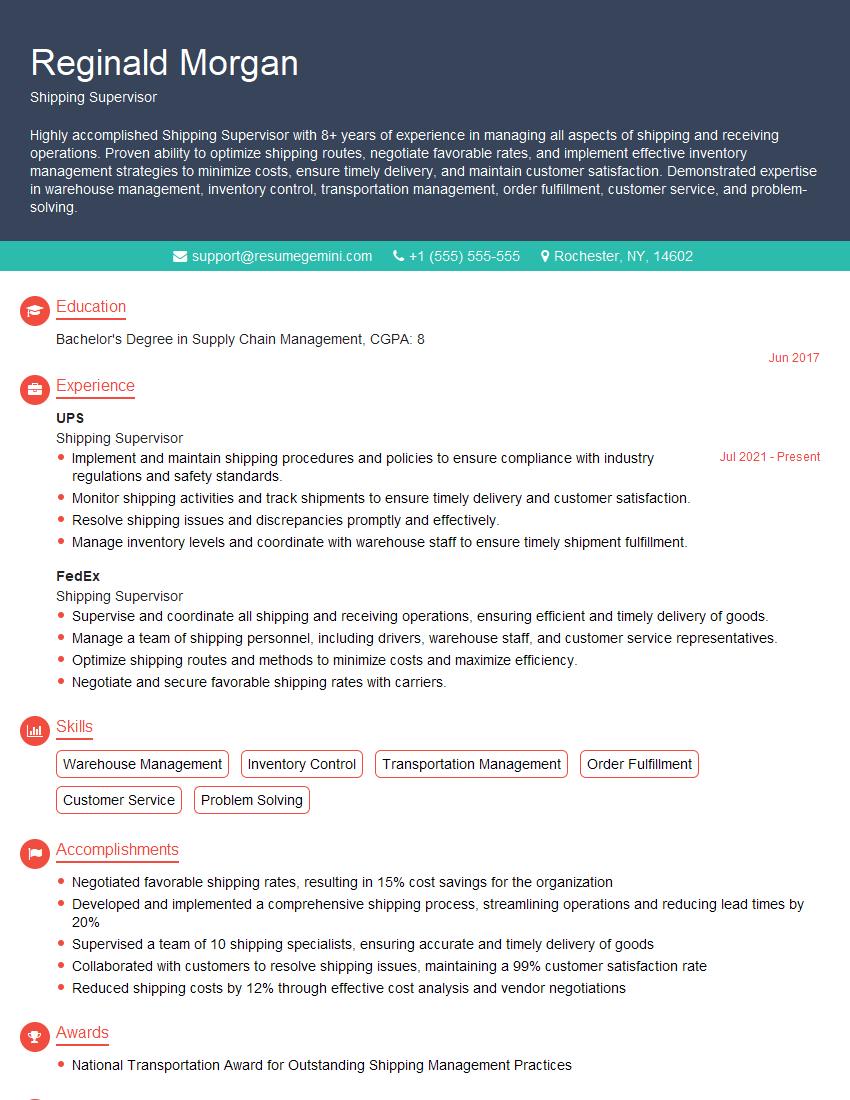

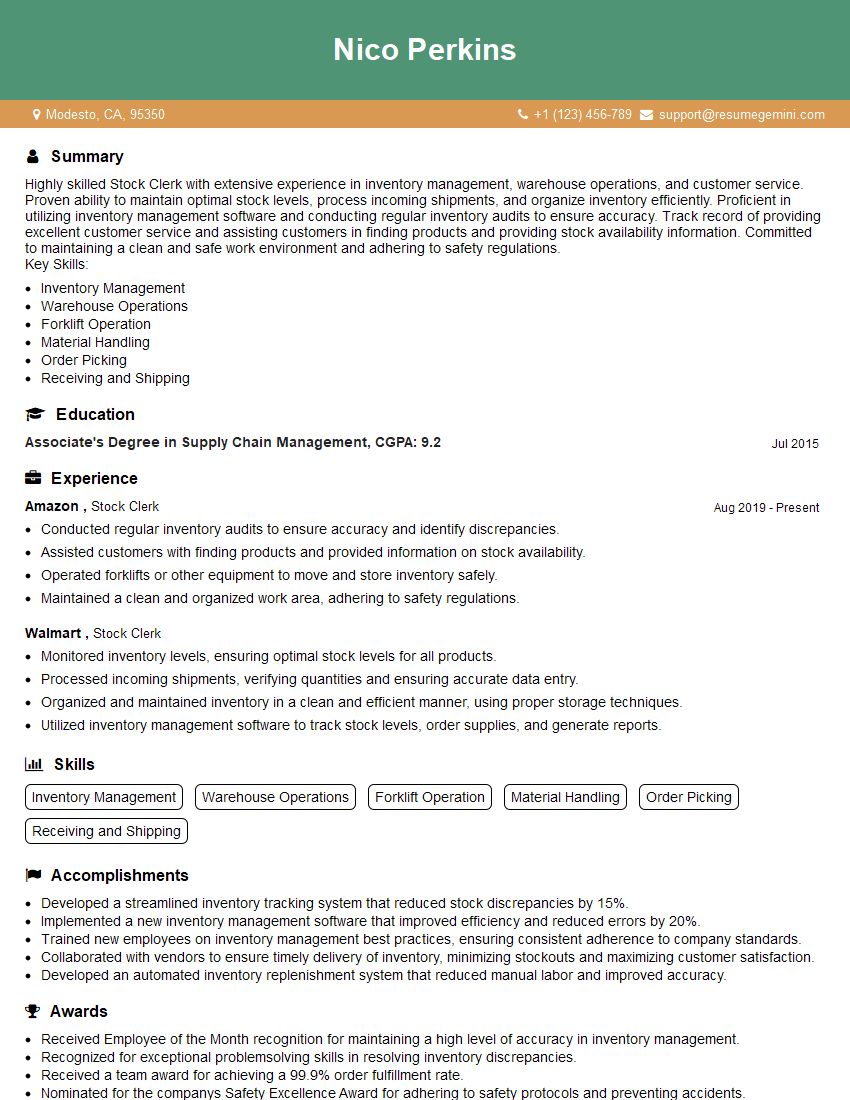

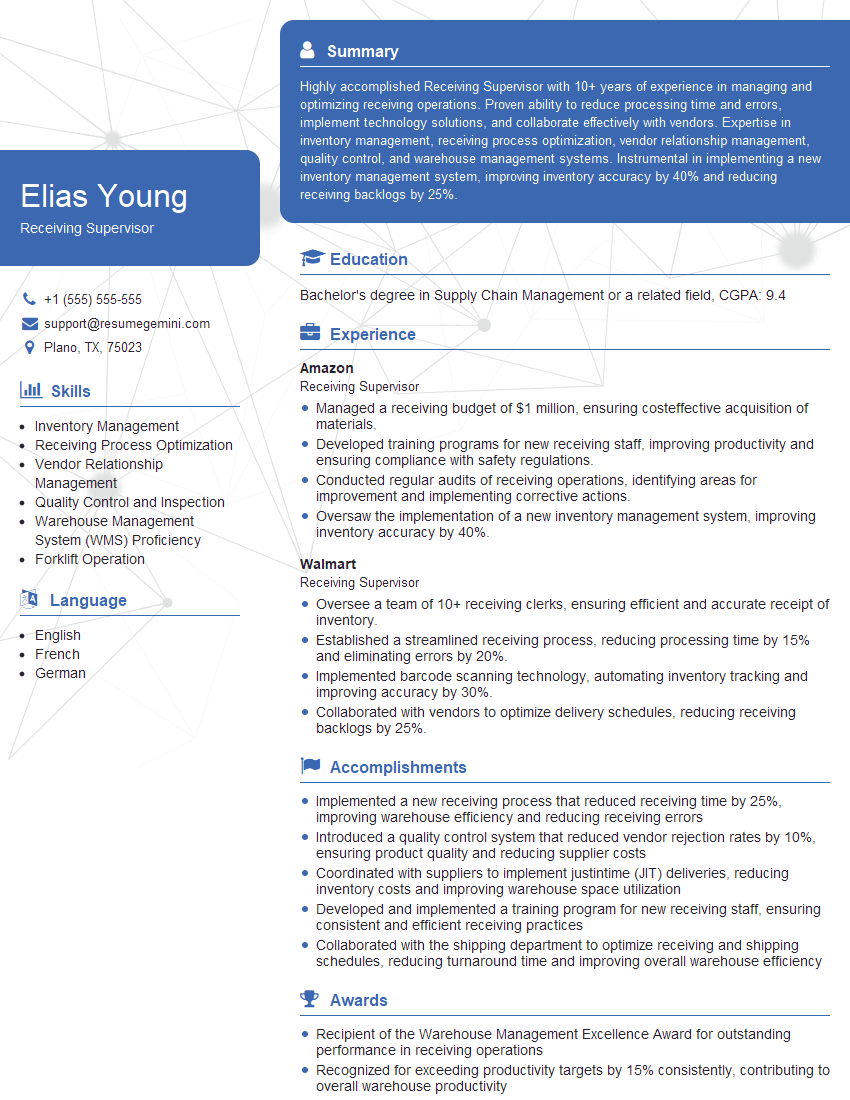

Mastering stacking and storage techniques is crucial for career advancement in logistics, warehousing, and supply chain management. A strong understanding of these principles opens doors to higher-paying roles and greater responsibility. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional, impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Stacking and Storage roles are available through ResumeGemini, providing you with valuable templates and guidance to showcase your qualifications.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.