Unlock your full potential by mastering the most common Jointer Setup interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Jointer Setup Interview

Q 1. Explain the process of setting up a jointer for a specific thickness.

Setting a jointer for a specific thickness involves adjusting the depth of cut to match your desired final board thickness. Imagine you’re shaving a piece of wood; the depth of cut is how much material you remove with each pass. It’s crucial to remember that you should only remove a small amount of material per pass to avoid tear-out or damaging the cutterhead.

- Start with a test piece: Before working on your final piece, practice on scrap wood of similar type and moisture content.

- Adjust the fence: Position the fence parallel to the cutterhead using a square and a measuring tape. This is essential for ensuring a consistent thickness along the entire length of the board.

- Set the depth of cut: Most jointers have a hand wheel or dial that controls the depth. Carefully adjust this to remove a small amount of material (1/32” to 1/16” is usually a good starting point). Start small; you can always make multiple passes.

- Make a test cut: Run the test piece across the cutterhead, carefully feeding it against the direction of the cutterhead rotation. Check the thickness using calipers or a measuring gauge.

- Adjust and repeat: If the thickness isn’t correct, adjust the depth of cut accordingly and repeat the process until you achieve your desired thickness.

Q 2. Describe how to adjust the jointer knives for optimal performance.

Adjusting jointer knives requires precision and care. Knives that are not properly aligned will result in uneven surfaces, tear-out, and potentially dangerous situations. The goal is to have all knives perfectly coplanar (sitting in the same plane) and sharp.

- Sharpening: Start with ensuring your knives are incredibly sharp. Dull knives require more force, are prone to tear-out, and can be dangerous. Professional sharpening is recommended, especially for beginners.

- Height Adjustment: Once sharpened, adjust the knives to the same height using a precision height gauge or dial indicator. This is commonly done by adjusting individual screws or bolts.

- Alignment: Check the lateral (side-to-side) alignment. Look across the top of all knives; they should form a perfectly straight line. Minor adjustments can often be made using shims or adjustments built into the knife mechanism.

- Test Cuts: Make several test cuts on scrap wood. Observe the cut surface for any inconsistencies. If you see tear-out, it may be a problem with your knife height or alignment, or sharpness.

Remember, always consult your jointer’s manual for specific instructions on knife adjustments.

Q 3. How do you check the alignment of jointer knives?

Checking jointer knife alignment involves visually inspecting the knives and using precision measuring tools. A slightly misaligned knife can significantly impact the quality of your work.

- Visual Inspection: Begin by carefully observing the knives from the side and the top. Look for any inconsistencies in the height or lateral alignment of the knives. Any visible discrepancies need to be addressed.

- Using a Straight Edge: Lay a precision straight edge across the knives. Use a feeler gauge to check for gaps between the straight edge and each knife. Even a slight gap indicates a problem.

- Dial Indicator: For more precise measurements, a dial indicator can be used to measure the height of each knife relative to a reference point. This method offers the highest level of accuracy.

- Test Cuts: As always, test cuts on scrap material are essential for verifying proper alignment. Uneven cuts, tear-out, or chatter are indicative of misalignment.

Q 4. What safety precautions are crucial when operating a jointer?

Safety is paramount when operating a jointer. Jointers are powerful machines capable of inflicting serious injury if not treated with respect. Here are crucial safety precautions:

- Use push sticks and featherboards: Never use your hands to feed wood near the cutterhead. Push sticks and featherboards help maintain control and keep your hands safely away from danger.

- Properly sized stock: Only feed stock that is long enough to safely support itself throughout the cut. Short pieces can easily kick back.

- Sharp knives: Dull knives require more force, increasing the risk of kickback and accidents. Keep your knives sharp.

- Eye and ear protection: Always wear eye protection and hearing protection. Wood chips and sawdust can cause serious eye injuries, and the noise from the jointer can damage hearing.

- Appropriate clothing: Wear close-fitting clothing and avoid loose clothing or jewelry that could get caught in the machine.

- Clear work area: Keep the work area clear of debris and distractions. A cluttered area can increase the risk of accidents.

- Never reach over running blade: Always turn the machine off before you make any adjustments or cleaning.

Q 5. How do you identify and address common jointer problems, such as sniping?

Identifying and addressing common jointer problems, like sniping, requires understanding the root causes. Sniping is where the cutterhead ‘grabs’ at the beginning of the cut, resulting in a ragged edge.

- Sniping: Often caused by dull knives, improper alignment, or feeding the wood too quickly. Sharpen your knives, check for alignment, and slow your feed rate. A slight chamfer on the leading edge of the board can also help.

- Chatter: Uneven cuts caused by dull knives, improper alignment, or unbalanced cutterheads. Sharpen your knives, check alignment, and check the cutterhead for balance issues.

- Tear-out: Ragged edges on the bottom of the board. Often due to dull knives, improper feed rate, or the wrong type of feed direction. Sharpen your knives, reduce feed rate, and check feed direction.

- Uneven thickness: Inconsistent thickness along the board’s length. Check fence alignment, cutterhead alignment, and the squareness of the stock.

Troubleshooting often involves a process of elimination. Start with the simplest solutions (sharpening knives, checking alignment), and work your way to more complex adjustments.

Q 6. Explain the importance of maintaining proper jointer blade sharpness.

Maintaining proper jointer blade sharpness is absolutely critical for safety, efficiency, and the quality of your work. Dull blades are dangerous, increasing the likelihood of kickback and accidents. They also produce poor quality surfaces with tear-out and chatter.

- Safety: Dull blades require more force, making them more prone to kickback.

- Surface Quality: Sharp blades produce a smooth, clean surface. Dull blades produce rough, torn surfaces.

- Efficiency: Sharp blades cut more easily and cleanly, requiring less force and reducing fatigue.

- Frequency: How often you need to sharpen depends on usage and material but regular checks are essential. Signs of dullness include tear-out, chatter, and the need to force the wood through the machine.

Regular sharpening, even preventative sharpening before noticeable dullness, is a significant investment in safety and good quality woodworking.

Q 7. How do you adjust the depth of cut on a jointer?

Adjusting the depth of cut on a jointer is usually done via a hand wheel or dial located on the jointer’s housing. This controls how much material is removed during each pass. Remember that small adjustments are safer and more effective.

- Locate the depth adjustment: Find the hand wheel or dial typically marked with depth of cut indicators (often in fractions of an inch or millimeters).

- Make small adjustments: Turn the wheel or dial to increase or decrease the depth. Small adjustments are recommended (1/32” to 1/16” per pass) to avoid tear-out or damage.

- Test Cut: Always make a test cut on scrap wood before proceeding with your workpiece.

- Repeat if necessary: Make multiple passes if needed, always adjusting for your desired final thickness.

Never force the wood through the machine. If the machine binds or feels overly difficult, stop and check your setup before proceeding.

Q 8. Describe the different types of jointer knives and their applications.

Jointer knives are the heart of a jointer’s ability to create perfectly flat and smooth surfaces. There are primarily two types: high-speed steel (HSS) and carbide-tipped knives.

- High-Speed Steel (HSS) Knives: These are the more traditional type, offering a good balance of sharpness and durability. They require regular sharpening, typically after a few hours of use, depending on the wood’s hardness. Think of them as the workhorses; dependable, but needing occasional maintenance. They are also generally less expensive than carbide-tipped knives.

- Carbide-Tipped Knives: These knives boast significantly longer life spans between sharpenings. The carbide tips are incredibly hard and resistant to wear, making them ideal for heavy-duty use and working with harder woods. They are, however, more expensive initially. Imagine them as the marathon runners—they may have a higher upfront cost, but they last considerably longer.

The choice between HSS and carbide depends on your budget, the frequency of use, and the types of wood you typically work with. For a hobbyist, HSS might suffice. For a professional shop working with various woods daily, carbide-tipped knives are often the preferred option due to their longevity.

Q 9. How do you ensure the jointer table is perfectly aligned?

Perfect alignment of the jointer tables is crucial for achieving a flat surface. This is a two-step process: checking and adjusting.

- Checking Alignment: Use a perfectly straight edge (at least as long as the jointer’s tables) and a feeler gauge. Place the straight edge across both the infeed and outfeed tables. Check for any gaps between the straight edge and the tables. A feeler gauge can help quantify the discrepancy. Aim for minimal to no gap between the straight edge and either table. Any gap indicates misalignment.

- Adjusting Alignment: Most jointers have adjustment screws located beneath the tables. Consult your jointer’s manual for exact locations and instructions. Carefully and gradually adjust these screws, frequently rechecking your alignment with the straight edge and feeler gauge until both tables are perfectly parallel and flush. Remember, small adjustments are key. Over-tightening can damage the jointer.

Regular checks for alignment are vital. Over time, even slight misalignment can accumulate leading to inaccurate cuts and potentially damaging your workpiece.

Q 10. What are the signs of a damaged jointer knife?

Recognizing damaged jointer knives is essential for safety and accurate cuts. Look for these signs:

- Chips or Cracks: Obvious chipping or fracturing of the knife’s edge is a clear indication of damage. This can lead to uneven cuts and potentially dangerous kickback.

- Dullness: A dull knife will result in torn wood fibers and a rough finish. You’ll notice a significant increase in resistance when feeding wood, a clear indication the knives need attention.

- Uneven Wear: Check for uneven wear patterns along the knife’s edge. If one section is more worn than others, it suggests an alignment problem or a hard knot in the wood that damaged a portion of the blade.

- Excessive chatter: If the jointer produces a vibrating or chattering sound, it can suggest a dull or damaged knife.

Never use a damaged knife. Replace or sharpen damaged knives immediately to prevent accidents and maintain accuracy.

Q 11. How often should jointer knives be sharpened or replaced?

The frequency of sharpening or replacing jointer knives depends heavily on the type of knife (HSS or carbide) and the intensity of use.

- High-Speed Steel (HSS): These typically require sharpening after a few hours of use, depending on the hardness of the wood being worked. Frequent checks for sharpness are necessary. You might notice a dull HSS knife by the way it starts to tear wood fibers instead of cleanly slicing through them.

- Carbide-Tipped: Carbide knives are much more durable, often lasting for hundreds of hours of use before needing sharpening or replacement. They will, eventually, become dull and require sharpening, but this is significantly less frequent than with HSS knives.

Rather than following a rigid schedule, regularly inspect your knives for signs of dullness or damage. Sharp knives are safer and ensure clean, precise cuts. A well-maintained set of jointer knives will significantly enhance your woodworking efficiency and the quality of your projects.

Q 12. How do you handle a jammed piece of wood in the jointer?

A jammed piece of wood in a jointer is a serious situation that requires immediate attention. Never attempt to force the wood.

- Turn off the machine immediately: This is the most critical step. Never try to clear a jam while the machine is running. Wait for the machine to fully stop.

- Disconnect the power: Unplug the jointer from the power source to ensure complete safety.

- Assess the situation: Carefully examine the jam. Determine if you can safely remove the wood by hand. Sometimes gently tapping the wood from the outfeed side can help release it.

- Use appropriate tools: If hand removal is not possible, use tools like a pry bar or a small chisel to carefully loosen the wood from the knives. Avoid damaging the knives if possible.

- Inspect for damage: After clearing the jam, thoroughly inspect the jointer knives, tables, and other parts for damage. If damage is discovered, repair or replace the damaged parts before continuing to use the machine.

Prevention is key. Always feed wood consistently and avoid forcing it through the jointer. Properly sized and sharpened knives also reduce the chance of jams.

Q 13. Describe the procedure for cleaning and lubricating a jointer.

Regular cleaning and lubrication are crucial for maintaining your jointer and extending its life. This process typically involves the following:

- Disconnect the power: Before cleaning or lubricating, always disconnect the jointer from the power source.

- Clean the tables: Use a brush or compressed air to remove wood chips and dust from the infeed and outfeed tables. A damp cloth can be used to wipe away any sticky residue.

- Clean the knives: Carefully remove the knives and clean them thoroughly using a brush and appropriate solvent (if needed). Make sure to handle them with care to avoid getting cut.

- Lubricate moving parts: Apply a high-quality machine lubricant to the moving parts, such as the fence, and any other points specified in your jointer’s manual. Over-lubrication can attract dust and debris.

- Inspect the machine: During the cleaning process, inspect the jointer for any signs of wear, damage, or loose parts.

Cleaning and lubrication should be a part of your regular jointer maintenance routine. The frequency depends on how frequently you use the machine, but a thorough cleaning at least once a month is recommended.

Q 14. What are the key differences between different types of jointers (e.g., 6-inch vs. 8-inch)?

The primary difference between various jointer sizes (e.g., 6-inch vs. 8-inch) lies in the length of the knives and the capacity of the machine.

- Knife Length: An 8-inch jointer has longer knives than a 6-inch jointer. This allows for longer cuts and smoother surfacing of wider boards. A longer knife also enables a smoother cut. Think of it like using a larger paintbrush for a bigger surface area.

- Capacity: The larger the jointer, the wider the boards it can handle. An 8-inch jointer can easily accommodate wider boards compared to a 6-inch model. This is significant for larger woodworking projects.

- Price: Larger jointers generally cost more than smaller ones due to their increased capacity and more robust construction.

The choice between different jointer sizes depends on your woodworking needs and the size of the projects you typically undertake. A 6-inch jointer might suffice for smaller projects and hobbyists, whereas an 8-inch or larger model is better suited for professional use and projects involving larger pieces of wood.

Q 15. How do you use a jointer to create a perfectly flat surface?

Creating a perfectly flat surface with a jointer involves a process of iterative passes, gradually removing material until the desired flatness is achieved. Think of it like sculpting – you don’t remove all the material at once. You start with rough stock, making several light passes, checking for flatness each time.

The key is to start with a surface that’s relatively flat and then use the jointer’s cutter head to carefully shave off material until you obtain a perfectly planar surface. Always check for flatness using a straightedge. A good jointer will have a perfectly aligned cutter head, but always check this to be sure it’s not out of alignment. A slightly unaligned cutter head will cause a concave or convex surface on the workpiece.

Process:

- Initial Pass: Make a light pass across the face of the wood, removing only a small amount of material.

- Check for Flatness: Use a long, straight edge (at least as long as the jointer knives) to check for high and low spots. If you see gaps under the straightedge, those areas need more material removed.

- Iterative Passes: Repeat the process, making light passes over any uneven areas until the straightedge shows complete contact across the entire length of the wood.

- Final Check: Once you’re satisfied with the flatness, perform a final check and make one last light pass if necessary. This ensures a very smooth and flat surface.

Example: If you’re working with a 6ft long board, you might only remove 1/64th of an inch per pass, carefully checking for flatness after each pass. Rushing this process can lead to inaccurate results, and even damage to your workpiece.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you safely change jointer knives?

Changing jointer knives is a crucial procedure that requires caution. Safety is paramount; always unplug the jointer from the power source before commencing any maintenance.

Procedure:

- Disconnect Power: Unplug the jointer from the power outlet. Don’t just rely on the switch.

- Secure the Knives: Use a wrench or suitable tool designed for your jointer model to loosen the knife clamping mechanism.

- Remove the Old Knives: Carefully remove the old knives, keeping them organized and noting their position. They can be re-sharpened later.

- Install New Knives: Carefully place the new knives in their slots, ensuring they’re aligned correctly. Tighten the clamping mechanism securely, ensuring that all knives are at the same height.

- Check Alignment: After installing the new knives, use a gauge to ensure they’re perfectly aligned with the cutter head. A misaligned knife can ruin boards, and worse, injure you.

- Test Run: Make a test pass on a scrap piece of wood to check for proper cutting action before using the jointer on a workpiece.

Safety Tip: Always wear safety glasses and gloves while handling knives.

Q 17. What is the correct feed rate for different types of wood on a jointer?

The correct feed rate on a jointer is crucial for preventing tearout and achieving a smooth finish. It’s not a fixed speed, but rather depends on the type of wood and its condition.

General Guidelines:

- Hardwoods: Hardwoods like maple and oak require a slower feed rate, allowing the cutter head sufficient time to cleanly remove the material.

- Softwoods: Softwoods such as pine and fir generally can tolerate slightly higher feed rates, but still need a controlled pace to avoid tearout.

- Green Wood: Green or damp wood requires an even slower feed rate than dry hardwoods. It’s more prone to tearout.

- Knotty Wood: Knotty wood should always be jointed slowly to help prevent tearout at the knots.

Practical Application: Start with a slower feed rate, and gradually increase it until you find the optimal speed that produces a clean cut without tearout. If you notice tearout, immediately slow down the feed rate. It’s always better to err on the side of caution and work slowly. A smooth surface takes less time than fixing tearout.

Q 18. How do you deal with tearout when using a jointer?

Tearout, the splintering of wood fibers on the exit side of the cut, is a common problem when using a jointer. It’s usually caused by the grain direction relative to the cut and too fast a feed rate. Several strategies can help mitigate tearout.

Solutions:

- Adjust the Feed Rate: Reducing the feed rate is often the most effective solution. Slower is almost always better.

- Reverse the Workpiece: Jointing the opposite side first and then the working side. The first pass on the opposite face will typically produce less tearout, and the face is less likely to tear out after the first cut.

- Use a Sharp Blade: Dull blades exacerbate tearout.

- Featherboard: A featherboard can help prevent tearout, especially on thinner stock. It supports the workpiece against the fence, preventing the wood from being pulled into the cutter head.

- Change Blade Angle: If tearout is persistent, adjust the depth of cut accordingly. A shallower depth of cut can help. On difficult wood, more passes are required, but this produces superior results.

- Reverse the Grain: If possible, adjust the orientation of the wood to avoid cutting directly against the grain. If that’s not possible, then pay very close attention to the strategies above.

Example: If you’re encountering tearout on a piece of softwood, try reducing the feed rate by half and using a featherboard. If that doesn’t work, consider reversing the workpiece or changing the angle of the blades.

Q 19. Explain the importance of using push blocks and featherboards when operating a jointer.

Push blocks and featherboards are essential safety devices when operating a jointer, preventing kickback and improving control of the workpiece.

Push Blocks: Push blocks provide a secure grip and control over the workpiece, especially when working with smaller pieces or those with unusual shapes. They help prevent your hands from getting anywhere near the knives.

Featherboards: Featherboards are used to keep the workpiece firmly pressed against the fence, preventing it from shifting during the cut and minimizing the chance of kickback. They help the wood move consistently and avoid tearout.

Importance: These tools are indispensable for safe and efficient jointer operation. Using them significantly reduces the risk of serious hand injuries, common occurrences with jointer accidents. Many injuries are caused by pieces of wood kicking back. The use of push blocks and featherboards is about safety and work quality. Using these tools reduces injury and also improves the quality of the finished product.

Example: When jointing a narrow board, always use a push block to maintain a firm grip. When working with pieces that are prone to tearout, a featherboard will help ensure a smooth finish and prevent kickback.

Q 20. What are the potential hazards of improper jointer setup?

Improper jointer setup can lead to a range of hazards, from minor inconveniences to serious injury. The hazards are directly proportional to the lack of knowledge of the operation of this potentially dangerous machine.

Potential Hazards:

- Kickback: Improper fence adjustment or using the jointer without proper safety devices can cause the workpiece to kick back toward the operator with considerable force.

- Injury: Fingers, hands, and arms are most commonly injured due to poor setup and inattention to safety. Never put your hands in the cutting area of a jointer.

- Tearout: Poorly aligned knives or an incorrect feed rate can lead to tearout, damaging the workpiece and potentially causing injury.

- Misaligned Knives: Knives that aren’t properly aligned can cause uneven surfaces, making the workpiece unsafe for use in subsequent operations.

- Machine Damage: Operating a jointer with an inadequate setup can damage the machine and lead to premature wear.

Example: A dull or misaligned knife, together with a failure to use safety devices, can have extremely bad results. The combination of poor setup, carelessness, and the power of the machine can lead to severe injury.

Q 21. Describe your experience with different types of jointer fences.

I’ve worked with several types of jointer fences, each with its own advantages and disadvantages.

Types of Fences:

- Standard Cast-Iron Fence: This is the most common type. It’s robust and durable, but can be difficult to adjust precisely. The key is making sure it’s very square to the table and the knives.

- Adjustable Cast-Iron Fence: Similar to the standard type but allowing for more precise adjustments to accommodate different workpiece widths. Precision is critical here.

- Aluminum Fences: These are lighter than cast iron and often offer finer adjustments. However, they may not be as robust.

Considerations: The most important consideration for any fence is its squareness to the cutter head and to the table. Precise alignment ensures accurate cuts. A well-maintained fence is also critical for consistent performance.

Example: In a professional setting, we commonly used adjustable cast iron fences for their robustness and precise adjustability. The combination of a well-maintained fence and correctly adjusted knives is critical for achieving high-quality results.

Q 22. How do you diagnose and fix a jointer that is not cutting straight?

A jointer that isn’t cutting straight is a common problem, usually stemming from misalignment. Diagnosing this requires a systematic approach. First, check the knives. Are they sharp and properly set? Dull knives will tear the wood, resulting in a rough and uneven cut. Next, inspect the fence. Is it perfectly square to the table? Use a square to verify. Any deviation will cause an angled cut. Finally, the most likely culprit is bed alignment. The tables must be perfectly parallel. To check, use a straight edge across the entire length of both tables, checking for any gaps.

Fixing the problem usually involves adjusting the knives (sharpening or replacing them and setting the height correctly), adjusting the fence (using the fence alignment screws), or correcting table alignment. Table alignment is typically adjusted with adjusting screws underneath the infeed or outfeed table; this is often done by carefully turning these screws (usually with an allen key) until the tables are perfectly parallel. If you’re not comfortable making these adjustments, consult a professional.

Example: Imagine you’re planing a board, and one edge is consistently thicker than the other. This indicates a problem with the fence alignment or the tables not being parallel. Careful inspection, using a square and a straight edge, will reveal the source of the misalignment.

Q 23. What is the proper procedure for testing the jointer’s alignment after maintenance?

After any maintenance, especially involving knife changes or table adjustments, verifying alignment is crucial. Start by ensuring the tables are clean and free of debris that might interfere with accurate measurements. You’ll need a precision straightedge, longer than the jointer’s tables.

- Test 1: Parallelism of Tables: Place the straightedge across both tables, checking the gap (or lack thereof) along the entire length. Any gap indicates a need for readjustment of the tables’ alignment screws. Even a slight gap can lead to significant inaccuracies.

- Test 2: Fence Squareness: Use a try square to check the fence’s squareness relative to the table. Place the square’s blade against the fence and the body against the table. Any gap indicates the fence needs adjustment. This typically involves using the fence alignment screws.

- Test 3: Knife Alignment: Visually inspect the knives to ensure they’re all at the same height and projection. Inconsistent knife heights can cause uneven cuts. This step requires careful adjustment of the individual knife settings.

Repeat these tests until you achieve satisfactory alignment. Remember, precision is key when working with jointers, and proper alignment is essential for safe and accurate operation.

Q 24. Describe your experience using different jointer models and brands.

My experience spans a variety of jointer models and brands, including the DeWalt DW735, Grizzly G0870, and Powermatic 63. Each model has its own strengths and weaknesses. The DeWalt is a popular choice for its reliability and ease of use; it’s particularly good for the occasional woodworker. The Grizzly offers excellent value for the price, providing a robust machine at a more affordable price point; however it requires more attention to fine-tuning and maintenance. The Powermatic represents a higher level of precision and build quality; ideal for professional use where accuracy and durability are paramount. I’ve also used smaller benchtop jointers and larger industrial models. My experience has taught me that proper setup and maintenance are crucial regardless of the brand or model to achieve optimal performance.

Working with these different models has honed my understanding of the nuances of jointer design and operation; it has allowed me to develop a practical and versatile skill set with jointers.

Q 25. Explain how to prevent kickback on a jointer.

Kickback on a jointer is a serious hazard, potentially causing injury. Prevention is paramount. The primary cause of kickback is feeding wood that’s too small or has become pinched in the cutterhead.

- Proper Feeding Technique: Always feed the wood with a smooth, controlled motion, keeping both hands firmly on the stock. Avoid forcing the wood.

- Piece Size: Never attempt to joint pieces that are too small or too thin. They can easily become trapped and cause kickback.

- Sharp Knives: Sharp knives cut cleanly, reducing the risk of binding or pinching. Dull knives are a significant kickback contributor.

- Outfeed Support: Ensure the workpiece is adequately supported after it passes over the cutterhead to prevent it from tilting or dropping and causing a dangerous situation.

- Clear the Area: Keep the area around the jointer free of clutter to prevent accidental contact during operation.

Think of it like this: you wouldn’t try to cut a very thin slice of cheese with a large bread knife. Similarly, you should avoid attempting to joint very thin pieces of wood.

Q 26. How do you maintain the accuracy of a jointer over time?

Maintaining jointer accuracy over time involves regular maintenance and careful use.

- Regular Inspection: Periodically check the alignment of the tables and fence using a straightedge and square, as previously described. Address any misalignment immediately.

- Knife Sharpening: Sharpen or replace the knives as needed. Dull knives lead to inaccuracies and increase the risk of kickback.

- Lubrication: Lubricate moving parts as recommended by the manufacturer. This will prevent wear and tear and ensure smooth operation.

- Cleanliness: Keep the jointer clean and free of debris; wood chips and sawdust can interfere with alignment and operation.

- Avoid Overuse: Don’t push the jointer beyond its capabilities. Avoid attempting to remove excessive material in a single pass.

Consistency is key. Regular, preventative maintenance is far easier and cheaper than fixing significant problems caused by neglect.

Q 27. What is your experience with preventative maintenance for jointers?

Preventative maintenance is essential for ensuring the longevity and accuracy of a jointer. My approach is proactive rather than reactive.

- Regular Cleaning: After each use, I thoroughly clean the jointer, removing all wood chips and sawdust. This prevents buildup that can interfere with alignment and operation.

- Scheduled Inspections: I perform a complete inspection of the jointer’s alignment and condition at least once a month, or more frequently if it’s used extensively. This includes checking the knives, fence, and tables for alignment and wear.

- Knife Sharpening/Replacement: I regularly sharpen or replace the knives, typically every few months, depending on usage. This ensures consistent, clean cuts and minimizes the risk of kickback.

- Lubrication: I lubricate the moving parts according to the manufacturer’s recommendations, usually every three months. This prevents wear and tear and ensures smooth operation.

Think of it like maintaining a car; regular servicing prevents major breakdowns. The same applies to a jointer. Preventative maintenance saves time, money, and potential injury.

Key Topics to Learn for Jointer Setup Interview

- Understanding Jointer Functionality: Thoroughly grasp the mechanical operation of a jointer, including its knives, tables, and fence adjustments.

- Safe Jointer Operation: Master safe practices, including proper push stick usage, workpiece handling, and machine maintenance procedures to ensure workplace safety.

- Jointer Setup for Different Wood Species: Learn to adjust the jointer based on the type and hardness of the wood being processed, optimizing for surface quality and minimizing tear-out.

- Achieving Flat and Square Surfaces: Understand the techniques involved in jointing boards to achieve perfectly flat and square edges, essential for precise woodworking projects.

- Troubleshooting Common Jointer Issues: Develop problem-solving skills to diagnose and rectify issues such as chatter marks, uneven surfaces, and knife alignment problems.

- Knife Sharpening and Maintenance: Learn how to sharpen and maintain jointer knives effectively, ensuring optimal performance and longevity of the machine.

- Understanding Jointer Types and Features: Familiarize yourself with different types of jointers (e.g., benchtop, floor-standing) and their unique features and capabilities.

- Project Applications: Be prepared to discuss how jointer skills are applied in various woodworking projects, demonstrating practical understanding and experience.

Next Steps

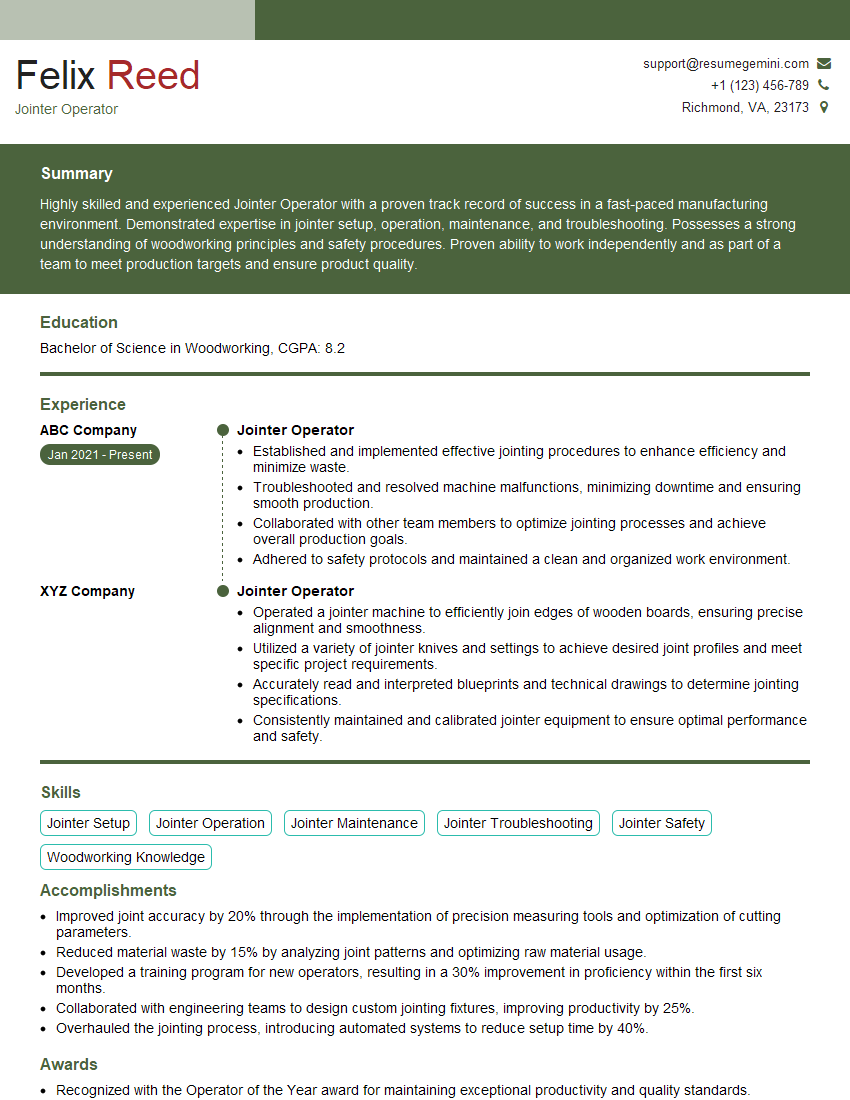

Mastering Jointer Setup is crucial for career advancement in woodworking and related fields. A strong understanding of safe and efficient jointer operation demonstrates valuable skills to potential employers. To significantly improve your job prospects, focus on crafting an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Jointer Setup positions are available to guide you through this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.