The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Underground Excavation Techniques interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Underground Excavation Techniques Interview

Q 1. Explain the different methods of underground excavation.

Underground excavation employs various methods, each chosen based on factors like ground conditions, project scale, and cost. These methods broadly fall into two categories: open-cut methods and tunneling methods.

Open-cut methods: These involve excavating a large open pit, suitable for shallower depths and stable ground. They include:

- Trenching: Used for narrow, deep excavations, often for utilities.

- Cut-and-fill: Excavation followed by backfilling with compacted material.

- Open-pit mining: Large-scale excavation for mineral extraction.

Tunneling methods: Used for deeper excavations, often involving the use of specialized machinery and support systems. They include:

- Drill and blast: Rocks are broken using explosives, a traditional method requiring careful planning and execution.

- Tunnel boring machine (TBM) method: Uses large rotating machines to excavate tunnels, suitable for long, straight sections in consistent geological conditions. Different TBM types cater to specific rock types.

- Roadheader method: Employs rotating cutting heads to excavate tunnels, particularly effective in weaker rocks.

- Pipe jacking: A less disruptive method involving pushing pre-fabricated sections of pipe or tunnel through the ground.

The selection of the appropriate method is crucial for project success and safety. For example, in an urban setting, pipe jacking minimizes surface disruption compared to open-cut methods.

Q 2. Describe the process of ground support in underground excavations.

Ground support is critical in underground excavations to prevent collapse, maintain stability, and ensure worker safety. The method employed depends on the ground conditions (rock type, strength, water presence).

The process generally involves:

Initial Support: This is often installed immediately after excavation, frequently using temporary supports like timber sets or steel ribs. This provides immediate stability and protects workers.

Permanent Support: Installed after initial support, typically involving shotcrete (sprayed concrete), rock bolts (steel bars anchored into the rock mass), or steel sets. These provide long-term stability.

Monitoring and Adjustment: Continuous monitoring using instruments like convergence meters helps detect any movement or instability. Adjustments to the support system might be necessary based on these readings.

Consider a scenario where we are excavating a tunnel in weak, fractured rock. Initial support would involve closely spaced timber sets to hold the immediate area, followed by the application of shotcrete for added strength, and rock bolts for long-term stability. The whole system is monitored for any movement which would necessitate adjustments.

Q 3. What are the common safety hazards associated with underground excavation?

Underground excavation poses many inherent safety hazards. These include:

Ground collapse: A major risk, especially in unstable ground. This necessitates robust ground support systems and careful monitoring.

Rockfalls: Falling rocks can cause serious injuries or fatalities. Safety precautions include proper support systems, protective barriers, and worker training.

Explosions: When using explosives, there’s a risk of premature detonation or uncontrolled blasts. Rigorous safety protocols and experienced personnel are mandatory.

Fire and gas hazards: Certain underground environments can contain flammable gases (methane) or have a risk of fire. Adequate ventilation, gas monitoring, and fire suppression systems are essential.

Flood hazards: Groundwater inflow can cause flooding, trapping workers or causing equipment failure. Effective dewatering and drainage are crucial.

Confined space hazards: Limited space, poor ventilation, and potential for hazardous atmospheres create confined space hazards requiring specific training and safety procedures.

Mitigation involves comprehensive risk assessments, strict adherence to safety regulations, worker training, and the use of appropriate safety equipment such as hard hats, respirators, and safety harnesses.

Q 4. How do you manage groundwater in underground excavations?

Groundwater management is critical in underground excavations to prevent flooding, instability, and delays. Methods vary based on the quantity and pressure of the groundwater.

Dewatering: This involves lowering the water table using wells, sumps, and pumps. It is effective when the groundwater flow is manageable.

Drainage: Installing drainage systems within the excavation to collect and channel away groundwater. This often complements dewatering.

Grouting: Injecting grout (a mixture of cement and water) into the ground to seal off water-bearing fissures and reduce permeability. This is useful in areas with high water inflow.

Watertight linings: Constructing watertight linings around the excavation, such as concrete or steel, to prevent water ingress. This is particularly applicable to tunnels or shafts.

For example, in an excavation near a river, a combination of dewatering using well points and drainage channels might be sufficient. In a more challenging situation with significant groundwater pressure, grouting and watertight linings might be necessary in conjunction with other measures.

Q 5. What are the different types of tunneling machines and their applications?

Tunneling machines are crucial for efficient and safe excavation of tunnels. Different machines cater to various ground conditions and project requirements.

Earth Pressure Balance (EPB) TBMs: These machines use a pressure-balancing system to excavate soft to medium-hard ground. They’re effective in areas with high groundwater pressure.

Slurry TBMs: These machines use a slurry (a mixture of water and bentonite clay) to support the tunnel face and carry excavated material to the surface. They’re suitable for soft, unstable ground.

Hard Rock TBMs: These machines use cutter heads with robust tooling to excavate hard rock formations. They are equipped with powerful cutting tools and robust structures.

Roadheaders: These machines utilize rotating cutting heads to excavate weaker rock formations. They are particularly useful in smaller tunnels or in situations where precise excavation is needed.

The choice of machine depends heavily on the geological profile. For instance, in a long tunnel through hard granite, a hard rock TBM would be the most efficient. Conversely, an EPB TBM would be more appropriate for a tunnel in soft clay.

Q 6. Explain the concept of rock mass classification and its importance in design.

Rock mass classification systems categorize rocks based on their geological characteristics and engineering properties. This is critical for designing safe and stable underground excavations.

Common systems include the RMR (Rock Mass Rating) and Q-system. These consider factors like:

- Rock strength: The compressive strength of the intact rock.

- Rock quality designation (RQD): A measure of the degree of fracturing in the rock mass.

- Spacing of discontinuities (joints): The distance between fractures or joints in the rock.

- Groundwater conditions: The presence and flow of groundwater.

- Orientation of discontinuities: The direction and angle of joints relative to the excavation.

A higher classification rating (e.g., RMR or Q-value) indicates a stronger, more stable rock mass, requiring less support. Conversely, a lower rating suggests a weaker, more unstable mass needing more extensive support measures. This classification informs design decisions such as support type, spacing, and overall excavation methodology.

For instance, a high RMR value might allow for a simpler support system, while a low RMR value would necessitate a robust support system including rock bolts, shotcrete, and possibly steel sets.

Q 7. Describe your experience with different types of explosives used in underground excavation.

My experience encompasses various explosives used in underground excavation, each tailored to specific rock types and excavation requirements. Safety and efficiency are paramount in selecting and using explosives.

Ammonium Nitrate Fuel Oil (ANFO): A widely used, cost-effective explosive mixture, suitable for mass blasting in weaker to medium-strength rock. Its sensitivity to initiation needs careful handling.

Emulsion explosives: These offer enhanced water resistance and performance compared to ANFO, suitable for both dry and wet conditions. They provide more predictable blasting results.

Water gels: Another type of water-resistant explosive, often used in challenging geological conditions, offering good performance and safety features.

The selection depends on factors such as rock strength, groundwater conditions, and environmental considerations. For instance, in a dry, hard rock environment, ANFO may be sufficient, while in a wet, fractured rock mass, a water-gel or emulsion explosive would be preferred to ensure reliable initiation and fragmentation.

In my practice, I always prioritize careful planning of blast designs, including the placement of explosives and initiation sequences, to ensure efficient fragmentation while minimizing damage to the surrounding rock mass and ensuring worker safety.

Q 8. How do you ensure the stability of an underground excavation?

Ensuring the stability of an underground excavation is paramount for worker safety and project success. It involves a multi-faceted approach that begins long before the first shovel of earth is moved. The primary goal is to prevent ground collapse or significant deformation. This is achieved through a combination of careful pre-excavation planning, appropriate support systems, and diligent monitoring.

- Geotechnical Investigation: A thorough understanding of the soil conditions is crucial. This includes soil type, strength, groundwater levels, and the presence of any potentially unstable geological features like faults or fissures. We use techniques like boreholes, in-situ testing (e.g., cone penetration tests, vane shear tests), and laboratory testing to accurately characterize the ground.

- Support System Design: The design of the support system is directly tied to the geotechnical investigation. Different ground conditions necessitate different support strategies. Options range from simple shoring (e.g., timber or steel sheet piles) for relatively stable soils to complex systems involving ground anchors, braced excavations, or even the construction of a temporary diaphragm wall for deeper, more challenging excavations. The support system acts to contain the ground and prevent its movement into the excavation.

- Sequential Excavation: Excavating in stages, rather than all at once, allows for the installation of support systems in a controlled manner. This minimizes the stress on the surrounding ground, reducing the risk of instability.

- De-watering: If groundwater levels are high, de-watering is often necessary to lower the water table and reduce the pore water pressure within the soil. This increases the soil’s effective stress, making it stronger and less prone to collapse.

For example, during the construction of a deep basement in a densely populated urban area, we might use a diaphragm wall to provide strong, impermeable support, preventing ground movement and protecting nearby structures. We would also carefully manage the de-watering process to avoid excessive settlement in adjacent buildings.

Q 9. What are the factors to consider when designing an underground support system?

Designing an underground support system is a complex engineering endeavor requiring a holistic approach. Several key factors must be considered:

- Geotechnical Data: The soil properties (strength, cohesion, angle of internal friction), groundwater conditions, and geological features (faults, fissures) are fundamental to determine the required support system type and its design parameters.

- Excavation Geometry: The depth, width, and shape of the excavation significantly influence the stresses on the surrounding soil and, hence, the required support capacity. Deeper and wider excavations require more robust support systems.

- Surrounding Environment: The presence of nearby structures, utilities, or sensitive environmental features dictates the level of ground movement that can be tolerated and influences the design of the support system to mitigate potential damage or disruption.

- Construction Methodology: The sequence of excavation, the rate of excavation, and the methods used (e.g., top-down, bottom-up) affect the soil’s response and must be factored into the design. A phased approach is often preferred to manage ground movement.

- Loads: The support system must be capable of withstanding the imposed loads, such as the weight of the excavated soil and any construction materials or equipment within the excavation. Surcharges from existing buildings must also be accounted for.

- Regulations and Codes: The support system must comply with all relevant local regulations and building codes regarding excavation safety and stability.

For example, designing a support system for a tunnel in soft clay requires a different approach compared to one in strong rock. In soft clay, we might use a combination of braced walls and ground anchors to provide sufficient support, while in strong rock, the need for extensive support could be minimized or even eliminated.

Q 10. Explain the process of risk assessment and mitigation in underground excavations.

Risk assessment and mitigation in underground excavations is a continuous, iterative process that starts during the planning phase and continues throughout the project’s life cycle. It’s crucial for minimizing hazards and preventing accidents.

- Hazard Identification: This involves systematically identifying potential hazards associated with the excavation, such as ground collapse, flooding, gas explosions, and equipment failure. Techniques like HAZOP (Hazard and Operability Study) and checklists are frequently used.

- Risk Analysis: Once hazards are identified, their likelihood and potential consequences are assessed. This helps prioritize risks and focus mitigation efforts on the most critical ones. Qualitative and quantitative risk assessment methods are employed.

- Risk Mitigation: Based on the risk assessment, appropriate mitigation measures are developed and implemented. This may involve engineering controls (e.g., installing support systems, de-watering), administrative controls (e.g., work permits, training programs), and personal protective equipment (PPE).

- Monitoring and Review: Ground movement, water levels, and other relevant parameters are continuously monitored to detect any signs of instability. Regular reviews of the risk assessment and mitigation plans are conducted to adapt to changing conditions.

A practical example involves excavating near a pipeline. The risk of damaging the pipeline is high. Mitigation measures could include using non-destructive testing methods to locate the pipeline precisely before excavation, employing trenchless excavation techniques to avoid direct contact, and establishing a protected zone around the pipeline.

Q 11. Describe your experience with ground improvement techniques.

Ground improvement techniques are frequently employed to enhance the stability of the ground before excavation. My experience spans a wide range of these techniques, including:

- Soil Stabilization: Methods like cement or lime stabilization chemically alter the soil properties, increasing its strength and reducing its permeability. This is particularly useful in dealing with weak or expansive soils.

- Grouting: Injecting grout (a mixture of cement, water, and additives) into the ground improves its strength and reduces permeability. It is commonly used to consolidate loose soils, seal cracks, or create impermeable barriers.

- Deep Compaction: Using heavy machinery to compact the ground at depth improves its bearing capacity and reduces settlement. This technique is effective in dealing with loose sands or fills.

- Vibro-compaction: Using vibratory equipment to compact granular soils. This method improves soil density and strength.

- Stone Columns: Installing vertical columns of compacted granular material improves the bearing capacity of soft, compressible soils. These columns transfer loads to stronger layers below.

In one project, we used stone columns to improve the bearing capacity of soft clay beneath a large building’s foundation before commencing basement excavation. This ensured the stability of the foundation and prevented excessive settlement during construction.

Q 12. How do you monitor ground movements during underground excavation?

Monitoring ground movements during underground excavation is critical to prevent instability and ensure safety. Various methods are used, ranging from simple visual inspections to sophisticated instrumentation:

- Survey Measurements: Regular surveying using total stations or GPS provides accurate measurements of ground surface displacements. Benchmarks are established before excavation to monitor any changes in elevation.

- Inclinometers: These instruments measure the tilt or deflection of the soil mass around the excavation. They provide data on the magnitude and direction of ground movement.

- Extensometers: These devices measure changes in distance between points in the soil mass, providing information on soil strain and potential deformation.

- Piezometers: These instruments measure pore water pressure in the soil. Changes in pore water pressure can indicate potential instability.

- Settlement Monitoring: Monitoring changes in elevation of buildings or structures near the excavation using leveling techniques.

The frequency of monitoring depends on the risk level and the ground conditions. In high-risk situations, continuous monitoring might be required, while less critical excavations may require less frequent measurements. Data obtained from these instruments is analyzed to assess the stability of the excavation and adjust support systems or construction methods as needed.

Q 13. Explain the role of ventilation in underground excavations.

Ventilation in underground excavations is essential for maintaining a safe and healthy working environment. It addresses several key concerns:

- Oxygen Supply: Adequate ventilation ensures a sufficient supply of fresh air containing adequate oxygen for workers and machinery.

- Removal of Contaminants: Ventilation removes harmful gases, dust, and other airborne contaminants produced during excavation activities. These contaminants can be toxic, explosive, or cause respiratory problems.

- Temperature Control: Ventilation can help regulate temperature within the excavation, preventing overheating or excessive cooling.

- Humidity Control: Ventilation helps maintain a comfortable humidity level, preventing condensation and promoting worker comfort.

Ventilation systems can range from simple natural ventilation using shafts and openings to more complex mechanical systems using fans and ducts. The type of system used depends on the size and depth of the excavation, the type of work being performed, and the potential hazards present. Failure to provide proper ventilation can lead to serious health issues or even fatalities for workers.

Q 14. What are the environmental considerations in underground excavation projects?

Environmental considerations are an integral part of underground excavation projects, focusing on minimizing disruption to the surrounding environment and ensuring sustainability. Key aspects include:

- Groundwater Protection: Preventing contamination of groundwater by implementing appropriate measures such as dewatering systems with appropriate treatment and containment of potential pollutants.

- Soil and Waste Management: Proper management of excavated soil and waste materials to prevent soil erosion and avoid environmental damage or disposal issues. This often includes recycling or reuse of materials where feasible.

- Noise and Vibration Control: Minimizing noise and vibration generated by excavation activities to reduce impacts on nearby communities and sensitive ecosystems.

- Air Quality Management: Implementing effective ventilation and dust suppression methods to control air quality and minimize emissions of pollutants.

- Protection of Flora and Fauna: Preventing damage to natural habitats and minimizing the impact on local flora and fauna. This may involve habitat restoration or translocation of sensitive species.

- Compliance with Regulations: Adhering to all environmental regulations and obtaining necessary permits before commencing work.

For example, when excavating near a river, we must design and implement a robust groundwater management plan to prevent the contamination of the water body. We would also implement measures to control sediment run-off, protecting the river’s ecosystem.

Q 15. Describe your experience with different types of shoring systems.

My experience with shoring systems spans a wide range, encompassing various techniques chosen based on the specific geological conditions, depth of excavation, and project requirements. I’ve worked extensively with:

- Sheet Piling: This involves interlocking steel sheets driven into the ground to form a continuous wall. I’ve used this successfully on several projects where groundwater was a significant concern, for example, a recent subway tunnel project in a high-water table area. The steel sheets provided excellent support and prevented soil collapse.

- Soldier Piles and Lagging: This method involves installing vertical steel piles (soldiers) at intervals, with horizontal timber or steel beams (lagging) placed between them to create a retaining structure. This is a versatile technique, especially suitable for excavations in less cohesive soils where sheet piling might be impractical. I used this approach during the construction of a large basement excavation, optimizing the design for the specific soil properties.

- Diaphragm Walls: These are constructed by excavating a narrow trench and immediately filling it with reinforced concrete. They’re exceptionally strong and commonly used for deep excavations in challenging conditions, such as those with high groundwater pressure. A significant project involved constructing diaphragm walls to support a deep foundation for a high-rise building near a river.

- Anchored Excavation: This utilizes ground anchors to resist lateral earth pressure, often in conjunction with other shoring systems like soldier piles and lagging. I have extensive experience designing and implementing anchor systems, carefully calculating tensile loads and anchor placements to ensure stability. One particular project involved complex anchor configurations to maintain the stability of an excavation adjacent to an existing structure.

Selecting the appropriate shoring system is crucial for safety and project success. Each system has its own strengths and limitations, and a thorough geotechnical investigation is essential before selecting the most suitable method.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage the disposal of excavated materials?

Managing excavated material disposal is a critical aspect of underground excavation, requiring careful planning and adherence to environmental regulations. My approach involves:

- Characterizing the Material: First, the material is thoroughly characterized to determine its composition and potential hazards (e.g., presence of asbestos, contaminants). This is essential for selecting the appropriate disposal method.

- On-site Stockpiling: Where feasible, materials are stockpiled on-site for potential reuse (e.g., as backfill). Proper segregation and management of different material types are crucial during this phase.

- Off-site Disposal: Material deemed unsuitable for reuse is transported to licensed landfills or recycling facilities, ensuring strict adherence to all relevant permits and regulations. Detailed documentation of transportation and disposal is maintained throughout.

- Waste Minimization: Strategies for waste minimization are integrated into the project from the planning stage. This includes careful planning of excavation volumes, optimizing material use, and exploring opportunities for recycling or repurposing.

For example, on a recent project, we were able to recycle a significant portion of the excavated clay, reducing disposal costs and environmental impact. This required coordinating with a local brick manufacturer who used the material in their production process.

Q 17. What are the legal and regulatory requirements for underground excavation?

Legal and regulatory compliance is paramount in underground excavation. Requirements vary by location but commonly include:

- Permitting: Obtaining necessary permits from local authorities is essential before commencing any excavation work. This process often involves submitting detailed plans, including shoring designs and site-specific risk assessments.

- Safety Regulations: Strict adherence to occupational safety and health regulations (OSHA or equivalent) is mandatory. This includes implementing safety protocols, providing proper personal protective equipment (PPE), and conducting regular safety inspections.

- Environmental Regulations: Excavation activities must comply with environmental protection laws, especially concerning groundwater protection, soil contamination, and waste disposal. This may involve environmental impact assessments and mitigation plans.

- Utility Locating: Prior to excavation, it’s crucial to locate and mark underground utilities (e.g., gas, water, electricity) to prevent damage. This is typically done through collaborations with utility companies.

- Public Safety: Measures must be in place to ensure public safety during the excavation, including appropriate barricades, signage, and traffic control.

Non-compliance can lead to significant penalties, project delays, and even serious accidents. Thorough planning and proactive engagement with regulatory bodies are essential for successful and compliant projects.

Q 18. Explain your experience with different types of surveying techniques used in underground excavations.

My experience in surveying techniques for underground excavations encompasses a variety of methods, selected based on the project’s complexity and required accuracy. These include:

- Traditional Surveying: This includes using theodolites, total stations, and leveling instruments for precise measurements and mapping of the excavation. It’s still a fundamental technique for establishing control points and monitoring excavation progress.

- GPS Surveying: GPS technology is frequently used for establishing site control and monitoring large-scale excavations. This provides a higher level of accuracy and efficiency, especially in challenging terrains.

- Laser Scanning: Laser scanning is a powerful tool for creating highly detailed 3D models of excavations, allowing for accurate volume calculations and detection of potential hazards. I’ve utilized laser scanning extensively to ensure that our excavations precisely matched the design.

- Underground Surveying: For deep excavations or tunnels, specialized techniques such as gyrotheodolites or inertial measurement units are employed to accurately measure distances and angles in environments where traditional surveying is challenging.

Accurate surveying is critical for ensuring the excavation proceeds as planned, minimizing errors, and preventing potential safety hazards. Combining multiple techniques frequently enhances the overall accuracy and completeness of the surveying data.

Q 19. Describe your experience with the use of Computer-Aided Design (CAD) software in underground excavation.

I’ve utilized Computer-Aided Design (CAD) software extensively throughout my career, integrating it seamlessly into all phases of underground excavation projects. This includes:

- 3D Modeling: Creating accurate 3D models of the excavation area, incorporating geological data and existing structures. This helps visualize the excavation plan, identify potential conflicts, and optimize the design.

- Design Coordination: CAD facilitates coordination between different disciplines (e.g., geotechnical engineers, structural engineers, contractors). This minimizes design clashes and improves overall efficiency.

- Quantity Takeoffs: Accurate quantity takeoffs of materials are generated, helping in cost estimation and procurement planning.

- As-Built Drawings: Updating drawings to reflect the actual construction progress is essential for documentation and future reference. CAD streamlines this process.

- Simulation and Analysis: Advanced CAD software allows for simulations of excavation processes, such as stress analysis of shoring systems, helping in optimizing the design and ensuring stability.

Specific software packages I’m proficient in include AutoCAD Civil 3D, Revit, and specialized geotechnical software. The use of CAD software is instrumental in minimizing errors, enhancing efficiency, and improving the overall quality of underground excavation projects.

Q 20. How do you ensure quality control in underground excavations?

Ensuring quality control in underground excavations requires a multi-faceted approach focusing on various aspects throughout the project lifecycle:

- Pre-Construction Quality Control: Thorough review of design documents, soil investigation reports, and material specifications. This stage involves verifying the accuracy of the design and ensuring that materials meet the required standards.

- Construction Phase Quality Control: Regular inspections of the excavation process, including monitoring of shoring systems, surveying measurements, and material handling procedures. This requires detailed checklists and documentation of all inspections.

- Testing and Monitoring: Regular testing of soil properties, groundwater levels, and the structural integrity of the shoring systems. This ensures that the excavation is stable and safe.

- Document Control: Maintaining a comprehensive record of all design documents, construction drawings, inspection reports, and test results. This ensures traceability and facilitates effective problem-solving.

- Third-Party Inspections: Employing independent third-party inspectors to verify the quality of work performed by contractors. This provides an unbiased assessment and helps maintain high standards.

A robust quality control program significantly reduces the risk of errors, ensures compliance with regulations, and ultimately contributes to the success of the project. For instance, regular monitoring of groundwater levels during a recent project prevented potential flooding and damage.

Q 21. Explain the process of planning and sequencing operations in underground excavation projects.

Planning and sequencing operations in underground excavation projects is a complex process requiring meticulous attention to detail. It’s a critical factor in ensuring safety, efficiency, and project success. The process typically involves:

- Detailed Project Planning: This involves developing a detailed construction schedule, including activities such as site preparation, excavation, shoring installation, utility relocation, and backfilling. The schedule takes into consideration potential delays and dependencies between different tasks.

- Sequencing Optimization: Optimizing the sequence of operations is crucial for efficiency and safety. For example, excavation in one area might need to be completed before work can commence in another area. This often involves detailed simulations and analysis.

- Resource Allocation: Efficient allocation of resources such as equipment, personnel, and materials is vital. This involves careful planning and coordination to minimize delays and ensure sufficient resources are available when needed.

- Risk Management: Identifying and mitigating potential risks, such as groundwater inflow, soil instability, or utility damage. This often involves contingency planning and implementing appropriate safety measures.

- Regular Monitoring and Adjustments: Regular monitoring of progress and making adjustments to the plan as needed. This ensures that the project stays on track and addresses any unforeseen challenges.

For instance, on a recent tunnel project, we developed a detailed sequencing plan that minimized conflicts between different crews and ensured efficient use of the limited space within the tunnel. This approach enabled us to complete the project on time and within budget.

Q 22. Describe your experience with project management in underground excavation projects.

My experience in project management for underground excavation projects spans over 15 years, encompassing a wide range of projects from small-scale utility installations to large-scale tunnel constructions. I’ve consistently employed a phased approach, meticulously planning each stage from initial site investigation and risk assessment through to completion and handover. This involves detailed scheduling, resource allocation (personnel, equipment, materials), and rigorous quality control. I’m proficient in using project management software like Primavera P6 and MS Project to track progress, manage resources, and identify potential delays proactively. For instance, on a recent highway tunnel project, I implemented a Just-in-Time delivery system for construction materials, optimizing storage space and minimizing disruption on site. This resulted in a 10% reduction in project completion time.

- Detailed Planning & Scheduling: Utilizing critical path analysis to identify critical activities and allocate resources effectively.

- Risk Management: Proactive identification and mitigation of potential risks, such as ground instability or equipment failure.

- Cost Control: Implementing robust cost monitoring and reporting systems to ensure adherence to budget.

- Team Leadership & Motivation: Fostering a collaborative and safe work environment to enhance team productivity and morale.

Q 23. How do you manage project budgets and schedules in underground excavations?

Managing budgets and schedules in underground excavation is a delicate balancing act, requiring constant vigilance and proactive adaptation. I utilize Earned Value Management (EVM) techniques to track progress against the baseline plan, identifying variances early and implementing corrective actions. This involves regular cost and schedule reporting, comparing actual performance against planned performance, and analyzing cost and schedule variances. For budget management, I emphasize accurate cost estimating during the planning phase, incorporating contingency reserves for unforeseen circumstances, and employing value engineering to optimize costs without compromising quality or safety. For example, on a recent project, we substituted traditional timber shoring with a more cost-effective and efficient steel support system without compromising safety standards, leading to significant cost savings.

In terms of scheduling, I rely on critical path method (CPM) analysis to pinpoint the most critical activities and allocate resources accordingly. Regular progress meetings with the project team and stakeholders help ensure everyone is on the same page and any deviations from the plan are addressed immediately.

Q 24. Explain your experience with conflict resolution in underground excavation projects.

Conflict resolution is an inevitable aspect of complex projects like underground excavations. My approach is rooted in open communication, active listening, and collaborative problem-solving. I believe in fostering a respectful environment where team members feel comfortable expressing their concerns. I usually start by identifying the root cause of the conflict, involving all parties in a neutral setting. Then, I facilitate a discussion where each party can voice their perspectives and collaboratively explore solutions. I have experience mediating disputes between contractors, subcontractors, and regulatory bodies using various techniques, including negotiation, mediation, and arbitration, always prioritizing a solution that benefits the overall project success. For instance, on a previous project, a dispute between two subcontractors regarding the scope of work was resolved using a collaborative approach, resulting in a win-win solution that avoided costly delays.

Q 25. How do you communicate effectively with different stakeholders in underground excavation projects?

Effective communication is crucial in underground excavation projects, given the complexity and involvement of diverse stakeholders. My communication strategy involves tailored approaches depending on the audience. Regular progress reports and meetings keep clients informed; daily briefings are used to keep the project team aligned; and clear, concise communication with regulatory bodies helps to ensure compliance. I utilize various communication tools, including email, video conferencing, and project management software, to ensure efficient and transparent information flow. I’ve found that visual aids such as diagrams and 3D models are extremely useful in conveying complex technical information to non-technical stakeholders.

On a challenging project involving a large-diameter tunnel boring machine (TBM), I utilized regular virtual site tours and 3D modeling software to keep the client and shareholders updated on the progress, improving transparency and maintaining strong relationships.

Q 26. Describe your experience with working in confined spaces.

My experience with confined spaces is extensive, having worked on numerous projects involving shafts, tunnels, and underground chambers. Safety is paramount in these environments. I’m fully certified in confined space entry procedures, and I ensure all personnel involved in such work are properly trained and equipped with the necessary safety gear, including respirators, harnesses, and communication devices. Before any entry, a thorough risk assessment is conducted, including atmospheric monitoring for hazardous gases, and emergency rescue plans are established and rehearsed regularly. We regularly use a ‘buddy system’ ensuring that no worker enters a confined space alone. Furthermore, stringent protocols are in place for ventilation and emergency evacuation procedures.

Q 27. How do you address potential delays or challenges during an underground excavation project?

Addressing potential delays or challenges is a critical aspect of project management in underground excavation. My approach involves a proactive, multi-pronged strategy. First, a thorough investigation is conducted to determine the root cause of the delay. This might involve reviewing design documents, site conditions, equipment performance, or unforeseen ground conditions. Once the cause is identified, I initiate a corrective action plan. This may involve adjustments to the schedule, reallocation of resources, or bringing in specialized equipment or expertise. Open and transparent communication with all stakeholders is crucial during this process. For instance, if unexpected geological conditions cause a delay, I would immediately communicate this to the client and explore options such as redesigning sections of the project, seeking regulatory approvals for necessary changes, or deploying alternate construction techniques.

Q 28. What is your experience with different ground conditions and how you adapt your approach?

Experience with diverse ground conditions is essential for success in underground excavation. My experience encompasses various soil types, including soft clays, dense sands, fractured rock, and groundwater conditions. My approach involves a thorough geotechnical investigation at the outset, including drilling and sampling to assess the ground’s bearing capacity, permeability, and potential for instability. This information informs the selection of appropriate excavation methods, support systems, and ground improvement techniques. For instance, in soft ground conditions, we might utilize slurry walls or ground freezing techniques to stabilize the excavation. In areas with high groundwater levels, dewatering systems will be crucial. For hard rock conditions, specialized drilling and blasting techniques would be employed. Adaptability is key—I regularly adjust our approach based on actual ground conditions encountered during construction, using innovative solutions to overcome challenges and maintain project safety and schedule.

Key Topics to Learn for Underground Excavation Techniques Interview

- Ground Conditions and Site Investigation: Understanding soil mechanics, geological surveys, and the impact of different ground conditions on excavation methods.

- Excavation Methods: Familiarize yourself with various techniques including trenchless technologies (e.g., microtunneling, auger boring), open-cut methods, and their suitability for different projects and ground conditions. Practical application: Analyzing a site plan and recommending the most appropriate excavation method.

- Support Systems and Ground Stabilization: Mastering the principles of shoring, underpinning, and ground improvement techniques to ensure worker safety and prevent ground collapse. Practical application: Designing a suitable support system for a specific excavation scenario.

- Safety and Risk Management: Deep understanding of OSHA regulations and best practices for underground excavation, including confined space entry procedures, hazard identification, and risk mitigation strategies. Practical application: Developing a site-specific safety plan.

- De-watering and Groundwater Control: Understanding methods for controlling groundwater inflow during excavation, including well points, sumps, and other dewatering techniques. Practical application: Evaluating the need for dewatering and selecting appropriate methods based on site conditions.

- Tunnel Construction Techniques: Knowledge of various tunnel boring machines (TBMs), their applications, and the challenges associated with tunnel construction in different geological environments.

- Equipment and Machinery: Familiarity with various excavation equipment (e.g., excavators, backhoes, cranes) and their operation, maintenance, and safety procedures.

- Project Management and Cost Estimation: Understanding the project lifecycle, scheduling, budgeting, and resource allocation for underground excavation projects.

- Environmental Considerations: Awareness of environmental regulations and best practices related to minimizing the environmental impact of underground excavation projects.

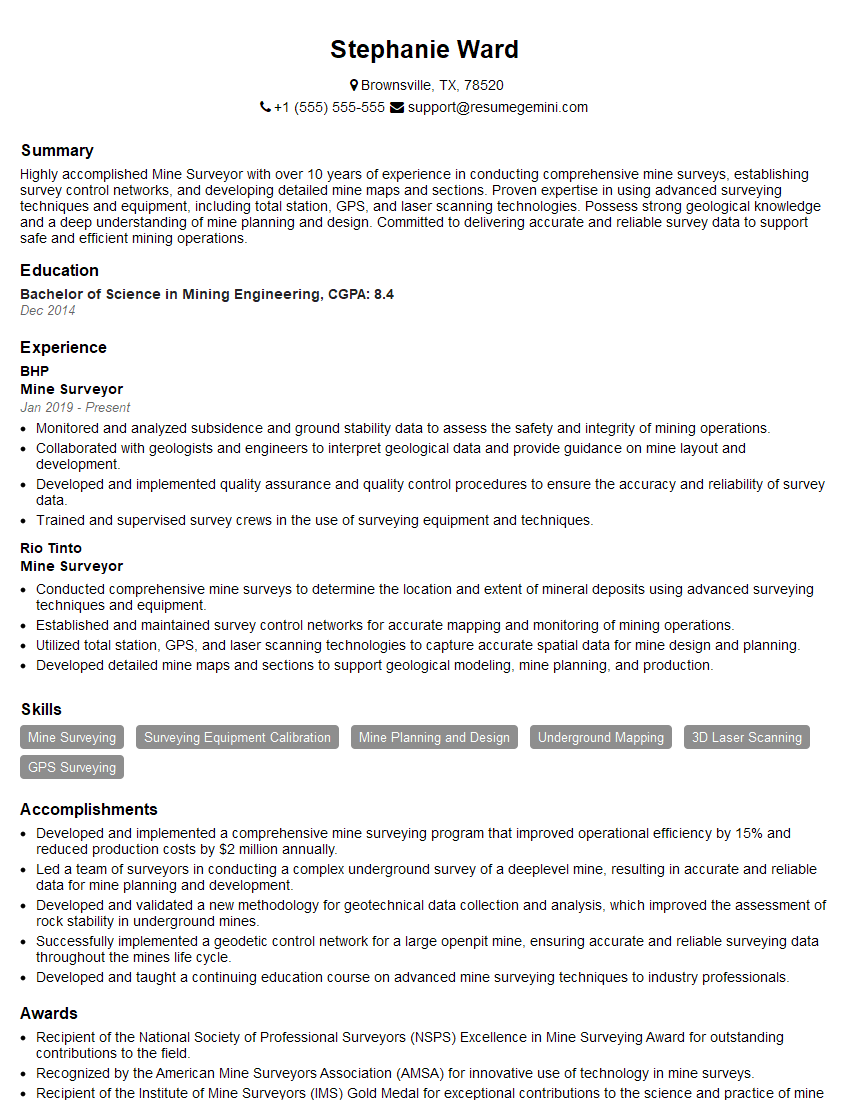

Next Steps

Mastering Underground Excavation Techniques is crucial for career advancement in the construction and engineering industries, opening doors to specialized roles and higher earning potential. To significantly boost your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Underground Excavation Techniques are available to guide you. Take the next step toward your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.