Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Shaft Mucking interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Shaft Mucking Interview

Q 1. Describe your experience with different types of mucking machines.

My experience encompasses a wide range of mucking machines, from small, crawler-mounted loaders ideal for smaller shafts to large, powerful raise borers used in massive deep mining projects. I’ve worked extensively with both mechanical and hydraulic systems. For instance, in one project, we used a slurry-based mucking system for efficient removal of soft, easily-fluidized material, minimizing dust and optimizing transportation. In another, we relied on a conventional bucket-type loader for harder rock requiring more robust excavation methods. The choice of mucking machine heavily depends on the shaft’s geometry, the type of material being excavated (rock type, presence of water, etc.), and the overall project scale. I’m proficient in operating and troubleshooting various makes and models, adapting my approach based on the specific equipment and site conditions.

- Crawler-mounted loaders: Ideal for confined spaces and varied terrain.

- Raise borers: High efficiency for large-scale operations, particularly in deep mines.

- Slurry mucking systems: Excellent for soft materials, reducing dust and improving transportation.

- Bucket-type loaders: Versatile for a wide range of materials, though less efficient in some situations.

Q 2. Explain the safety procedures you follow during shaft mucking operations.

Safety is paramount in shaft mucking. Our procedures begin with thorough pre-shift inspections of equipment and the work area, verifying that all safety systems are functioning correctly. We strictly adhere to confined space entry protocols, including atmospheric testing for hazardous gases before any personnel enter. Every worker wears appropriate PPE, including hard hats, safety glasses, hearing protection, and high-visibility clothing. Regular communication is crucial; we employ a system of hand signals and radios to coordinate activities and avoid accidents. We also implement strict procedures for loading and unloading muck, ensuring that no personnel are in the danger zone during these operations. Regular safety training and toolbox talks are conducted to keep everyone informed of hazards and best practices. For example, we have rigorous procedures for dealing with potential rockfalls, including deploying safety nets and employing controlled blasting techniques where necessary.

Q 3. How do you ensure efficient muck removal and transportation?

Efficient muck removal and transportation involves careful planning and execution. This starts with optimizing the mucking cycle time; choosing the right equipment for the task is vital. We also ensure that the muck disposal system – whether it’s conveyor belts, trucks, or a combination – has sufficient capacity to keep pace with excavation. The design of the muck handling system is crucial; minimizing transfer points and using efficient conveying methods reduce bottlenecks and improve overall efficiency. For instance, in a project involving a long, sloping shaft, we implemented a series of strategically placed transfer points along a conveyor system to move the muck efficiently to the surface. Regular maintenance of the transportation equipment is essential to prevent breakdowns and delays. Continuous monitoring and analysis of the process allows for fine-tuning and optimization, improving efficiency over time.

Q 4. What are the common challenges faced during shaft mucking, and how do you overcome them?

Shaft mucking presents unique challenges. Ground instability, unexpected water inflows, equipment breakdowns, and limited space are common issues. We mitigate ground instability risks through careful geological surveying and ground support measures. Water inflow is managed using effective drainage systems and appropriate sealing techniques. Regular equipment maintenance minimizes breakdowns, and preventative maintenance schedules play a crucial role. Limited space demands precise maneuvering of equipment and careful planning of material handling. In one instance, dealing with an unexpected water inflow, we swiftly implemented a secondary drainage system and adjusted the mucking strategy to accommodate the change, minimizing downtime and ensuring safety. Problem-solving in shaft mucking often involves creative adaptation and quick decision-making.

Q 5. Describe your experience with maintaining mucking equipment.

Maintaining mucking equipment is critical for safety and efficiency. We follow a rigorous preventative maintenance program, which includes regular inspections, lubrication, and replacement of worn parts. Detailed records are kept for each piece of equipment, tracking maintenance history and identifying potential issues early. Operators are trained to perform basic maintenance tasks and report any malfunctions immediately. We also have a dedicated maintenance crew who carry out more complex repairs and overhaul operations. This proactive approach minimizes downtime and extends the lifespan of the equipment. For instance, we developed a predictive maintenance system using sensor data to anticipate potential failures, allowing us to schedule maintenance proactively rather than reactively.

Q 6. How do you manage muck disposal and environmental impact?

Muck disposal and environmental impact are crucial considerations. We comply with all relevant environmental regulations, focusing on safe and responsible disposal methods. This often involves carefully classifying and managing different types of muck, separating materials that can be recycled or reused from those requiring special disposal. We minimize dust generation through water sprays and efficient dust suppression systems. Runoff water is managed to prevent contamination. The final disposal site is chosen carefully, considering potential environmental effects. We often work with environmental consultants to develop and implement sustainable muck disposal strategies and minimize the project’s overall environmental footprint. Documentation and reporting are crucial to demonstrate compliance with regulations.

Q 7. Explain your understanding of ventilation control in shaft mucking environments.

Ventilation control is essential for safety and productivity in shaft mucking. Inadequate ventilation can lead to the buildup of hazardous gases, such as methane or carbon monoxide, posing serious risks to personnel. We employ various ventilation strategies, including using powerful fans to ensure sufficient airflow within the shaft. Monitoring the air quality is crucial; we use gas detectors to continually measure the concentrations of hazardous gases. Ventilation plans are developed based on the geological conditions, the type of excavation, and the potential for gas emissions. For instance, in a project involving potential methane release, we implemented a system of strategically placed ventilation shafts and powerful exhaust fans to maintain a safe atmospheric environment. Regular monitoring and adjustments to the ventilation system ensure a consistently safe working environment.

Q 8. How do you identify and mitigate potential hazards in a shaft mucking operation?

Identifying and mitigating hazards in shaft mucking requires a proactive and multi-faceted approach. It starts with a thorough risk assessment, identifying potential dangers like ground instability, equipment malfunctions, falling objects, and exposure to hazardous materials.

- Ground Control: Regular geological surveys and monitoring of ground conditions are crucial. We use techniques like rock bolting, shotcreting, and installing wire mesh to reinforce unstable areas. For instance, in one project where we encountered highly fractured rock, we implemented a comprehensive rock support system, including resin-grouted rock bolts and a layer of shotcrete, which significantly reduced the risk of rockfalls.

- Equipment Inspection: Daily pre-shift inspections of all equipment – from the mucking machine itself to the hoisting system – are mandatory. Any defects, however minor, are addressed immediately. We maintain a meticulous record of these inspections. For example, we might find a worn brake pad on a hoist, which, if ignored, could cause a serious accident.

- Personnel Safety: Strict adherence to safety protocols, including the use of personal protective equipment (PPE) like hard hats, safety glasses, high-visibility clothing, and hearing protection, is paramount. Regular safety training and refresher courses ensure everyone is aware of the risks and proper procedures.

- Ventilation: Adequate ventilation is essential to prevent the buildup of harmful gases like methane or carbon monoxide. Regular air quality monitoring is necessary, especially in deeper shafts. In one project, we implemented a sophisticated ventilation system, including booster fans and air quality sensors, to maintain a safe working environment.

- Emergency Preparedness: Detailed emergency response plans, including evacuation procedures and communication protocols, must be in place and regularly practiced. This might involve drills simulating power outages or equipment failures.

By combining these measures, we create a safer and more efficient mucking operation. It’s not just about following regulations; it’s about fostering a safety-conscious culture where everyone feels responsible for their own safety and the safety of their colleagues.

Q 9. What are the different types of muck encountered in shaft mining?

The type of muck encountered in shaft mining varies significantly depending on the geological formation. It can range from relatively soft and easily manageable material to hard, abrasive rock requiring specialized equipment. Common types include:

- Broken Rock: This is the most common type, resulting from blasting or drilling and comprises fragments of varying sizes. The size and nature of the fragments influence the choice of mucking equipment.

- Loose Material: This includes sand, gravel, or other unconsolidated materials, which can be easily transported but might present challenges regarding stability and dust control.

- Slurry: A mixture of water and fine particles, slurry can be very difficult to handle and may require specialized pumping equipment and dewatering techniques.

- Clay or Shale: These materials can be very sticky and difficult to remove, often requiring specialized tools and techniques to prevent clogging of the mucking equipment. They can also swell upon contact with water, posing additional challenges.

- Hard Rock: This requires more robust equipment, like heavy-duty loaders, and often necessitates pre-breaking techniques before mucking.

Understanding the specific characteristics of the muck is crucial for selecting appropriate equipment, developing efficient mucking strategies, and ensuring worker safety. For instance, if we encounter unexpectedly unstable ground, we may need to adjust the mucking plan and implement additional ground support measures.

Q 10. Describe your experience with ground support systems in shaft mucking.

Ground support systems are integral to safe and efficient shaft mucking. My experience encompasses a wide range of systems, tailored to the specific geological conditions of each project.

- Rock Bolts: These are essential for stabilizing fractured or unstable rock masses. We use various types, including grouted bolts and expansion bolts, depending on the ground conditions. For instance, in a project with highly fractured rock, we opted for resin-grouted bolts for superior strength and better load distribution.

- Shotcrete: A pneumatically applied concrete mixture, shotcrete provides a protective layer on the shaft walls, preventing rockfalls and improving stability. The thickness and type of shotcrete are determined by the specific ground conditions and the required level of protection.

- Wire Mesh and Steel Sets: These are employed to reinforce the ground and protect against falling rocks. We use a combination of wire mesh and steel sets (a structural framework) in many projects to create a robust support system. The spacing and configuration of these elements are carefully designed based on the geological assessment.

- Mesh and cable support system: These offer an effective support for the shaft walls that is both flexible and strong.

- Monitoring Systems: We regularly monitor ground conditions using instruments such as convergence meters and extensometers to detect any signs of movement or instability. This allows for proactive intervention and prevents potential accidents. A proactive approach to monitoring allows for early detection of issues such as the potential for a ground collapse.

The design and implementation of ground support systems require a thorough understanding of geotechnical principles and experience in assessing and mitigating ground-related risks. Failure to adequately support the shaft walls can lead to serious accidents, delays, and increased costs.

Q 11. How do you ensure the safe operation of mucking equipment?

Ensuring the safe operation of mucking equipment is a top priority. This involves a combination of preventative maintenance, operator training, and adherence to strict safety procedures.

- Regular Maintenance: A strict maintenance schedule is followed, including regular inspections, lubrication, and repairs. This prevents equipment failure and reduces the risk of accidents. We use computerized maintenance management systems (CMMS) to track maintenance activities and ensure compliance.

- Operator Training: Operators receive thorough training on the safe operation and maintenance of the equipment, including emergency procedures. Regular refresher courses and competency assessments are conducted to maintain high standards of operator proficiency.

- Safety Systems: The equipment is fitted with safety features such as emergency stops, interlocks, and warning systems. These features are regularly checked and maintained to ensure they are functioning correctly. For example, emergency stop buttons must be readily accessible and clearly marked.

- Risk Assessments: Regular risk assessments are conducted to identify and mitigate potential hazards associated with equipment operation. This may involve analyzing potential points of failure and implementing control measures to reduce risks.

- Lockout/Tagout Procedures: Stringent lockout/tagout procedures are followed during maintenance or repairs to prevent accidental starts.

A proactive approach to equipment safety minimizes the risk of accidents and ensures that mucking operations are both efficient and safe. This involves not just technical proficiency but a strong safety culture within the team.

Q 12. What are your strategies for improving productivity in shaft mucking?

Improving productivity in shaft mucking involves optimizing various aspects of the operation. My strategies include:

- Optimized Equipment Selection: Choosing the right equipment for the specific geological conditions and muck type is crucial. For example, using a high-capacity loader for broken rock and a specialized excavator for challenging terrain significantly impacts productivity.

- Efficient Mucking Cycle: Analyzing and optimizing the mucking cycle – from loading to hauling – helps minimize downtime and maximize efficiency. This might involve adjusting the loading angle or optimizing the haul routes. Careful consideration of the cycle, including time for loading, unloading and travel to minimize overall time.

- Improved Ground Support: Efficient ground support systems reduce delays caused by instability and allow for faster mucking. A well-planned support system allows for quicker and more consistent mucking operations.

- Effective Material Handling: Implementing effective methods for handling and disposing of muck, such as optimized chute systems or conveyor belts, significantly improves efficiency. Automated material handling processes can greatly increase efficiency and safety.

- Technology Integration: Using technology such as automated guidance systems, remote monitoring, and predictive maintenance can optimize equipment performance and reduce downtime. These technologies provide more real-time data which enables improved response to issues and optimization of work processes.

- Crew Training and Management: Well-trained and motivated personnel are essential for productivity. Regular training programs, effective communication, and good teamwork are crucial for a high-performing mucking crew. A well-trained crew can also quickly identify issues that might negatively impact efficiency.

By systematically addressing these areas, we can achieve significant improvements in productivity while maintaining a strong focus on safety.

Q 13. Explain your understanding of the relevant safety regulations for shaft mucking.

My understanding of safety regulations for shaft mucking is comprehensive and includes both national and international standards, as well as site-specific regulations. These regulations cover various aspects of the operation, including:

- Ground Control: Regulations dictate the required ground support measures based on geological conditions, including the type and frequency of inspections and the standards for rock bolting, shotcreting, and other support systems.

- Equipment Safety: Standards specify requirements for equipment design, maintenance, and operation, including safety features, operator training, and regular inspections. Equipment needs to meet strict standards, be properly maintained and regularly inspected.

- Ventilation: Regulations specify minimum ventilation requirements to maintain safe air quality, including monitoring standards and emergency procedures for gas detection.

- Personal Protective Equipment (PPE): Specific regulations mandate the use of appropriate PPE, including hard hats, safety glasses, respirators, and hearing protection.

- Emergency Procedures: Detailed emergency response plans, including evacuation procedures, communication protocols, and rescue plans, are required and must be regularly practiced.

- Permit-to-Work Systems: Many operations utilize a permit-to-work system to control access to hazardous areas and ensure adherence to safety procedures. This includes strict control over who may access the work areas, ensuring adherence to strict safety procedures.

Staying updated with the latest regulations is crucial for ensuring compliance and maintaining a safe working environment. Non-compliance can result in serious consequences, including accidents, fines, and legal action.

Q 14. How do you handle emergency situations during shaft mucking operations?

Handling emergency situations in shaft mucking requires a rapid and coordinated response. Our procedures are based on a clear hierarchy and communication protocol.

- Immediate Actions: The first step is to secure the area and ensure the safety of personnel. This might involve halting operations, evacuating the immediate vicinity, and activating the emergency response plan.

- Communication: Clear and effective communication is crucial, using designated communication channels to inform relevant personnel, including supervisors, rescue teams, and emergency services. A dedicated communication system is important for disseminating information quickly and effectively.

- Rescue Operations: If required, rescue operations are initiated, with trained personnel using appropriate equipment and following established procedures. The type of equipment and procedures may vary based on the type of emergency and severity.

- Investigation and Reporting: A thorough investigation is conducted to determine the cause of the emergency and identify any contributing factors. Detailed reports are prepared and submitted to relevant authorities to prevent future occurrences.

- Post-Incident Review: A post-incident review is conducted to evaluate the effectiveness of emergency response procedures and to identify areas for improvement. This is a crucial step in continuously improving emergency response capabilities.

Regular emergency drills and training sessions ensure that all personnel are prepared to handle various emergency situations effectively. A well-rehearsed and practiced response greatly enhances safety and reduces the impact of emergency situations.

Q 15. Describe your experience with different mucking techniques.

My experience encompasses a wide range of shaft mucking techniques, from traditional methods to the latest technological advancements. I’ve worked extensively with various methods depending on the project’s specifics, including:

- Conventional Mucking: This involves using loaders and excavators to load muck into skips or trucks for hauling. I’ve overseen projects using both crawler and wheel loaders, adapting techniques based on the shaft’s geometry and ground conditions. For instance, in a narrow shaft, a smaller, more maneuverable loader would be crucial.

- Slurry Mucking: This technique is particularly useful in dealing with soft or unconsolidated ground. I’ve utilized slurry systems where muck is mixed with water to create a pumpable slurry, then transported via pipelines to a disposal area. This minimizes dust and speeds up the removal process compared to conventional methods, especially when dealing with large volumes of muck.

- Automated Mucking Systems: I have experience integrating automated guidance and control systems into mucking operations, improving efficiency and safety. This often involves remote-controlled loaders or automated muck handling systems. This experience helps to mitigate risks associated with human error in confined and hazardous environments.

Each method requires a distinct approach to safety, equipment selection, and operational planning. The choice depends on factors like shaft size, ground conditions, muck characteristics, and budget.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate effectively with your team during a shaft mucking operation?

Effective communication during shaft mucking is paramount for safety and efficiency. I use a multi-faceted approach:

- Pre-shift briefings: Before each shift, I conduct thorough briefings covering the day’s tasks, potential hazards, equipment status, and safety procedures. These are interactive sessions; I encourage team input to ensure everyone is informed and aware.

- Clear and concise instructions: I use plain language, avoiding technical jargon whenever possible. I ensure everyone understands their roles and responsibilities, visually reinforcing information with diagrams or sketches if needed.

- Two-way communication: I actively encourage my team to communicate any concerns or problems immediately. I foster an open environment where team members feel comfortable raising questions and reporting hazards without fear of reprisal.

- Visual communication: Using hand signals, light signals, and radios is crucial in the noisy environment of a shaft. We have established a clear system of visual communication for safety and operational efficiency.

- Regular check-ins: Throughout the shift, I regularly check in with individual team members to monitor progress and address any issues promptly.

Effective communication is not just about giving orders; it’s about building a team where everyone feels valued, understands the tasks, and can contribute to a safe and productive work environment.

Q 17. What are your experience with different types of loaders and excavators used in shaft mucking?

My experience with loaders and excavators used in shaft mucking includes a variety of models suited for different shaft configurations and ground conditions:

- Wheel Loaders: I’ve used various sized wheel loaders depending on the shaft dimensions and muck volume. These are versatile for loading muck into skips or trucks in wider shafts.

- Crawler Loaders: Their excellent traction makes them ideal for uneven or unstable ground conditions frequently encountered in shafts. I’ve found them particularly useful in smaller diameter shafts where maneuverability is a critical factor.

- Hydraulic Excavators: These are effective for breaking up large chunks of muck and loading into skips, particularly in shafts with challenging geology. Different sizes and configurations are utilized to match the space and muck characteristics.

- Specialized Mucking Machines: I have experience working with specialized mucking machines designed for specific applications, like those equipped with grabs or clamshells for efficient muck handling in tight spaces.

The selection criteria for these machines include reach, lifting capacity, maneuverability within the shaft, safety features, and maintenance requirements. Understanding these factors is crucial for optimizing mucking operations.

Q 18. How do you monitor the performance of the mucking operation?

Monitoring the performance of a mucking operation involves tracking several key metrics. I use a combination of methods:

- Production Rate: I track the volume of muck removed per unit of time (e.g., tons per hour) to assess the efficiency of the operation. This helps to identify bottlenecks and areas for improvement.

- Equipment Utilization: Monitoring the operating time versus downtime of equipment helps identify maintenance needs or operational inefficiencies. I maintain detailed logs of equipment performance.

- Safety Performance: This is a critical aspect. I monitor accident rates, near misses, and adherence to safety protocols. Regular safety audits and toolbox talks are integral to our processes.

- Cost Tracking: Tracking labor costs, equipment costs, and material costs allows for a comprehensive analysis of overall operational efficiency and profitability.

- Data Logging and Analysis: Modern equipment is often equipped with data loggers that record operational parameters. Analyzing this data provides valuable insights for optimization.

By regularly reviewing these metrics, I can identify trends, predict potential problems, and implement corrective actions to enhance productivity and safety.

Q 19. What are your experience with troubleshooting mucking equipment breakdowns?

Troubleshooting mucking equipment breakdowns requires a systematic approach. My experience involves:

- Immediate Safety Measures: Prioritize safety by securing the area and ensuring the safety of personnel before attempting any repairs.

- Visual Inspection: Begin with a thorough visual inspection to identify obvious problems, such as leaks, broken components, or damaged wiring.

- Diagnostic Testing: Utilize diagnostic tools and equipment to pinpoint the root cause of the breakdown. This often involves checking hydraulic systems, electrical systems, and mechanical components.

- Consult Maintenance Manuals: Refer to the equipment’s maintenance manuals for troubleshooting guides and repair procedures. These manuals provide detailed information on the equipment’s workings, common issues and repair recommendations.

- Communication with Technicians: If necessary, promptly contact specialized technicians or maintenance personnel for assistance with complex repairs.

- Preventive Maintenance: Implementing a rigorous preventive maintenance schedule significantly reduces the likelihood of breakdowns. Routine checks and lubrication are crucial.

A proactive approach to maintenance, combined with systematic troubleshooting, minimizes downtime and keeps the mucking operation running smoothly.

Q 20. How do you ensure the quality of the muck removal process?

Ensuring the quality of the muck removal process involves several key aspects:

- Complete Removal: The process should ensure the complete removal of muck from the shaft, leaving a clean and safe working environment. This minimizes the risk of instability or future complications.

- Efficient Handling: Muck should be handled efficiently to prevent spillage, dust generation, and potential environmental impact. Proper dust suppression methods are often essential.

- Proper Disposal: Muck should be disposed of according to environmental regulations and safety guidelines. This may involve dedicated disposal sites or specialized treatment methods.

- Regular Inspections: Regular inspections of the muck removal process, including the condition of the equipment and the efficiency of the operations, help maintain quality standards.

- Documentation: Detailed records of the muck removal process, including quantities, disposal methods, and any incidents, are essential for compliance and future reference.

By focusing on these aspects, we maintain consistent quality throughout the muck removal process, ensuring safety, minimizing environmental impact, and achieving project goals.

Q 21. Explain your understanding of the geological aspects relevant to shaft mucking.

Understanding the geological aspects relevant to shaft mucking is critical for safe and efficient operations. My knowledge encompasses:

- Rock Mass Characterization: Identifying the type of rock, its strength, fracturing, and weathering patterns is essential for selecting appropriate mucking techniques and equipment. For instance, hard rock may require blasting and specialized equipment, while soft ground might necessitate slurry mucking.

- Groundwater Conditions: Assessing groundwater levels and potential inflows is vital for planning dewatering strategies and preventing flooding. This impacts excavation stability and worker safety.

- Geological Hazards: Identifying potential hazards like unstable ground, fault zones, and the presence of potentially hazardous materials (e.g., methane gas) is crucial for implementing appropriate safety measures. Geological surveys and mapping are paramount.

- Ground Support: Understanding the need for ground support (e.g., rock bolts, shotcrete) during excavation is vital for maintaining shaft stability and safety. The design of ground support systems directly relates to the geological conditions.

My expertise ensures that the mucking operation considers the geological context, minimizing risks and optimizing the overall process. This prevents unexpected issues and ensures a safe and efficient operation.

Q 22. How do you assess the stability of the shaft walls during mucking operations?

Assessing shaft wall stability during mucking is crucial for safety and efficiency. It’s a multi-faceted process involving visual inspections, geotechnical data analysis, and sometimes, specialized instrumentation. We start with a thorough review of the pre-construction geotechnical reports, which provide insights into the rock mass characteristics – strength, fracturing, and water content.

During mucking operations, regular visual inspections are paramount. We look for signs of instability such as cracks, loose rock, or bulging walls. Any deviation from the expected condition, even minor ones, is flagged. We might employ techniques like rock bolting or shotcreting (applying a sprayed concrete layer) proactively to reinforce unstable sections. In more complex scenarios, we might use instrumentation like inclinometers or extensometers to monitor wall movement continuously and get precise data. For instance, during a project in a highly fractured rock mass, we installed inclinometers to detect even slight wall movements, allowing us to adjust our mucking strategy and support systems in real-time, preventing potential collapses.

The ultimate goal is to develop a proactive, risk-based approach – anticipating potential problems rather than reacting to them. This involves ongoing communication between the geotechnical engineer, the mucking crew, and the project management team.

Q 23. Describe your experience with using specialized tools and equipment in shaft mucking.

My experience encompasses a wide range of specialized tools and equipment used in shaft mucking. This includes everything from basic mucking buckets and conveyors to highly sophisticated robotic systems. I’m proficient in operating various types of excavators and loaders adapted for shaft work, including those equipped with specialized buckets designed for different material types (e.g., rock, muck, loose soil). I’ve worked extensively with different types of conveyors for transporting muck from the shaft bottom to the surface. My experience includes using remote-controlled equipment in challenging or hazardous conditions, enhancing both productivity and safety. I’m also familiar with specialized ventilation systems critical for maintaining a breathable atmosphere within the shaft, which is especially relevant during extensive mucking operations.

For example, on one project involving the excavation of a deep, narrow shaft in a challenging geological formation, we used a small, highly maneuverable robotic excavator equipped with a high-capacity mucking bucket. This allowed us to efficiently remove material in tight spaces while minimizing the risk to human workers. This significantly improved both the speed and safety of the operation. This experience underscored the importance of choosing the right tools for the job and how technological advancements can increase productivity while mitigating risks.

Q 24. How do you maintain accurate records of mucking operations?

Maintaining accurate records of mucking operations is vital for project management, safety analysis, and regulatory compliance. We use a combination of digital and paper-based systems to track all aspects of the process. This includes daily logs detailing the volume of muck removed, equipment used, personnel involved, any incidents or near misses, and the condition of the shaft walls. We also maintain detailed records of all maintenance performed on the equipment used. Crucially, we meticulously document any geological observations made during the process, noting any changes in ground conditions or the presence of unexpected materials.

Our digital systems often incorporate dedicated software for tracking the progress of mucking, creating detailed reports and generating analyses on efficiency, safety trends, and costs. For example, we might use software to create 3D models of the shaft and track the progress of excavation visually. This provides a clear overview of the project and identifies any potential delays or issues proactively. This integrated approach to record-keeping ensures that data is readily accessible for analysis and reporting, enhancing both transparency and accountability.

Q 25. What are your experience with different types of ground conditions during shaft mucking?

My experience with various ground conditions during shaft mucking is extensive. I’ve worked in formations ranging from competent, hard rock to soft, unconsolidated soils, and everything in between. Each condition presents unique challenges and requires a tailored approach. Working in hard rock requires specialized drilling and blasting techniques before mucking can commence, followed by the removal of the broken rock fragments. Soft ground conditions often necessitate the use of support systems such as shoring or ground freezing to prevent collapses and maintain shaft stability. I’ve also encountered areas with high groundwater inflow, requiring efficient dewatering strategies to maintain a safe working environment.

For example, a project in a particularly unstable, clay-rich area required the implementation of a comprehensive ground freezing system before we could even begin excavation. The precise control and monitoring of the freezing process were essential to ensure both the structural integrity of the shaft and the safety of the personnel. Successfully completing this project demonstrated the value of adaptability and expertise in various ground conditions. Understanding the behavior of different ground types is essential for developing appropriate excavation and support strategies that prioritize both efficiency and safety.

Q 26. How do you contribute to a safe and productive work environment in shaft mucking?

Contributing to a safe and productive work environment in shaft mucking is my top priority. This involves adhering to strict safety protocols, regular equipment inspections, and continuous training for all personnel. We conduct thorough risk assessments before each mucking operation, identifying potential hazards and implementing appropriate control measures. This includes providing the crew with the right personal protective equipment (PPE) tailored to the specific hazards. Clear communication and teamwork are paramount, with regular safety briefings and open communication channels to address any concerns or issues promptly.

For instance, on a project with multiple subcontractors, I implemented a daily toolbox talk program to discuss specific safety concerns and reinforce the importance of safe work practices. This proactive approach minimized the potential for accidents and fostered a strong safety culture. The successful completion of all my projects without major incidents speaks volumes of my commitment to safety. In essence, safety isn’t just a policy; it’s a culture built upon diligence, collaboration, and unwavering commitment.

Q 27. Describe your experience working under pressure and meeting deadlines in a shaft mucking operation.

Shaft mucking operations often involve working under pressure to meet tight deadlines. I’ve consistently demonstrated the ability to manage demanding schedules while maintaining high standards of safety and quality. This involves careful planning, efficient resource allocation, and proactive problem-solving. I’m adept at prioritizing tasks, adjusting plans as needed, and coordinating with other teams to ensure smooth workflow. It’s not just about speed, but about smart, controlled execution. My approach includes careful monitoring of progress against schedule, proactive identification of potential delays, and efficient implementation of contingency plans to address unforeseen circumstances.

One memorable instance involved a challenging project with a very aggressive schedule. We faced several unexpected setbacks, including difficult ground conditions and equipment malfunctions. By implementing a rapid response plan, coordinating closely with the engineering team, and motivating the crew through effective communication, we managed to complete the project on time and within budget, maintaining a safe working environment despite the added pressure.

Q 28. How do you adapt to changing conditions and priorities during shaft mucking?

Adaptability is key to success in shaft mucking. Conditions and priorities can change rapidly, requiring flexibility and quick decision-making. I’m proficient in adjusting strategies in response to unexpected challenges, such as changes in ground conditions, equipment failures, or shifts in project priorities. This involves close collaboration with the project management team to assess the impact of changes and develop effective solutions. Regular communication and careful monitoring are vital, allowing for proactive adjustments rather than reactive measures. My approach is founded on maintaining clear communication with the team, utilizing my expertise in problem-solving, and remaining adaptable while keeping safety as the utmost priority.

For example, I once encountered a situation where a sudden influx of groundwater threatened to halt the operation. By swiftly analyzing the situation, coordinating with the engineering team to implement a new dewatering strategy, and reassigning crew members to support these efforts, we successfully mitigated the problem and minimized the project’s delay. This response highlighted the value of adaptability, swift problem-solving, and maintaining clear communication within the team to ensure continuous and safe operations.

Key Topics to Learn for Shaft Mucking Interview

- Understanding Mucking Equipment: Familiarize yourself with various types of mucking equipment, their functionalities, and operational limitations. This includes loaders, scoops, and their respective safety protocols.

- Safety Procedures and Regulations: Mastering safety protocols is paramount. Understand confined space entry procedures, emergency response plans, and the use of Personal Protective Equipment (PPE) specific to shaft mucking.

- Ground Control and Support Systems: Learn about the different ground control techniques used in shaft mucking to prevent collapses and ensure worker safety. Understand the role and application of various support systems.

- Material Handling and Transportation: Gain a clear understanding of efficient material handling and transportation methods within the shaft environment. This includes understanding the limitations of space and the importance of organized workflows.

- Environmental Considerations: Become familiar with environmental regulations and best practices relevant to shaft mucking operations, including dust control and waste management.

- Problem-Solving and Troubleshooting: Develop your ability to identify and solve common problems encountered during shaft mucking operations. Practice analyzing situations and devising effective solutions under pressure.

- Teamwork and Communication: Shaft mucking often requires collaborative efforts. Understand the importance of clear communication and effective teamwork in a high-risk environment.

Next Steps

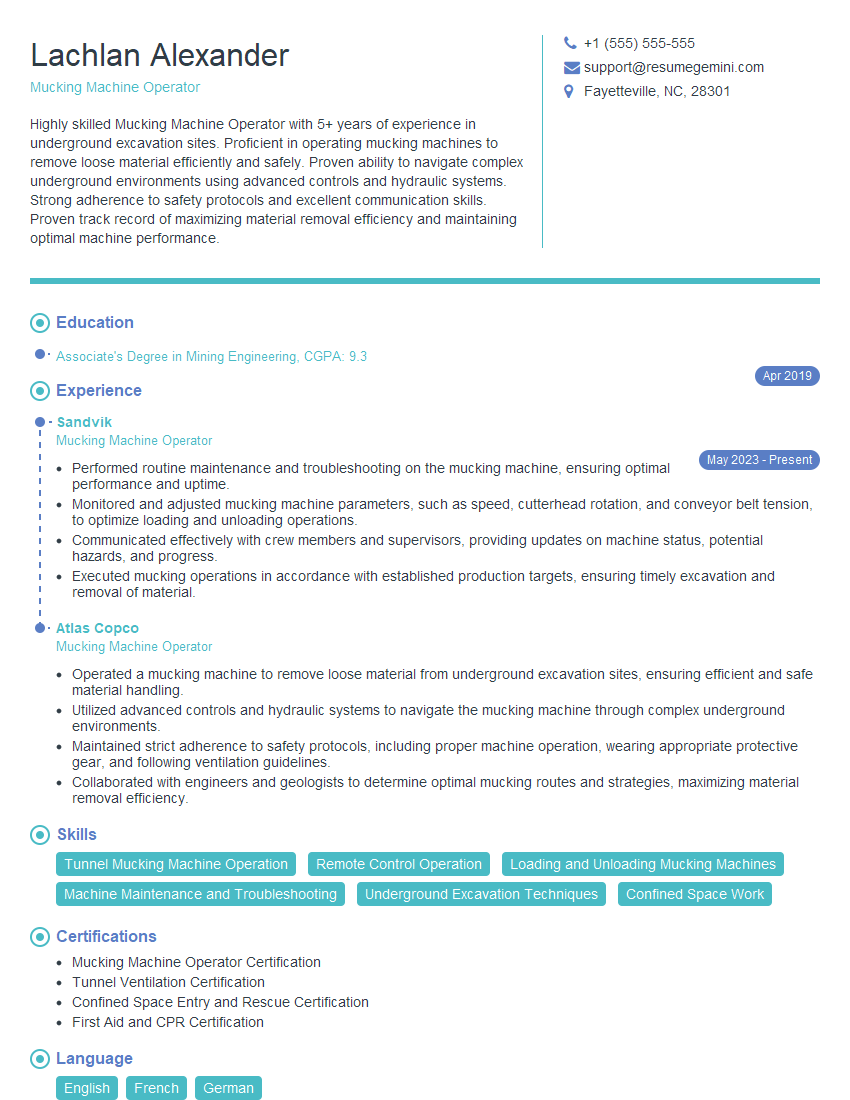

Mastering shaft mucking opens doors to exciting career opportunities within the mining and construction industries, offering a pathway to specialized roles and enhanced earning potential. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out from the competition. We provide examples of resumes tailored to the Shaft Mucking field to guide you in showcasing your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.