Preparation is the key to success in any interview. In this post, we’ll explore crucial Plastic Injection interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Plastic Injection Interview

Q 1. Explain the different types of injection molding machines.

Injection molding machines are categorized primarily by their clamping mechanism and the type of plastic they process. The most common types include:

- Hydraulic Injection Molding Machines: These machines use hydraulic cylinders to generate the clamping force needed to hold the mold closed during injection. They are known for their high clamping force capacity and are suitable for large and complex parts. Think of them as the workhorses of the industry, capable of handling heavy-duty molding tasks.

- All-Electric Injection Molding Machines: These machines utilize electric motors for both clamping and injection, offering advantages in terms of energy efficiency, precision, and reduced noise. They’re excellent for applications requiring high repeatability and precise control over injection parameters. Consider them the precision instruments of the injection molding world.

- Hybrid Injection Molding Machines: These machines combine hydraulic and electric systems. They often use hydraulics for the clamping force and electric motors for injection, blending the strengths of both approaches. They represent a good balance between power and precision.

- Two-Platoon Injection Molding Machines: Designed for higher production rates, these machines have two injection units, allowing for simultaneous molding of two parts or faster cycles for a single part. This significantly improves efficiency and overall output. Imagine this as an assembly line for plastic parts, producing them twice as fast.

The choice of machine depends heavily on the size and complexity of the parts, production volume, budget, and desired level of automation.

Q 2. Describe the injection molding process in detail.

The injection molding process is a multi-stage procedure that transforms molten plastic into a finished product. Here’s a breakdown:

- Clamping: The mold halves are clamped together tightly, creating a sealed cavity. Think of it as preparing the canvas for your painting.

- Injection: Molten plastic, heated to the correct temperature and pressure, is injected into the mold cavity under high pressure, filling the mold completely. This is like spreading the paint onto the canvas.

- Holding/Dwelling: The molten plastic is held under pressure to ensure it fills all details of the mold and eliminates any air pockets. This is like allowing the paint to settle and ensuring a uniform layer.

- Cooling: The mold is cooled to allow the plastic to solidify and take the shape of the cavity. This is analogous to letting the paint dry.

- Ejection: Once the plastic has solidified, ejection pins push the finished part out of the mold. This is like taking your finished artwork off the easel.

- Mold Opening: The mold opens, and the finished part is removed. The cycle then repeats for the next part.

This entire process is controlled by a sophisticated machine control system, constantly monitoring parameters like temperature, pressure, and injection time to ensure quality and consistency.

Q 3. What are the key parameters to control in the injection molding process?

Precise control of several key parameters is vital for successful injection molding. These parameters include:

- Melt Temperature: Too low, and the plastic won’t flow properly. Too high, and it can degrade the material.

- Mold Temperature: Affects cooling time and part quality. A well-maintained mold temperature is crucial to reduce cycle time and increase consistency.

- Injection Pressure: Determines how effectively the plastic fills the mold cavity. Insufficient pressure can lead to short shots, while excessive pressure may cause warping or flash.

- Injection Speed: The rate at which the plastic is injected into the mold. A controlled injection speed helps to prevent defects like weld lines.

- Holding Pressure: Maintains pressure on the molten plastic during cooling to ensure complete filling and minimize shrinkage.

- Cooling Time: Insufficient cooling leads to dimensional inaccuracies and warping. Proper cooling time ensures the part’s structural integrity.

- Clamping Force: Ensures the mold halves stay closed during the injection process, preventing leakage and ensuring accurate part formation.

Monitoring these parameters through process control systems allows for adjustments and optimization for high-quality part production.

Q 4. How do you troubleshoot common injection molding defects like short shots, flash, and sink marks?

Troubleshooting injection molding defects requires a systematic approach. Here’s how to tackle common issues:

- Short Shots: This occurs when the plastic doesn’t fully fill the mold cavity. Troubleshooting: Check injection pressure, melt temperature, injection speed, and ensure no blockages in the flow path. A clogged nozzle or sprue can be the culprit.

- Flash: Excess plastic escaping between the mold halves. Troubleshooting: Examine the mold for wear, damage, or misalignment. Check clamping force and ensure proper mold closure.

- Sink Marks: Indentations on the surface of the part caused by shrinkage during cooling. Troubleshooting: Adjust the mold temperature, cooling time, and potentially the material used. Thicker sections of the part need more time to cool evenly. Consider redesigning the part to have more uniform wall thickness.

Careful analysis of the defect and a methodical approach to adjust the relevant process parameters are key to solving these issues.

Q 5. What are the different types of resins used in injection molding?

A wide variety of resins are used in injection molding, each with its own properties and applications:

- Thermoplastics: These materials can be repeatedly melted and reshaped without significant degradation. Examples include:

- Polyethylene (PE): Flexible, low-cost, used for films, bottles, and containers.

- Polypropylene (PP): Stiff, chemical-resistant, used in packaging and automotive parts.

- Polyvinyl Chloride (PVC): Versatile, used in pipes, window frames, and flooring.

- Acrylonitrile Butadiene Styrene (ABS): Tough, impact-resistant, used in toys, housings, and automotive parts.

- Polycarbonate (PC): High impact strength, transparency, used in safety glasses, lenses, and automotive components.

- Thermosets: These materials undergo an irreversible chemical change during molding, resulting in a rigid, strong, and heat-resistant product. Examples include:

- Epoxy resins: Used for high-performance applications like electronics and aerospace components.

- Polyurethane (PU): Used in coatings, foams, and elastomers.

The choice of resin depends on the application’s requirements for properties like strength, flexibility, temperature resistance, and chemical resistance.

Q 6. Explain the importance of mold design in injection molding.

Mold design is paramount in injection molding. A well-designed mold ensures the efficient and consistent production of high-quality parts. Key aspects include:

- Gate Location: The point where the molten plastic enters the mold. Optimal gate location minimizes weld lines and ensures complete filling.

- Runner and Sprue Design: The channels that guide the molten plastic to the mold cavity. Efficient design minimizes pressure drop and ensures uniform flow.

- Ejection System: The mechanism that removes the finished part from the mold. Properly designed ejection systems prevent damage to the part.

- Cooling System: Channels within the mold that circulate coolant, ensuring efficient cooling and part quality. A poorly designed cooling system can lead to warping or sink marks.

- Material Selection: The mold material itself must be chosen for durability and resistance to the high pressures and temperatures involved.

Poor mold design can lead to numerous production problems, including defects, increased cycle times, and higher production costs. A strong emphasis on mold design is crucial for successful injection molding.

Q 7. How do you select the appropriate material for a given application?

Material selection is critical for the success of any injection molding project. The process involves careful consideration of several factors:

- Application Requirements: What are the necessary mechanical, thermal, and chemical properties? Will the part be exposed to extreme temperatures, chemicals, or impacts?

- Part Design: The part’s geometry, wall thickness, and features will influence material selection. Thin-walled parts require materials with good flow characteristics.

- Cost Considerations: The cost of the material is a significant factor, particularly for high-volume production.

- Environmental Concerns: The material’s environmental impact, recyclability, and potential health risks should be considered.

- Processing Characteristics: Some materials process better than others on specific equipment, affecting melt flow, cooling rates, and overall moldability.

Often, a combination of material properties and cost considerations must be weighed, making material selection a key decision in the injection molding process.

For example, if a part requires high impact resistance and is for outdoor use (UV exposure), ABS or polycarbonate might be suitable choices. However, if the application is for a low-cost disposable item, polypropylene might be preferred. Each application demands a unique assessment of material properties and constraints.

Q 8. What are the different types of mold gates and runners?

Mold gates and runners are crucial pathways that deliver molten plastic from the injection nozzle into the mold cavity. Think of them as the veins and arteries of the injection molding process. The choice of gate and runner type significantly impacts part quality, cycle time, and overall efficiency.

- Gate Types: These control the flow of molten plastic into the cavity. Common types include:

- Pin Gate: Small, precisely controlled gate, ideal for thin-walled parts, minimizes weld lines.

- Edge Gate: Located at the edge of the part, easy to remove, good for simple geometries.

- Tab Gate: Creates a small tab that’s later removed, often used when aesthetics are important.

- Submarine Gate: Hidden below the part surface, resulting in a clean, almost invisible gate location.

- Hot Runner Gate: No runner system; the molten plastic flows directly to the gate, reducing material waste.

- Runner Types: These channels carry the molten plastic from the nozzle to the individual gates. Common types include:

- Cold Runner System: The runner is a separate piece that solidifies with each shot. The solidified runner is later removed and recycled.

- Hot Runner System: The runner is heated, keeping the plastic molten and eliminating the runner waste. More expensive upfront, but more efficient overall.

The selection of gate and runner type is carefully considered based on the part design, material properties, and desired production efficiency. For instance, a complex part with intricate details might benefit from a hot runner system with submarine gates to ensure flawless surface finish and minimize material waste.

Q 9. Describe the importance of proper mold temperature control.

Mold temperature control is paramount in injection molding, directly influencing the part’s quality, dimensional accuracy, and cycle time. Think of it as baking a cake – the oven temperature is critical for a perfect outcome. Precise temperature control ensures consistent plastic melt viscosity and proper cooling, preventing defects.

Importance:

- Consistent Melt Viscosity: Maintaining optimal mold temperature ensures the plastic melt flows smoothly and consistently fills the mold cavity, avoiding short shots or air traps.

- Dimensional Accuracy: Controlled cooling minimizes shrinkage and warping, leading to parts that meet precise specifications.

- Surface Finish: Proper temperature prevents sink marks, weld lines, and other surface imperfections, leading to an improved aesthetic appeal and functionality.

- Cycle Time Optimization: Efficient cooling shortens the cycle time and increases production rate.

- Mold Lifespan: Avoiding excessive temperature fluctuations prolongs the lifespan of the mold, reducing maintenance costs.

Mold temperature is typically controlled using temperature controllers connected to heating and cooling systems. Thermocouples strategically placed within the mold monitor the temperature, ensuring accurate regulation.

Q 10. How do you measure and control melt flow index (MFI)?

Melt Flow Index (MFI), also known as Melt Index (MI), measures the ease with which a thermoplastic polymer flows under controlled conditions. Imagine squeezing toothpaste – a high MFI indicates a free-flowing tube of toothpaste, whereas a low MFI signifies a thicker consistency. This test determines the material’s processability and helps in selecting appropriate injection molding parameters.

Measurement and Control:

MFI is measured using a standardized extrusion plastometer. A precisely weighed amount of molten plastic is forced through a calibrated die under specific temperature and pressure. The amount extruded in a set time (usually 10 minutes) determines the MFI value, expressed in grams per 10 minutes. This process is regulated by standards such as ASTM D1238.

Controlling MFI involves managing the material’s processing temperature, pressure and flow rate during processing. While we can’t directly control the MFI of a specific material batch (it is a material property), careful monitoring ensures consistent processing conditions leading to predictable results.

Variations in MFI can occur due to material degradation or processing issues. For instance, if the material is overheated during processing, its MFI may increase, indicating changes in its molecular structure. Hence, routine MFI testing is crucial for quality control.

Q 11. What are the different types of injection molding processes (e.g., gas assist, overmolding)?

Injection molding offers various specialized processes to meet diverse application needs. Beyond standard injection molding, several advanced techniques are widely employed. Let’s explore a few key examples:

- Gas-Assist Injection Molding: A gas (usually nitrogen) is injected into the molten plastic during the filling stage. This allows for the creation of hollow parts with thinner walls, reducing material usage and weight. Think of creating a hollow plastic bottle – gas-assist is a great choice.

- Overmolding: Two or more different materials are injected into the mold in successive stages. This allows for creating parts with multiple material properties in a single component. Think of a rubber grip over a plastic handle—this technique creates a part with both hard and soft components.

- In-Mold Decorating (IMD): A decorative film is placed within the mold cavity before injection. The molten plastic encapsulates the film, resulting in a high-quality, durable decoration. This method is widely used in creating decorated appliance parts or car interiors.

- Reaction Injection Molding (RIM): Two or more liquid components are mixed and immediately injected into the mold, where they react to form a solid part. This technique is often used for creating large, complex parts with high impact resistance.

Each technique offers unique advantages, depending on the specific application requirements. The choice depends heavily on the part’s geometry, the desired material properties, and production volume requirements.

Q 12. Explain the role of clamping force in injection molding.

Clamping force is the force exerted by the injection molding machine to hold the mold halves together during the injection phase. Imagine two strong hands holding a mold shut tightly; that’s the role of the clamping force. This force is crucial for preventing the mold from opening due to the high pressure of the molten plastic.

Importance:

- Mold Closure: Adequate clamping force ensures the mold remains tightly closed against the high pressure exerted by the injected molten plastic. Insufficient clamping force can lead to flash – excess plastic escaping between mold halves.

- Part Quality: Proper clamping force contributes to consistent part quality and dimensional accuracy. Insufficient force can result in incomplete filling and distorted parts.

- Mold Protection: Sufficient force helps protect the mold from damage caused by excessive plastic pressure. This helps extend the mold’s useful life.

The clamping force required depends on factors such as mold size, part geometry, and plastic material used. The injection molding machine is selected to provide sufficient clamping force for the specific application.

Q 13. How do you calculate cycle time for an injection molding process?

Cycle time in injection molding is the total time required to complete one cycle of production – from mold closure to part ejection. Optimizing cycle time is crucial for maximizing production efficiency. Think of it like a well-oiled assembly line; minimizing downtime between each cycle is vital.

Calculation: Cycle time comprises several key components:

- Molding time: Time taken to fill the mold cavity with molten plastic.

- Cooling time: Time required for the plastic to cool and solidify within the mold.

- Clamping time: Time the mold remains closed.

- Ejection time: Time for removing the finished part from the mold.

- Other times: Additional time for activities like mold opening/closing, robot movement, etc.

Cycle time is calculated by summing these individual times. For instance:

Cycle Time = Molding Time + Cooling Time + Clamping Time + Ejection Time + Other Times

Accurate cycle time calculation requires careful observation and measurement of each of the components mentioned above. Optimizing cycle time often involves adjustments to cooling system efficiency, material selection, and mold design.

Q 14. Describe different types of mold steels and their applications.

Mold steels are the backbone of injection molds, determining their durability, lifespan, and ability to withstand high temperatures and pressures. Choosing the right steel is crucial for efficient and reliable production. It’s like choosing the right foundation for a house—a weak foundation will lead to problems down the line.

Types and Applications:

- P20: A general-purpose tool steel, widely used for its good machinability, relatively low cost, and adequate hardness for many applications. Ideal for low to medium volume production runs.

- H13: A hot work tool steel, offering high hardness and wear resistance. Suitable for high-temperature applications and long production runs. Used for molds producing parts with high surface quality and dimensional tolerances.

- S7: A shock-resistant tool steel, ideal for applications involving high impact forces. Often used for large, complex molds or those facing significant stress.

- 420 Stainless Steel: Offers corrosion resistance, making it suitable for molding parts that come into contact with chemicals or corrosive environments.

- Maraging Steels: High-strength steels offering superior hardness and toughness. Used for demanding applications requiring high dimensional precision and long-term mold life.

The selection of mold steel depends on several factors including part geometry, production volume, material properties, required surface finish, and budget. For example, a high-volume application demanding precise part dimensions might necessitate the use of H13, while a low-volume application with less demanding requirements could utilize the more cost-effective P20.

Q 15. How do you ensure the quality of injection molded parts?

Ensuring the quality of injection molded parts is a multifaceted process that begins even before the molding process itself. It involves meticulous planning, precise execution, and rigorous inspection at every stage. We need to think about the quality of the raw material, the design of the mold, the parameters of the injection molding machine, and the final inspection of the parts.

Firstly, selecting the right material is crucial. The material’s properties must perfectly match the intended application of the part. Secondly, robust mold design is essential to prevent defects like sink marks, short shots, or warping. Thirdly, precise control of injection molding parameters – injection pressure, melt temperature, mold temperature, and cycle time – are critical to consistent part quality. Finally, a well-defined quality control plan, including visual inspection, dimensional measurement, and potentially destructive testing, is necessary to ensure parts meet specifications.

For example, in a project involving the production of precise medical components, we implemented a multi-stage quality control plan. This involved rigorous material testing, 100% visual inspection using automated systems, and dimensional checks using CMM (Coordinate Measuring Machine) for critical dimensions. This ensured that all parts met stringent tolerances and quality standards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common quality control methods used in injection molding?

Common quality control methods in injection molding encompass a range of techniques, from visual inspection to sophisticated statistical analysis. These methods are crucial for identifying and addressing defects early on, preventing costly rework and ensuring product consistency.

- Visual Inspection: This is the simplest and often first step, checking for obvious defects like flash, short shots, sink marks, and warping. It can be done manually or automated using vision systems.

- Dimensional Measurement: Using tools like calipers, micrometers, and CMMs, precise measurements of critical dimensions are taken to ensure parts conform to design specifications.

- Weight Measurement: Consistent part weight often indicates consistent filling of the mold cavity, providing insights into the injection process.

- Material Testing: Tests such as tensile strength, impact resistance, and flexural strength help verify that the chosen material meets the required performance characteristics.

- Leak Testing: For parts intended to contain liquids or gases, leak testing is essential to ensure their integrity.

- Destructive Testing: Techniques such as tensile testing and impact testing may be performed to assess the strength and durability of the parts.

Q 17. Explain the principles of statistical process control (SPC) in injection molding.

Statistical Process Control (SPC) is a powerful methodology for monitoring and controlling the variation within a manufacturing process. In injection molding, SPC helps us identify trends and patterns in the process parameters and part characteristics, allowing for proactive adjustments before defects become widespread.

SPC relies on the use of control charts, which graphically display data collected over time. These charts typically include control limits that define the acceptable range of variation. Data points falling outside these limits indicate potential process issues. Common control charts used in injection molding include X-bar and R charts (for average and range of measurements) and p-charts (for the proportion of defective parts).

For instance, we used X-bar and R charts to monitor the wall thickness of a particular injection molded part. By regularly collecting data and plotting it on the chart, we could quickly identify any shifts in the average wall thickness or an increase in variability. This early detection allowed us to adjust the injection parameters before producing a large batch of defective parts.

Q 18. How do you perform root cause analysis for injection molding defects?

Root cause analysis for injection molding defects requires a systematic approach to identify the underlying reason behind a quality issue. It’s not enough to simply address the symptom; we need to find the root cause to prevent recurrence.

A structured approach, such as the ‘5 Whys’ technique, is helpful. We ask ‘why’ repeatedly to delve deeper into the issue. For example, if we find excessive flash on a part, the first ‘why’ might be ‘incorrect mold clamping pressure’. The second ‘why’ could be ‘worn mold clamping components’. We continue asking ‘why’ until we reach the root cause, which might be ‘lack of preventative maintenance on the molding machine’.

Other techniques include Pareto analysis (identifying the vital few causes contributing to the majority of problems) and Fishbone diagrams (also known as Ishikawa diagrams), which help visualize potential causes categorized by various factors (materials, machine, method, man, measurement, environment).

In one instance, we experienced sink marks on a complex part. Applying the 5 Whys, we identified the root cause to be insufficient melt temperature, leading to inadequate flow of the molten plastic into the mold. After adjusting the melt temperature, the problem was resolved.

Q 19. What are the safety precautions to consider when working with injection molding machines?

Safety is paramount when working with injection molding machines. These machines operate under high pressure and temperature, posing significant risks if safety procedures aren’t strictly followed. A comprehensive safety program is essential and includes regular safety training for all personnel.

- Lockout/Tagout Procedures: Before any maintenance or repair, the machine must be completely shut down and locked out to prevent accidental start-up.

- Personal Protective Equipment (PPE): Employees must wear appropriate PPE, including safety glasses, hearing protection, heat-resistant gloves, and safety shoes.

- Emergency Stop Buttons: Easy access to emergency stop buttons is crucial for immediate shutdowns in case of accidents.

- Machine Guards: All moving parts should be adequately guarded to prevent accidental contact.

- Hot Runner Safety: Careful handling is needed to avoid burns from hot runners and sprues.

- Ejection System Safety: Proper maintenance of the ejection system prevents injuries from malfunctioning components.

- Regular Maintenance: Preventative maintenance is key to identifying and addressing potential hazards before they lead to accidents.

Q 20. Describe your experience with different CAD/CAM software used in mold design.

Throughout my career, I have extensive experience using various CAD/CAM software packages for mold design. Proficiency in these tools is vital for creating efficient and high-quality molds.

My expertise includes software such as SolidWorks, Autodesk Inventor, and Creo Parametric. I am proficient in creating 3D models of molds, designing parting lines, and generating 2D drawings for manufacturing. I am also experienced in utilizing CAM software for creating CNC machining programs for mold construction. This includes programming for milling, EDM (Electrical Discharge Machining), and wire EDM processes.

For example, in a recent project, I used SolidWorks to design a complex multi-cavity mold for a small electronic component. I leveraged the software’s advanced features to simulate mold filling and optimize the gate locations to prevent defects such as air traps and short shots. The resulting mold design was highly efficient and produced parts with excellent quality.

Q 21. Explain your experience with different types of injection molding machines (hydraulic, electric, hybrid).

My experience encompasses a wide range of injection molding machines, including hydraulic, electric, and hybrid systems. Each type has its own strengths and weaknesses, making them suitable for different applications.

- Hydraulic Machines: These machines are known for their high clamping force and injection pressure, making them suitable for molding large and complex parts. However, they tend to be less energy-efficient than electric machines.

- Electric Machines: Electric machines offer precise control over injection parameters, leading to improved part quality and consistency. Their energy efficiency and lower noise levels are significant advantages. However, they may have limitations in terms of clamping force compared to hydraulic machines.

- Hybrid Machines: These machines combine the advantages of both hydraulic and electric systems. They use electric motors for precise control of injection and clamping functions while utilizing hydraulic systems for high clamping forces when needed. They represent a good compromise between precision, energy efficiency, and power.

In my experience, selecting the right type of injection molding machine depends heavily on the specific application requirements, including part size, complexity, material properties, and production volume. I have successfully operated and maintained all three types of machines, always prioritizing safety and efficiency.

Q 22. What is your experience with mold maintenance and repair?

Mold maintenance and repair are crucial for ensuring consistent production quality and minimizing downtime in injection molding. My experience encompasses preventative maintenance, troubleshooting, and executing repairs on a wide range of molds, from simple to complex multi-cavity designs. This involves understanding mold components like the cavity, core, runner system, and ejection system.

Preventative maintenance includes regular inspections for wear and tear, cleaning, lubrication of moving parts, and the timely replacement of worn components. For example, I’ve implemented a schedule of weekly inspections for small molds and monthly inspections for larger, more complex molds, including detailed documentation of each inspection.

Troubleshooting involves diagnosing the root cause of molding defects. This might involve analyzing part defects (e.g., short shots, flash, sink marks) and correlating them to potential mold issues like wear on ejector pins, damage to the cavity surface, or problems with the cooling system. I use a systematic approach, combining visual inspection with specialized tools like a surface roughness tester and CMM measurements to pinpoint the problem. For instance, I once identified a subtle cavity erosion causing sink marks by carefully inspecting the mold surface under a microscope. Repairs range from simple tasks like polishing a worn surface to more complex procedures involving mold component replacement or even specialized welding techniques.

Q 23. How do you handle production issues and downtime?

Handling production issues and downtime requires a proactive and systematic approach. My strategy involves immediately identifying the problem, implementing immediate corrective actions, and then conducting a root cause analysis to prevent future occurrences. Think of it like diagnosing a patient: quick assessment, immediate treatment, and then a deeper investigation to determine the underlying cause of the illness.

For instance, if a machine suddenly stops, I first ensure the safety of the operators and then proceed with troubleshooting, checking for power supply issues, hydraulic leaks, or sensor malfunctions. Simultaneously, I’ll initiate a backup plan if possible (like using another machine or adjusting the production schedule) to minimize downtime. After resolving the immediate problem, I meticulously document the entire incident, including the cause, corrective actions taken, and any improvements needed to the process or equipment.

Root cause analysis often involves using tools like fishbone diagrams or 5 Whys to identify the underlying causes of recurring problems. This allows for the implementation of long-term solutions to prevent similar issues in the future. This could involve operator training, improving maintenance procedures, or even upgrading equipment.

Q 24. Describe your experience with process optimization techniques.

Process optimization is a continuous effort in injection molding, aiming to improve efficiency, reduce costs, and enhance product quality. My experience involves applying various techniques like Design of Experiments (DOE), Statistical Process Control (SPC), and Lean Manufacturing principles.

DOE allows for a systematic investigation of process parameters, such as injection pressure, melt temperature, and cycle time, to determine their impact on part quality. I’ve used DOE to optimize the injection molding process of a complex part, resulting in a 15% reduction in cycle time and a significant improvement in dimensional accuracy. SPC helps monitor and control the process parameters to maintain consistency. I routinely use control charts to track key parameters and identify any deviations from the target values. This early detection of variation prevents costly defects and scrap.

Lean principles, like value stream mapping, are crucial to identifying and eliminating waste in the process. I’ve successfully used value stream mapping to optimize material handling and reduce lead times, significantly improving overall production efficiency. I’m also well-versed in Six Sigma methodologies, applying DMAIC (Define, Measure, Analyze, Improve, Control) to systematically address process variations.

Q 25. How familiar are you with different types of automation used in injection molding?

I am familiar with a wide array of automation technologies commonly used in injection molding. This includes robotic automation for part handling, automated material handling systems, and sophisticated control systems for machine operation and monitoring. Imagine a well-oiled machine—each piece working in perfect harmony. That’s the goal of automated injection molding.

Robotic systems are frequently used for tasks such as removing parts from the mold, placing them onto conveyor belts, and performing secondary operations like assembly or packaging. I have experience programming and troubleshooting robotic systems from various manufacturers. Automated material handling systems optimize the flow of raw materials and finished goods, reducing handling time and minimizing waste. Advanced control systems utilize sensors and data analytics to monitor key process parameters, providing real-time feedback and enabling predictive maintenance. I’m proficient in using these systems to optimize parameters, leading to improved product quality and reduced downtime.

Furthermore, I’m experienced with integrating vision systems for quality control. These systems automatically inspect parts for defects and ensure consistency, improving efficiency and reducing scrap rates. The use of PLCs (Programmable Logic Controllers) for automated machine control is also a key area of my expertise.

Q 26. What is your experience with lean manufacturing principles?

Lean manufacturing principles are central to my approach to injection molding. It’s about maximizing value while minimizing waste. I’ve implemented various lean techniques, focusing on streamlining processes and reducing inefficiencies. Think of it as sculpting a block of marble—chipping away at the unnecessary parts to reveal the beautiful, functional piece within.

Specific examples include implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) to organize the workspace, improving material flow through kanban systems, and reducing setup times using SMED (Single-Minute Exchange of Die) techniques. I’ve successfully implemented Kaizen events (continuous improvement workshops) to identify and eliminate waste in various aspects of the production process. For example, through a Kaizen event we reduced lead times by 20% by identifying and eliminating unnecessary steps in the material handling process.

By focusing on value stream mapping and eliminating non-value-added activities, I have consistently achieved significant improvements in production efficiency and reduced costs while maintaining high product quality.

Q 27. How do you manage projects and timelines in an injection molding environment?

Managing projects and timelines in injection molding necessitates a structured approach. I typically use project management tools, like Gantt charts and PERT diagrams, to visualize project timelines and dependencies. This ensures that all activities are scheduled effectively and that potential bottlenecks are identified and mitigated early on.

From project initiation to completion, I follow a well-defined process, starting with a clear definition of project scope and objectives. This involves close collaboration with stakeholders, including engineers, designers, and production personnel, to ensure everyone is aligned with the project goals. Regular progress meetings and status reports are crucial for monitoring progress, identifying any deviations from the plan, and taking timely corrective actions. I use a combination of critical path method and agile methodologies based on project complexity and needs.

Risk management is a key aspect of my approach. I proactively identify potential risks and develop contingency plans to mitigate their impact. For example, I might establish buffer time in the schedule to account for potential delays in mold fabrication or material delivery. Throughout the project, I focus on clear communication, collaboration, and proactive problem-solving to ensure projects are completed on time and within budget.

Q 28. Describe your experience with different types of plastics and their properties.

My experience encompasses a wide range of plastics, including thermoplastics like ABS, PP, PE, PC, and engineering plastics like PEEK and PEI, as well as thermosets such as epoxy and polyurethane. Each material exhibits unique properties, and choosing the right plastic for a specific application is critical for both functionality and cost-effectiveness.

For instance, ABS is known for its good impact resistance and ease of processing, making it suitable for consumer products. PP offers excellent chemical resistance and is often used in food packaging. PC excels in high-temperature applications due to its high heat deflection temperature. Engineering plastics like PEEK and PEI offer exceptional mechanical strength and chemical resistance and are used in demanding applications such as aerospace and medical devices. Understanding the material properties, including melting point, flow behavior, and mechanical properties, is essential to optimize the injection molding process for each material.

My experience also extends to the selection of additives such as fillers, colorants, and flame retardants to modify material properties to meet specific application requirements. This includes considering the compatibility of these additives with the chosen plastic to prevent degradation or other unwanted effects.

Key Topics to Learn for Plastic Injection Interview

- Material Selection: Understanding the properties of various thermoplastics and thermosets (e.g., ABS, PP, PC, Nylon) and their suitability for different applications. Consider factors like strength, flexibility, temperature resistance, and cost.

- Mold Design & Engineering: Familiarize yourself with the principles of mold design, including gate locations, runner systems, cooling channels, and ejection mechanisms. Be prepared to discuss different mold types and their advantages/disadvantages.

- Injection Molding Process Parameters: Master the key process parameters like injection pressure, melt temperature, holding pressure, cooling time, and their impact on part quality and cycle time. Understand how to optimize these parameters for different materials and mold designs.

- Troubleshooting & Problem Solving: Practice identifying and resolving common injection molding defects such as short shots, flash, sink marks, weld lines, and warping. Be ready to discuss root cause analysis and corrective actions.

- Quality Control & Inspection: Understand various quality control methods used in injection molding, including dimensional inspection, visual inspection, and material testing. Be prepared to discuss statistical process control (SPC) techniques.

- Automation & Robotics: Familiarize yourself with automated systems used in injection molding, including robotic handling, automated part removal, and material handling systems. Discuss the benefits of automation in terms of efficiency and consistency.

- Safety Procedures & Regulations: Demonstrate understanding of relevant safety protocols and regulations within a manufacturing environment, especially those related to machinery operation and material handling.

Next Steps

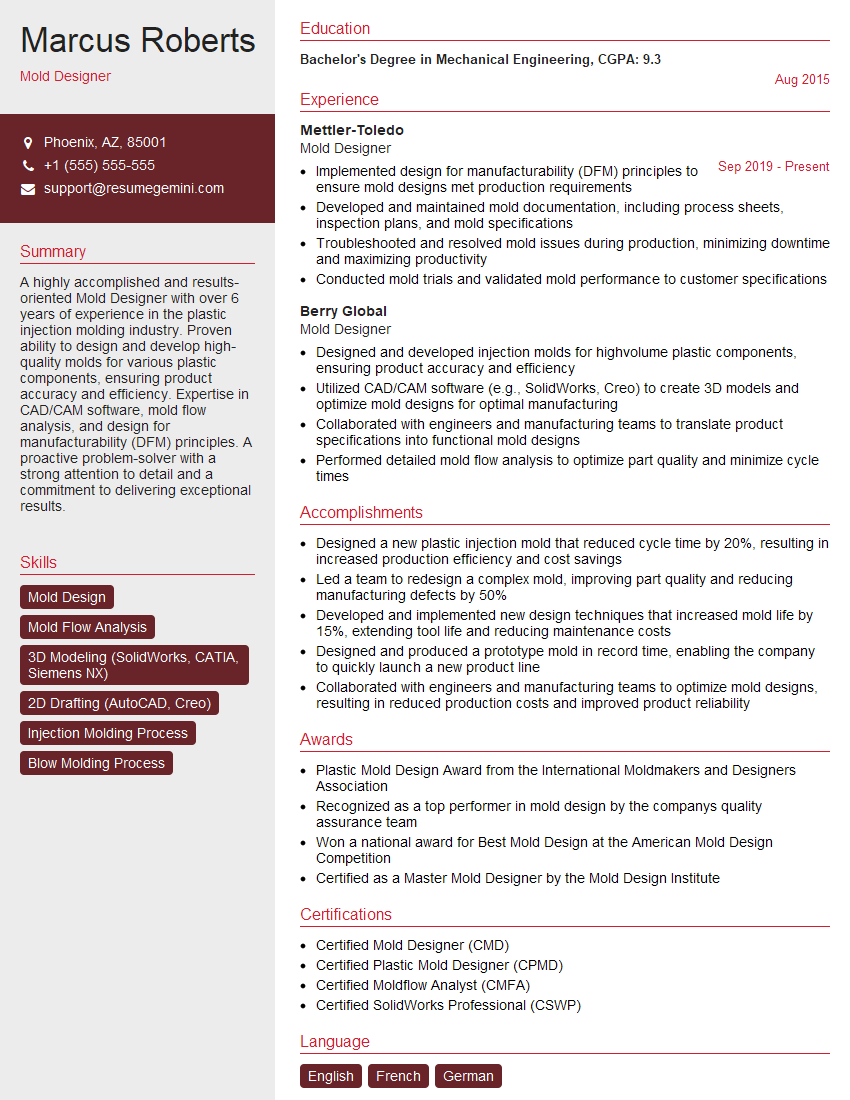

Mastering plastic injection molding opens doors to rewarding careers in manufacturing, engineering, and quality control. A strong understanding of this process is highly sought after, leading to increased job opportunities and career advancement. To maximize your chances of landing your dream job, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of the Plastic Injection industry. Examples of resumes tailored to Plastic Injection roles are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.