The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Miner Certification interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Miner Certification Interview

Q 1. Describe the different types of miner certifications and their requirements.

Miner certification varies significantly depending on location and the specific mining operation. Generally, certifications are tiered, reflecting increasing levels of responsibility and expertise. For example, many jurisdictions offer certifications for:

- Entry-Level Miners: These certifications usually cover basic safety procedures, emergency response, and fundamental mining techniques. Requirements often include completing a safety training program and passing a written and/or practical exam.

- Experienced Miners/Supervisors: These certifications build upon the entry-level requirements and include training on more complex tasks, supervisory responsibilities, and advanced safety protocols. Additional experience is usually required, along with potentially more rigorous exams and practical demonstrations of skill.

- Specialized Certifications: Some regions offer specialized certifications for specific mining tasks or environments, such as those involving explosives handling, ventilation management, or heavy equipment operation. These typically require significant experience and specialized training beyond standard certification.

The specific requirements for each certification will be outlined by the relevant regulatory authority, which varies by country and state/province. For instance, the Mine Safety and Health Administration (MSHA) in the United States has detailed requirements for certification, while other countries will have their own equivalent bodies and standards. It’s crucial for miners to understand the specific requirements in their jurisdiction.

Q 2. Explain the importance of mine ventilation and its impact on safety.

Mine ventilation is paramount to miner safety and productivity. It’s the controlled movement of air within a mine to dilute and remove harmful gases and airborne contaminants like methane, carbon monoxide, and respirable dust. Inadequate ventilation can lead to:

- Oxygen Deficiency: Insufficient air supply can create oxygen-deficient environments, resulting in hypoxia and potentially fatalities.

- Gas Buildup: The accumulation of flammable or toxic gases can create explosion or poisoning hazards.

- Heat Stress: Poor ventilation can lead to excessive heat buildup, causing heat stroke and other heat-related illnesses.

- Dust Accumulation: High dust concentrations can trigger respiratory illnesses like silicosis.

Effective ventilation systems use a combination of fans, shafts, and ventilation controls to maintain safe air quality and airflow. Regular monitoring of air quality using sensors and appropriate safety equipment is essential to mitigate risks associated with inadequate ventilation. Think of it like the lungs of the mine; without proper ventilation, the mine ‘suffocates’.

Q 3. What are the key elements of a comprehensive mine safety plan?

A comprehensive mine safety plan is a proactive document outlining procedures and measures to minimize risks and ensure the safety of miners. Key elements include:

- Hazard Identification and Risk Assessment: A thorough assessment of all potential hazards, from equipment failure to geological instability, and evaluating their associated risks.

- Emergency Response Plan: Detailed procedures for handling various emergencies, including evacuation plans, communication protocols, and first aid procedures. This should include regular drills.

- Training and Education: Comprehensive training programs for all miners, covering safety procedures, emergency response, and hazard recognition. This should be ongoing and cover specific hazards related to the mine.

- Personal Protective Equipment (PPE): Provision and mandatory use of appropriate PPE, such as helmets, respirators, and safety boots, tailored to the specific hazards encountered.

- Maintenance and Inspection Programs: Regular inspection and maintenance of equipment and infrastructure to prevent malfunctions and failures. This includes ventilation systems and ground support.

- Communication and Reporting Systems: Effective communication systems for reporting hazards, incidents, and near misses, coupled with an incident investigation process.

- Compliance with Regulations: Adherence to all relevant health and safety regulations and standards.

A well-executed safety plan is a living document, regularly reviewed and updated based on changes in operations, regulatory requirements, and incident investigation findings. It’s not just a document; it’s a culture of safety.

Q 4. How do you handle emergency situations in a mining environment?

Handling emergency situations in a mining environment requires swift, decisive action and adherence to established protocols. My approach involves:

- Immediate Assessment: Quickly assess the nature and extent of the emergency, identifying immediate threats and the number of individuals affected.

- Initiating Emergency Response: Activating the mine’s emergency response plan, which includes notifying emergency services, initiating evacuation procedures, and deploying appropriate rescue teams.

- Communication and Coordination: Maintaining clear and concise communication with all personnel involved, coordinating rescue efforts and ensuring the safety of responders.

- Evacuation and Rescue: Implementing the pre-determined evacuation routes, utilizing appropriate rescue techniques and equipment to safely evacuate or rescue any trapped personnel.

- First Aid and Medical Assistance: Providing immediate first aid to injured individuals and ensuring timely access to medical care.

- Post-Incident Investigation: Conducting a thorough investigation to determine the root cause of the incident, implement corrective actions to prevent future occurrences, and update the emergency response plan.

Experience has taught me the value of clear communication, well-defined protocols, and continuous training in maintaining a safe working environment. A well-rehearsed emergency response plan can mean the difference between a near-miss and a tragedy.

Q 5. Describe your experience with ground control and risk mitigation.

Ground control and risk mitigation are critical aspects of mine safety. My experience includes:

- Geological Surveys and Modeling: Working with geological data to understand the rock mass properties and identify potential instability zones. This involves techniques like stress analysis and mapping of geological structures.

- Ground Support Design and Implementation: Designing and implementing appropriate ground support measures such as bolting, shotcrete, and other support systems to reinforce unstable areas and prevent roof falls.

- Monitoring and Instrumentation: Utilizing various instruments, such as extensometers and convergence meters, to monitor ground movement and identify potential problems before they escalate.

- Risk Assessment and Mitigation: Conducting regular risk assessments to identify potential ground control hazards and implement appropriate mitigation strategies. This includes evaluating the effectiveness of support systems and adjusting strategies as needed.

For example, in one project, I utilized advanced modeling techniques to identify a previously undetected area of high stress within the mine. This enabled us to proactively implement additional ground support, preventing a potential roof collapse and saving both equipment and lives. This highlighted the importance of continuous monitoring and adaptation of ground control strategies.

Q 6. Explain different methods for preventing mine collapses.

Preventing mine collapses requires a multi-faceted approach combining proactive engineering, monitoring, and effective emergency response. Methods include:

- Proper Ground Support: This is the cornerstone of collapse prevention, encompassing various techniques like rock bolting, roof bolting, and installing rock support beams. The type of support will vary based on geological conditions and the mine’s geometry.

- Geological Surveys and Mapping: Understanding the rock mass’s geological structure, strength, and potential weaknesses is paramount. Detailed geological surveys help identify areas of increased instability.

- Stress Analysis: Analyzing stress within the rock mass to determine the level of support needed. Numerical modeling techniques are commonly used.

- Monitoring and Instrumentation: Continuous monitoring of ground movement using instruments such as convergence meters, inclinometers, and extensometers is vital for early detection of instability.

- Controlled Blasting Techniques: Careful blasting practices to minimize ground vibrations and reduce the risk of fracturing rock masses.

- Mine Design and Layout: Optimizing mine design to minimize stress concentrations and maintain structural stability.

- Regular Inspections and Maintenance: Routine inspections of ground support systems and prompt repairs of any damage or deterioration.

Prevention is always better than cure. A proactive approach that incorporates all these methods is the most effective way to minimize the risk of mine collapses.

Q 7. What are the common hazards associated with underground mining?

Underground mining presents numerous hazards, broadly categorized as:

- Geological Hazards: Ground instability leading to roof falls, sidewall collapses, and rock bursts. Water ingress and flooding are also significant geological risks.

- Environmental Hazards: Exposure to harmful gases (methane, carbon monoxide, etc.), respirable dust (silicosis risk), and extreme temperatures.

- Equipment Hazards: Risks associated with heavy machinery operation, including crush injuries, entanglement, and electrocution.

- Human Factors: Fatigue, lack of training, improper procedures, and poor communication can contribute to accidents.

- Fire and Explosion Hazards: The presence of flammable gases and dust increases the risk of fire and explosions.

Effective risk management involves recognizing these hazards, implementing control measures such as proper ventilation, robust ground support, regular equipment maintenance, thorough worker training, and strict adherence to safety regulations. Each hazard needs a tailored mitigation strategy, but the central theme remains proactive safety management.

Q 8. How do you ensure compliance with all relevant health and safety regulations?

Ensuring compliance with health and safety regulations in mining is paramount. It’s a multi-faceted process involving proactive measures, rigorous documentation, and continuous improvement. My approach begins with a thorough understanding of all applicable legislation, including the Mine Safety and Health Administration (MSHA) regulations in the US, or equivalent regulations in other jurisdictions. This involves staying updated on changes and amendments through regular training and participation in industry conferences.

- Regular Safety Meetings: I conduct and participate in regular safety meetings, ensuring that all personnel are aware of regulations and potential hazards. These meetings often involve hazard identification and risk assessment exercises.

- Training Programs: I oversee and actively participate in the development and delivery of comprehensive training programs for all mine personnel, covering aspects like hazard recognition, emergency response, and the safe operation of equipment. This includes both classroom-based and hands-on training.

- Documentation and Reporting: Meticulous record-keeping is essential. This includes maintaining accurate records of safety inspections, training records, incident reports, and any corrective actions taken. This documentation serves as proof of compliance and helps identify trends or areas for improvement.

- Incident Investigation: A thorough investigation of every incident, no matter how minor, is crucial. This involves identifying root causes, implementing corrective actions, and preventing recurrence. I utilize root cause analysis techniques to ensure effective solutions.

- Audits and Inspections: Regular internal and external audits are conducted to ensure continued compliance and identify any gaps in safety procedures. This involves reviewing documentation, conducting site inspections, and interviewing personnel.

For example, during my time at [Previous Mine Name], we implemented a new system for tracking and reporting near misses, resulting in a significant reduction in actual incidents. This demonstrates the importance of proactive measures and data-driven safety management.

Q 9. What is your experience with mine rescue procedures and equipment?

My experience with mine rescue procedures and equipment is extensive. I’ve been involved in numerous rescue drills and training exercises, including simulations of various emergency scenarios like roof collapses, fires, and gas leaks. I’m proficient in using and maintaining a range of rescue equipment, including self-contained breathing apparatus (SCBA), emergency communication systems, and rescue hoists.

- SCBA Proficiency: I am certified in the use, maintenance, and inspection of SCBA, ensuring its proper functionality in emergency situations. This includes understanding the limitations of the equipment and proper procedures for its use in confined spaces.

- Rescue Techniques: I am skilled in various mine rescue techniques, including rope rescue, confined space rescue, and victim extrication. This includes working with teams and utilizing specialized equipment.

- Emergency Response Planning: I have participated in the development and review of emergency response plans for various mine scenarios. This includes establishing clear communication protocols, evacuation procedures, and emergency contact information.

- Equipment Maintenance: Regular maintenance and inspection of rescue equipment are crucial for ensuring its effectiveness in an emergency. I actively participate in this process to ensure readiness.

In one instance, during a simulated mine fire drill, I effectively led a rescue team, successfully navigating the hazardous environment and rescuing trapped personnel. This experience highlights my ability to lead under pressure and apply learned techniques in a practical setting.

Q 10. Describe your experience with mine mapping and surveying techniques.

My experience with mine mapping and surveying techniques encompasses both traditional and modern methods. I am proficient in using various surveying instruments, including total stations, GPS systems, and laser scanners. I understand the importance of accurate mapping for planning, safety, and efficient resource extraction.

- Traditional Surveying: I’m experienced in using traditional surveying techniques like transit and level surveying, and understand the principles behind them.

- Modern Surveying: I’m proficient in using advanced technologies like GPS and laser scanning for creating accurate 3D models of mine workings.

- Data Analysis: I’m skilled in analyzing survey data to identify potential hazards and optimize mining operations. This includes using software for data processing and visualization.

- Mine Mapping Software: I’m familiar with various mine mapping software packages, including [mention specific software examples], and can create and interpret mine maps for various purposes, including ventilation planning and geotechnical analysis.

For example, I utilized laser scanning technology to create a detailed 3D model of an underground mine, which proved invaluable in identifying areas of structural weakness and optimizing ventilation strategies. This allowed for a safer and more efficient mining operation.

Q 11. Explain different types of mining equipment and their safety features.

Mining involves a wide array of equipment, each with its own safety features. Understanding these features is crucial for preventing accidents.

- Excavating Equipment: This includes excavators, loaders, and bulldozers. Safety features include roll-over protection structures (ROPS), seatbelts, backup alarms, and emergency shut-off switches.

- Haulage Equipment: This covers trucks, trains, and conveyors. Safety features include speed limiters, automatic braking systems, warning lights, and collision avoidance systems.

- Drilling Equipment: This includes drills, blast hole drills, and raise borers. Safety features include dust suppression systems, emergency shut-off mechanisms, and operator protective cabs.

- Underground Mining Equipment: This can include continuous miners, shuttle cars, and roof bolters. Safety features include emergency communication systems, methane detection systems, and collision avoidance technologies.

For instance, understanding the ROPS on an excavator is critical. It’s a safety cage that protects the operator in case of a rollover, and regular inspection and maintenance of this feature are vital.

Q 12. How do you conduct regular safety inspections and audits?

Regular safety inspections and audits are the backbone of a safe mining operation. My approach is systematic and comprehensive, combining planned inspections with impromptu checks.

- Planned Inspections: I develop a schedule for regular inspections of all mine areas, equipment, and facilities. These inspections are documented and any issues are reported and addressed.

- Impromptu Inspections: In addition to scheduled inspections, I perform unplanned inspections to assess the general safety awareness and practices of personnel.

- Checklists: Detailed checklists are used to ensure all aspects of safety are reviewed, including equipment functionality, housekeeping, and adherence to safety procedures.

- Corrective Actions: Any identified hazards or deficiencies are addressed immediately with appropriate corrective actions. This includes implementing engineering controls, administrative controls, and personal protective equipment (PPE).

- Audits: Regular audits are conducted to ensure the effectiveness of the safety management system. These may include internal audits by mine personnel and external audits by regulatory bodies.

For example, during a routine inspection, we discovered a loose cable near a piece of heavy equipment. Immediate action was taken to secure the cable, preventing a potential trip hazard.

Q 13. What are the different types of respiratory protection used in mining?

Respiratory protection in mining is essential due to potential exposure to dust, gases, and fumes. The choice of respirator depends on the specific hazards present.

- Dust Masks: These are used for protection against respirable dust. N95 masks are commonly used, offering a certain level of protection. More specialized respirators may be needed depending on the type and concentration of dust.

- Gas Masks: These offer protection against specific gases and vapors. The type of gas mask used depends on the type of gas present, and proper fit testing is crucial for effectiveness.

- Self-Contained Breathing Apparatus (SCBA): SCBAs provide a complete respiratory protection system, independent of the surrounding atmosphere. They are used in emergency situations and in areas with immediately dangerous to life or health (IDLH) conditions.

- Supplied-Air Respirators (SAR): SARs supply breathable air from a source outside the hazardous area, offering protection in areas with high concentrations of contaminants.

Proper training and fit testing are critical to ensure the effective use of any respirator. Improperly fitted or used respirators offer limited or no protection.

Q 14. Describe your understanding of mine ventilation planning and design.

Mine ventilation planning and design is crucial for ensuring the safety and health of miners. It involves controlling airflow to dilute and remove harmful gases, maintain acceptable temperatures, and provide adequate oxygen.

- Airflow Modeling: Computer modeling is used to simulate airflow patterns within the mine, ensuring adequate dilution of harmful gases and proper distribution of fresh air.

- Ventilation Network Design: The mine ventilation system needs to be designed to efficiently move air throughout the mine workings, taking into account factors like airflow resistance, fan capacity, and the location of air intakes and exhausts.

- Gas Monitoring: Continuous monitoring of gas levels (methane, carbon monoxide, etc.) is crucial to ensure the ventilation system is effective and to identify potential hazards promptly.

- Emergency Ventilation: Plans must be in place for maintaining ventilation during emergencies, such as power outages or equipment failures. This often involves backup power sources and alternative ventilation pathways.

- Regulatory Compliance: Ventilation plans must comply with all relevant health and safety regulations, ensuring adequate airflow and gas control.

For example, I was involved in the design of a ventilation system for a new underground mine. Through careful modeling and planning, we ensured adequate airflow throughout the mine, preventing the buildup of hazardous gases and maintaining comfortable working conditions for miners.

Q 15. How do you manage risk assessment and control in a mining operation?

Risk assessment and control in mining is a systematic process crucial for ensuring worker safety and operational efficiency. It involves identifying potential hazards, analyzing their risks, implementing control measures, and monitoring their effectiveness. Think of it like building a house – you wouldn’t start without blueprints and safety precautions.

The process typically follows these steps:

- Hazard Identification: This involves systematically identifying all potential hazards present in the mining operation, from equipment malfunctions and ground instability to chemical exposure and ergonomic issues. Methods include site inspections, job hazard analyses (JHAs), and reviewing historical incident reports.

- Risk Assessment: Once hazards are identified, we assess the likelihood and severity of each hazard occurring and the potential consequences. This often involves using a risk matrix that categorizes risks as low, medium, or high. For example, a high risk might be a potential roof collapse in an underground mine.

- Control Measures Implementation: Based on the risk assessment, we implement control measures to mitigate the risks. These measures can be hierarchical, following the hierarchy of controls: Elimination, Substitution, Engineering Controls, Administrative Controls, and Personal Protective Equipment (PPE). For a high-risk roof collapse, engineering controls like bolting and supporting the roof would be implemented.

- Monitoring and Review: The effectiveness of the implemented controls is regularly monitored through inspections, audits, and data analysis. The risk assessment is reviewed and updated periodically to reflect changes in the operation or new information.

For example, in a surface mining operation, identifying the risk of equipment collisions would involve reviewing traffic patterns, implementing speed limits, and providing clear signage and communication systems. Regular monitoring would involve checking for compliance with these rules.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the signs and symptoms of common mining-related illnesses?

Mining-related illnesses are a serious concern, often stemming from exposure to hazardous substances or demanding working conditions. Early detection is crucial for effective treatment and prevention.

- Silicosis: This lung disease is caused by inhaling silica dust, common in mining operations. Symptoms include shortness of breath, cough, and fatigue. It can progress to severe respiratory impairment.

- Coal Workers’ Pneumoconiosis (Black Lung): This lung disease affects coal miners due to inhaling coal dust. Symptoms are similar to silicosis, but the dust accumulation can cause progressive lung damage.

- Asbestosis: Exposure to asbestos fibers, historically used in mining equipment and infrastructure, can lead to this debilitating lung disease, with symptoms including shortness of breath and chest pain.

- Noise-Induced Hearing Loss: Prolonged exposure to loud machinery and equipment can cause significant hearing loss. Symptoms include tinnitus (ringing in the ears) and difficulty understanding speech.

- Musculoskeletal Disorders (MSDs): Repetitive movements and awkward postures can cause MSDs like back pain, carpal tunnel syndrome, and tendonitis.

Regular medical examinations, including lung function tests and hearing tests, are essential for early detection and management of these illnesses. Implementing stringent dust control measures, using hearing protection, and promoting ergonomic practices are vital preventative measures.

Q 17. What is your experience with emergency response and evacuation planning?

Emergency response and evacuation planning are paramount in mining, given the inherent risks involved. My experience encompasses developing and implementing comprehensive plans tailored to various mining scenarios. This involves detailed risk assessments, establishing clear communication protocols, and conducting regular drills to ensure preparedness.

I have been involved in creating evacuation plans for both underground and surface mines, factoring in factors such as escape routes, refuge chambers, communication systems, and emergency response teams. We conduct regular drills to ensure familiarity and competence in responding to various emergencies like equipment failures, ground collapse, or fires. We also incorporate various technologies such as GPS tracking systems to monitor personnel locations during evacuations.

For instance, in one project, we developed a tiered evacuation plan for an underground mine, considering different scenarios and levels of urgency. This involved establishing clear communication protocols using both dedicated radio systems and personal emergency response systems. Regular drills and simulations ensured that every worker was familiar with their assigned roles and escape routes.

Q 18. Describe your knowledge of mine emergency procedures and protocols.

Mine emergency procedures and protocols are crucial for safeguarding lives and minimizing damage during unforeseen events. They should be clearly defined, regularly reviewed and updated, and practiced frequently to ensure effectiveness. These procedures need to cover all aspects of an emergency, from initial detection to post-incident investigation.

My knowledge includes:

- Emergency Response Plans: These plans outline the procedures to follow during various emergencies, including fire, explosions, ground collapse, flooding, and equipment malfunctions. The plans should specify roles and responsibilities for emergency response teams, communication protocols, evacuation routes, and assembly points.

- Emergency Communication Systems: Reliable and redundant communication systems are crucial for coordinating rescue efforts and providing information during an emergency. These could include dedicated radio systems, personal emergency response systems, or satellite communication systems.

- Rescue and Recovery Procedures: Detailed procedures should be in place for locating, rescuing, and providing first aid to injured personnel. These procedures should take into account the specific hazards present in the mining operation.

- Post-Incident Investigation: A thorough investigation of every incident is necessary to identify root causes, implement corrective actions, and prevent future occurrences. This investigation should involve analyzing the incident, interviewing witnesses, and reviewing relevant documentation.

For example, I’ve helped implement a system using color-coded warning signals and pre-established emergency assembly points for a surface mine operation. The system improved communication and response time during drills significantly.

Q 19. Explain the importance of proper training for mine workers.

Proper training for mine workers is non-negotiable. It’s the cornerstone of a safe and productive mining operation. Untrained workers are a recipe for accidents and injuries. Think of it as providing a skilled surgeon with the best tools but no training; the outcome would be disastrous.

The importance lies in several key areas:

- Safety Awareness: Training instills a strong safety culture and awareness of potential hazards, emphasizing safe work practices and the importance of following procedures.

- Competency Development: Training equips workers with the necessary skills and knowledge to perform their jobs safely and efficiently, reducing the risk of accidents and injuries.

- Emergency Preparedness: Training in emergency response and evacuation procedures ensures that workers know what to do in case of an emergency, improving the chances of survival and minimizing the impact of incidents.

- Compliance with Regulations: Adequate training is crucial for meeting regulatory requirements and ensuring legal compliance.

- Productivity Improvement: Well-trained workers are more efficient and productive, reducing operational costs and improving the overall performance of the mining operation.

For example, training on safe equipment operation prevents accidents and protects the operator and those nearby. Training on hazard recognition and risk management can reduce the occurrence of incidents and injuries.

Q 20. How do you conduct effective training and ensure competency?

Effective training requires a multifaceted approach that ensures competency and retention of knowledge. It’s not just about delivering information; it’s about fostering understanding and practical application.

My approach involves:

- Needs Assessment: A thorough needs assessment identifies the specific training requirements for each role and the gaps in existing knowledge and skills.

- Curriculum Development: A well-structured curriculum is developed, incorporating various training methods such as classroom instruction, hands-on training, simulations, and e-learning modules. The curriculum should be regularly updated to reflect changes in technology, regulations, and best practices.

- Delivery Methods: I use a variety of delivery methods to cater to different learning styles and ensure effective knowledge transfer. This includes interactive sessions, case studies, practical exercises, and on-the-job training.

- Assessment and Evaluation: Training effectiveness is assessed through practical evaluations, written tests, and observation of performance. This helps identify areas for improvement in the training program.

- Competency Verification: Competency verification is essential to ensure that workers have acquired the necessary skills and knowledge to perform their tasks safely and efficiently. This might involve practical demonstrations, certifications, or licensing.

For example, I’ve developed a training program for heavy equipment operators using a combination of classroom instruction, simulated exercises, and hands-on training on actual equipment in a controlled environment. This ensures operators are proficient and confident before operating heavy machinery in the field.

Q 21. What is your experience with the use of personal protective equipment (PPE)?

Personal Protective Equipment (PPE) is the last line of defense in preventing workplace injuries. My experience encompasses selecting, implementing, and maintaining appropriate PPE for various mining operations, emphasizing both worker comfort and regulatory compliance. It’s about finding the right balance between protection and practicality.

My experience covers:

- PPE Selection: The selection of PPE depends on the specific hazards present in the work environment. This involves identifying the risks, selecting appropriate PPE based on standards and regulations (e.g., hard hats, safety glasses, respirators, hearing protection, safety footwear, high-visibility clothing).

- Training and Fit Testing: Workers must be trained on the proper use and maintenance of PPE. For respirators, proper fit testing is crucial to ensure effective protection.

- Inspection and Maintenance: Regular inspection and maintenance of PPE are vital to ensure its continued effectiveness. Damaged or worn-out PPE must be replaced immediately.

- Enforcement: Enforcing the use of PPE is essential to ensure worker safety. This involves regular monitoring, providing feedback, and addressing non-compliance.

For example, in an underground mining operation, we implemented a comprehensive PPE program that included specialized respirators for dust control, reinforced safety footwear to protect against falling objects, and self-rescuers for emergency situations. Regular inspections and training ensured that all workers understood the importance of using the provided PPE correctly.

Q 22. How do you ensure effective communication among the mining team?

Effective communication in a mining team is paramount for safety and productivity. It’s not just about talking; it’s about ensuring everyone understands, participates, and feels heard. My approach involves a multi-faceted strategy:

- Regular Toolbox Talks: Short, frequent meetings to address immediate safety concerns, upcoming tasks, and share best practices. For example, before starting a blasting operation, we’d review procedures and emergency protocols.

- Open-Door Policy: Creating a culture where team members feel comfortable raising concerns, no matter how small. I’ve personally found that addressing minor issues proactively prevents them from escalating into major problems.

- Formal Communication Channels: Utilizing email, reports, and documented procedures ensures clarity and accountability. This includes incident reports, safety audits, and training records.

- Utilizing Technology: Implementing communication platforms like instant messaging for quick updates, especially in remote areas, enhances communication efficiency. This helps prevent misunderstandings arising from delayed or missed communications.

- Regular Feedback Sessions: Conducting one-on-one meetings to gather feedback, address individual concerns, and provide constructive criticism allows for continuous improvement in communication and teamwork.

By combining these methods, I foster a culture of transparent and effective communication, leading to a safer and more productive mining environment.

Q 23. Describe your experience with accident investigation and reporting.

Accident investigation and reporting are critical for preventing future incidents. My approach follows a structured methodology consistent with best practices:

- Immediate Response: Securing the accident site, ensuring the safety of personnel, and providing immediate medical attention.

- Fact-Finding: Gathering evidence systematically – witness statements, photos, videos, equipment data – and using detailed checklists to ensure nothing is overlooked.

- Root Cause Analysis: Employing techniques like the ‘5 Whys’ to identify the underlying cause of the accident, not just the immediate trigger. This process helped me uncover a systemic issue with equipment maintenance in a previous investigation, leading to significant improvements.

- Corrective Actions: Implementing preventative measures – improved training, new safety procedures, equipment modifications – based on the root cause analysis to prevent recurrence. In one case, we implemented a new system of tagging and inspecting high-voltage equipment.

- Reporting: Generating comprehensive reports including accident details, root cause analysis, corrective actions, and recommendations for future improvements. These reports are distributed to relevant stakeholders and used for continuous safety improvement.

Accurate, thorough investigation and transparent reporting are crucial for demonstrating accountability and building a safer workplace. My experience demonstrates a commitment to continuous improvement and learning from mistakes.

Q 24. What is your understanding of the legal and regulatory framework for mining?

The legal and regulatory framework for mining is complex and varies by jurisdiction. My understanding encompasses several key areas:

- Mine Health and Safety Regulations: I’m intimately familiar with the specific regulations related to mine safety, including those covering ventilation, ground control, hazard identification and risk assessment, emergency response, and worker training. These are not merely guidelines but legally binding requirements that I meticulously ensure are followed.

- Environmental Regulations: I understand regulations regarding waste disposal, water management, air emissions, and land reclamation. Sustainable mining practices are essential, and compliance is crucial for operational license renewal and avoiding legal penalties.

- Occupational Health and Safety Legislation: I am well versed in laws concerning worker rights, safety training requirements, and reporting protocols for injuries and illnesses. We ensure regular training and the provision of necessary safety equipment.

- Mining Licenses and Permits: I understand the process of obtaining and maintaining necessary permits for mining operations, including those relating to environmental impact and land use. Compliance ensures the legality of our operations.

Staying updated on changes to regulations and ensuring strict compliance are fundamental responsibilities, as any non-compliance can lead to serious legal repercussions, including fines, operational shutdowns, and even criminal charges.

Q 25. How do you handle conflicts and disputes related to safety issues?

Conflicts and disputes regarding safety issues require a tactful and decisive approach. My strategy involves:

- Immediate Intervention: Addressing any safety concerns raised immediately, preventing escalation. This may involve mediating between individuals or teams.

- Formal Investigation: If the conflict involves a safety violation or incident, a thorough investigation is carried out according to established protocols. This ensures impartiality and a fair outcome.

- Mediation and Negotiation: Where appropriate, I facilitate mediation between conflicting parties to reach a mutually agreeable solution. This process often involves listening to all perspectives, identifying the root causes of disagreement, and proposing constructive compromises.

- Disciplinary Action: In cases of serious safety violations or willful disregard for rules, disciplinary action, as per company policy and relevant regulations, is taken. This step is never taken lightly, but ensuring adherence to safety standards is of paramount importance.

- Documentation: All actions and resolutions are thoroughly documented to provide a record of events and demonstrate accountability.

My goal is to resolve conflicts fairly and swiftly, ensuring that safety remains the top priority. Transparency and a commitment to due process are crucial to maintaining a positive and productive working environment.

Q 26. Describe your experience with the implementation of new safety technologies.

Implementing new safety technologies is a key element of modern mining. My experience includes:

- Automated Haulage Systems: We’ve successfully implemented automated truck systems in our operations, reducing human error in transportation and improving overall safety. The training involved simulating scenarios to ensure all personnel were fully prepared for the transition.

- Ground Control Monitoring Systems: Integrating real-time ground movement monitoring systems helped us detect potential instability issues early, allowing for proactive intervention to prevent cave-ins. The data analysis provided insights into ground behavior, allowing more effective preventative strategies.

- Personal Protective Equipment (PPE) Upgrades: Introducing advanced PPE, such as improved respirators or impact-resistant clothing, has minimized the risk of injuries. This also involved robust training programs on the proper use and maintenance of these technologies.

- Remote Operations and Tele-Robotics: We’ve explored the potential of remote operations for hazardous tasks, such as underground inspections. This reduces human exposure to dangerous environments.

Technology adoption requires careful planning, employee training, and ongoing monitoring. My focus is on choosing technologies that demonstrably improve safety and productivity while minimizing disruption to operations.

Q 27. Explain your understanding of different types of mining methods.

Mining methods vary widely depending on the type of ore body, geological conditions, and economic factors. My understanding encompasses:

- Open-Pit Mining: This method is used for large, near-surface deposits, typically involving excavation and removal of overlying material. It’s cost-effective but has a significant environmental impact if not managed correctly.

- Underground Mining: Several techniques fall under this umbrella, including:

- Room and Pillar: Used for relatively flat, thick deposits, creating rooms supported by pillars of ore.

- Longwall Mining: Efficient for extensive, flat seams of coal or other minerals, using a long wall of machinery to extract the ore.

- Sublevel Stoping: Suitable for steeply dipping ore bodies, involving drilling and blasting from sub-levels.

- Solution Mining: This method involves dissolving the ore in situ using a solvent, then extracting the solution. It is less disruptive to the environment but suitable only for soluble ores.

Choosing the appropriate mining method requires a thorough understanding of geological conditions, resource characteristics, and economic factors. Safety considerations are paramount in selecting and implementing each method.

Q 28. How do you ensure the sustainability of mining operations?

Sustainable mining operations prioritize environmental protection, social responsibility, and economic viability. My approach to sustainability includes:

- Environmental Impact Assessment (EIA): Conducting thorough EIAs to understand potential environmental impacts and design mitigation strategies. This involves careful planning and collaboration with environmental agencies.

- Water Management: Implementing water management strategies to minimize water usage and prevent contamination. This includes recycling water for industrial processes and treating wastewater before discharge.

- Waste Management: Developing effective waste management plans to minimize waste generation and properly manage tailings and other waste products. This may involve the implementation of tailings dams that meet the highest safety standards.

- Rehabilitation and Reclamation: Planning for site rehabilitation and reclamation after mining operations cease, restoring the land to a productive state. This includes the careful planning and implementation of revegetation projects.

- Community Engagement: Engaging with local communities to address their concerns and build trust. Transparency and open communication are vital for achieving social license to operate.

Sustainable mining isn’t just an environmental issue; it’s about building a responsible business that benefits both the environment and the community while ensuring long-term economic success. It’s about leaving a positive legacy after mining operations have concluded.

Key Topics to Learn for Miner Certification Interview

- Mine Safety Regulations and Procedures: Understanding and applying relevant safety regulations, emergency procedures, and hazard identification techniques.

- Ventilation Systems: Analyzing ventilation plans, troubleshooting ventilation problems, and ensuring adequate airflow in underground mines.

- Ground Control: Principles of ground support, understanding geological factors affecting mine stability, and implementing effective ground control measures.

- Mine Surveying and Mapping: Interpreting mine maps, understanding surveying techniques, and applying this knowledge to practical mine planning and development.

- Emergency Response and Rescue: Knowledge of emergency procedures, rescue techniques, and effective communication during critical situations.

- Mine Equipment Operation and Maintenance: Understanding the safe operation and maintenance of various mining equipment, including preventative maintenance strategies.

- Hazard Recognition and Risk Assessment: Identifying potential hazards, conducting risk assessments, and implementing control measures to mitigate risks.

- Mine Planning and Design: Understanding the principles of mine design, including layout, extraction methods, and environmental considerations.

- Environmental Regulations and Compliance: Understanding and adhering to environmental regulations related to mining operations, including waste management and water treatment.

- Communication and Teamwork: Effective communication skills and the ability to collaborate effectively within a team environment are crucial for mine safety and productivity.

Next Steps

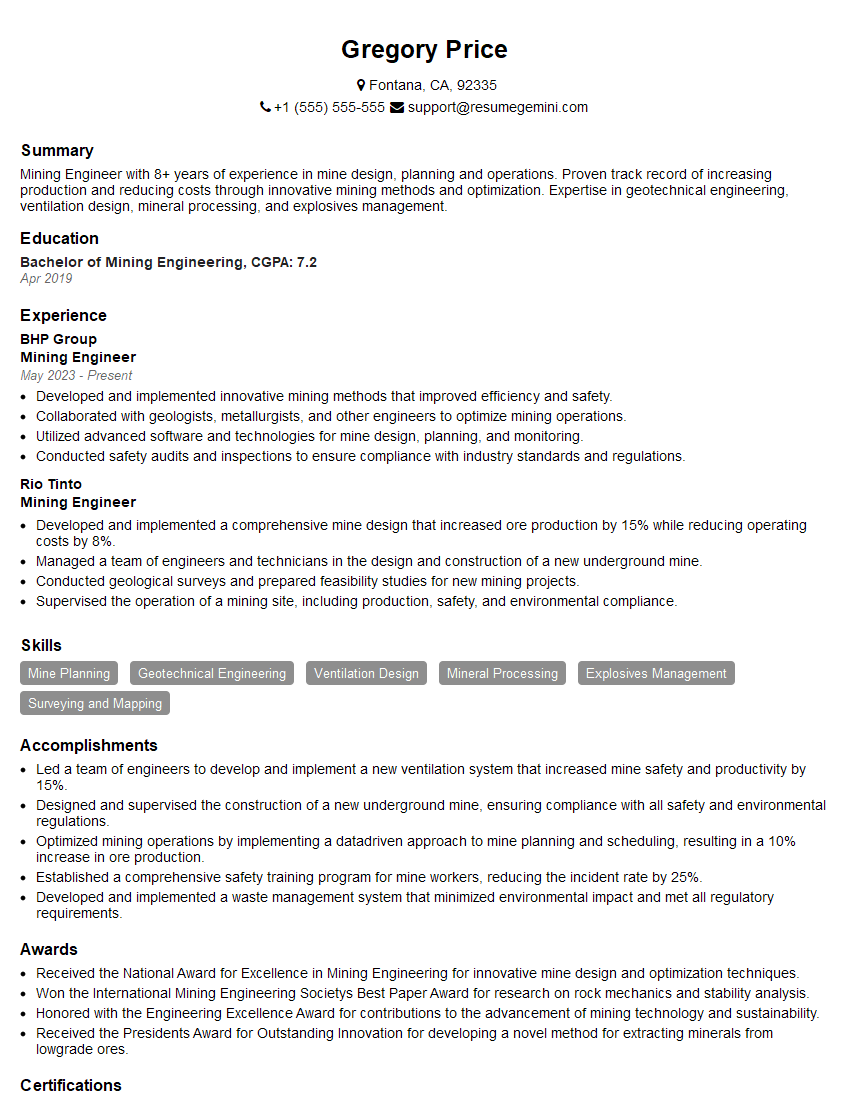

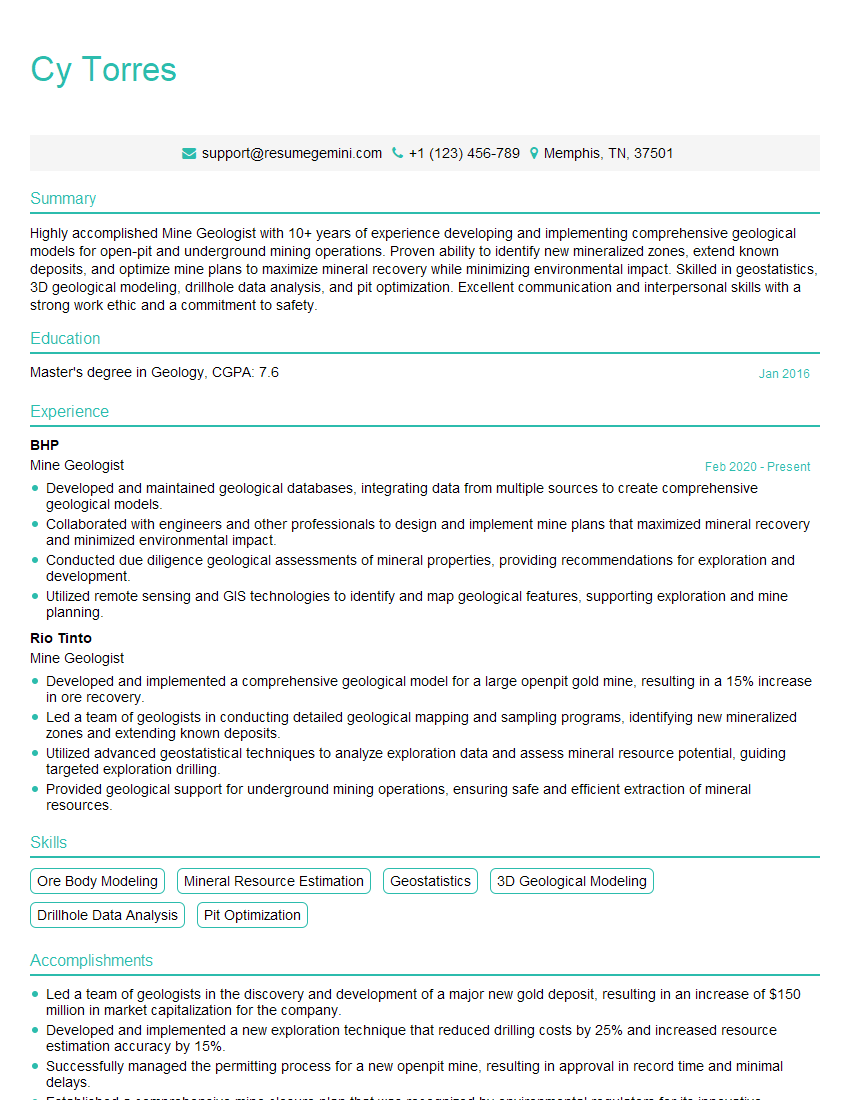

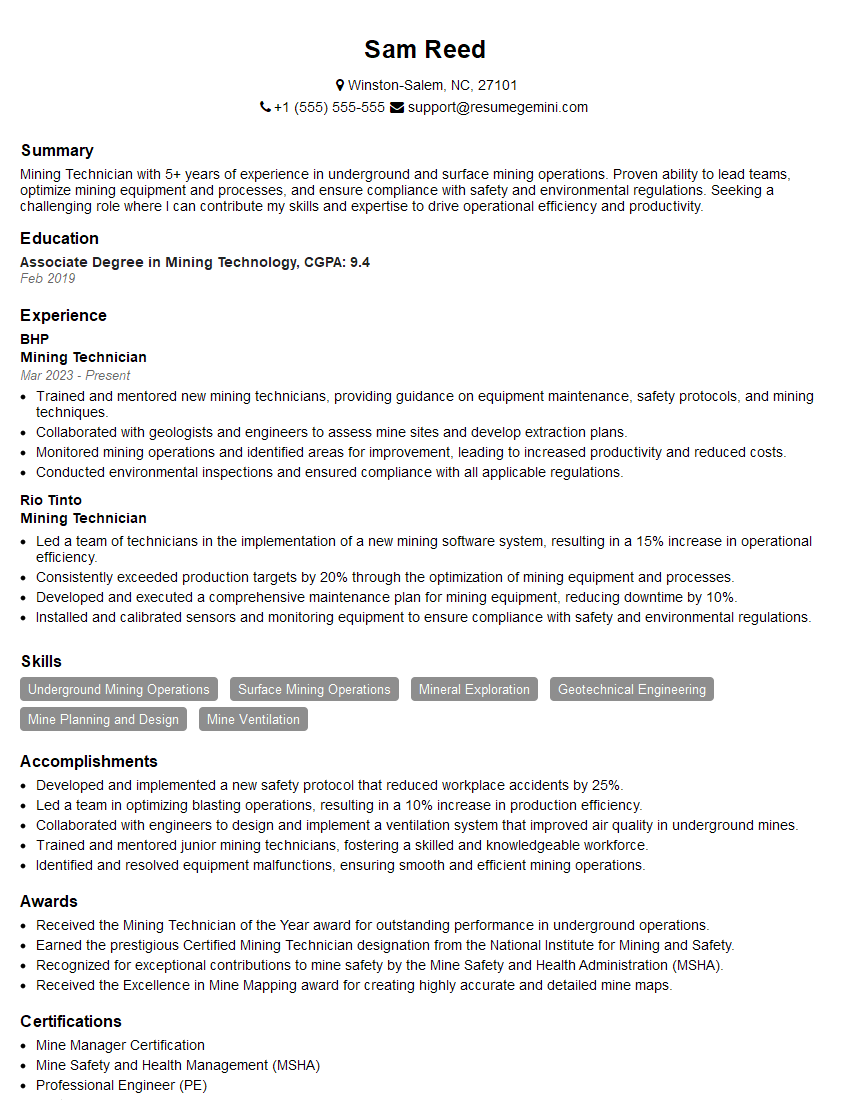

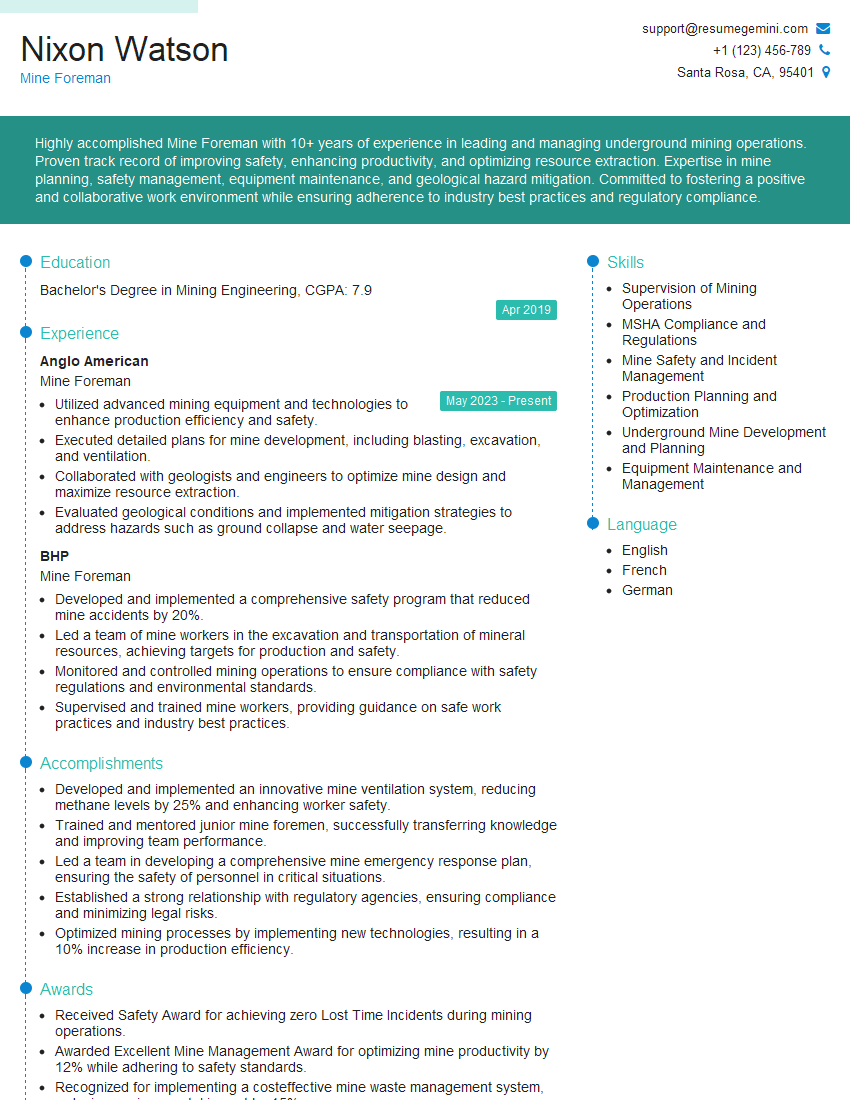

Mastering Miner Certification significantly enhances your career prospects, opening doors to higher-paying roles and increased responsibility within the mining industry. A strong resume is your key to unlocking these opportunities. To ensure your qualifications shine, create an ATS-friendly resume that effectively highlights your skills and experience. We recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored specifically to Miner Certification, helping you present yourself in the best possible light to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.