Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Veneer Cutting and Preparation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Veneer Cutting and Preparation Interview

Q 1. Explain the difference between rotary cut, sliced, and peeled veneer.

The three main methods for cutting veneer – rotary, sliced, and peeled – each produce a distinct product with unique characteristics. Think of it like slicing a loaf of bread: each method yields a different texture and appearance.

- Rotary Cut: This is the fastest and most economical method. A large log is rotated against a very sharp knife, creating a continuous, long sheet of veneer. The resulting grain is often characterized by a distinctive, swirling or ‘cathedral’ pattern. It’s ideal for applications where cost-effectiveness is crucial, like plywood backing.

- Sliced Veneer: Here, the log is sliced like a salami, yielding thinner sheets than rotary cutting. The knife moves parallel to the growth rings, resulting in a flatter, more consistent grain pattern with less pronounced figure. This method is preferred for higher-quality applications where a refined grain is desired, such as fine furniture.

- Peeled Veneer: This method, similar to rotary cutting, involves rotating a log, but against a smaller, more precise blade. It produces thinner sheets than rotary-cut veneer and is particularly suited for smaller logs or those with challenging grain structures. Peeled veneer often has a more uniform appearance than rotary cut.

The choice of cutting method depends heavily on the desired aesthetic, the type of wood, and the budget. For example, a high-end piano might use sliced veneer for its delicate figure, while mass-produced furniture might utilize rotary-cut for its affordability.

Q 2. Describe the process of veneer splicing.

Veneer splicing is the process of joining two or more veneer pieces end-to-end to create longer sheets. Imagine it like creating a longer piece of fabric by sewing together smaller pieces. It’s crucial for maximizing the use of valuable veneer and achieving long, continuous runs for large projects.

The process generally involves:

- Careful selection: Matching veneer pieces in terms of color, grain pattern, and thickness is crucial for an invisible join.

- Preparation: The ends of the veneer sheets are precisely trimmed and prepared for joining. This often includes precise planing to ensure a flat, even surface.

- Joining: The prepared edges are aligned and bonded using an appropriate adhesive, often a high-strength, water-resistant glue. The joint is then pressed firmly to ensure proper adhesion.

- Finishing: After the glue has cured, the joint is carefully sanded and finished to create a seamless appearance. Special techniques like feather-edge splicing, where the edges are tapered to blend seamlessly, can be used for even more refined results.

The quality of the splice depends on the precision of the preparation and the choice of adhesive. A poorly executed splice will be immediately noticeable and detract from the final product.

Q 3. What are the common defects found in veneer and how are they addressed?

Veneer, despite its beauty, can suffer from various defects. These can be inherent to the wood itself or arise during the cutting and processing stages. These defects need careful consideration and sometimes require specific solutions.

- Knots: These are imperfections where branches were once attached to the tree. While some knots add character, large or loose knots can weaken the veneer and may need to be filled or avoided entirely.

- Splits and Checks: These are cracks in the veneer, usually caused by stresses within the wood or drying issues. These can be filled with wood filler and carefully sanded, or the affected area may need to be cut out if severe.

- Wane: This refers to the presence of bark or lack of wood on the edge of a veneer sheet. This is often acceptable at the edges, but large areas of wane in the center of a sheet would compromise the piece.

- Pitch Pockets: These are small pockets of resin trapped in the wood. While aesthetically undesirable in some instances, they can be addressed with filling or sanding.

- Mineral Streaks: These dark lines in the wood are caused by mineral deposits and can be challenging to address but may add to the character of some woods.

Addressing defects often involves a combination of careful selection of veneers, filling techniques, and creative cutting to minimize the impact of flaws. The approach taken depends entirely on the severity of the defect and the intended use of the veneer.

Q 4. How do you ensure the proper alignment and matching of veneer sheets?

Proper alignment and matching of veneer sheets are critical for creating aesthetically pleasing and structurally sound panels. Think of it as constructing a mosaic – each piece must be carefully placed to create the desired overall image.

Techniques for achieving this include:

- Bookmatching: Sheets are arranged so that the grain mirrors each other, creating a symmetrical effect. This is particularly effective for highlighting the wood’s figure.

- Slipmatching: Sheets are laid side-by-side with a slight offset, creating a more continuous grain pattern.

- Random Matching: Sheets are arranged in a seemingly random pattern, which can work well for certain aesthetics and minimizes noticeable repeating patterns.

- Using Templates: Pre-cut templates can be utilized to lay out veneer sheets and ensure proper alignment, especially helpful for complex designs.

- Careful Layout and Planning: Prior to gluing, a careful layout of the veneer sheets is critical to minimize waste and ensure a consistent pattern.

Careful planning and execution are crucial. Software tools can assist with generating accurate layouts, while skilled craftsmanship is essential for precise placement and gluing.

Q 5. What safety precautions are necessary when operating veneer cutting equipment?

Veneer cutting equipment involves sharp blades and powerful machinery, demanding strict adherence to safety protocols. Neglecting these can lead to severe injury.

- Personal Protective Equipment (PPE): Always wear appropriate safety glasses, hearing protection, and gloves. Cut-resistant gloves are essential when handling sharp blades.

- Machine Guards: Ensure all safety guards are in place and functioning correctly before operating any machinery. Never attempt to bypass safety features.

- Proper Training: Only operate equipment after receiving adequate training and understanding all safety procedures.

- Machine Maintenance: Regularly inspect and maintain machinery to ensure it’s in safe operating condition. Report any malfunctions immediately.

- Clear Work Area: Maintain a clean and organized work area to prevent accidents caused by tripping or cluttered surroundings.

- Emergency Procedures: Be familiar with emergency procedures and know the location of first-aid equipment and emergency shut-off switches.

Safety is not an option, but a paramount concern in veneer cutting. A moment of carelessness can lead to life-altering consequences.

Q 6. Explain the importance of veneer moisture content and its effect on processing.

Veneer moisture content is critical throughout the entire processing chain, impacting everything from cutting and gluing to the final stability and appearance of the product. Think of it as the ‘hydration’ level of the veneer – too much or too little can lead to problems.

High moisture content can lead to:

- Dimensional Instability: The veneer will shrink and warp as it dries, leading to unsightly distortions and potentially affecting structural integrity.

- Glue Failure: Excessive moisture can interfere with the curing process of adhesives, leading to weak bonds.

Low moisture content can result in:

- Brittleness: The veneer becomes fragile and prone to cracking or breaking during processing or in the finished product.

- Difficulty in Gluing: Dry veneer is more difficult to glue effectively because it absorbs less adhesive.

Optimal moisture content is typically determined by the wood species and the intended application. Careful monitoring and control of moisture content using methods like kilning and conditioning is crucial for ensuring the quality and durability of the final product.

Q 7. How do you determine the appropriate glue type for veneer applications?

Selecting the right glue is crucial for achieving a strong, durable, and aesthetically pleasing bond in veneer applications. The choice depends on several factors.

- Substrate: The type of wood being used will influence glue selection. Some glues bond better to certain species than others.

- Application: The intended use of the finished product influences the type of glue needed. Interior applications might require a different glue than exterior applications where water resistance is paramount.

- Open Time: The glue’s open time refers to the time before it sets. This is important for determining the time available for positioning and clamping the veneer.

- Temperature and Humidity: Environmental conditions influence glue performance. Some glues are more sensitive to temperature and humidity changes.

Common glue types include:

- Polyvinyl Acetate (PVA): This is a common, water-based glue suitable for many interior applications.

- Polyurethane (PU): Often chosen for its excellent water resistance, often preferred for exterior use or high-humidity environments.

- Animal Glue: A traditional glue known for its flexibility but less water resistance compared to modern glues.

Consulting glue manufacturers’ recommendations and conducting tests are vital to determine the best glue for a specific application. The wrong glue can lead to glue failure and compromise the structural integrity of the final product.

Q 8. Describe your experience with different veneer cutting tools and machinery.

My experience with veneer cutting tools and machinery spans over 15 years, encompassing a wide range of technologies. I’m proficient in operating both traditional and modern equipment. This includes rotary slicing lathes for producing large quantities of consistent veneer, splicing machines for seamlessly joining veneer sheets, and various types of veneer clippers for cutting veneer to precise dimensions. I’ve also worked extensively with more specialized tools like veneer peeling machines for working with burls and other uniquely figured wood, and specialized knives and blades for different veneer types and thicknesses. For example, I’ve found that using a sharper knife on a rotary lathe significantly reduces veneer tear-out, resulting in higher yields and less waste. My understanding extends beyond operation to maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

- Rotary Lathes: These are crucial for high-volume production of consistent veneer sheets.

- Veneer Clippers: Used for precise cutting to size and shape.

- Splicing Machines: Essential for joining veneer sheets, minimizing visible seams.

- Peeling Machines: Specialized for working with figured wood, demanding precise control.

Q 9. What are the best practices for storing veneer to prevent damage?

Proper veneer storage is paramount to preventing damage and preserving its quality. Think of veneer as a delicate fabric; it needs to be handled with care. The key is to maintain a stable environment. This includes controlling humidity and temperature to prevent warping, cupping, or checking (cracking). Ideally, veneer should be stored in a climate-controlled space with a consistent humidity level between 40% and 60%. Veneer should be stored flat, ideally on a clean, flat surface and separated by layers of acid-free paper or protective interleaving sheets to prevent sticking. Furthermore, the storage area should be free from dust, direct sunlight, and extreme temperature fluctuations. Stacking the veneer carefully, avoiding excessive weight on any one area, prevents deformation. For large-scale operations, utilizing specialized veneer storage racks with adequate support is crucial. Remember, preventing damage at this stage saves considerable time and resources down the line.

Q 10. How do you handle veneer waste and disposal?

Veneer waste management involves a multi-pronged approach focused on responsible disposal and resource optimization. The first step is minimizing waste during the cutting process. This requires expertise in efficient cutting techniques and the use of optimized cutting patterns to maximize veneer yield from each log. Waste wood is often used for creating smaller, less demanding items such as utility blocks or fuel for kilns, depending on the wood type and local regulations. Additionally, scraps and unusable veneer can sometimes be recycled for other purposes like biomass energy production or even composted. Proper segregation and labeling of waste streams are essential, particularly for any hazardous waste such as adhesives or finishes. All disposal must comply with relevant environmental regulations and local waste management ordinances.

Q 11. How do you inspect veneer for quality before and after processing?

Veneer inspection is a critical step, performed both before and after processing. Pre-processing inspection involves evaluating the veneer logs for defects such as knots, splits, and discoloration. This allows for selection of the most suitable logs and appropriate cutting strategies to minimize defects in the final product. I use a combination of visual inspection and sometimes specialized tools like moisture meters to assess wood quality. Post-processing inspection involves scrutinizing the cut veneer sheets for any flaws arising from the cutting process, such as knife marks, tear-out, or inconsistencies in thickness. Quality standards are rigorously applied to ensure uniformity and the absence of defects that would compromise the final product’s quality and aesthetics. Rejecting substandard veneer prevents costly mistakes later in the manufacturing process.

Q 12. Explain the process of edge banding veneer.

Edge banding veneer involves applying a thin strip of veneer to the edges of a substrate, such as plywood or MDF, for aesthetic and functional reasons. The process typically begins with preparing the substrate edges, ensuring they are smooth and clean. The veneer strip is then carefully applied, often using an adhesive that’s compatible with both the veneer and the substrate. The method varies based on the type of adhesive and the equipment being used. Some processes involve using specialized edge banding machines that precisely apply heat and pressure to ensure strong adhesion and a smooth finish. After applying the veneer, excess material is trimmed, and the edge is often sanded and finished to match the surface of the substrate. The goal is to create a seamless and visually appealing edge that complements the overall design. A well-executed edge band increases durability and prevents chipping or damage to the substrate edges.

Q 13. What are the different types of veneer finishes and their applications?

Veneer finishes play a crucial role in enhancing the appearance and durability of the final product. A wide variety of finishes are available, each with specific properties and applications. Some common types include:

- Lacquer: Offers a hard, durable surface with excellent clarity and gloss. It’s widely used for high-end furniture and cabinetry.

- Varnish: Provides a protective layer with varying degrees of gloss, from high-gloss to satin. It’s a popular choice for its durability and water resistance.

- Oil finishes: Enhance the natural beauty of the wood grain and provide a protective layer. They are often preferred for rustic or traditional styles. Examples include tung oil or linseed oil.

- Polyurethane: A very durable and resistant finish often used for flooring and other applications requiring high protection.

The choice of finish depends on factors such as the type of wood, the desired aesthetic, and the intended application of the finished product. The finish is applied in multiple coats allowing for proper curing between coats. Sanding between coats is common to ensure a smooth finish.

Q 14. Describe your experience with troubleshooting common veneer cutting problems.

Troubleshooting veneer cutting problems requires a systematic approach, combining practical experience and a good understanding of the machinery. Common problems include:

- Knife dullness: This leads to tear-out and uneven cuts. The solution is to sharpen or replace the knife.

- Improper blade alignment: Results in inconsistent veneer thickness. Careful alignment and calibration of the machine are necessary.

- Wood defects: Knots, splits, or other defects in the log can cause problems during cutting. Careful log selection and appropriate cutting techniques are essential.

- Moisture content issues: Variations in wood moisture content can lead to warping or cracking. Proper drying of the logs is crucial.

My approach starts with careful observation of the problem, followed by methodical checks of each potential cause. For example, if I encounter excessive tear-out, I would first check the sharpness of the knife and then examine the wood for any inherent defects. Documenting the problem and the steps taken to resolve it allows for learning and improvement over time.

Q 15. How do you maintain veneer cutting equipment to ensure optimal performance?

Maintaining veneer cutting equipment is crucial for consistent quality and safety. It’s akin to regularly servicing a high-performance car – preventative maintenance is key. This involves a multi-pronged approach focusing on cleanliness, lubrication, and blade sharpness.

- Regular Cleaning: After each use, remove all wood chips and dust from the cutting head, knives, and surrounding areas using compressed air and a brush. Failing to do this leads to premature wear and tear and potential damage to the machine.

- Blade Sharpening and Replacement: The sharpness of the knives directly impacts veneer quality. Dull blades create uneven cuts, tear the veneer, and ultimately reduce the machine’s efficiency. Regular honing or replacement, depending on the type of blade and usage frequency, is essential. Think of it like sharpening a chef’s knife – a sharp blade makes all the difference.

- Lubrication: Moving parts need lubrication to function optimally. Regularly check and lubricate all moving parts according to the manufacturer’s instructions using appropriate lubricants. This reduces friction, extends the lifespan of components, and prevents malfunctions. Neglecting this can lead to costly repairs.

- Safety Checks: Before each use, inspect the machine for any loose parts, damaged components, or safety hazards. This includes checking guards, emergency stops, and electrical connections. Safety should always be the top priority.

By following this routine maintenance, you ensure the longevity of your equipment, produce high-quality veneers, and maintain a safe working environment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of preparing veneer for various applications (e.g., furniture, cabinets).

Preparing veneer for different applications involves a series of steps, varying slightly depending on the final use. The common thread is ensuring the veneer is clean, consistently sized, and ready for adhesion.

- Cleaning: Veneer often arrives with dust and debris. Thorough cleaning using brushes or compressed air is essential to ensure proper adhesion. Think of it like preparing a surface for painting; a clean surface provides a better result.

- Sizing and Cutting: Veneer sheets are usually trimmed to the required dimensions for each application. Precise cutting is crucial, especially for intricate designs. Laser cutting is often used for high-precision applications.

- Joint Matching (for large surfaces): For large surfaces, several veneer pieces need to be joined. Careful attention to grain matching and alignment is needed to avoid visible seams and enhance the aesthetic appeal. Bookmatching (discussed later) is a popular method.

- Surface Preparation (for certain applications): Sometimes, a finish needs to be applied before bonding (e.g., a sealant). This may depend on the type of wood or adhesive used.

- Application Specifics: For furniture, you might need to carefully plan veneer placement to avoid waste and maximize the beauty of the grain. In cabinet making, ensuring consistent thickness for smooth closing and opening of doors is paramount.

Proper preparation guarantees a successful outcome; a poorly prepared veneer will negatively impact the quality of the end product. For example, neglecting cleaning can lead to weak bonding and veneer lift in furniture, which would be unacceptable.

Q 17. How do you read and interpret veneer specifications?

Veneer specifications are crucial for selecting the right material and ensuring project success. They provide detailed information about the veneer’s properties. Understanding these specifications requires careful reading and attention to detail.

- Species: The type of wood, e.g., American Walnut, European Oak.

- Grade: Indicates the quality and consistency of the veneer. Higher grades generally mean fewer imperfections.

- Thickness: Measured in millimeters (mm), crucial for application and strength.

- Width and Length: Dimensions of the veneer sheet, affecting yield and cost.

- Treatment: Any treatments applied, such as staining or pre-finishing, impacts the look and adhesion.

- Matching: Describes how the veneer pieces are matched for larger projects. Examples include book-matching, slip-matching, etc.

For example, American Walnut, Grade A, 0.6mm, 1200mm x 2400mm, Pre-finished tells us it’s a high-quality walnut veneer, thin, and pre-treated, ready for immediate use. Misinterpreting these specifications can lead to the wrong material being used or issues during the application process.

Q 18. What are the different types of veneer patterns and their aesthetic effects?

Veneer patterns significantly influence the aesthetic outcome of a finished product. They are created by arranging veneer sheets during the cutting process. Different patterns have different visual impacts.

- Bookmatching: Creates a mirrored effect, offering symmetry and visual appeal (explained in more detail below).

- Slipmatching: Adjacent sheets are aligned to follow the same grain pattern, creating a uniform look.

- Random Matching: Sheets are arranged without regard for grain alignment, offering a more natural and less formal appearance.

- Running Match: Sheets are arranged to create continuous grain flow, often used for larger surfaces.

- Quarter-Sawn: Creates a distinctive figure known for its vertical grain pattern, often more durable and less susceptible to shrinkage.

The choice of pattern depends entirely on the desired aesthetic, with bookmatching providing a classic and elegant look while random matching offers a more rustic or modern feel. Consider the application and the desired mood when choosing.

Q 19. Explain the concept of veneer bookmatching and its importance.

Veneer bookmatching involves arranging veneer sheets as if they were pages in a book, reflecting the grain pattern across the fold. This creates a visually striking symmetrical pattern.

Imagine opening a book – the pages on either side reflect each other. Similarly, in bookmatching, the grain pattern on one veneer piece mirrors its counterpart, creating a visually balanced and impressive design.

Importance: Bookmatching is highly valued for its aesthetic appeal, particularly in high-end furniture and cabinetry. The mirrored pattern enhances the beauty of the wood grain, highlighting its natural characteristics. It is also frequently used in larger panels to minimize the visibility of any joints.

However, it is more time-consuming and wasteful than other matching methods, as it requires cutting a larger log block to get the symmetrical slices.

Q 20. Describe your experience with different types of veneer adhesives.

My experience encompasses a variety of veneer adhesives, each with its own strengths and weaknesses. The choice of adhesive depends on several factors, including the type of veneer, substrate, and intended application.

- Polyurethane Adhesives: Excellent strength, water resistance, and durability. Suitable for most veneer applications, including outdoor use. However, they can be more challenging to clean up.

- PVAc (Polyvinyl Acetate) Adhesives: Common, versatile, and relatively easy to use. Suitable for interior applications but offer less water resistance compared to polyurethane.

- Contact Adhesives: Fast-setting adhesives ideal for projects requiring quick bonding. Excellent for high-pressure lamination applications. However, they require precise application and have a short open time.

- Hot Melts: Used in high-speed automated applications and offer very fast setting time. They require specialized equipment for application.

I always consider the specific project requirements when selecting an adhesive, prioritizing safety, efficiency, and the long-term performance of the final product. A poorly chosen adhesive can result in veneer failure, which would be costly and time consuming to fix.

Q 21. What are the challenges of working with high-value or exotic veneers?

Working with high-value or exotic veneers presents unique challenges that demand extra care and attention to detail. The cost and rarity of these materials raise the stakes significantly.

- Cost and Waste Minimization: High cost means careful planning is needed to minimize waste, through optimized cutting layouts and designs.

- Fragility and Handling: Exotic veneers can be more fragile than standard veneers, demanding gentler handling and precise cutting techniques to avoid damage.

- Specialized Knowledge: Understanding the specific characteristics of each exotic species, including their grain patterns, reactivity to adhesives, and susceptibility to moisture, is critical for success.

- Quality Control: Rigorous quality control is essential to identify and address imperfections early on. Any defects are more noticeable and costly to correct in high-value veneers.

- Repair Difficulty: Repairing damage to expensive veneers is complex and frequently cost prohibitive.

For example, working with highly figured burl veneers requires meticulous planning and a skilled touch to fully showcase their unique beauty while avoiding errors that would ruin the expensive piece. The higher the value, the greater the pressure to ensure flawless execution.

Q 22. How do you ensure consistency in veneer cutting and preparation?

Consistency in veneer cutting and preparation is paramount for achieving high-quality finished products. It’s a multi-faceted process that starts long before the knife touches the log. We begin by carefully selecting logs with consistent grain patterns and minimal defects. This is followed by precise log preparation, ensuring the wood is properly seasoned to minimize warping and cracking during cutting.

During the actual cutting process, we rely on state-of-the-art equipment, precisely calibrated for thickness and width. Regular maintenance and calibration checks are crucial. For example, we use digital micrometers to monitor blade alignment and regularly inspect the cutting heads for wear and tear. This meticulous approach ensures each veneer sheet is remarkably similar to the next. Finally, consistent environmental controls in the drying and storage areas maintain optimal moisture content, preventing distortions.

- Careful Log Selection: Choosing logs with uniform grain structure minimizes variations.

- Precise Equipment Calibration: Regular checks ensure consistent veneer dimensions.

- Environmental Control: Maintaining a stable environment prevents warping and cracking.

Q 23. Describe your experience with quality control procedures in veneer processing.

Quality control in veneer processing is an ongoing process, not just a final check. It involves rigorous checks at every stage, from initial log inspection to the final veneer sheet packaging. We implement a multi-stage system incorporating visual inspection, precision measurement tools, and sometimes even specialized software for analyzing grain patterns.

Visual inspection is our first line of defense, identifying defects such as knots, splits, and discoloration. We then use digital calipers and micrometers to ensure the veneers meet the specified thickness and width tolerances. We also employ moisture meters to verify that the veneers have reached the optimal moisture content for optimal performance and stability. If discrepancies are found, the affected veneer sheets are sorted accordingly. Detailed records of each stage, including any issues encountered, are carefully documented, which helps us identify trends and improve our processes. Our adherence to these rigorous standards results in a consistently high-quality product.

Q 24. What software or systems have you used to manage veneer inventory or production?

Throughout my career, I’ve used several software systems to manage veneer inventory and production. Early in my career, we used basic spreadsheet software for tracking inventory levels and production data. However, as the industry advanced, I’ve transitioned to more sophisticated Enterprise Resource Planning (ERP) systems that integrate all aspects of production, from initial order placement to final shipment. These systems provide real-time visibility into inventory levels, production schedules, and quality control data. For example, I’ve worked with systems that allow for barcode scanning of individual veneer sheets, providing precise tracking and efficient management of our vast inventory.

Specific examples include SAP and Oracle based ERP systems. These systems provide dashboards showing key performance indicators (KPIs) such as production efficiency and waste levels, allowing us to identify areas for improvement and optimization.

Q 25. How do you handle variations in veneer thickness or width?

Variations in veneer thickness and width are inevitable due to the natural characteristics of wood. However, we have strategies to minimize and manage these variations. First, careful selection of logs and precise cutting techniques, as discussed earlier, are key to reducing the initial variations. Then, during the sorting process, we categorize veneers based on their dimensions. Thin veneers are typically used for certain applications, such as inlays, while wider veneers are suitable for larger panels. Any significant deviations outside acceptable tolerance levels are set aside for specialized applications or are rejected depending on the severity. This efficient sorting system ensures we maximize the use of every veneer sheet, minimizing waste.

Q 26. How do you identify and address veneer defects during the layup process?

Identifying and addressing veneer defects during the layup process is crucial for producing high-quality panels. This requires a keen eye and experience. We typically use a two-step process: pre-layup inspection and in-process inspection. During pre-layup, each veneer sheet is carefully examined for imperfections like knots, splits, mineral streaks, and discoloration. The defects are then marked and considered in the layup plan, ensuring that imperfections are minimized or strategically hidden within the panel design.

During the actual layup, we maintain vigilant inspection to catch any unforeseen issues like glue misapplication or alignment problems. If a defect is discovered during the layup, it may be possible to correct it depending on its severity and location. Small defects may be carefully patched, while more severe ones may necessitate replacing the affected veneer sheet. Maintaining detailed records helps analyze and improve our defect-detection and correction processes over time.

Q 27. Explain your understanding of different wood species and their suitability for veneering.

Understanding different wood species and their suitability for veneering is fundamental. Each species has unique characteristics that influence its suitability for veneering. For example, hardwoods such as cherry, walnut, and maple are prized for their rich colors and beautiful grain patterns, making them highly desirable for high-end furniture and cabinetry. However, some hardwoods may be more challenging to work with due to hardness or tendency to tear during cutting.

Softwoods like pine and fir are more readily available and often less expensive, making them suitable for more economical applications. However, their grain patterns may be less dramatic. The choice of wood species depends on the intended application, desired aesthetic, and budget constraints. We consider factors such as the wood’s density, strength, grain structure, and its ability to accept stains and finishes when selecting a species for a specific project. Experience and knowledge of various wood properties help in making informed decisions.

Q 28. Describe a time you had to troubleshoot a complex veneer-related problem.

One challenging situation involved a large order of walnut veneer for a high-profile project. During the layup process, we noticed an unusual amount of veneer sheets exhibiting a consistent pattern of small, internal checks. These weren’t apparent during the initial inspection. We suspected the issue might stem from the drying process of the logs, possibly due to inconsistencies in the kiln’s temperature control or humidity levels. We immediately stopped production and initiated a thorough investigation.

We reviewed the logs’ history, examined the kiln’s operational data, and analyzed the affected veneer sheets using a moisture meter. It turned out that a faulty sensor in the kiln had caused inconsistent temperature fluctuations, resulting in the internal checks. We had to adjust the layup process to accommodate the flawed veneer by implementing extra quality control steps and carefully selecting the veneer pieces to reduce the visible defects. The problem was solved, but it highlighted the importance of preventative maintenance and meticulous record-keeping in veneer processing.

Key Topics to Learn for Veneer Cutting and Preparation Interview

- Understanding Veneer Types and Grades: Learn to differentiate between various veneer species, their properties (e.g., hardness, grain patterns), and quality grades. Be prepared to discuss the implications of each type for different applications.

- Cutting Techniques and Equipment: Familiarize yourself with different cutting methods (e.g., rotary slicing, slicing, half-round slicing) and the machinery involved. Understand the advantages and limitations of each technique and how to select the appropriate method based on veneer type and desired outcome.

- Veneer Drying and Conditioning: Master the principles of veneer drying and its impact on the final product. Understand how to prevent warping, cracking, and other defects during the drying process and the importance of maintaining proper humidity levels.

- Defect Identification and Repair: Learn to identify common veneer defects (e.g., splits, knots, stains) and discuss various repair techniques, including patching, filling, and sanding. This demonstrates a practical understanding of quality control.

- Matching and Bookmatching Techniques: Gain proficiency in understanding and applying different matching methods to create aesthetically pleasing veneer panels. Discuss the visual impact of various matching styles on the final product.

- Safety Procedures and Regulations: Demonstrate awareness of workplace safety protocols associated with veneer cutting and preparation equipment. Highlight your understanding of relevant safety regulations and best practices.

- Waste Reduction and Sustainability: Discuss efficient cutting techniques to minimize waste and environmentally conscious practices within the veneer preparation process. This demonstrates a forward-thinking approach.

- Troubleshooting and Problem Solving: Be prepared to discuss how you would approach common challenges encountered during veneer cutting and preparation, demonstrating your analytical and problem-solving skills.

Next Steps

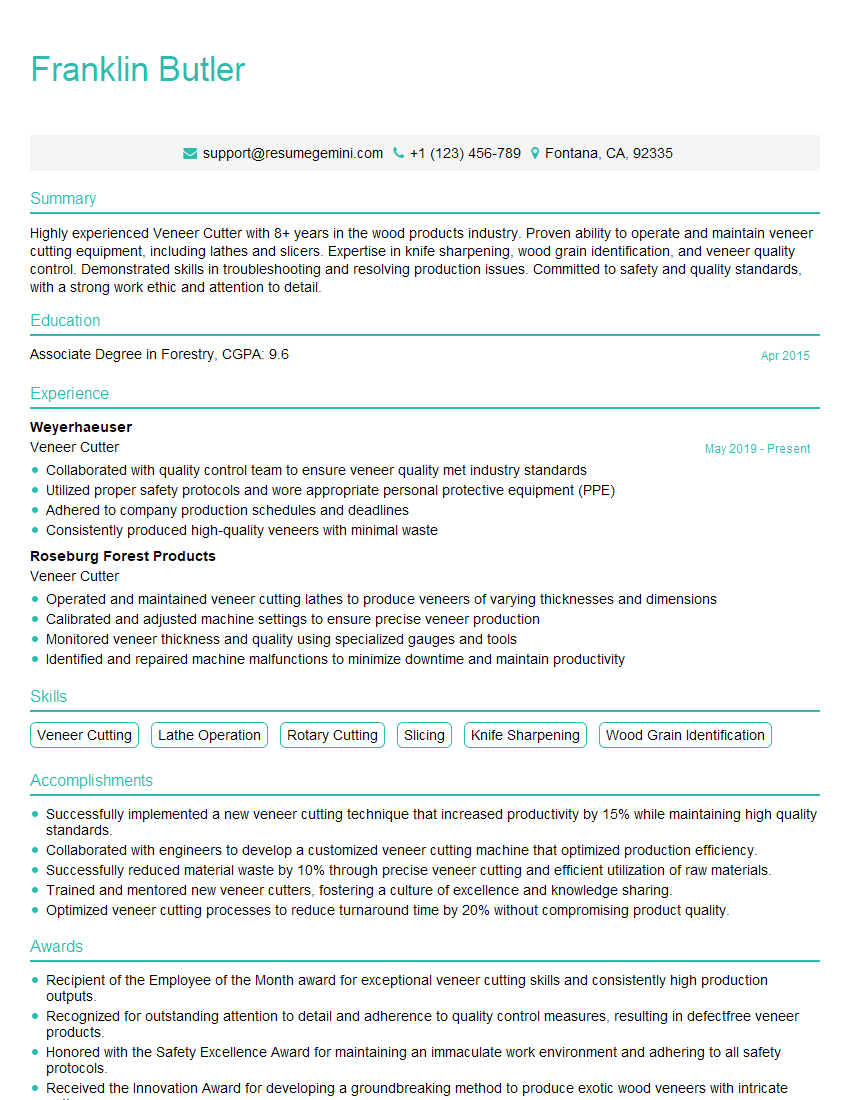

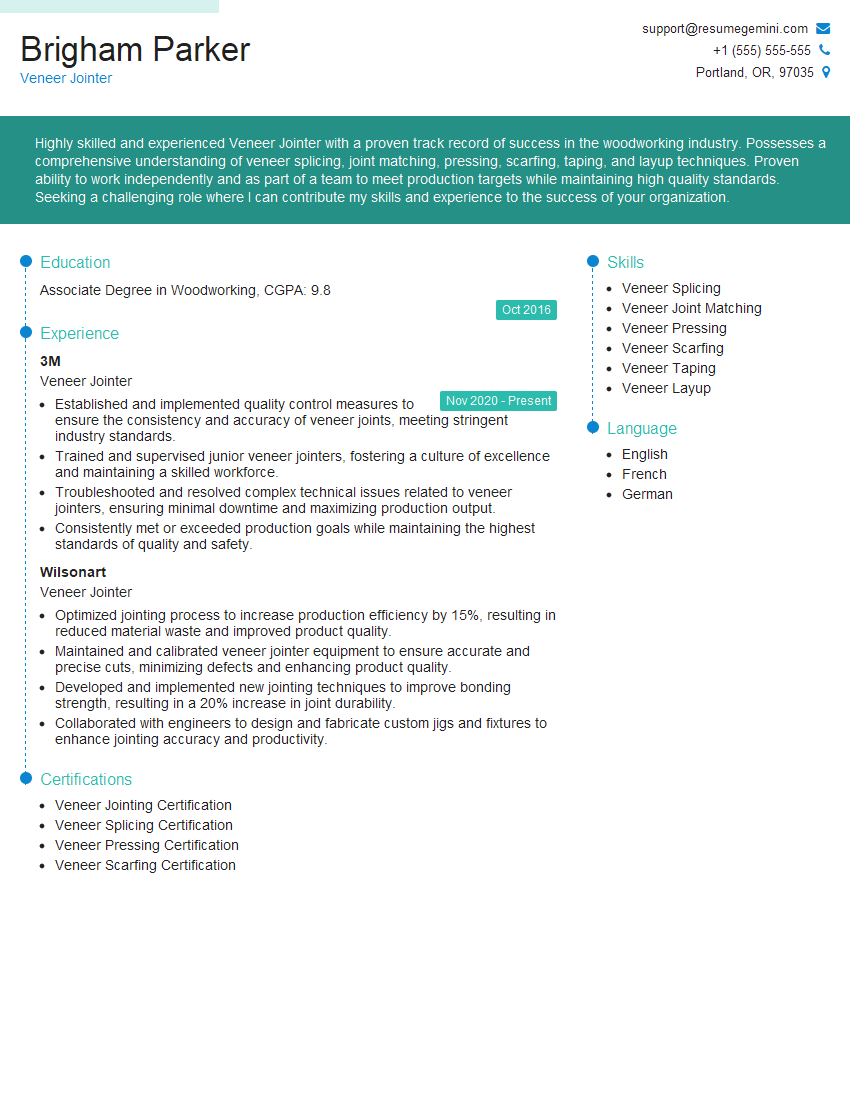

Mastering Veneer Cutting and Preparation opens doors to exciting career opportunities in woodworking, furniture manufacturing, and interior design. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience in this specialized field. Examples of resumes tailored to Veneer Cutting and Preparation are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.