Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Custom Furniture Making interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Custom Furniture Making Interview

Q 1. Describe your experience with various woodworking joints (e.g., mortise and tenon, dovetail).

Woodworking joints are the backbone of strong and aesthetically pleasing furniture. My experience encompasses a wide range of techniques, each chosen based on the specific design requirements and the type of wood being used. For example, the robust mortise and tenon joint, a classic choice for its strength and stability, is ideal for chair legs or table frames. Think of it like a male (tenon) and female (mortise) fitting perfectly together, creating an incredibly strong bond. I frequently use this for pieces requiring significant weight-bearing capacity.

Dovetail joints, on the other hand, are known for their beautiful interlocking appearance and exceptional strength, especially in drawers and casework. The interlocking ‘tails’ and ‘pins’ create a joinery that resists racking (twisting) and pulling apart. It’s like a complex puzzle that locks itself together, resulting in a visually stunning and incredibly durable joint.

Beyond these, I’m proficient with other joints such as biscuit joints (ideal for quick assembly and alignment), dowel joints (offering a strong, yet simpler alternative to mortise and tenon), and finger joints (providing a decorative and strong edge-to-edge connection). The choice of joint is always a careful consideration, balancing aesthetics, strength requirements, and the overall design vision.

Q 2. What types of wood are best suited for different furniture applications?

Selecting the right wood is crucial for both the longevity and the aesthetic appeal of a piece. The choice depends heavily on the intended use, the desired look, and the client’s budget. For instance, hardwoods like oak, maple, and cherry are excellent choices for high-traffic areas due to their durability and resistance to wear and tear. Oak, with its strong grain and rich color, often features in tables and chairs, while maple’s fine grain and light color provides a clean, modern look.

Softwoods, such as pine and fir, are generally less expensive and easier to work with, making them suitable for less demanding applications, perhaps for a less frequently used piece or where a more rustic aesthetic is desired. Pine, for example, is a popular choice for shelving units due to its affordability and workability.

Beyond these common choices, exotic hardwoods like mahogany and walnut offer stunning visual appeal and exceptional durability, though they come with a higher price tag. The final decision always involves a careful discussion with the client, balancing their vision with practical considerations and budgetary constraints.

Q 3. Explain your process for creating a detailed furniture design from a client’s concept.

Turning a client’s concept into a detailed design is a multi-stage process. It begins with a thorough consultation to understand their needs, lifestyle, and aesthetic preferences. We discuss functionality, dimensions, materials, and stylistic elements – everything from the desired wood type and finish to hardware choices. Then, I create detailed sketches, often incorporating several design iterations to ensure the final design reflects the client’s vision perfectly.

Following the sketches, I develop comprehensive working drawings, including precise measurements, joinery details, and material specifications. These drawings serve as blueprints during the construction phase, ensuring accuracy and minimizing errors. We’ll often use 3D modeling software to further refine the design and allow clients a more immersive preview of the final product before construction begins. This iterative process of collaboration and refinement ensures the final product not only meets but exceeds expectations.

Q 4. How do you manage project timelines and budgets for custom furniture projects?

Effective project management is critical in custom furniture making. I start by creating a detailed project schedule, breaking down the process into manageable phases, from design and material sourcing to construction and finishing. Each phase is assigned a realistic timeframe, considering factors such as material availability and the complexity of the design. This schedule is reviewed regularly with the client to ensure transparency and address any potential delays.

Budget management involves meticulous cost estimation, taking into account material costs, labor hours, and any additional expenses. I provide a detailed breakdown of the estimated costs to the client upfront, outlining the different components and allowing for flexibility where possible. Regular updates are provided throughout the project to track expenses and prevent cost overruns.

Q 5. What finishing techniques are you proficient in (e.g., staining, lacquering, painting)?

Finishing is the final touch that brings a piece to life, enhancing its beauty and durability. I’m skilled in a variety of finishing techniques, choosing the most appropriate based on the wood type, desired aesthetic, and client preferences. Staining allows me to enhance the natural wood grain and color, offering a wide palette of shades and finishes. Lacquering provides a durable, protective layer with a beautiful sheen, while painting provides the opportunity for bold colors and unique designs.

Beyond these, I also work with oil finishes, which provide a natural look and feel, enhancing the wood’s character. The application of each requires meticulous attention to detail, ensuring an even, flawless finish. The client’s desired level of sheen and the piece’s intended function also influence the final finish selection.

Q 6. How do you ensure the accuracy and precision of your cuts and joinery?

Accuracy and precision are paramount in custom furniture making. I employ a combination of hand tools and precision machinery to ensure the highest quality results. Hand tools, such as chisels and hand planes, allow for fine adjustments and detailed work, while power tools, such as table saws and jointers, provide efficiency and precision for larger cuts. The use of accurate measuring tools and jigs ensures consistent results throughout the construction process.

Moreover, I prioritize the use of high-quality materials and employ techniques like test fitting throughout the process to identify and correct any errors early on. Regular checks during each step ensure that the final product adheres strictly to the design specifications.

Q 7. Describe your experience working with different types of hardware and fasteners.

My experience includes working with a variety of hardware and fasteners, selecting each based on the specific requirements of the project. This ranges from traditional wooden dowels and pegs for a classic look to modern metal screws and bolts for added strength and durability. For decorative applications, I often use high-quality cabinet knobs, pulls, and hinges, carefully selecting these to complement the overall design.

Careful consideration is given to the material and finish of the hardware, ensuring that it complements the style and finish of the furniture. I am familiar with different types of finishes, such as brass, nickel, and chrome, and choose them based on the client’s preferences and the aesthetic direction of the piece.

Q 8. How do you handle unexpected issues or challenges during a furniture build?

Unexpected issues are inevitable in custom furniture making. My approach is systematic and proactive. I begin with thorough planning and communication with the client, ensuring clear expectations and detailed designs. However, if problems arise—say, a knot in the wood unexpectedly weakens a joint—I address them calmly and methodically.

- Assessment: I carefully evaluate the issue, determining its severity and potential impact on the overall piece.

- Problem Solving: I explore several solutions. For example, reinforcing the weakened joint with additional dowels or using epoxy resin to consolidate the wood. Sometimes, a small design alteration is needed.

- Communication: I immediately update the client, explaining the problem, the proposed solutions, and their potential impact on the timeline and cost. Transparency builds trust.

- Implementation and Review: I implement the chosen solution, carefully documenting each step. Following completion, I conduct a thorough inspection to ensure the structural integrity and aesthetic quality.

For instance, I once encountered a significant warp in a large slab of cherry wood intended for a dining table top. Instead of discarding it, we decided to embrace the natural imperfection, integrating it into the design by creating a unique, asymmetrical edge, which ultimately became a design feature the client loved.

Q 9. What software programs are you familiar with for furniture design (e.g., SketchUp, AutoCAD)?

Proficiency in design software is crucial. I’m highly experienced with SketchUp, which I use for 3D modeling and visualization. Its intuitive interface allows for easy client collaboration and modification of designs. I’m also familiar with AutoCAD for more precise technical drawings, particularly for complex joinery details. These programs help me create detailed plans, accurately calculate material requirements, and effectively communicate design ideas to the client and the workshop team. Using SketchUp, I can easily create photorealistic renderings, allowing the client to fully envision the final product before construction even begins.

Q 10. Explain your understanding of different wood drying methods and their impact on furniture.

Wood drying is paramount to the longevity and stability of furniture. Improper drying leads to warping, cracking, and other defects. There are two main methods: air drying and kiln drying.

- Air Drying: This traditional method involves stacking lumber outdoors under a shelter, allowing slow, natural moisture evaporation. It’s gentler, but takes much longer – often years – resulting in less stress but higher risk of fungal attack.

- Kiln Drying: This accelerated process uses controlled heat and humidity to remove moisture. It’s faster but can cause internal stresses if not done carefully. The lumber needs to be monitored closely to prevent cracking.

The choice of method significantly impacts the final product. Air-dried wood often boasts superior character and stability, minimizing internal stresses but at the expense of time. Kiln-dried wood offers speed and consistency but requires careful control to avoid damage. I always specify the drying method required based on the type of wood, intended use of the furniture and the client’s timeline.

Q 11. How do you ensure the structural integrity of your furniture designs?

Structural integrity is my top priority. I achieve this through a combination of sound design principles, appropriate joinery techniques, and careful material selection.

- Joinery: I select joinery methods (e.g., mortise and tenon, dovetail, dowel) appropriate to the specific piece and its intended use. Strong joinery is the backbone of furniture’s strength and longevity.

- Material Selection: Choosing wood with appropriate characteristics for the project is critical. Hardwoods offer superior durability, while softwoods might be preferable for specific aesthetics or cost considerations.

- Design Principles: I use sound engineering principles in my design, ensuring proper weight distribution, reinforcing stress points, and employing techniques to minimize racking (twisting or distortion).

- Testing: Where appropriate, I conduct stress tests, especially on larger or more complex projects, to verify the structural soundness.

For example, a large dining table requires robust joinery and careful consideration of wood grain orientation to prevent splitting under stress. I often incorporate bracing within the structure of larger pieces to enhance stability.

Q 12. Describe your experience with upholstery techniques (if applicable).

While my primary expertise is woodworking, I have experience with upholstery in collaboration with skilled upholsterers. I manage the structural aspects, creating the underlying frame and ensuring compatibility with the chosen upholstery materials. My knowledge extends to selecting appropriate padding, fabrics, and understanding the proper techniques for applying and securing upholstery. I work closely with upholsterers to ensure a seamless integration of the wood frame and the upholstered components resulting in a beautiful and durable finish.

Q 13. What safety procedures do you follow in the workshop?

Safety is paramount in my workshop. I adhere strictly to a comprehensive set of procedures.

- Personal Protective Equipment (PPE): I always use appropriate PPE, including safety glasses, hearing protection, dust masks, and appropriate clothing.

- Machine Safety: All machinery is regularly maintained and inspected. Safety guards are always in place and operating correctly. I follow manufacturer’s instructions for each tool.

- Workshop Organization: My workshop is meticulously organized to minimize clutter and trip hazards. Tools are stored properly, and walkways are kept clear.

- Emergency Procedures: I have a well-defined plan for dealing with emergencies, including a readily accessible first-aid kit and knowledge of local emergency services.

Regular safety training and continuous awareness of potential hazards are part of my everyday routine.

Q 14. How do you handle client feedback and revisions?

Client feedback is invaluable. I actively encourage and welcome it at every stage of the project. I use a multi-step process to handle feedback and revisions.

- Initial Consultation: Thorough communication at the outset establishes clear expectations. I encourage questions and ensure the client understands the design process.

- Progress Updates: I provide regular updates, including photos and videos, so the client can track the progress. This helps identify potential issues early on.

- Revisions: I’m receptive to constructive feedback and propose realistic solutions. I discuss any potential impact on the timeline and budget.

- Final Approval: Before the final finish, I present the piece to the client for final approval.

I view feedback as an opportunity for collaboration, enabling me to refine the design and create a piece that truly meets the client’s vision. I’ve often incorporated client suggestions that significantly enhanced the final product, leading to greater satisfaction.

Q 15. How do you manage inventory and materials for custom furniture projects?

Managing inventory for custom furniture is a delicate balance between efficiency and avoiding waste. It’s not like stocking a retail store; each project has unique material requirements. My system relies on a combination of digital and physical tracking.

Digital Inventory Management: I use a spreadsheet software to meticulously track all materials – wood types (species, grade, dimensions), hardware (hinges, knobs, drawer slides), finishes, and even consumables like glue and sandpaper. Each project gets its own entry, detailing the quantity of each material needed and the actual quantity used. This allows for accurate cost tracking and forecasting.

Physical Organization: My workshop is organized to maximize space and accessibility. Wood is stored according to species and dimensions, while hardware and finishes are categorized in clearly labeled bins and containers. This ensures I can quickly locate materials when needed, reducing project downtime.

Waste Minimization: I meticulously plan each cut to minimize waste. Software like SketchUp helps visualize projects and optimize material usage. Leftover wood of sufficient size is carefully stored for future smaller projects, demonstrating a commitment to sustainability and resource management.

Vendor Relationships: I maintain strong relationships with lumber suppliers to ensure reliable access to high-quality materials and to manage lead times effectively. This allows me to plan purchases based on upcoming projects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with CNC machinery (if applicable)?

I have extensive experience operating CNC machinery, specifically a ShopBot router. My expertise goes beyond simply operating the machine; I understand the intricacies of CAM (Computer-Aided Manufacturing) software, such as Vectric VCarve Pro. This allows me to translate designs directly into CNC instructions, creating intricate cuts, carvings, and even complex joinery with high precision and repeatability.

For example, I recently used the CNC to create the intricate fretwork for a custom headboard. The level of detail and the speed at which the machine accomplished this task far exceeded what was possible using traditional hand tools alone. The precision ensured a perfect fit and a flawless finish. It also streamlined the process, allowing me to complete the project faster and more efficiently. My skills extend to setting up, maintaining, and troubleshooting the machine, ensuring it runs smoothly and produces consistently high-quality results.

Q 17. How do you maintain and care for your woodworking tools?

Maintaining woodworking tools is crucial for both safety and the quality of the finished product. My routine involves regular cleaning, sharpening, and lubrication.

Cleaning: After each use, I thoroughly clean tools with a brush and compressed air to remove sawdust and debris. This prevents rust and ensures smooth operation.

Sharpening: Sharp tools are essential for precision and safety. I use a combination of honing guides, sharpening stones, and a grinder to keep my chisels, planes, and hand saws razor sharp. This improves the quality of the work and makes the process much easier.

Lubrication: I regularly lubricate moving parts on tools such as hand planes and saws with appropriate lubricants. This minimizes friction, prolongs the tool’s lifespan, and ensures smooth operation.

Storage: Proper storage is vital. Tools are stored in a dry place, away from moisture, with blades covered to prevent damage. Each tool has its designated spot in my organized workshop.

Think of it like taking care of a fine instrument; the better you maintain it, the better the results, and the longer it will last.

Q 18. Describe a time you had to troubleshoot a problem during a furniture build.

During the construction of a custom dining table with a complex live-edge slab, I encountered a significant problem. The slab, despite being kiln-dried, started to warp slightly during the finishing process. This threatened to compromise the structural integrity and the overall aesthetic appeal of the table.

My troubleshooting involved several steps:

Careful Observation: I first carefully examined the warping to understand its nature and extent. I used a moisture meter to check for localized moisture variations.

Research: I researched various techniques for correcting warping in wood. This included exploring options like using clamps and cauls to apply counter-pressure.

Testing: I conducted small-scale tests on scrap wood to find the optimal clamping method and time to avoid further damage to the slab.

Implementation: I carefully implemented the chosen solution, using strategically placed clamps and cauls to gently correct the warp. I monitored the progress regularly.

Refinement: I adjusted the clamping pressure as needed and monitored the slab for several days to ensure the correction was stable.

This problem required patience, attention to detail, and a willingness to adapt my approach. The final result was a dining table that met the client’s expectations and showcased my problem-solving skills.

Q 19. What is your experience with different wood finishing techniques?

My experience with wood finishing techniques is broad, encompassing various stains, lacquers, and oils. I select the finishing technique based on the wood type, the desired aesthetic, and the intended use of the furniture.

Stains: I use water-based and oil-based stains to enhance the natural color of the wood or to achieve a specific tone. Understanding the penetration and drying times of different stains is crucial.

Lacquers: I use both spray and brush-on lacquers for a durable, protective finish. This involves several coats, each carefully sanded between applications to achieve a smooth surface.

Oils: I utilize various oils, such as linseed oil and tung oil, for a more natural finish that enhances the wood’s texture and provides protection. This requires understanding oil penetration and curing times.

Shellacs and Waxes: These provide unique finishes. Shellac offers a warm, amber tone, while waxes offer a subtle sheen and protection.

The choice of finish is a key aspect of the overall aesthetic and longevity of the piece. I always discuss finishing options with clients to ensure their vision is realized.

Q 20. Describe your experience working with various types of veneers.

Working with veneers allows me to use luxurious and rare wood species in ways that would be impractical or cost-prohibitive using solid wood. My experience includes working with a wide variety of veneers including:

Hardwood Veneers: I frequently work with veneers such as cherry, walnut, mahogany, and maple. Each has unique properties regarding grain pattern, color, and workability.

Exotic Veneers: I have experience with exotic veneers like zebrawood, burl wood, and ebony, adding unique visual interest to projects. These require more specialized techniques during application and finishing.

Wood Veneer Types: I’m familiar with rotary-cut, sliced, and quarter-sliced veneers. Understanding the characteristics of each type is crucial for achieving the desired visual effect and proper application.

Veneering requires precision and skill. I use techniques like steam bending, vacuum pressing, and hand-applied veneer to create flawless surfaces and intricate designs. The result can be stunning, allowing for intricate patterns and economical use of high-quality wood.

Q 21. How do you ensure the durability and longevity of your furniture creations?

Durability and longevity are paramount in custom furniture making. I prioritize these aspects through careful material selection, precise joinery, and appropriate finishing techniques.

Material Selection: I select high-quality, appropriately seasoned wood, avoiding wood with excessive knots or defects. The choice of wood species also considers its inherent durability and resistance to environmental factors.

Joinery Techniques: I employ robust joinery techniques such as mortise and tenon, dovetail, and through-tenons, ensuring strong and lasting connections. These joints are far superior in strength and longevity compared to simple butt joints.

Finishing Techniques: I select finishes that protect the wood from damage and wear. Several coats of high-quality lacquer, oil, or other appropriate finishes provide protection against scratches, moisture, and UV damage, preventing deterioration over time.

Construction Methods: I use time-tested construction techniques and avoid shortcuts. This ensures the integrity of the piece, meaning it will endure years of use.

Building furniture to last is a combination of art and science. It’s about understanding the properties of materials, employing the right techniques, and having a deep respect for the craft.

Q 22. How do you create accurate measurements and templates for furniture parts?

Accurate measurements are the cornerstone of successful custom furniture making. It’s not just about using a tape measure; it’s about understanding the nuances of the space and the piece itself. I begin by carefully sketching the design, noting all dimensions and detailing specific features. Then, I use a combination of tools for precise measurement. For example, I might use a laser measure for large spaces, ensuring straight lines and accurate distances are captured. For smaller, more intricate components, I rely on a high-quality steel tape measure and a combination square for angles.

Creating templates is equally critical. I usually start with full-size paper templates, carefully drawn to scale. For curved or irregular shapes, I might use flexible plastic templates. This allows me to accurately transfer the design onto the wood, minimizing waste and ensuring a perfect fit between parts. For complex joinery, I often create smaller templates for individual joints, helping maintain consistency and accuracy throughout the project.

Example: When crafting a curved armrest for a chair, I’d create a flexible template by carefully shaping a strip of heavy-duty plastic to match the exact curve of my design. This template would then be transferred to the wood, ensuring the armrest’s final curve is precisely as intended.

Q 23. What is your experience with different types of wood stains and finishes?

My experience with wood stains and finishes is extensive. I’m proficient in using a wide range of products, from traditional oil-based stains to modern water-based options. The choice of stain and finish depends largely on the wood type, the desired aesthetic, and the client’s preferences. For example, a darker stain on oak can enhance its grain, while a lighter stain on cherry can highlight its subtle reddish tones. Each stain reacts differently with different wood species; therefore, test applications are crucial before proceeding with the final finish.

Finishes include shellac, lacquer, polyurethane, and oil-based varnishes, each offering distinct characteristics in terms of durability, appearance, and application. For example, polyurethane offers excellent durability and scratch resistance, making it ideal for high-traffic furniture. Shellac, on the other hand, provides a warm, lustrous finish suitable for fine furniture. I prioritize environmentally friendly, low-VOC (volatile organic compound) finishes whenever possible.

Q 24. Explain your understanding of wood grain patterns and how they affect furniture design.

Understanding wood grain patterns is crucial for both aesthetic and structural reasons. Wood grain is essentially the arrangement of wood fibers, and it significantly affects the strength, appearance, and workability of the wood. The direction of the grain influences the way the wood behaves during cutting, shaping, and finishing. For example, cutting across the grain can weaken the wood, while cutting with the grain generally results in a cleaner, stronger cut.

From a design perspective, wood grain can be a striking feature. The beauty of the grain can dictate the direction of a panel, the placement of joints, or even the overall design of the piece. I often select wood with exceptional grain patterns to enhance the piece’s visual appeal. Sometimes, I intentionally orient the grain to create a specific effect – for example, bookmatching panels to achieve a mirrored effect.

Example: When designing a table top, I would carefully consider the grain pattern to avoid disrupting its flow. A continuous, flowing grain pattern can dramatically increase the visual appeal and create a sense of elegance.

Q 25. What is your experience with hand tools versus power tools?

I’m equally comfortable with both hand tools and power tools. Hand tools, such as chisels, hand planes, and saws, allow for precise, detailed work, and are indispensable for fine joinery and shaping. They offer a level of control and feel that power tools can’t always match. However, power tools, like routers, planers, and band saws, dramatically increase efficiency, especially for larger projects or repetitive tasks.

My approach is to use the right tool for the job. For intricate detailing or small projects, I prefer hand tools. For larger pieces or mass production elements, power tools are more efficient. Safety is paramount regardless of the tool; I always prioritize safe working practices and maintain my tools meticulously.

Q 26. Describe your understanding of ergonomic principles in furniture design.

Ergonomic principles are paramount in my furniture design. This means considering how people will interact with the piece – how they will sit, stand, or use it – and designing to promote comfort, support, and minimize strain. For example, chair seat height and backrest angle are critical for proper posture and reducing back pain. The armrest height should support the forearms when seated, and the table height should be suitable for both sitting and standing tasks.

I often consult ergonomic guidelines and incorporate features such as adjustable height mechanisms, contoured seating, and supportive lumbar support. Understanding human anatomy and body mechanics informs the design process, ensuring the final product is both aesthetically pleasing and comfortable to use.

Q 27. How do you stay up-to-date with the latest trends and technologies in custom furniture making?

Staying current is crucial in this dynamic field. I regularly attend woodworking conferences and workshops to learn about new techniques, tools, and materials. I subscribe to industry publications and follow leading designers and makers online. I also actively explore new technologies, such as CNC machining, 3D modeling, and digital design software, to improve precision and efficiency in my work. This constant learning allows me to offer clients innovative solutions and cutting-edge designs.

Q 28. How do you price your custom furniture projects?

Pricing custom furniture involves a detailed breakdown of costs. I consider several factors, including the type and quality of wood, the complexity of the design, the time required for construction, and the cost of materials and finishes. I provide clients with a detailed estimate that outlines all costs transparently. This often includes a consultation fee, material costs, labor costs, and any additional charges for specialized techniques or custom features.

My pricing is competitive yet reflects the quality of materials, craftsmanship, and the unique design elements involved in each project. I also emphasize the value proposition to the client; custom furniture is an investment, offering superior quality, personalized style, and enduring value.

Key Topics to Learn for Your Custom Furniture Making Interview

- Design & Blueprint Reading: Understanding client briefs, translating them into detailed plans, and utilizing CAD software for accurate visualization.

- Wood Selection & Treatment: Knowing different wood types, their properties (hardness, grain, workability), and appropriate finishing techniques for durability and aesthetics. This includes understanding sustainable sourcing practices.

- Joinery Techniques: Mastering various joinery methods (e.g., mortise and tenon, dovetail, dowel) for strength, stability, and aesthetic appeal. Be prepared to discuss the advantages and disadvantages of each.

- Tool Knowledge & Operation: Demonstrating proficiency with hand tools (chisels, planes, saws) and power tools (routers, planers, sanders). Safety procedures are crucial here.

- Finishing Techniques: Understanding different finishing processes (staining, painting, varnishing, lacquering) and their impact on the final product’s appearance and longevity.

- Project Management & Time Estimation: Accurately estimating project timelines, managing materials, and adhering to budgets. This includes understanding project scope and potential challenges.

- Client Communication & Collaboration: Effectively communicating with clients, addressing concerns, and managing expectations throughout the entire process. This includes understanding how to handle changes to the initial design.

- Troubleshooting & Problem-Solving: Demonstrating the ability to identify and resolve common woodworking issues, adapting to unexpected challenges, and finding creative solutions.

- Quality Control & Inspection: Understanding the importance of meticulous craftsmanship and quality control measures to ensure the final product meets the highest standards.

Next Steps

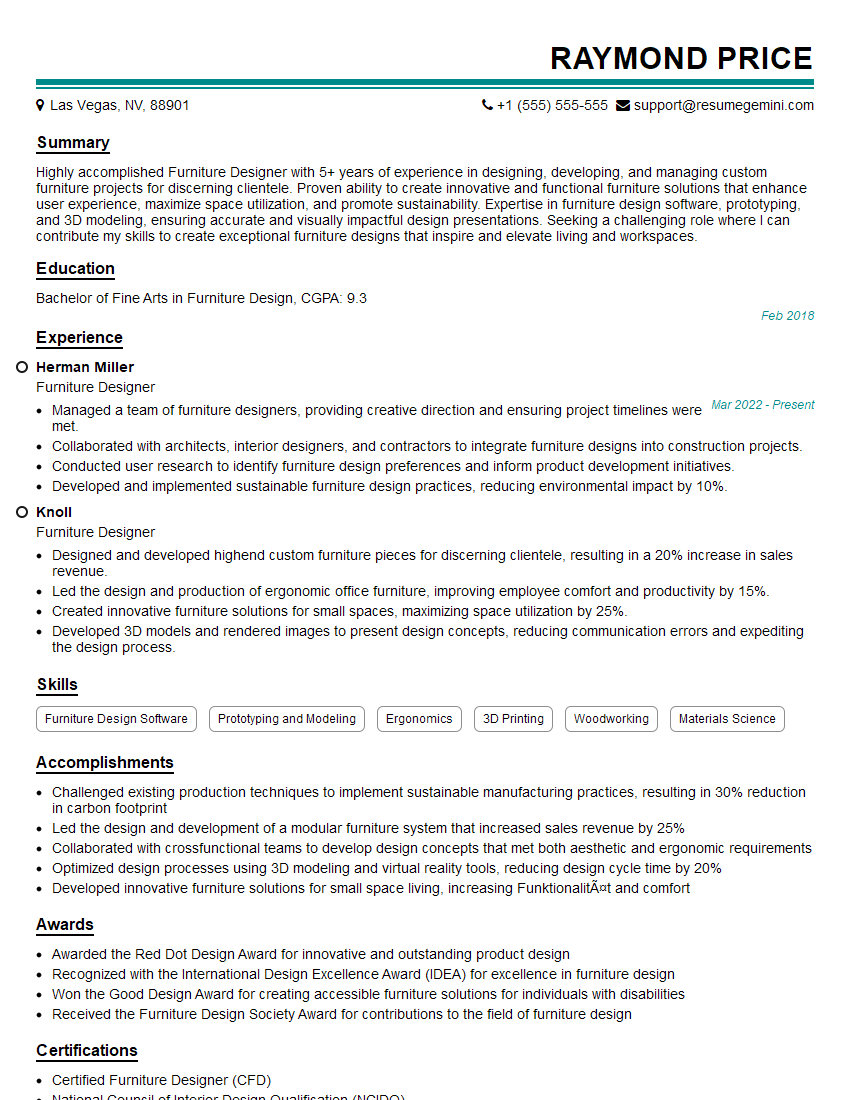

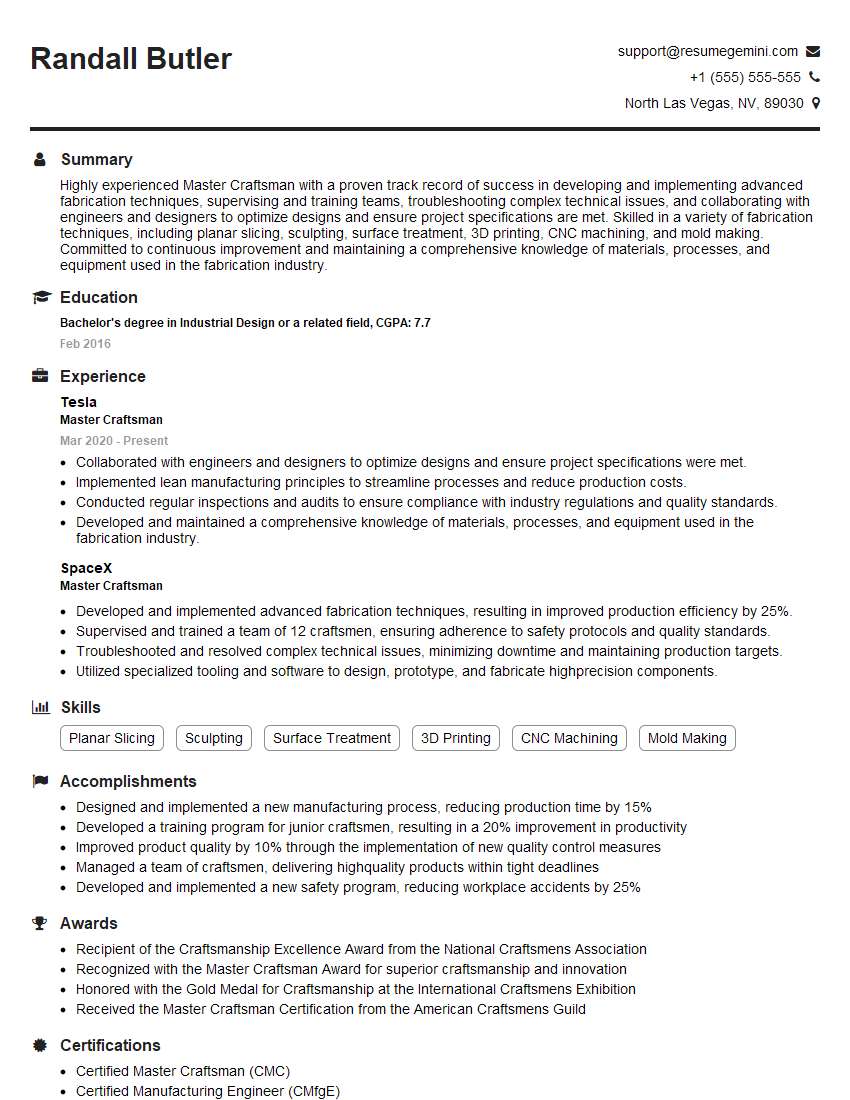

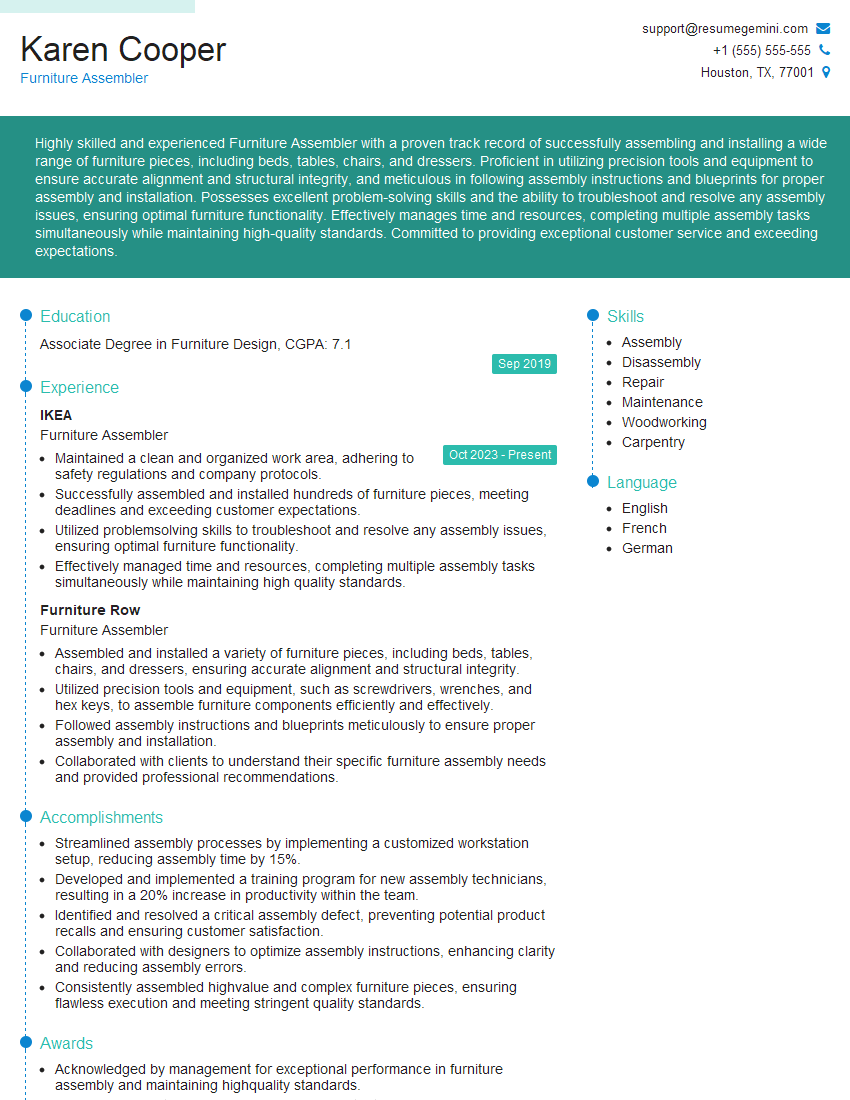

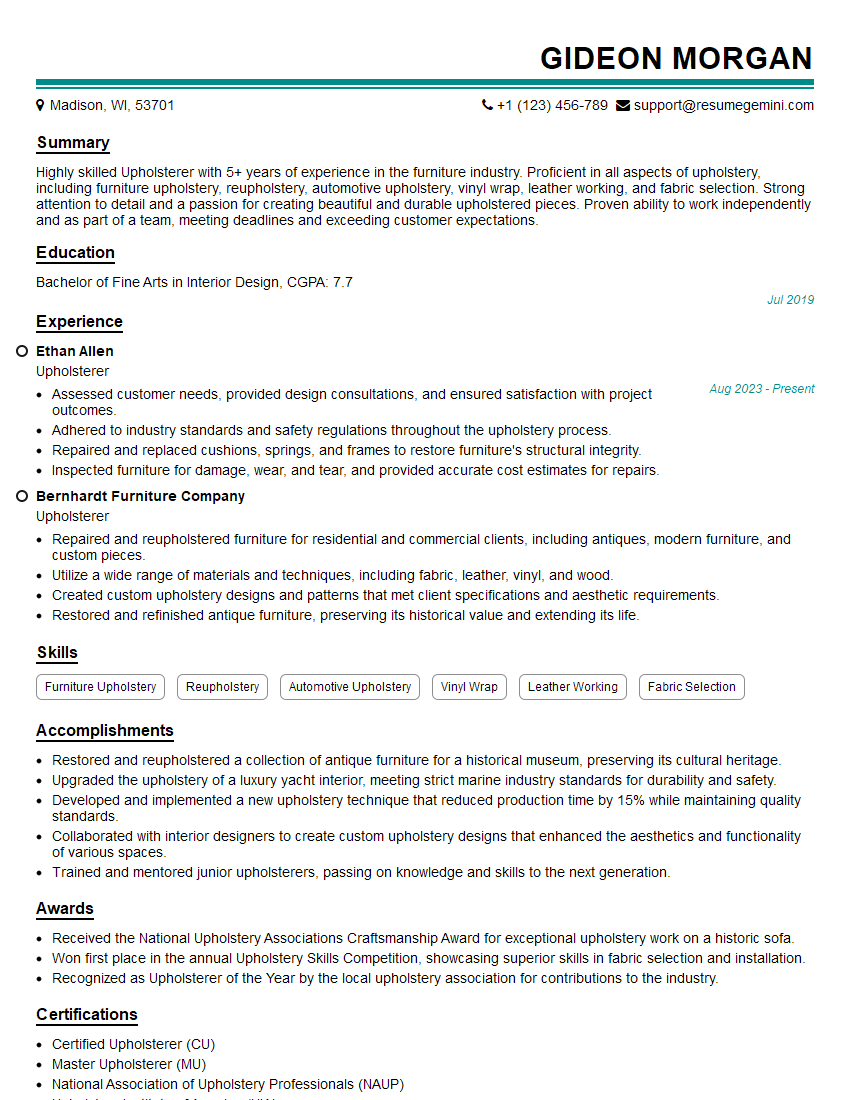

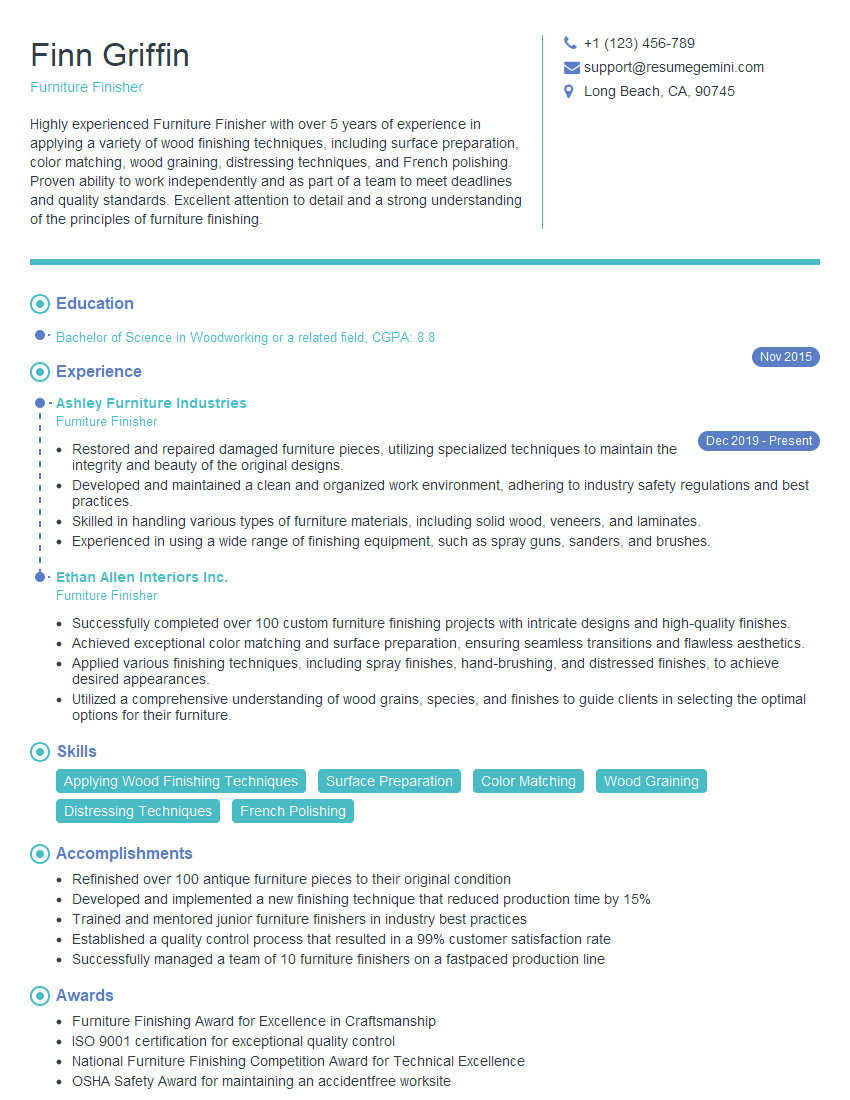

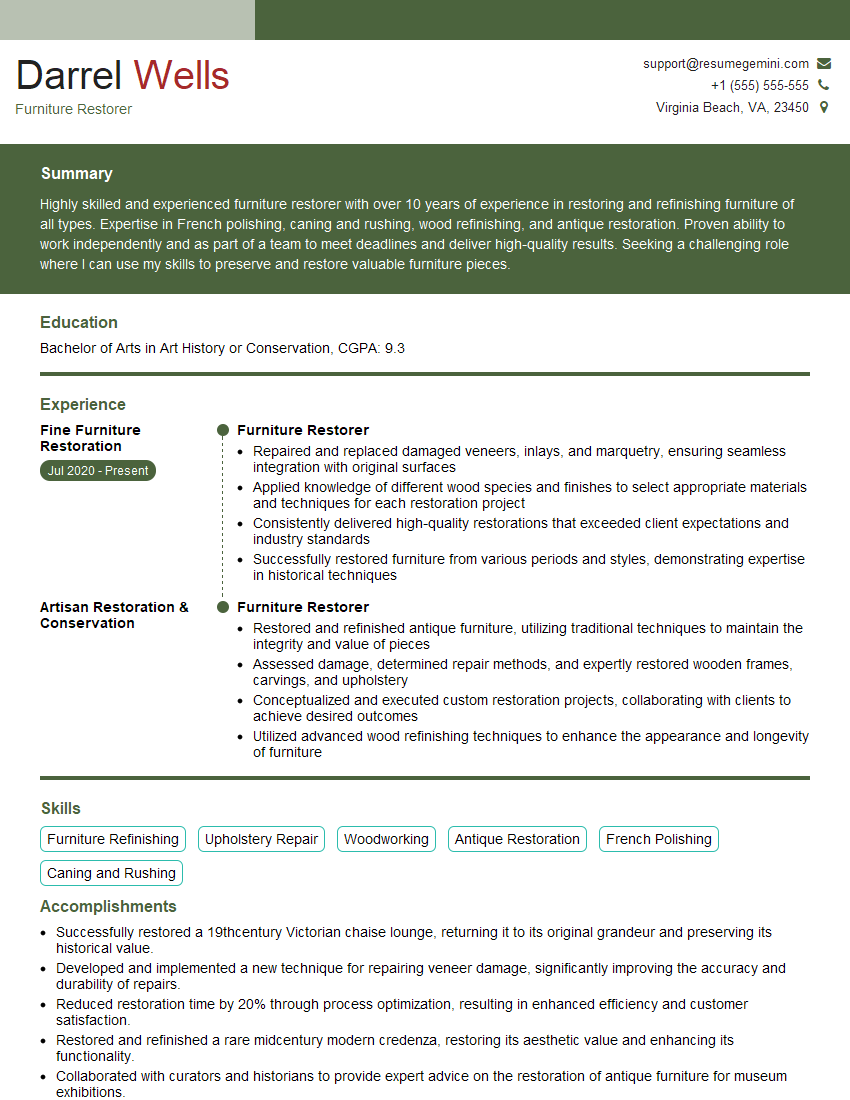

Mastering custom furniture making opens doors to a rewarding career with diverse opportunities for growth, from independent craftsmanship to leading teams in larger workshops. To showcase your skills and experience effectively, an ATS-friendly resume is crucial for maximizing your job prospects. ResumeGemini is a trusted resource that can help you build a professional resume designed to get noticed. They provide examples of resumes tailored to the custom furniture making field, giving you a head start in crafting the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.