Are you ready to stand out in your next interview? Understanding and preparing for Neon Glass Bending interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Neon Glass Bending Interview

Q 1. Describe the different types of neon glass used in bending.

Neon glass tubing comes in various compositions, each affecting its bending properties and final appearance. The most common types are soda-lime glass and borosilicate glass. Soda-lime glass is less expensive and easier to work with, making it ideal for simpler signs. However, it has a lower softening point, meaning it’s more prone to cracking under stress. Borosilicate glass, on the other hand, boasts a higher softening point and greater resistance to thermal shock, making it suitable for intricate designs and larger installations, even though it requires more precise heating techniques.

- Soda-lime glass: Think of this as the ‘everyday’ glass – inexpensive and widely available, but less durable.

- Borosilicate glass: Imagine this as the ‘premium’ glass – more resistant to heat and breakage, but it requires a bit more skill to work with.

- Specialty glasses: There are also specialty glasses available with different colors and properties, offering greater creative flexibility. These can include glasses that produce vibrant colors even at lower gas pressures, which can be beneficial in certain application scenarios.

Q 2. Explain the process of heating and bending neon glass tubing.

Heating and bending neon glass tubing is a delicate balance of heat control and precision. The goal is to heat the glass to its softening point, allowing it to be shaped without breaking. This is typically achieved using a gas-fired glass bending torch, a powerful instrument capable of producing intense heat. The process involves carefully rotating the glass tubing in the torch flame, ensuring even heating. Once the glass softens and becomes pliable, the tubing is gently bent to the desired angle using bending tools, avoiding any sudden jerks or movements that might cause cracking. The process is repeated for each bend in the design. The temperature must be carefully monitored to avoid overheating, which could cause the glass to become too thin or deform unevenly. Think of it like working with taffy – too much heat and it becomes too thin, too little and it’s brittle and cracks easily.

Q 3. What safety precautions are essential when working with neon glass and high voltage?

Safety is paramount when working with neon glass and high voltage. The high temperatures involved in bending and the high voltage used in operation pose significant risks. Essential precautions include:

- Eye protection: Always wear safety glasses to protect your eyes from flying glass fragments or intense light from the torch.

- Gloves and protective clothing: Heat-resistant gloves and clothing are crucial to prevent burns from the hot glass tubing.

- Ventilation: Good ventilation is vital to remove harmful fumes and gases produced during the heating process. This is especially relevant when working in a closed space.

- High-voltage safety: Once the sign is electrified, it carries a lethal voltage. Always turn off the power before making any adjustments or repairs and utilize insulated tools. Never work alone when dealing with energized neon signs.

- Proper grounding: Ensure all equipment is properly grounded to prevent electrical shocks.

Q 4. How do you measure and cut neon glass tubing to precise dimensions?

Precise measurement and cutting are crucial for creating accurate neon signs. A glass cutter, designed specifically for neon glass tubing, is used to score the glass. The score line should be clean and precise. After scoring, a gentle snap, often aided by applying pressure on either side of the score, separates the tubing. To ensure precision, using a measuring tape or ruler before scoring the glass is essential. Some glass bending professionals use specialized cutting tools and jigs to maintain high levels of accuracy and consistency, allowing for mass production or replicable designs. For intricate designs, multiple cuts may be necessary. Clean, precise cuts minimize the chances of accidental breaks during bending and create a professional-looking finish.

Q 5. Explain the process of filling neon glass tubing with inert gases.

Filling neon glass tubing with inert gases is a critical step that involves specialized equipment. First, the tubing is thoroughly cleaned and evacuated using a vacuum pump to remove any air or moisture. Once the tubing is sufficiently evacuated, inert gas, such as neon, argon, helium, or krypton, is introduced using a gas filling system. The pressure is monitored carefully and adjusted to achieve the desired brightness and color. The gas is chosen based on the desired color – neon for the classic orange-red glow, argon for blue, etc. After filling, the glass tubing is sealed by melting the ends with a glass torch. The gas purity is critical because impurities can degrade the color, reduce the sign’s lifespan, or even affect its operational safety. After filling the gases, a final visual inspection is always conducted to spot any leaks or obvious irregularities.

Q 6. Describe different methods for creating bends in neon glass tubing (e.g., hand bending, machine bending).

Bending neon glass tubing can be done manually or with specialized equipment.

- Hand bending: This is a traditional technique requiring significant skill and precision. The glass is heated using a torch, and the bender carefully shapes the glass using bending irons and their hands. It allows for greater artistic control and flexibility but is more time-consuming and demanding.

- Machine bending: This automated process uses specialized machines to heat and bend the glass according to a pre-programmed design. It is significantly faster and more consistent than hand bending, especially for mass production. However, it may offer less flexibility for highly intricate or custom designs. Many modern workshops employ a combination of both hand bending and machine bending based on the design needs and project demands.

Q 7. How do you troubleshoot common issues such as leaks or gas impurities in neon signs?

Troubleshooting leaks and gas impurities requires a systematic approach.

- Leaks: Leaks are often detected by visual inspection, looking for discoloration or darkening of the glass near the leak. A more precise method is to use a vacuum pump and pressure gauge to check for pressure loss. Leaks can often be repaired by carefully re-melting and resealing the affected area.

- Gas impurities: Impurities can manifest as unusual colors or dimness in the sign. This typically requires removing the impure gas and refilling the tube with clean gas, utilizing a dedicated gas purification system.

Q 8. What are the different types of electrodes used in neon signs, and how are they installed?

Neon signs primarily use two types of electrodes: solid rod electrodes and wire electrodes. The choice depends on the design and size of the tube. Solid rod electrodes, often made of nickel or tungsten, are durable and suitable for larger tubes and more complex designs. Wire electrodes, typically nickel or a nickel-iron alloy, are more flexible and are commonly used in smaller tubes or where intricate bending is required.

Installation involves carefully inserting the electrode into the end of the glass tubing. For solid rod electrodes, a special glass-to-metal seal is created to ensure a vacuum-tight and electrically conductive connection. This often requires a high-temperature process and specialized equipment. Wire electrodes are typically sealed using a similar process, often with a slightly smaller seal.

Think of it like sealing a wire into a glass bottle – you need a strong, air-tight seal to maintain the vacuum inside the tube. The precise technique will vary based on the size and shape of the electrode and the glass tube.

Q 9. Describe the process of sealing and evacuating neon glass tubing.

Sealing and evacuating neon glass tubing is a critical step in neon sign fabrication, ensuring the proper operation and longevity of the sign. It’s done in several stages.

- Tube Preparation: After bending the glass to the desired shape, the ends are carefully cleaned and prepared for sealing. This might involve pre-sealing the electrode into place.

- Sealing: A glassblowing torch is used to melt and fuse the glass at the end of the tube, sealing the electrode within and creating a closed system. This requires precision and skill to avoid cracking the glass.

- Evacuation: Once sealed, the tube is connected to a vacuum pump to remove the air and other gases inside. This is crucial because these gases would interfere with the neon’s glow.

- Filling: After evacuation, the tube is filled with the desired gas mixture (neon, argon, helium, etc.). The pressure is carefully controlled, as this affects the color and brightness of the sign.

- Final Sealing: The tube is finally sealed to complete the process. This whole process needs to be done in a controlled environment to avoid contamination.

Imagine it like making a perfectly sealed glass bottle; any air leaks would ruin the contents. The vacuum ensures the gas inside glows correctly.

Q 10. Explain the role of a vacuum pump in neon sign fabrication.

A vacuum pump is absolutely essential in neon sign fabrication. Its primary role is to remove air and other gases from the glass tubing before filling it with the neon or other noble gases. The presence of air would greatly reduce the efficiency and lifespan of the sign, leading to a weak or non-existent glow.

Removing the air creates a vacuum inside the tube, allowing the noble gas to ionize easily and produce the characteristic bright glow. Without the vacuum, the gas molecules would collide more frequently, reducing their ability to emit light efficiently. You would essentially have a dim or non-functioning neon sign.

Think of it like clearing a path for the light. The vacuum removes obstacles, allowing the neon to shine brightly.

Q 11. How do you test a completed neon sign for proper operation?

Testing a completed neon sign involves several steps to ensure it functions correctly and safely. It’s a crucial part of quality control.

- Visual Inspection: A thorough visual inspection is performed to check for any cracks, leaks, or other visible defects in the glass tubing.

- High-Voltage Test: The sign is carefully connected to a high-voltage transformer, and the voltage is gradually increased. This is where the specialized knowledge really comes into play as you need the right equipment to do this safely. Any sparking or arcing indicates a problem needing immediate attention.

- Glow Check: Once the voltage is at the correct level, the sign should glow evenly and brightly. Any dim or flickering areas point to a potential gas leak or electrode issue.

- Electrical Safety Check: A multi-meter is used to check the continuity and resistance of the wiring and electrodes. This ensures that there are no electrical shorts or open circuits that could lead to malfunction or hazard.

Imagine a doctor giving a full check-up to a patient – this is just as important to ensure the neon sign is working as intended and safely.

Q 12. What are the common types of transformers used in neon signs?

Neon signs typically use high-voltage transformers to convert the standard household voltage (typically 120V or 240V) to the much higher voltage (several kilovolts) required to ionize the noble gas inside the tubing. This high voltage is essential to create the glowing plasma.

Common types include:

- Step-up transformers: These are the most common type and are specifically designed to increase the voltage. They often include safety features to protect both the sign and the user.

- Autotransformers: These are simpler transformers that use a single winding, providing a more compact and cost-effective solution for smaller signs. However, they might offer less safety protection.

The choice of transformer depends on the size and voltage requirements of the neon sign. The transformer acts as the power source, allowing the neon gas to glow.

Q 13. How do you diagnose and repair a faulty neon sign?

Diagnosing and repairing a faulty neon sign requires systematic troubleshooting. This is where experience and problem-solving abilities are paramount.

- Visual Inspection: Look for any obvious signs of damage, such as cracks in the glass, loose connections, or burned-out electrodes.

- Testing with a Multi-meter: Using a multi-meter, check for continuity in the wiring and the electrodes. An open circuit would prevent the flow of electricity, while a short circuit could cause damage or fire.

- Gas Pressure Check: A pressure gauge can help identify any gas leaks, indicating the need for resealing the tube.

- Electrode Check: Examine the electrodes for signs of wear or damage. Electrode deterioration can lead to dimming or failure of the sign.

- Transformer Check: Test the transformer to ensure it’s providing the correct high voltage. A malfunctioning transformer could be the root cause of the problem.

Repair methods can range from simple rewiring to more complex tasks involving resealing, refilling, or replacing damaged components. Sometimes, replacing the entire tube section is necessary.

Think of it like fixing a car; you need to systematically check each part to identify the problem before undertaking the repairs.

Q 14. Describe different techniques for creating complex shapes and designs in neon glass.

Creating complex shapes and designs in neon glass requires skill and specialized techniques.

- Manual Bending: The glass tubing is heated using a gas torch and carefully bent using specialized tools. This method allows for precise control over the shape and is ideal for intricate designs. However it takes years to master.

- Jig Bending: Templates or jigs are used to guide the bending process, ensuring consistent shapes and angles. This method is suitable for mass production or designs requiring high accuracy and repeatability.

- Multiple Tube Sections: Complex designs are often achieved by combining multiple shorter glass tubes, sealed and connected together. This technique allows for more intricate designs that wouldn’t be feasible with a single long tube.

- Internal/External Features: Techniques such as adding internal or external elements, like decorative glass or small added figures, can enhance the visual appeal.

The choice of technique depends on the complexity of the design and the desired level of precision. It’s a blend of artistry and technical skill.

Q 15. Explain the importance of maintaining consistent internal gas pressure in neon tubing.

Maintaining consistent internal gas pressure in neon tubing is paramount for several reasons. Think of it like inflating a balloon – you need the right amount of air for it to hold its shape and not burst. In neon bending, the pressure determines the structural integrity and the final shape of the tubing.

Firstly, too little pressure can lead to collapse of the tubing during bending, resulting in uneven shapes and potentially breaking the glass. Conversely, too much pressure can cause the glass to expand excessively while hot, making it brittle and prone to cracking or exploding once cooled. A consistent pressure ensures the glass remains malleable during the bending process while preventing dangerous pressure build-up.

We typically monitor pressure using a pressure gauge connected to the tubing during the heating and bending phases. This allows for real-time adjustments and ensures the optimal pressure is maintained throughout the entire process. Consistent pressure also helps to maintain a uniform wall thickness throughout the tube, which is essential for a high-quality, durable neon sign.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you work with different color gases to create various neon sign colors?

Different neon sign colors are achieved by filling the glass tubing with various gases or gas mixtures. Pure neon gas produces a bright reddish-orange glow, which is the classic neon color. However, a whole spectrum of colors is attainable by incorporating other gases or by using phosphors.

- Neon (Ne): Produces a classic reddish-orange.

- Argon (Ar): Creates a light blue or lavender, often used for pastel shades.

- Helium (He): Offers a pale pinkish-white or lilac glow.

- Krypton (Kr): Produces a light yellowish-white.

- Xenon (Xe): Generates a bluish-white.

- Mercury (Hg): Combined with argon, it enhances the color and brightness of other gases.

- Phosphors:** Coated inside the tube, these create various colors, including vibrant reds, greens, blues, and yellows, far beyond the natural colors of the gases. For example, a blue neon tube usually utilizes a phosphor coating with argon gas. This method allows for a much greater range of colors compared to the limited range of gases alone.

The process involves carefully evacuating the tubing, then filling it with the selected gas(es) using a vacuum pump and precise gas-filling equipment to reach the desired pressure and color. Precise measurements are crucial for consistent and predictable results.

Q 17. What are the different types of glass seals used in neon sign fabrication?

Several types of glass seals are used in neon sign fabrication, each serving a specific purpose in ensuring the integrity of the gas-filled tubing.

- Butt Seals: This is the most common type where two pieces of tubing are butted together and carefully heated until melted to create a hermetic seal. Precision and practice are vital for achieving a leak-free seal.

- Compression Seals: Used for joining tubing to metal electrodes. Here, a metal electrode is inserted into the tubing and a compression fitting is applied to create a tight seal. This often involves using a specialized sealant.

- Glass-to-Metal Seals: These are sophisticated seals that use special glasses with thermal expansion coefficients similar to that of the metal electrodes to ensure a durable and leak-proof seal. These are frequently employed when high pressure or larger tubing are used.

Selecting the appropriate seal type depends heavily on the specific design, the gas used, and the intended operating conditions of the neon sign. In my experience, the success of a seal largely depends on cleanliness and the skill of the glassblower in achieving the proper temperature and pressure during the sealing process.

Q 18. How do you prepare the glass tubing before bending?

Preparing the glass tubing is crucial for successful bending. This involves several steps:

- Cleaning: The glass must be meticulously cleaned to remove any grease, dust, or other contaminants that could compromise the seal integrity. This typically involves washing with soap and water, rinsing with distilled water, and then thoroughly drying. We may also use specialized cleaning agents.

- Flaming: The glass is then carefully flamed to remove any lingering moisture or surface impurities. This process also helps improve the bonding during the sealing and bending processes.

- Pre-heating: Before bending, the glass is preheated to a specific temperature. This softening of the glass makes it pliable and less prone to cracking during the bending process. The pre-heating temperature is carefully controlled to minimize the risk of overheating. This often involves observing color change in the glass tubing as it heats up.

Improper preparation can lead to stress fractures, uneven bends, or even breakage during the bending process itself. Therefore, careful and thorough preparation is a non-negotiable aspect of the work.

Q 19. What are the signs of overheating during glass bending?

Overheating during glass bending is a serious concern that can lead to irreparable damage. Here are some key indicators:

- Excessive Sagging: If the glass starts to sag excessively under its own weight, it’s a clear sign of overheating. The glass becomes too soft and loses its structural integrity.

- Color Changes: The glass’s color might change noticeably to become darker or duller. This indicates the glass has exceeded its ideal working temperature and may have been damaged.

- Bubbles: The appearance of bubbles in the heated area suggests excessive heat and possible decomposition of the glass.

- Cracking/Fracturing: In severe cases, overheating can lead to cracking or fracturing of the glass. This necessitates discarding the damaged piece.

Identifying these signs early is critical. Immediate removal of the heat source is crucial to prevent further damage. If the glass shows even slight signs of overheating, it may need to be discarded depending on severity to ensure the quality and safety of the final product.

Q 20. Explain the importance of proper annealing after bending.

Annealing is a crucial post-bending process that involves slowly cooling the bent glass. Think of it as a relaxation period for the glass. The bending process puts stress on the glass structure. Annealing relieves this internal stress by allowing the glass to cool uniformly, preventing the formation of internal stresses and cracks. It’s like letting a stretched rubber band slowly return to its original shape, thus preventing it from snapping.

Improper annealing can lead to significant problems down the line, such as cracks or spontaneous breakage of the finished neon sign, potentially leading to safety hazards. We accomplish this through controlled cooling in a digitally controlled annealing oven. The cooling rate is carefully managed to avoid rapid temperature changes that could cause cracking. The time spent in the annealing oven depends on several factors such as the size of the sign and the complexity of the bends.

This process is essential for the long-term durability and structural integrity of the neon sign, ensuring it lasts for years without breaking or showing signs of internal stress.

Q 21. Describe your experience with different types of neon sign designs.

Throughout my career, I’ve had the privilege of working on a diverse range of neon sign designs. From classic, straightforward lettering for businesses to intricate, artistic pieces featuring curves, spirals, and complex shapes, the possibilities are endless.

- Traditional Neon Signs: These include classic storefront signs with bold lettering, often using a limited color palette.

- Artistic Neon Sculptures: I’ve worked on projects creating custom neon art pieces with complex curves, shapes, and designs, often integrated into larger installations.

- Custom Designs: I also take on projects that include replicating logos, drawing detailed illustrations, or making neon versions of existing artworks.

- Custom Color Schemes: The colors are not limited to the standard palette. We often use custom phosphors to create vibrant and unique color combinations based on client requests.

Each project presents unique challenges and opportunities to showcase creativity and technical skill. The ability to understand a client’s vision and translate it into a functional and aesthetically pleasing neon sign is what makes this work so rewarding.

Q 22. Explain your familiarity with relevant safety regulations and codes related to neon sign installation.

Safety is paramount in neon glass bending and sign installation. My familiarity with relevant regulations and codes, such as OSHA guidelines and local electrical codes, is comprehensive. This includes understanding and adhering to regulations concerning high-voltage electricity, handling of glass, and proper ventilation during the glass bending process. For example, I always ensure that the work area is well-ventilated to prevent exposure to harmful gases produced during the heating process. I meticulously follow lockout/tagout procedures when working with electrical components, preventing accidental energization. Before any installation, I thoroughly review building codes and ensure compliance with all relevant safety standards, often collaborating with the client and other contractors to create a safe working environment.

- Personal Protective Equipment (PPE): Consistent use of safety glasses, gloves, and respiratory protection is non-negotiable.

- Proper grounding: All electrical components are properly grounded to prevent electrical shocks.

- Elevated work platforms: When working at heights during installation, I always utilize appropriate safety harnesses and fall protection equipment.

Q 23. How do you ensure the longevity and durability of a neon sign?

Ensuring the longevity and durability of a neon sign involves careful consideration throughout the entire process, from material selection to installation and maintenance. High-quality glass tubing, properly filled with inert gases like neon or argon, and expertly crafted electrodes are crucial. Avoiding sharp bends and ensuring proper electrode placement minimizes stress points and premature failure. After bending, the sign is carefully cleaned and sealed to protect against moisture and corrosion. Proper installation also plays a significant role; shielding the sign from harsh weather conditions with a suitable canopy or enclosure significantly extends its lifespan. Finally, regular maintenance, including visual inspection for cracks or loose connections, will help identify potential problems before they escalate.

For example, I once worked on a coastal sign where saltwater corrosion was a significant concern. We addressed this by using specialized weatherproof seals and coatings, ensuring the sign continued to operate flawlessly for years after installation.

Q 24. Describe your experience working with various types of neon sign power supplies.

My experience encompasses a wide range of neon sign power supplies, from traditional high-voltage transformers to more modern, energy-efficient options. I’m proficient in working with both magnetic and electronic ballasts, understanding their respective strengths and weaknesses. Magnetic ballasts are known for their reliability but are less energy-efficient. Electronic ballasts, on the other hand, offer better energy efficiency but can be more susceptible to surges. I’ve worked extensively with both types, choosing the appropriate supply based on the specific requirements of the project—factors like sign size, desired brightness, and budget constraints all come into play. I also have experience troubleshooting and repairing various power supply issues, including diagnosing faulty transformers, capacitors, and rectifiers.

For instance, on a recent large-scale project, we opted for electronic ballasts due to their energy savings. This required careful planning to ensure compatibility with the neon tubes and the overall electrical system.

Q 25. What is your experience with troubleshooting electrical issues in neon signs?

Troubleshooting electrical issues in neon signs requires a systematic approach. I begin by visually inspecting the entire system for loose connections, damaged wires, or faulty components. This often involves using a multimeter to test voltage and current levels at various points in the circuit. I systematically isolate the problem area by checking individual components and comparing readings to known good values. Understanding the basic electrical principles governing neon signs, such as the relationship between voltage, current, and gas pressure, is essential for effective troubleshooting. Common problems I’ve encountered include blown fuses, faulty transformers, or gas leaks within the tubes. In the case of a gas leak, we might employ specialized equipment to locate the precise point of leakage before implementing the necessary repairs.

For example, I once encountered a flickering sign. Through systematic checks, I discovered a loose connection within the transformer, easily fixed by tightening the connection, restoring the sign’s functionality.

Q 26. Describe your process for estimating materials and labor for a neon sign project.

Estimating materials and labor for a neon sign project involves a multi-step process. First, I carefully review the client’s design, noting the size, complexity, and specific requirements (like colors and fonts). Based on this, I calculate the length of glass tubing needed, taking into account waste factors during bending. Then, I determine the required amount of electrodes, gas, and other materials. Labor costs are estimated based on the project’s complexity and the number of hours involved in glass bending, installation, and electrical work. I’ll also factor in travel time and any unforeseen circumstances. I use historical data from past projects as a reference point to refine my estimates and ensure accuracy. This ensures that both I and the client have a clear understanding of the project’s costs before we begin.

Q 27. How do you maintain clean work habits and practices in neon glass bending?

Maintaining clean work habits is crucial for both safety and quality in neon glass bending. This includes having a well-organized workspace with appropriate storage for tools and materials. Regularly cleaning the work area removes dust and debris, preventing contamination of the glass tubing and reducing the risk of accidents. I always wear appropriate PPE, like gloves to prevent glass cuts, and ensure proper ventilation to reduce the risk of inhaling harmful fumes. Careful handling of the glass tubing minimizes the risk of breakage and maintains the integrity of the finished product. Proper disposal of waste materials is also very important, in accordance with local environmental regulations.

Q 28. Describe your experience with working on large-scale neon sign projects.

I have extensive experience working on large-scale neon sign projects, often involving multiple sign elements, complex designs, and intricate installation requirements. This has included coordinating with other professionals, such as structural engineers and electricians, to ensure the successful completion of the project. Large-scale projects demand meticulous planning, accurate material estimations, and effective on-site management. Effective communication and collaboration are key to success. For instance, I recently completed a project involving a series of interconnected signs spanning several blocks in a downtown area. The coordination of fabrication, transportation, and installation required careful planning and collaboration with the city’s utilities and traffic management teams.

Key Topics to Learn for Your Neon Glass Bending Interview

- Glass Properties and Selection: Understanding the different types of glass suitable for bending, their thermal properties, and how these influence the bending process. Consider factors like softening point, coefficient of expansion, and potential for cracking.

- Bending Techniques and Equipment: Familiarity with various bending methods (e.g., flame bending, gravity bending, oven bending) and the operation of associated equipment like torches, ovens, and bending molds. Practical experience is invaluable here.

- Gas Handling and Safety Procedures: Demonstrate a thorough understanding of safe handling practices for fuel gases (e.g., propane, butane) and inert gases (e.g., argon). This includes recognizing potential hazards, using appropriate safety equipment, and adhering to safety regulations.

- Design and Fabrication: Understanding how designs translate into the bending process. This includes pattern creation, template construction, and considering factors like glass thickness and bend radius for successful outcomes.

- Troubleshooting and Problem Solving: Be prepared to discuss common problems encountered during the bending process (e.g., cracking, uneven bending, color variations) and the strategies employed to address them. Thinking critically and offering solutions is key.

- Finishing and Post-Processing: Knowledge of techniques used to refine the bent glass, such as cleaning, polishing, and sealing, to achieve a high-quality, professional finish.

Next Steps

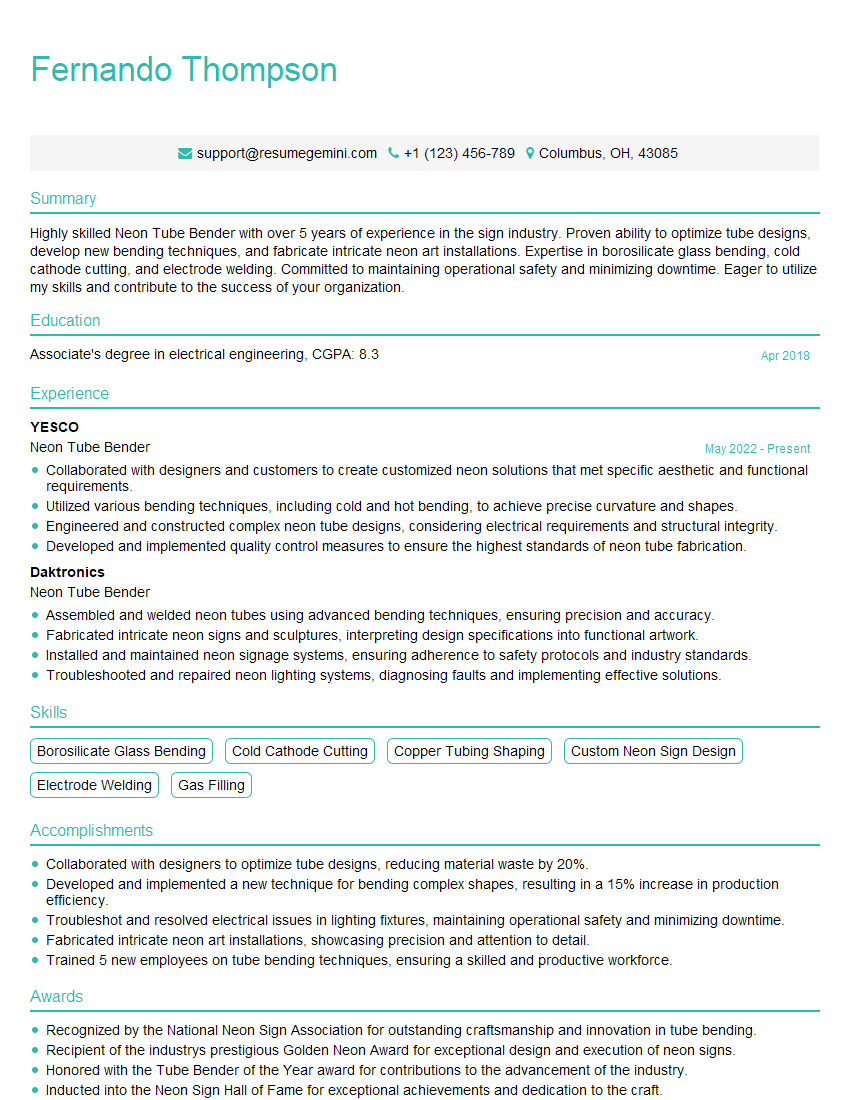

Mastering neon glass bending opens doors to exciting career opportunities in a specialized and creative field. To maximize your chances of landing your dream job, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume designed to get noticed. Examples of resumes tailored to the Neon Glass Bending field are available to guide you. Invest the time to craft a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.