The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Adhering to safety and environmental regulations interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Adhering to safety and environmental regulations Interview

Q 1. Describe your experience with OSHA regulations.

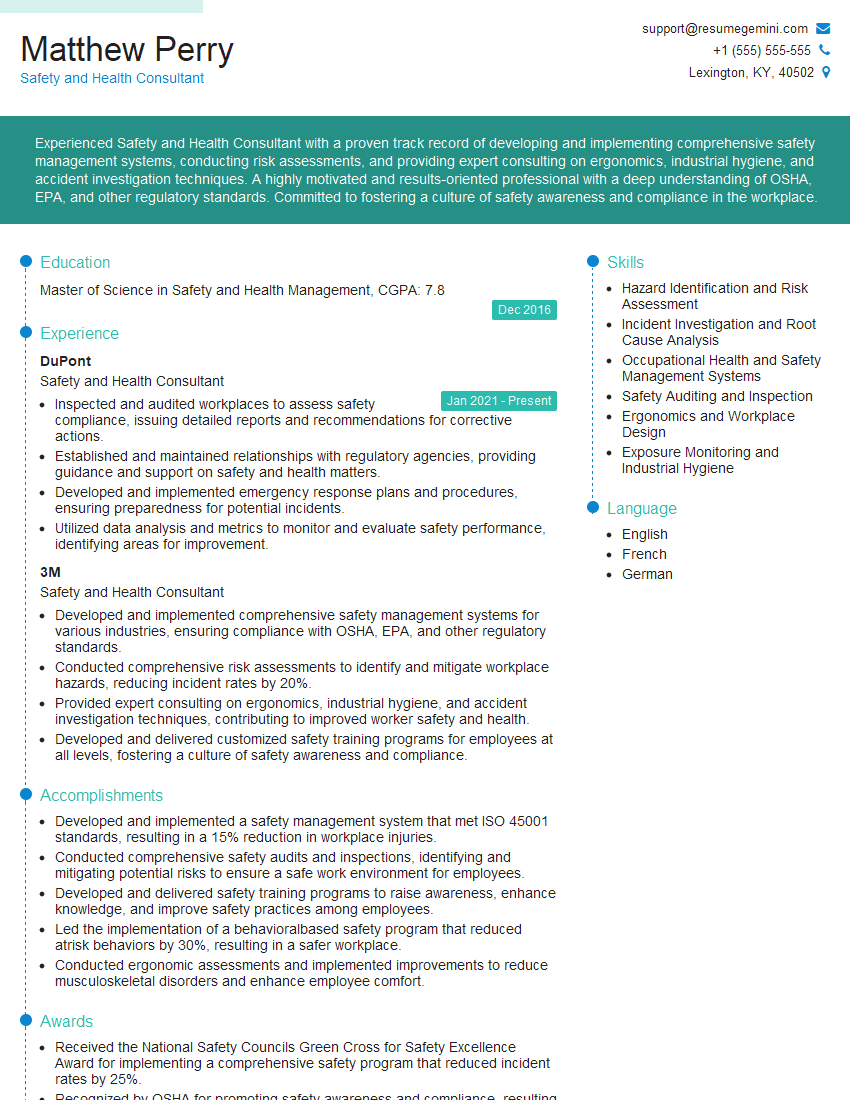

My experience with OSHA regulations spans over ten years, encompassing various roles from safety officer to environmental manager. I’ve worked extensively with OSHA’s General Industry Standards, specifically focusing on hazard communication, lockout/tagout procedures, and personal protective equipment (PPE) requirements. I’ve been directly involved in conducting OSHA inspections, developing and implementing corrective actions following citations, and training employees on OSHA compliance. For example, in my previous role at a manufacturing plant, I successfully implemented a comprehensive lockout/tagout program that significantly reduced the risk of machine-related injuries, leading to a 30% decrease in recordable incidents. This involved detailed training, regular audits, and meticulous documentation, all in strict adherence to OSHA’s guidelines.

I’m also familiar with OSHA’s recordkeeping requirements, understanding the importance of accurately documenting incidents, injuries, and illnesses. This data is crucial for identifying trends, implementing preventative measures, and demonstrating compliance to regulatory bodies. A clear understanding of OSHA’s reporting procedures is paramount to avoiding penalties and fostering a safe work environment.

Q 2. Explain the process for conducting a safety audit.

Conducting a thorough safety audit involves a systematic approach, combining observation, interviews, and documentation review. It starts with defining the scope – identifying the specific areas or processes to be audited. Next, we develop a checklist tailored to the relevant regulations and industry best practices. This checklist might include items like PPE usage, machine guarding, emergency procedures, and hazardous material handling. The audit itself involves a combination of physical inspections to identify hazards and interviews with employees to understand their perspectives and experiences.

Following the on-site assessment, all findings are documented, categorized by severity, and prioritized based on the potential for harm. A detailed report is then generated, outlining the identified hazards, non-compliances, and recommended corrective actions. This report is crucial for communicating the findings to management and implementing the necessary improvements. Follow-up audits are crucial to ensure the implemented corrective actions are effective and sustainable. Think of it like a doctor’s checkup for your workplace – regular check-ups help prevent major issues.

Q 3. How do you identify and mitigate environmental risks?

Identifying and mitigating environmental risks requires a proactive and comprehensive approach. It begins with a thorough environmental assessment, evaluating potential sources of pollution, such as air emissions, wastewater discharges, and hazardous waste generation. This assessment often involves conducting site surveys, reviewing existing environmental data, and consulting relevant regulations and permits. For example, if a facility uses solvents, we’d assess their storage, handling, and disposal to prevent spills and air emissions.

Once identified, risks are prioritized based on their likelihood and potential severity. Mitigation strategies are then developed, which might include implementing pollution control technologies, improving waste management practices, and implementing spill prevention and response plans. Regular monitoring and reporting are also critical to ensure the effectiveness of these mitigation measures. Think of it like a layered defense; the more layers you have, the better you protect the environment.

Q 4. What are your methods for ensuring compliance with environmental permits?

Ensuring compliance with environmental permits requires meticulous record-keeping and regular monitoring. We maintain detailed records of all permitted activities, including the quantities of materials handled, emissions generated, and waste disposed of. This data is crucial for demonstrating compliance during regulatory inspections. Regular self-audits and internal inspections are conducted to identify any potential non-compliances early on, allowing for prompt corrective action. For instance, if a permit limits wastewater discharge to a specific level, regular monitoring and analysis are performed to ensure we stay within the limits. Any deviations are immediately reported to the regulatory agency.

In addition, we regularly update our understanding of evolving regulations and ensure our practices remain current. This involves participating in industry workshops and staying informed through professional organizations and regulatory updates. Proactive compliance minimizes the risk of penalties and maintains a positive relationship with regulatory agencies.

Q 5. Describe your experience with incident investigation and reporting.

My experience in incident investigation and reporting is extensive. I follow a structured approach, starting with securing the scene and ensuring the safety of personnel. The investigation then involves collecting evidence – taking photos, interviewing witnesses, reviewing operational data, and analyzing equipment failures. The goal is to determine the root cause of the incident, not just the immediate cause. For example, if a worker was injured by falling debris, the investigation wouldn’t stop at identifying the debris; we’d look into why the debris fell, identifying potential failures in maintenance, safety procedures, or training.

A comprehensive report is prepared, detailing the findings and recommended corrective actions. This report is shared with relevant stakeholders, including management and regulatory agencies as required. This process helps prevent similar incidents from occurring in the future. The lessons learned are incorporated into safety training and process improvements.

Q 6. How do you develop and implement safety training programs?

Developing and implementing effective safety training programs requires a needs assessment to identify training gaps. This involves evaluating current safety practices, assessing employee knowledge and skills, and reviewing incident reports. Training programs are designed to address these gaps, using a variety of methods, such as classroom lectures, hands-on training, simulations, and online modules. For example, a training program on lockout/tagout would involve both classroom instruction on the theory and hands-on practice using actual equipment.

Regular refresher training is critical to ensure that employees maintain their knowledge and skills. Training effectiveness is monitored through assessments and evaluations. The success of a safety training program is measured not just by the number of hours of training, but by a demonstrable reduction in incidents and improved safety behaviors. Training should be engaging and relevant, making use of interactive methods to keep employees involved and invested in their own safety.

Q 7. Explain your understanding of ISO 14001.

ISO 14001 is an internationally recognized standard for environmental management systems (EMS). It provides a framework for organizations to systematically manage their environmental impacts. The standard emphasizes a Plan-Do-Check-Act (PDCA) cycle for continual improvement. It requires organizations to establish an environmental policy, identify environmental aspects and impacts, set environmental objectives and targets, and develop and implement environmental programs. This includes aspects such as waste management, energy efficiency, pollution prevention, and compliance with environmental regulations.

Achieving ISO 14001 certification demonstrates an organization’s commitment to environmental responsibility. It helps reduce environmental risks, improve operational efficiency, enhance stakeholder relations, and achieve a competitive advantage. It’s not just about meeting minimum requirements; it’s about establishing a culture of continuous improvement in environmental performance. Think of it as a roadmap for sustainable operations.

Q 8. How do you manage environmental waste disposal?

Environmental waste disposal is managed through a rigorous system that prioritizes waste reduction, reuse, and recycling before considering disposal. It begins with a comprehensive waste characterization process to identify the types and quantities of waste generated. This allows for proper segregation and handling according to regulatory guidelines.

- Waste Segregation: Different waste streams (e.g., hazardous, recyclable, non-hazardous) are separated at the source to prevent contamination and facilitate efficient processing.

- Recycling and Reuse: We actively promote recycling programs for materials like paper, plastic, and metals. Reusable materials are identified and repurposed wherever possible to minimize waste generation.

- Disposal: Non-recyclable and hazardous wastes are disposed of through licensed and permitted facilities, adhering strictly to all local, state, and federal regulations. We maintain detailed records of all waste disposal activities for auditing and compliance purposes. This includes manifest tracking and ensuring proper labelling and packaging of hazardous materials.

- Treatment: Certain wastes might require specific treatment before disposal (e.g., neutralization of acidic waste). We select treatment methods based on the waste’s characteristics and regulatory requirements.

For instance, in a previous role, we implemented a new waste management system that reduced our overall waste by 25% and increased recycling rates by 15% within a year, saving the company significant disposal costs and reducing our environmental footprint.

Q 9. Describe your experience with emergency response planning.

Emergency response planning is crucial for protecting personnel, the environment, and company assets. It involves a proactive, multi-layered approach that anticipates potential hazards and establishes procedures for effective response.

- Hazard Identification and Risk Assessment: We identify potential hazards such as chemical spills, fires, equipment malfunctions, and natural disasters. A comprehensive risk assessment evaluates the likelihood and potential consequences of each hazard.

- Emergency Response Plan Development: Based on the risk assessment, we develop a detailed plan that outlines roles, responsibilities, communication protocols, evacuation procedures, and emergency contact information. This plan is regularly reviewed and updated to ensure its effectiveness.

- Emergency Drills and Training: Regular drills and training exercises are conducted to ensure personnel are familiar with the emergency response plan and procedures. This includes hands-on training with emergency equipment and simulated scenarios.

- Communication System: A reliable communication system is essential for coordinating response efforts during an emergency. This may involve using two-way radios, emergency alerts, and designated communication channels.

- Post-Incident Review: After any incident, a thorough review is conducted to identify areas for improvement in the emergency response plan and procedures.

For example, I led the development and implementation of a comprehensive emergency response plan at a chemical manufacturing facility. This plan successfully guided our response to a minor chemical spill, minimizing environmental impact and preventing injuries.

Q 10. How do you monitor and control air emissions?

Air emission monitoring and control involve continuous efforts to ensure that emissions from our operations comply with regulatory limits and protect air quality. This is accomplished through a combination of techniques.

- Emission Inventory: We first conduct a comprehensive inventory of all emission sources, quantifying the types and amounts of pollutants released. This inventory helps identify areas needing the most attention.

- Continuous Emission Monitoring (CEM): For significant emission sources, CEM systems are used to continuously monitor and record pollutant concentrations. This provides real-time data, enabling prompt responses to any deviations from permitted limits.

- Source Control Technologies: We employ various technologies to control emissions, such as scrubbers for removing particulate matter and pollutants from exhaust gases, and catalytic converters for reducing harmful emissions from combustion processes.

- Regular Inspections and Maintenance: Emission control equipment is regularly inspected and maintained to ensure its proper functioning and prevent malfunctions that could lead to increased emissions.

- Data Reporting and Compliance: All emission data is meticulously recorded and reported to regulatory agencies as required. This ensures transparency and helps track compliance with permits and regulations.

In a past project, we implemented a new stack monitoring system that allowed for real-time detection and correction of deviations in air emissions, preventing potential environmental violations and significantly improving air quality compliance.

Q 11. How do you handle hazardous materials safely?

Safe handling of hazardous materials requires a multi-faceted approach emphasizing prevention, control, and emergency preparedness. This begins with proper identification and classification of hazardous materials based on their properties (e.g., flammability, toxicity, reactivity).

- Material Safety Data Sheets (MSDS): We maintain up-to-date MSDS for all hazardous materials used or stored on-site. These sheets provide vital information on handling, storage, and emergency response.

- Proper Storage and Handling: Hazardous materials are stored in designated areas, following strict guidelines on compatibility and segregation to prevent accidental reactions or spills. Personnel receive comprehensive training on safe handling procedures, including the use of personal protective equipment (PPE).

- Spill Prevention and Control: Spill kits and containment procedures are implemented to prevent and mitigate accidental spills. Regular inspections ensure that storage areas are properly maintained and free from leaks or spills.

- Waste Management: Hazardous waste is managed according to strict regulatory guidelines, ensuring proper labelling, packaging, and transportation to licensed disposal facilities.

- Employee Training: Regular training is crucial to ensure that employees are fully aware of the risks associated with hazardous materials and have the skills and knowledge to handle them safely.

For example, I developed and implemented a comprehensive hazardous material management program that resulted in a significant reduction in workplace accidents and environmental incidents.

Q 12. What is your experience with spill response procedures?

Spill response procedures are crucial for minimizing the environmental and health impacts of accidental releases. A well-defined spill response plan should be in place for all potential spills, including detailed procedures for containment, cleanup, and reporting.

- Spill Prevention: Prevention is the first and most important step. This involves implementing measures to minimize the risk of spills, such as proper equipment maintenance, safe handling procedures, and spill containment barriers.

- Emergency Response Team: A trained emergency response team should be readily available to respond to spills promptly and effectively. The team should be equipped with the necessary protective gear and cleanup materials.

- Containment and Cleanup: Spill response procedures should outline steps to contain the spill, prevent its spread, and remove the spilled material safely. This may involve using absorbent materials, booms, or other containment devices.

- Waste Disposal: Spilled materials should be properly collected, packaged, and disposed of according to regulatory requirements.

- Reporting and Documentation: All spills should be reported to the appropriate authorities, and detailed records should be maintained for future reference and compliance purposes.

In a previous incident, our well-rehearsed spill response team quickly contained and cleaned up a chemical spill, preventing significant environmental damage and demonstrating the importance of preparedness.

Q 13. Explain your understanding of risk assessment methodologies.

Risk assessment methodologies are systematic processes for identifying, analyzing, and evaluating potential hazards and their associated risks. The goal is to determine the likelihood and severity of adverse events and to implement appropriate control measures to mitigate these risks.

- Hazard Identification: This involves systematically identifying all potential hazards associated with a particular activity or process. This can include brainstorming sessions, hazard checklists, and process flow diagrams.

- Risk Analysis: This step involves assessing the likelihood and severity of each identified hazard. This often involves using qualitative or quantitative techniques, such as fault tree analysis or event tree analysis. The likelihood is usually expressed as a probability, and the severity is often categorized as minor, moderate, or major.

- Risk Evaluation: This stage combines the likelihood and severity of hazards to determine the overall risk. This may involve using a risk matrix to prioritize risks based on their potential impact.

- Risk Control: Once the risks are evaluated, appropriate control measures are implemented to mitigate the risks. These can range from administrative controls (e.g., training, procedures) to engineering controls (e.g., safety devices, barriers) to personal protective equipment (PPE).

- Monitoring and Review: The effectiveness of risk controls should be regularly monitored and reviewed to ensure that they remain effective and to identify any new hazards or changes in risk levels.

For example, I utilized a Failure Modes and Effects Analysis (FMEA) to identify and mitigate potential hazards in a manufacturing process, ultimately reducing the risk of accidents and equipment failures.

Q 14. How do you ensure compliance with water discharge permits?

Ensuring compliance with water discharge permits involves a multi-pronged approach focused on monitoring, record-keeping, and proactive management.

- Understanding Permit Requirements: The first step is to thoroughly understand the specific requirements outlined in the discharge permit. This includes limits on pollutants, monitoring frequencies, and reporting requirements.

- Effluent Monitoring: Regular monitoring of wastewater effluent is critical to ensure that discharge limits are met. This typically involves collecting samples and sending them to a laboratory for analysis of various parameters such as pH, suspended solids, and specific pollutants. Frequency of monitoring is dictated by the permit.

- Process Control: Effective process control is essential for preventing the discharge of pollutants beyond permitted limits. This may involve implementing treatment technologies to remove pollutants, optimizing processes to minimize waste generation, and implementing regular equipment maintenance.

- Record Keeping: Detailed records of all effluent monitoring data, treatment processes, and maintenance activities must be kept. These records are vital for demonstrating compliance with the permit requirements and for auditing purposes.

- Reporting: Discharge monitoring reports are regularly submitted to the regulatory agency as specified in the permit. These reports should accurately reflect the monitoring results and any deviations from permitted limits.

In a past role, I implemented a new wastewater treatment system that reduced pollutant concentrations below the permit limits, ensuring compliance and improving water quality.

Q 15. Describe your experience with environmental impact assessments.

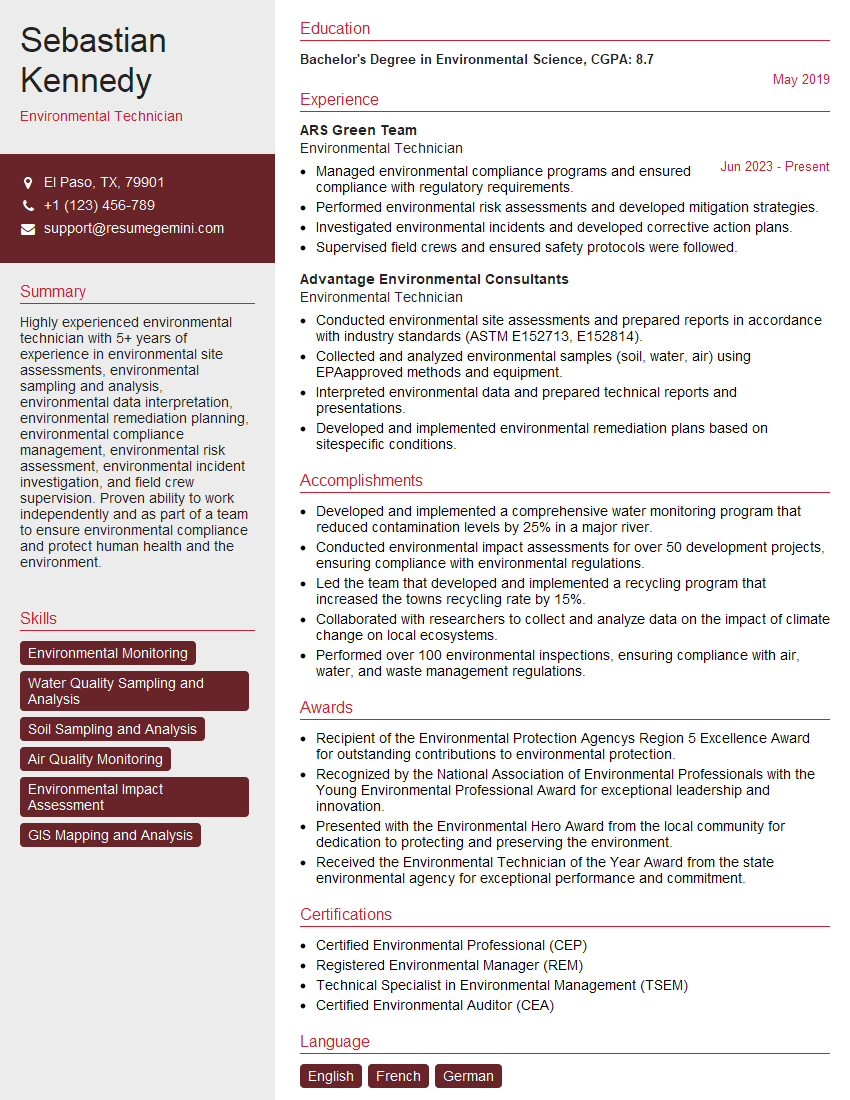

Environmental Impact Assessments (EIAs) are crucial processes for predicting and evaluating the likely environmental consequences of a project or development before it commences. They involve a systematic study of potential impacts, considering factors like air and water quality, biodiversity, and climate change. My experience encompasses conducting EIAs across various sectors, including renewable energy projects, infrastructure development, and industrial expansions.

For example, during an EIA for a proposed wind farm, I led a team in analyzing potential impacts on avian populations. This involved field surveys, habitat assessments, and modeling potential bird mortality. The EIA report then presented mitigation strategies, such as turbine placement optimization and bird deterrent measures, to minimize negative impacts. Another example involves a pipeline project where assessing potential soil erosion and water contamination risk was crucial. We implemented rigorous soil sampling and hydrological modeling to understand potential problems and suggest robust mitigation and monitoring plans.

The process typically involves baseline data collection, impact prediction using various models, and identifying potential mitigation measures. The final EIA report informs decision-making, guiding developers to make environmentally responsible choices.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you use data to improve environmental performance?

Data is the backbone of effective environmental performance improvement. I utilize data from various sources – environmental monitoring programs, energy consumption records, waste generation logs, and emissions inventories – to pinpoint areas needing improvement. This data is then analyzed using statistical methods and visualization tools to identify trends and patterns.

For instance, by analyzing energy consumption data over time, I identified a significant increase in energy use in a specific facility. Further investigation revealed inefficiencies in the HVAC system. Implementing upgrades and operational changes based on this data analysis resulted in a 15% reduction in energy consumption, reducing both costs and our carbon footprint. Similarly, analysis of waste generation data helped identify opportunities for waste reduction and recycling, significantly reducing our reliance on landfills.

Ultimately, data-driven decision-making allows for a proactive, targeted approach to environmental management, leading to significant and measurable improvements.

Q 17. What is your experience with environmental monitoring and sampling?

Environmental monitoring and sampling are essential for assessing environmental conditions and ensuring compliance with regulations. My experience spans various sampling methodologies, including water quality testing, soil analysis, air quality monitoring, and noise level measurements. I am proficient in using various analytical equipment and adhering to stringent quality assurance and quality control (QA/QC) procedures.

For example, I’ve overseen water quality monitoring programs for industrial discharge permits, collecting samples according to regulatory guidelines and analyzing them for various pollutants. Ensuring proper chain of custody, accurate sample labeling, and appropriate preservation techniques were paramount to the reliability of the results. Similarly, during a soil remediation project, I managed extensive soil sampling and analysis to determine the extent of contamination and to evaluate the effectiveness of the remediation efforts. Proper documentation and QA/QC procedures were critical for ensuring the integrity and defensibility of the data. We used GPS mapping for precise sample location recording and a detailed laboratory analysis process for accurate results.

Q 18. How do you communicate safety and environmental regulations effectively?

Effective communication is crucial for ensuring adherence to safety and environmental regulations. I utilize a multi-faceted approach, including training programs, regular briefings, clear signage, and accessible documentation. The key is tailoring the communication method to the audience.

For example, I developed and delivered a comprehensive safety training program for construction workers, covering topics such as hazard identification, personal protective equipment (PPE) use, and emergency response procedures. For management, I use data visualizations and reports to communicate environmental performance, highlighting successes and areas for improvement. For the broader community, I employed public forums and informational brochures to address concerns and build trust.

Clear, consistent, and accessible communication ensures that everyone understands their responsibilities and the importance of adhering to safety and environmental protocols.

Q 19. Describe your experience with developing and implementing environmental management systems (EMS).

Developing and implementing Environmental Management Systems (EMS) based on internationally recognized standards like ISO 14001, is a key part of my expertise. This involves establishing a framework for identifying, controlling, and monitoring environmental aspects and impacts within an organization.

In one project, I led the implementation of an EMS for a manufacturing facility. This included conducting environmental audits, defining environmental objectives and targets, developing procedures and training materials, and establishing monitoring and review mechanisms. This systematic approach ensured compliance with regulatory requirements, reduced environmental risks, and enhanced the company’s environmental performance. We documented all processes using a combination of physical records and digital databases, and regularly updated the EMS to reflect changes in company operations or regulatory guidelines.

The result was a more efficient and environmentally responsible operation, leading to improved resource management, reduced waste, and enhanced stakeholder trust.

Q 20. How do you stay current with changes in environmental regulations?

Staying current with changes in environmental regulations requires a proactive and multi-pronged approach. I regularly review updates from relevant government agencies, subscribe to industry newsletters and journals, and attend professional development workshops and conferences.

I actively participate in professional organizations like the Society of Environmental Toxicology and Chemistry (SETAC) and utilize online resources and legal databases to stay informed on emerging legislation and best practices. This continuous learning is essential to ensure that our operations remain compliant and that we are implementing the most effective environmental protection strategies.

Furthermore, maintaining a network of colleagues and experts allows for the sharing of information and best practices, further enhancing our understanding of the evolving regulatory landscape.

Q 21. How do you ensure the safety of employees and contractors on site?

Ensuring the safety of employees and contractors is paramount. My approach involves a layered safety management system, encompassing proactive risk assessments, comprehensive safety training programs, robust safety protocols, and regular inspections.

Before any work commences, I conduct thorough risk assessments identifying potential hazards, and develop control measures. These measures are then communicated through detailed safety plans and incorporated into the project’s execution. We use a permit-to-work system for high-risk activities, ensuring proper authorization and adherence to safety procedures. Regular safety meetings and toolbox talks reinforce safe work practices and address any emerging concerns. We closely monitor safety performance data to identify trends and implement corrective actions. This includes incident reporting and investigation, with lessons learned communicated across the workforce to prevent future occurrences.

Ultimately, creating a strong safety culture where everyone takes ownership of safety is crucial for preventing accidents and injuries.

Q 22. Describe a time you identified a safety hazard and how you addressed it.

During a routine inspection of a chemical storage facility, I noticed several containers lacking proper labeling, indicating missing or incomplete hazard information. This posed a significant safety risk to personnel handling these chemicals, as they might not be aware of potential hazards like flammability or toxicity. I immediately addressed this by:

- Halting all operations involving those containers.

- Reporting the issue to my supervisor and the safety officer.

- Working with the team to properly label each container according to the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) standards.

- Implementing a retraining program for all personnel involved in handling chemicals to emphasize proper hazard identification and safe handling procedures.

- Developing a more robust inspection checklist to prevent similar occurrences in the future.

This proactive approach not only prevented potential accidents but also strengthened our safety protocols. It demonstrated the importance of diligent oversight and immediate action when safety hazards are identified.

Q 23. How familiar are you with relevant environmental legislation (e.g., Clean Air Act, Clean Water Act)?

I’m very familiar with key environmental legislation, including the Clean Air Act (CAA), Clean Water Act (CWA), and the Resource Conservation and Recovery Act (RCRA). The CAA, for example, sets standards for air quality and regulates emissions from various sources. I understand the different permitting requirements under Title V for major stationary sources, and the National Ambient Air Quality Standards (NAAQS). Similarly, the CWA governs the discharge of pollutants into U.S. waters and regulates the issuance of National Pollutant Discharge Elimination System (NPDES) permits. RCRA focuses on hazardous waste management, from generation to disposal, and dictates stringent regulations for handling, transporting, and storing hazardous materials. I also have working knowledge of state-specific environmental regulations, which often incorporate or enhance federal standards.

My understanding encompasses not just the legal text but also the practical implications for businesses, such as compliance strategies, reporting requirements, and potential penalties for non-compliance. I have experience interpreting these regulations and advising companies on how to meet their obligations.

Q 24. What are your strategies for promoting a safety-conscious culture?

Promoting a safety-conscious culture involves a multi-pronged approach focused on education, engagement, and accountability. My strategies include:

- Regular safety training: Providing comprehensive training programs that are tailored to specific roles and risks. This goes beyond just basic safety rules; it includes emergency response procedures, hazard recognition, and the importance of reporting near misses.

- Open communication: Fostering a culture where employees feel comfortable reporting safety concerns without fear of reprisal. This often involves implementing anonymous reporting systems and actively addressing reported issues.

- Leading by example: Demonstrating a commitment to safety at all levels of the organization. This means adhering strictly to safety procedures and actively participating in safety inspections and training.

- Incentivizing safe behavior: Recognizing and rewarding employees who demonstrate exemplary safety practices. This can include awarding certificates, providing bonuses, or publicly acknowledging their contributions.

- Regular safety meetings and audits: Conducting regular safety meetings to discuss safety concerns, review incidents, and brainstorm improvements. Regular audits ensure compliance and highlight areas for improvement.

Ultimately, creating a safety-conscious culture requires a consistent and ongoing effort, involving every member of the organization.

Q 25. Explain your understanding of different types of environmental permits and licenses.

Environmental permits and licenses are crucial for ensuring compliance with environmental regulations. They authorize specific activities that could potentially impact the environment. Different types of permits address various aspects of environmental protection. Some key examples include:

- Air permits: Issued to facilities emitting air pollutants, these permits specify emission limits and monitoring requirements. They often involve complex modeling and calculations to ensure compliance with NAAQS.

- Water discharge permits (NPDES): These permits authorize the discharge of wastewater into surface waters, outlining the permitted pollutants and their allowable concentrations. Regular monitoring and reporting are essential.

- Solid waste permits: These permits regulate the management of solid and hazardous waste, covering aspects like storage, treatment, and disposal. They typically require detailed waste characterization and management plans.

- Stormwater permits: These permits address stormwater runoff from industrial sites and construction sites, often requiring implementation of Best Management Practices (BMPs) to minimize pollution.

- Wastewater treatment permits: These permits are issued to wastewater treatment plants and detail effluent limitations and monitoring requirements.

The specific requirements for each permit vary depending on the nature of the activity and the applicable regulations. Obtaining and maintaining these permits requires a thorough understanding of environmental regulations and often involves extensive documentation and reporting.

Q 26. Describe your experience with conducting root cause analysis of safety incidents.

Conducting a root cause analysis (RCA) of safety incidents is critical for preventing future occurrences. My approach involves a structured methodology, often using techniques like the ‘5 Whys’ or Fishbone diagrams. For example, if a worker was injured due to a falling object, I wouldn’t simply stop at documenting the injury. I would systematically investigate:

- Why did the object fall? (e.g., inadequate storage, damaged support structure)

- Why was the object inadequately stored? (e.g., lack of training, insufficient equipment)

- Why was there a lack of training? (e.g., insufficient budget, ineffective training program)

- Why was there an ineffective training program? (e.g., outdated materials, lack of management support)

- Why was there a lack of management support? (e.g., inadequate prioritization of safety)

This process continues until the root causes are identified. Then, I would develop corrective actions to address those root causes, ranging from procedural changes to equipment upgrades and improved training programs. The key is to go beyond simply addressing the immediate problem and preventing similar events from happening again.

Q 27. How do you prioritize safety and environmental considerations within a budget?

Prioritizing safety and environmental considerations within a budget requires a strategic approach that focuses on risk assessment and cost-benefit analysis. While cost is a factor, it shouldn’t outweigh the potential cost of accidents or environmental damage. My strategy involves:

- Risk assessment: Identifying potential hazards and assessing the likelihood and severity of their consequences. This allows for focusing resources on the most critical risks.

- Cost-benefit analysis: Evaluating the cost of implementing safety and environmental measures against the potential cost of not doing so (e.g., fines, lawsuits, environmental damage). This helps demonstrate the value of investments in safety and environmental protection.

- Phased implementation: Prioritizing investments based on risk and cost-effectiveness, implementing high-impact, cost-effective measures first.

- Creative solutions: Exploring cost-effective alternatives to expensive safety equipment or procedures. This might involve innovative technologies or process improvements.

- Continuous monitoring: Tracking safety and environmental performance to demonstrate the effectiveness of investments and identify areas for further improvement.

By focusing on the long-term benefits of safety and environmental protection, even within budget constraints, we can create a safer and more sustainable work environment.

Q 28. What are your strategies for continuous improvement in EHS performance?

Continuous improvement in Environmental, Health, and Safety (EHS) performance requires a systematic and data-driven approach. My strategies include:

- Regular performance monitoring: Tracking key EHS indicators (e.g., incident rates, emission levels, waste generation) to identify trends and areas for improvement.

- Data analysis: Using data to pinpoint the root causes of incidents and near misses, allowing for targeted interventions.

- Benchmarking: Comparing EHS performance against industry best practices and identifying opportunities for improvement.

- Regular audits and inspections: Conducting regular internal audits and inspections to identify compliance gaps and areas for improvement. This is often coupled with external audits for independent verification.

- Employee involvement: Encouraging employees to participate in identifying and solving EHS issues through suggestion schemes and active participation in safety committees.

- Implementation of corrective and preventive actions (CAPA): Establishing a systematic CAPA process to address identified deficiencies and prevent future occurrences.

- Staying current with regulations and best practices: Staying up-to-date on changes in EHS regulations and industry best practices to maintain compliance and improve performance.

By consistently applying these strategies, we can achieve continuous improvement in EHS performance, creating a safer and more sustainable work environment.

Key Topics to Learn for Adhering to Safety and Environmental Regulations Interview

- Regulatory Frameworks: Understanding relevant legislation (e.g., OSHA, EPA regulations) and their practical implications in your field.

- Hazard Identification & Risk Assessment: Methods for identifying potential hazards (chemical, biological, physical) and assessing associated risks, including quantitative and qualitative risk analysis techniques.

- Safety Procedures & Protocols: Developing and implementing safe work practices, emergency response plans, and incident reporting procedures. This includes understanding lockout/tagout procedures and personal protective equipment (PPE) selection and use.

- Environmental Monitoring & Compliance: Techniques for monitoring environmental parameters (air, water, soil quality), interpreting data, and ensuring compliance with discharge permits and other environmental regulations.

- Waste Management & Disposal: Proper handling, storage, and disposal of hazardous and non-hazardous waste materials according to relevant regulations.

- Sustainability Practices: Implementing environmentally friendly practices within operations, including energy efficiency, resource conservation, and pollution prevention strategies.

- Incident Investigation & Reporting: Conducting thorough investigations of safety and environmental incidents, documenting findings, and implementing corrective actions to prevent recurrence.

- Communication & Training: Effectively communicating safety and environmental policies and procedures to colleagues and conducting relevant training programs.

- Ethical Considerations: Understanding the ethical implications of decisions related to safety and environmental compliance.

Next Steps

Mastering adherence to safety and environmental regulations is crucial for career advancement in any industry. It demonstrates your commitment to responsible operations and significantly enhances your employability. A strong resume is your first step towards showcasing these skills. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. We strongly encourage you to utilize ResumeGemini to build a professional and impactful resume that highlights your expertise in this critical area. ResumeGemini provides examples of resumes tailored to professionals in Adhering to safety and environmental regulations to help you craft your perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.