Are you ready to stand out in your next interview? Understanding and preparing for Experience with DCS and PLC systems interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Experience with DCS and PLC systems Interview

Q 1. Explain the difference between a PLC and a DCS.

PLCs (Programmable Logic Controllers) and DCSs (Distributed Control Systems) are both industrial automation systems, but they differ significantly in scale, complexity, and application. Think of a PLC as a powerful, single-brain system controlling a smaller, localized process, like a single machine on a factory floor. A DCS, on the other hand, is a distributed, multi-brain system managing a much larger, complex process, such as an entire refinery or power plant.

- Scale: PLCs handle simpler, smaller-scale processes; DCSs handle larger, more complex processes.

- Redundancy: DCSs typically incorporate significant redundancy for higher reliability; PLCs may or may not have built-in redundancy.

- Application: PLCs are ideal for discrete manufacturing, while DCSs are suited for continuous process industries.

- Cost: PLCs are generally less expensive than DCSs.

- Software: PLCs often use simpler programming languages, while DCSs utilize more sophisticated software packages.

For example, a PLC might control a robot arm on an assembly line, while a DCS might manage the temperature and pressure in a chemical reactor.

Q 2. Describe your experience with different PLC programming languages (e.g., Ladder Logic, Structured Text).

My experience encompasses a variety of PLC programming languages. I’m most proficient in Ladder Logic, but also have considerable experience with Structured Text and Function Block Diagram. Ladder Logic is my go-to for its intuitive visual representation, especially when dealing with discrete logic and simple sequencing. It’s very easy for technicians familiar with relay logic diagrams to grasp. However, for more complex algorithms and mathematical calculations, Structured Text offers a more efficient and readable approach. I’ve used Structured Text to develop sophisticated control algorithms, such as PID controllers, for temperature and pressure regulation. Function Block Diagrams provide a good middle ground, offering modularity and readability while still maintaining a visual approach.

For example, I used Ladder Logic to program the sequence of operations for a packaging machine, while I leveraged Structured Text to develop a complex PID control algorithm for a temperature control system in a food processing plant. In both cases, proper documentation and comments were critical for maintainability.

// Example of Structured Text PID controller snippet FUNCTION_BLOCK PIDController VAR_INPUT setpoint : REAL; processValue : REAL; END_VAR VAR_OUTPUT output : REAL; END_VAR // ... PID algorithm implementation ... END_FUNCTION_BLOCKQ 3. How do you troubleshoot a PLC program?

Troubleshooting a PLC program is a systematic process. My approach begins with a thorough understanding of the system’s intended functionality. Then, I follow these steps:

- Gather Information: Start by collecting all relevant information, including alarm logs, historical data, and operator observations. This helps pinpoint the problem area.

- Inspect the Program: Carefully review the PLC program code, looking for potential errors in logic, timing issues, or incorrect data types. Utilizing the PLC’s debugging tools is crucial here, allowing me to step through the code line by line and monitor variables in real-time.

- Check I/O: Verify that the inputs and outputs are functioning correctly. This often involves using a multimeter to test sensors, actuators, and wiring. I’ll simulate input signals to isolate problems in the PLC program from hardware issues.

- Monitor Variables: Observe the values of critical variables during operation. This helps identify where the program’s behavior deviates from the expected functionality.

- Utilize Simulation: If possible, I utilize simulation tools to test the PLC program offline, identifying errors before deployment to the actual system. This greatly speeds up the troubleshooting process and reduces risks.

- Consult Documentation: Thorough documentation of the PLC program is extremely valuable when troubleshooting. Comments within the code, circuit diagrams, and system descriptions are all key.

For example, if a conveyor belt stops unexpectedly, I would first check the PLC’s alarm logs for error messages. Then I’d review the relevant section of the Ladder Logic program, checking the status of sensor inputs signaling the belt’s position and the outputs controlling the motor.

Q 4. What are the common communication protocols used in industrial automation (e.g., Modbus, Profibus, Ethernet/IP)?

Industrial automation relies on various communication protocols to enable seamless data exchange between different devices. The choice of protocol depends on factors such as speed, distance, and network topology. Some common protocols include:

- Modbus: A widely used, simple, and robust protocol for serial communication. It’s often used for connecting PLCs, HMIs, and other field devices in relatively small networks.

- Profibus: A high-speed fieldbus protocol commonly used in industrial automation, suitable for demanding applications requiring fast data transfer and precise timing. It’s often found in large-scale automation projects.

- Ethernet/IP: An industrial Ethernet protocol using the TCP/IP protocol stack, providing high-speed communication over large distances. It’s well-suited for complex, distributed systems.

- Profinet: Another popular industrial Ethernet protocol that provides a robust and reliable connection for various devices. It’s known for its ability to integrate seamlessly with different Siemens products.

- OPC UA: (Unified Architecture) is a platform-independent, interoperable protocol for data exchange. Its ability to support diverse communication protocols makes it crucial for heterogeneous systems.

In a project I worked on, we used Modbus for connecting sensors and actuators to a PLC, and Ethernet/IP to communicate between the PLC and the DCS, ensuring efficient data flow and central monitoring of the entire system.

Q 5. Explain your experience with DCS hardware architectures.

My experience with DCS hardware architectures encompasses various configurations, from simpler, centralized systems to highly redundant, distributed architectures. I’m familiar with the components of a typical DCS, including:

- Controllers: The processing units that execute control algorithms, often with redundancy for high availability.

- I/O Modules: Interfaces between the controllers and field devices, converting analog and digital signals. These can be remotely located, simplifying wiring and system expansion.

- Operator Stations (HMI): Human-machine interfaces that provide operators with visual feedback of the process, allowing control and monitoring. Often equipped with large touchscreens.

- Communication Network: This connects all components of the DCS, typically high-speed Ethernet networks with redundant paths to ensure reliability.

- Redundant Power Supplies: Critical for uninterrupted operation; uninterruptible power supplies (UPS) are often used for controllers and critical components.

In one project, we implemented a highly redundant architecture with dual controllers, hot standby power supplies, and dual Ethernet networks. This ensured continuous process operation even in case of hardware failure or network disruptions.

Q 6. Describe your experience with DCS software configuration and programming.

My experience with DCS software configuration and programming involves setting up various parameters, configuring communication networks, and developing custom control applications. This includes:

- Database Configuration: Setting up databases for storing process data, historical trends, and alarm records.

- Control Strategy Development: Designing and implementing complex control algorithms and sequences using the DCS’s programming environment.

- HMI Design and Configuration: Developing intuitive operator interfaces for monitoring and controlling the process, making them user friendly.

- Alarm and Event Management: Configuring alarm thresholds and defining actions to be taken when specific events occur.

- Networking: Configuring the communication network between the controllers, I/O modules, and operator stations.

I’ve worked with several DCS platforms, and I’m proficient in configuring and programming various aspects of the system. For instance, I once developed a custom control algorithm for a wastewater treatment plant using the DCS’s advanced process control functionalities. This included tuning PID controllers, implementing cascade control strategies, and generating detailed reports.

Q 7. How do you handle alarms and events in a DCS system?

Handling alarms and events in a DCS is crucial for efficient operation and safe shutdown procedures. A well-configured alarm system provides timely notification of abnormal conditions. My approach involves:

- Alarm Prioritization: Classifying alarms based on severity and urgency, ensuring that critical alarms receive immediate attention.

- Alarm Suppression: Configuring the system to temporarily suppress nuisance alarms that might obscure important ones.

- Alarm Acknowledgment: Ensuring operators acknowledge alarms and take appropriate action; a delay in acknowledgment triggers escalation procedures.

- Event Logging: Maintaining comprehensive records of all alarms, events, and operator actions for analysis and future improvements.

- Alarm Reporting: Generating reports summarizing alarm trends and frequencies to identify potential system weaknesses.

- Integration with other systems: Integrating the alarm system with other safety or security systems, such as SMS or email notifications, for wider notification coverage.

In a recent project, I implemented an advanced alarm management system that reduced alarm flooding by optimizing alarm thresholds and implementing intelligent alarm suppression rules. This improved operator efficiency and reduced the likelihood of critical alarms being missed.

Q 8. Explain your experience with different types of sensors and actuators used in industrial automation.

My experience encompasses a wide range of sensors and actuators commonly used in industrial automation. Sensors provide input data reflecting the state of a process, while actuators execute control actions. Let’s look at some examples:

- Temperature Sensors: Thermocouples, RTDs (Resistance Temperature Detectors), and thermistors are used extensively to measure temperature in processes ranging from chemical reactors to HVAC systems. I’ve worked with systems using thermocouples for high-temperature applications because of their wide temperature range and robustness, and RTDs for more precise, lower-temperature measurements.

- Pressure Sensors: These, using technologies like piezoresistive or capacitive sensing, are crucial for monitoring pressure in pipelines, vessels, and hydraulic systems. I’ve used pressure sensors to control the flow of fluids in a water treatment plant, ensuring optimal operation and preventing equipment damage.

- Flow Sensors: Devices like Coriolis flow meters, ultrasonic flow meters, and turbine flow meters are essential for monitoring fluid flow rates. In one project, I integrated Coriolis flow meters for precise measurement of liquids with varying viscosities in a chemical blending process.

- Level Sensors: Ultrasonic, radar, and float-type level sensors are vital for monitoring liquid levels in tanks and reservoirs. I’ve worked with systems utilizing ultrasonic sensors for their non-contact measurement capabilities, preventing wear and tear in harsh environments.

- Actuators: These execute control commands. Examples include:

- Valves: Solenoid valves, pneumatic valves, and motor-driven valves control fluid flow. I have extensive experience configuring and troubleshooting various valve types in both pneumatic and hydraulic systems.

- Motors: AC and DC motors drive pumps, conveyors, and other machinery. Experience includes programming motion controllers for precise motor control in robotic systems.

Understanding the strengths and limitations of each sensor and actuator type is crucial for selecting the most appropriate technology for a given application. This includes factors like accuracy, reliability, cost, and environmental compatibility.

Q 9. How do you perform data logging and historical trending in a DCS system?

Data logging and historical trending in a DCS (Distributed Control System) are essential for process monitoring, optimization, and troubleshooting. Most DCS platforms provide built-in tools for this. Typically, the process involves:

- Configuration: First, you define which tags (process variables) you want to log. This might involve selecting specific temperatures, pressures, flow rates, or other parameters relevant to the process. The sampling rate (how often data is recorded) is also configurable, depending on the process dynamics and desired data resolution. I’ve used both event-based and time-based logging in different applications.

- Data Storage: The DCS stores this logged data in its database. The storage capacity and retention policies are configurable, allowing you to store historical data for specified durations.

- Trending: The DCS provides graphical tools to visualize the logged data as trends. You can create custom trend displays showing multiple parameters over time, allowing for easy identification of patterns, anomalies, and trends. I have often used these trends to pinpoint the root cause of process upsets, optimize control parameters, and validate the effectiveness of control strategies.

- Reporting: Many DCS systems offer features to generate reports from the logged data, which are essential for regulatory compliance and process analysis. This can include generating summary statistics, exporting data to spreadsheets, or creating customized reports.

For example, in a chemical process, trending the temperature and pressure over a batch cycle can reveal deviations from the desired profile and help in identifying potential problems with the process or equipment.

Q 10. Describe your experience with safety instrumented systems (SIS).

My experience with Safety Instrumented Systems (SIS) focuses on ensuring the safe operation of industrial processes by mitigating hazardous events. SIS are independent systems designed to shut down or mitigate hazardous situations in case of equipment failure or process deviations. I’ve worked on projects involving the design, implementation, and testing of SIS according to industry standards (like IEC 61511).

- Safety Requirements Specification: This initial phase involves identifying potential hazards and determining the necessary safety functions to mitigate those risks. This includes analyzing risk levels and selecting appropriate safety integrity levels (SILs) for each safety function.

- Hardware Selection and Design: This stage involves selecting appropriate safety instrumented function (SIF) components, including sensors, logic solvers, and final control elements, all meeting the required SIL levels. I’ve had experience specifying and integrating various safety PLCs, emergency shutdown systems, and high-integrity pressure protection systems (HIPPS).

- Software Configuration and Testing: This involves programming the safety logic solvers (often using specialized safety-rated programming languages) and rigorously testing the system’s functionality through various techniques, including functional safety testing, simulation, and safety integrity level (SIL) verification. This testing is crucial to ensure the system will reliably perform its safety function under various fault conditions.

- Documentation and Compliance: Thorough documentation of the SIS design, implementation, and testing is critical for demonstrating compliance with safety standards and regulations. I’m experienced in creating safety manuals, operating procedures, and compliance documentation.

A real-world example involves a high-pressure gas pipeline. The SIS would monitor pressure and, if it exceeded a predefined limit, automatically shut down the pipeline, preventing a potential catastrophic failure.

Q 11. What is a PID controller and how does it work?

A PID controller is a feedback control loop mechanism widely used in industrial automation to maintain a process variable at a desired setpoint. PID stands for Proportional, Integral, and Derivative.

- Proportional (P): This component responds to the error (difference between the setpoint and the measured value) proportionally. A larger error results in a larger corrective action. The proportional gain (Kp) determines the strength of this response.

- Integral (I): This component addresses persistent errors. It accumulates the error over time, providing a corrective action that eliminates steady-state errors. The integral gain (Ki) determines how quickly the integral action eliminates the error. Think of it as correcting for any persistent drift.

- Derivative (D): This component anticipates future errors based on the rate of change of the error. It dampens rapid changes and prevents overshoot. The derivative gain (Kd) determines the sensitivity to the rate of change.

The PID controller output is the sum of the proportional, integral, and derivative actions: Output = Kp * Error + Ki * ∫Error dt + Kd * d(Error)/dt. Tuning these gains (Kp, Ki, Kd) is critical for optimal control performance. Poorly tuned PID controllers can lead to oscillations, slow response, or even instability.

Imagine controlling the temperature of an oven. The proportional term adjusts the heating element based on the current temperature difference. The integral component addresses slow temperature drift, while the derivative component prevents sudden temperature swings when the setpoint is changed.

Q 12. Explain your experience with HMI (Human Machine Interface) design and configuration.

My HMI design and configuration experience involves creating user-friendly interfaces for operators to monitor and control industrial processes. This includes selecting appropriate hardware, designing intuitive screen layouts, and configuring the communication between the HMI and the underlying PLC or DCS.

- Hardware Selection: Choosing the right HMI hardware involves considering factors like screen size, resolution, processing power, and environmental ruggedness. I’ve worked with various HMI platforms, from panel-mounted HMIs to large-scale visualization systems.

- Screen Design: Effective HMI design prioritizes clear and concise information presentation. This involves using appropriate graphics, alarm displays, and data visualization techniques to ensure operators can quickly understand the process state and take appropriate actions. I follow human factors principles to optimize usability.

- Software Configuration: This stage involves configuring the HMI software to communicate with the PLC or DCS, mapping process variables to screen elements, and designing the user interface’s logic and functionality, including alarm management and historical data access. I’m proficient in using various HMI software packages and scripting languages to achieve complex functionality.

- Testing and Validation: Thorough testing is crucial to ensure the HMI functions correctly and meets operational requirements. This includes simulating various scenarios, testing alarm responses, and ensuring ease of use for operators with various levels of experience.

For example, in a manufacturing plant, the HMI might display real-time data from multiple machines, allowing operators to monitor production rates, detect potential problems, and make adjustments as needed.

Q 13. How do you ensure the safety and security of a PLC or DCS system?

Ensuring the safety and security of PLC and DCS systems requires a multi-layered approach that considers both physical and cyber threats.

- Physical Security: This includes physical access control to the control room and equipment, protecting against unauthorized access, vandalism, or theft. This may involve access control systems, security cameras, and environmental protection measures.

- Network Security: This involves securing the network infrastructure connecting PLCs and DCS to other systems. This includes firewalls, intrusion detection/prevention systems, network segmentation, and regular vulnerability assessments. Using virtual private networks (VPNs) for remote access helps to secure communication.

- Software Security: Regular updates and patching of PLC and DCS firmware and software are essential to mitigate vulnerabilities. Implementing strong password policies and access control mechanisms at the software level restricts unauthorized access and configuration changes.

- Data Security: Protecting sensitive process data from unauthorized access, use, disclosure, disruption, modification, or destruction is crucial. This may involve encryption, data loss prevention (DLP) techniques, and access controls. Regular backups are vital for disaster recovery.

- Regular Audits and Security Assessments: Regular security audits and penetration testing help to identify vulnerabilities and ensure that security measures remain effective. I have experience conducting these assessments to verify compliance with relevant standards.

Ignoring these measures could lead to production downtime, data breaches, or even safety hazards.

Q 14. Describe your experience with industrial network security.

Industrial network security is critical to protect industrial control systems (ICS) from cyber threats. My experience includes implementing and maintaining security measures for various industrial networks.

- Network Segmentation: Dividing the network into smaller, isolated segments limits the impact of a breach. This isolates critical control systems from less secure areas, like the corporate network.

- Firewall Management: Implementing and configuring firewalls to control network traffic is vital. This includes defining rules to allow only necessary communication and blocking unauthorized access attempts.

- Intrusion Detection and Prevention Systems (IDS/IPS): These systems monitor network traffic for suspicious activity, alerting administrators to potential threats and automatically blocking malicious traffic.

- Virtual Private Networks (VPNs): Securely connecting remote users and devices to the industrial network prevents unauthorized access.

- Protocol Security: Implementing security protocols like Secure Shell (SSH) for remote access and HTTPS for web interfaces ensures secure communication.

- Vulnerability Management: Regularly scanning for and patching vulnerabilities in network devices and software is crucial to prevent exploitation.

- Security Information and Event Management (SIEM): SIEM systems collect and analyze security logs from various network devices, providing a centralized view of security events.

A real-world scenario could involve a manufacturing plant protecting its PLC network from ransomware attacks by using network segmentation, firewalls, and intrusion detection systems. These security measures would prevent malicious actors from disrupting production and potentially causing physical damage.

Q 15. Explain your experience with process control strategies (e.g., cascade control, feedforward control).

Process control strategies are the heart of automation, ensuring efficient and safe operation. Let’s look at two common ones: cascade and feedforward control.

Cascade Control: Imagine controlling the temperature of a reactor. A primary controller manipulates a valve controlling steam input (outer loop). However, the steam valve’s response is slow. To speed things up, we add a secondary controller (inner loop) that directly monitors and controls the reactor’s temperature using a faster-responding element like an electric heater. The secondary controller’s output becomes the setpoint for the primary controller. This setup improves speed and accuracy by having a fast inner loop supporting the slower outer loop. I’ve used this extensively in chemical processing plants to maintain precise temperature profiles during reactions.

Feedforward Control: This anticipates disturbances before they affect the process. Think of a system where the input flow rate affects the output pressure. With feedforward, we measure the input flow rate and calculate the necessary adjustments to a control valve *before* the pressure changes significantly. This proactive approach minimizes deviations and improves stability. I implemented this strategy in a wastewater treatment plant to control effluent quality by anticipating changes in influent flow. The system adjusted chemical dosages based on predicted flow variations.

In both cases, proper tuning is critical to prevent oscillations or sluggish response. I’ve utilized Ziegler-Nichols and other tuning methods to optimize performance depending on the system’s dynamics.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you perform system backups and restores for PLCs and DCS systems?

Backing up and restoring PLC and DCS systems is crucial for data integrity and disaster recovery. My approach is always methodical and adheres to strict safety protocols.

PLCs: Backups typically involve downloading the PLC program (including logic, tags, and configurations) to a secure location. This can be a network drive, USB drive, or a dedicated backup server. The specific method depends on the PLC manufacturer and model; some PLCs have integrated backup functions within their programming software. I always ensure version control, documenting each backup with a timestamp and description. Restoring involves uploading the backed-up program to the PLC, often verifying the integrity before releasing it to the production environment.

DCS: DCS backups are more complex, often involving multiple layers: application programs, configuration databases, historical data, and system settings. These systems usually have built-in backup utilities that create full or incremental backups. I ensure regular backups are performed, including both system and application data. We use a rigorous testing strategy during restoration in a separate test environment before deploying changes to live systems. We’ve used both automated backup systems and manual methods and I understand the importance of ensuring offline copies are kept for true resilience.

Regardless of the system, I always follow a strict change management process, ensuring appropriate approvals and documentation at each step. The safety and reliability of the process is paramount.

Q 17. Describe your experience with commissioning and validation of automation systems.

Commissioning and validation are essential for ensuring the new automation system meets requirements and operates safely and reliably. My experience encompasses all phases, from design review to final acceptance.

Commissioning: This involves testing and verifying the system against design specifications. This includes checking hardware functionality, software performance, communication networks, and control strategies. I use structured testing procedures and generate comprehensive reports documenting the results. For example, in a recent project involving a new packaging line, I developed detailed test plans for each subsystem (PLC, HMI, robotics), meticulously verifying sensor readings, actuator performance, and safety interlocks.

Validation: This demonstrates that the system consistently performs as intended. This usually involves executing validation tests and documenting the results. The specifics depend on industry regulations (e.g., FDA 21 CFR Part 11 for pharmaceutical applications) and involve executing validation protocols based on quality risk management assessments. I have experience in developing and executing IQ (Installation Qualification), OQ (Operational Qualification), and PQ (Performance Qualification) tests to demonstrate compliance. This requires meticulous record-keeping and documentation for audit trails.

Throughout the process, I maintain close communication with all stakeholders (engineering, operations, and clients) to resolve issues promptly and ensure a smooth transition to operation.

Q 18. How do you troubleshoot communication issues between PLCs and DCS systems?

Troubleshooting communication issues between PLCs and DCS systems requires a systematic approach, starting with the basics and progressing to more complex diagnostics.

Initial Checks: First, I verify physical connections (cables, connectors) and check network connectivity (ping tests, IP address configuration). Simple issues like loose cables or incorrect IP addresses can be easily overlooked but account for a large portion of communication errors. I always have a comprehensive network diagram to guide me.

Intermediate Troubleshooting: If physical and basic network connections are good, I’ll check communication settings on both the PLC and the DCS. This includes baud rates, parity settings, and communication protocols (e.g., Modbus, Profibus, Ethernet/IP). Many systems have built-in diagnostic tools that provide communication status information. Analyzing these logs can pinpoint the source of the problem.

Advanced Diagnostics: If the issue remains, I’ll utilize more specialized tools. Network analyzers can capture communication traffic, allowing for detailed inspection of packets and identifying potential errors or delays. For example, a network analyzer helped me identify a timing issue between two devices that were not synchronised correctly. Sometimes, the problem lies within a faulty network component (switch, router), requiring replacement or reconfiguration.

Throughout the troubleshooting process, I meticulously document my findings and corrective actions. This not only ensures proper resolution but also assists in preventing future occurrences.

Q 19. What are your experiences with different types of industrial drives (e.g., VFDs)?

Variable Frequency Drives (VFDs) are essential for controlling motor speed and torque, offering energy savings and precise control. My experience spans various types and applications.

Types: I’ve worked with several types, including scalar VFDs (simpler, cost-effective, but less precise), vector VFDs (more sophisticated, offering better control over torque and speed), and servo drives (highest precision, often used for robotics and high-speed applications). The choice depends on the specific motor and application requirements. For example, scalar VFDs are suitable for applications like fans and pumps where precise torque control is less critical, while vector VFDs are preferred for conveyor systems that require accurate speed and torque control under varying loads. Servo drives are crucial when rapid and precise positioning is required.

Applications: I have experience integrating VFDs into a wide range of systems, including pump control in water treatment plants, conveyor systems in manufacturing, and robotic arms in automated assembly lines. This work encompasses selecting the appropriate VFD model, parameter tuning for optimal performance, safety integration (e.g., emergency stops), and communication integration with PLCs and DCS systems. In one instance, we replaced inefficient fixed-speed motors with VFD-controlled motors, resulting in significant energy savings and improved process control. Properly sizing and integrating VFDs requires a good understanding of the motor’s characteristics and the system’s dynamics.

Q 20. Describe your experience with SCADA systems.

Supervisory Control and Data Acquisition (SCADA) systems are the human-machine interface (HMI) of industrial automation. They provide operators with a centralized view of the entire process, allowing for monitoring, control, and data analysis. My experience involves various aspects of SCADA systems, from configuration to troubleshooting.

Configuration: I’ve worked with various SCADA platforms (e.g., Wonderware, Rockwell Automation, Siemens), configuring them to interface with PLCs and other field devices. This involves creating screens displaying process parameters, defining alarms and events, configuring data logging, and setting up user permissions. In one instance, we implemented a new SCADA system to improve visualization and control of a large-scale chemical process, improving operator awareness and response times to abnormal situations.

Troubleshooting: SCADA systems can be complex, and troubleshooting involves systematically identifying and resolving issues that can range from minor display errors to major system malfunctions. I often employ diagnostic tools included within the SCADA system to trace and resolve these issues. It is crucial to keep detailed documentation and to ensure that any changes made to the system are properly tracked and controlled.

Data analysis: SCADA systems collect vast amounts of operational data. I can analyze this data using built-in reporting tools or exporting it to external systems for more in-depth analysis. This provides valuable insights into process performance, efficiency, and potential areas for improvement.

Q 21. How familiar are you with different types of industrial databases used for process data?

Industrial databases play a critical role in storing and managing process data from automation systems. I’m familiar with several types, each offering different benefits and drawbacks.

Relational Databases (e.g., SQL Server, Oracle): These are commonly used for structured data, such as process parameters, alarms, and events. They’re excellent for complex queries and data analysis. I’ve used SQL Server extensively for historical data archiving and reporting from DCS and SCADA systems.

NoSQL Databases (e.g., MongoDB, Cassandra): These are better suited for unstructured or semi-structured data, such as sensor readings or sensor logs. They offer scalability and flexibility for handling large volumes of data. In specific applications, such as high-speed data acquisition, I’ve employed NoSQL solutions for their responsiveness.

Time-Series Databases (e.g., InfluxDB, Prometheus): These are optimized for storing and retrieving time-stamped data, making them ideal for process historical data. They offer features such as efficient querying and aggregation. I’ve used these databases to support advanced analytics and visualization of process trends.

The choice of database depends on specific application requirements, such as the volume of data, data structure, query patterns, and performance needs. A good understanding of these factors is crucial when designing a data management strategy.

Q 22. Explain your experience with process optimization techniques.

Process optimization is about identifying inefficiencies in industrial processes and implementing changes to improve performance. This involves analyzing data, identifying bottlenecks, and implementing solutions to increase throughput, reduce costs, and improve product quality. My experience spans various techniques, including:

- Statistical Process Control (SPC): I’ve used SPC extensively to monitor process variability, identify assignable causes of variation, and implement corrective actions. For instance, in a chemical plant, I used control charts to detect anomalies in temperature and pressure readings, leading to the identification and repair of a faulty valve that significantly improved product consistency.

- Lean Manufacturing Principles: I’ve applied lean methodologies like Value Stream Mapping to visualize the entire process flow, identify waste (muda), and eliminate non-value-added steps. In one project involving a packaging line, we reduced cycle time by 15% by optimizing material flow and eliminating unnecessary movements.

- Model Predictive Control (MPC): I have experience with implementing MPC algorithms in DCS systems to optimize complex processes in real-time, considering multiple variables and constraints. For example, I helped optimize an oil refinery’s crude distillation unit, resulting in improved yield and reduced energy consumption.

- Root Cause Analysis (RCA): Proficient in conducting root cause analysis using techniques like 5 Whys, Fishbone diagrams, and Fault Tree Analysis to understand the underlying reasons for process deviations and implement lasting solutions. A recurring issue in a food processing plant’s filling machine was addressed by systematically investigating multiple potential causes, ultimately leading to a simple adjustment that resolved consistent underfilling.

My approach is always data-driven, utilizing historical data, real-time process data, and simulations to inform decisions and measure the impact of optimization efforts.

Q 23. What is your experience with using simulation software for testing PLC and DCS programs?

Simulation software is crucial for testing PLC and DCS programs before deployment in a real-world environment. This prevents costly downtime and potential safety hazards. I have extensive experience using various simulation packages, including:

- FactoryTalk Simulation: Used for simulating Rockwell Automation PLC and DCS systems. I’ve employed this to test various scenarios, including equipment failures and process upsets, verifying the controller’s response and ensuring the safety mechanisms function correctly. For instance, I simulated a power outage scenario to verify the emergency shutdown sequence worked as designed.

- Siemens PLCSIM Advanced: Utilized for simulating Siemens PLC programs. This allows for offline testing and debugging of code, reducing the time spent on troubleshooting during commissioning. I used this to debug complex logic involving interlocks and sequential operations before deployment to the actual production environment.

- OPL (Optimization Programming Language): I’ve also employed OPL to model and simulate complex process scenarios for optimization studies, particularly in situations involving significant operational constraints. It allowed for rapid exploration of different operational strategies to identify optimal settings.

Simulation not only reduces risk but also facilitates training for operators and maintenance personnel by allowing them to practice handling various situations in a safe environment.

Q 24. Describe a challenging automation project you worked on and how you overcame the obstacles.

One challenging project involved automating a highly complex batch process in a pharmaceutical plant. The challenge stemmed from the intricate recipe management, stringent quality control requirements, and the need for seamless integration with existing legacy systems. Obstacles included:

- Legacy System Integration: Integrating the new automation system with the older, disparate systems required careful planning and a phased approach. We overcame this by developing custom interfaces and using message-queuing systems to ensure smooth data transfer.

- Recipe Management Complexity: Managing numerous recipes with varying parameters required a robust recipe management system. We addressed this by developing a user-friendly interface that allowed operators to easily select and modify recipes.

- Validation Requirements: Meeting stringent FDA validation requirements was critical. This involved meticulous documentation, rigorous testing, and comprehensive training for operators.

We overcame these obstacles through meticulous planning, a collaborative team effort, and a phased implementation approach. We broke down the project into smaller, manageable modules, allowing for iterative testing and refinement. This approach reduced the risk and allowed for early detection and correction of issues.

Q 25. How do you stay up-to-date with the latest technologies and trends in industrial automation?

Staying current in the rapidly evolving field of industrial automation is critical. I employ several strategies:

- Industry Publications and Conferences: I regularly read industry publications such as Control Engineering and Automation World and attend conferences like Automation Fair and Hannover Messe to learn about the latest advancements.

- Online Courses and Webinars: I leverage online platforms like Coursera, edX, and LinkedIn Learning to enhance my skills in specific areas, such as advanced control techniques and cybersecurity for industrial control systems.

- Vendor Training: I participate in vendor training programs offered by companies like Rockwell Automation, Siemens, and Schneider Electric to gain in-depth knowledge of their specific products and technologies. This is particularly valuable for understanding the latest software features and best practices.

- Professional Networks: Engaging with professional organizations like the ISA (International Society of Automation) and networking with colleagues through online forums and industry events helps me stay abreast of new trends and best practices.

Continuous learning is essential for maintaining expertise in this dynamic field. This approach ensures I am well-equipped to tackle new challenges and implement innovative solutions.

Q 26. Explain your understanding of functional safety standards (e.g., IEC 61508, IEC 61511).

Functional safety standards, like IEC 61508 (general principles) and IEC 61511 (application to process industries), are critical for ensuring the safe operation of automated systems. My understanding encompasses:

- Safety Lifecycle: I am proficient in applying the safety lifecycle, from hazard identification and risk assessment to safety requirements specification, design, implementation, verification, validation, and ongoing maintenance.

- Safety Instrumented Systems (SIS): I have experience designing, implementing, and testing SIS using various safety instrumented functions (SIFs) to mitigate major hazards. This includes selecting appropriate safety devices and ensuring proper redundancy and fail-safe mechanisms. Understanding the different safety integrity levels (SILs) and their implications is paramount.

- Safety Integrity Levels (SILs): I understand the concept of SILs and how they relate to the risk level and the required performance of safety functions. This knowledge helps determine the appropriate safety measures to ensure that the system meets the necessary safety requirements.

- Safety Instrumented Functions (SIFs): I am experienced in developing and implementing SIFs to mitigate specific hazards, ensuring that the safety logic is correctly implemented and that the system is properly tested and validated.

Adherence to functional safety standards is paramount to prevent accidents and protect personnel and the environment. My experience ensures that safety is integrated into every stage of automation projects.

Q 27. Describe your experience with using engineering documentation tools (e.g., AutoCAD, Visio).

Effective engineering documentation is essential for clear communication and efficient project execution. My experience includes the use of several tools:

- AutoCAD: I use AutoCAD for creating detailed electrical schematics, P&IDs (Process and Instrumentation Diagrams), and other engineering drawings. This ensures clear and precise communication of system design and layout.

- Visio: I use Visio to create functional block diagrams, network diagrams, and other process flowcharts. This aids in visualizing the overall system architecture and the interaction between different components.

- Specialized DCS/PLC Software: Most DCS and PLC platforms have integrated documentation tools that are critical for generating system documentation, including ladder logic diagrams, function block diagrams, and I/O lists. Proficiency in these tools is essential for maintaining and updating system documentation.

I understand that well-structured documentation is not just for record-keeping; it is also critical for troubleshooting, maintenance, and future modifications to the automated system. Creating clear, concise, and well-organized documentation is a key aspect of my workflow.

Key Topics to Learn for DCS and PLC Systems Interviews

- DCS Fundamentals: Understand the architecture, components (HMI, controllers, I/O), and communication protocols of Distributed Control Systems. Be prepared to discuss different DCS vendors and their platforms.

- PLC Programming: Demonstrate proficiency in ladder logic, function block diagrams, and structured text programming. Be ready to explain your experience with specific PLC brands (e.g., Siemens, Allen-Bradley, Rockwell Automation).

- Process Control Theory: Showcase your understanding of control loops (PID controllers, cascade control, feedforward control), process variables, and tuning techniques. Be able to discuss stability and performance.

- Troubleshooting and Diagnostics: Explain your approach to identifying and resolving faults in DCS and PLC systems. Highlight your experience with alarm management and data analysis.

- Safety Systems: Discuss your familiarity with safety instrumented systems (SIS) and their role in industrial automation. Mention any experience with safety standards (e.g., IEC 61508).

- Networking and Communication: Demonstrate knowledge of industrial communication protocols (e.g., Profibus, Profinet, Ethernet/IP) and their application in DCS and PLC networks.

- Data Acquisition and Reporting: Explain your experience with data acquisition systems, historical data analysis, and report generation for process optimization.

- Practical Applications: Be ready to discuss specific projects where you’ve utilized DCS and PLC systems, highlighting your contributions and problem-solving skills. Quantify your achievements whenever possible.

Next Steps

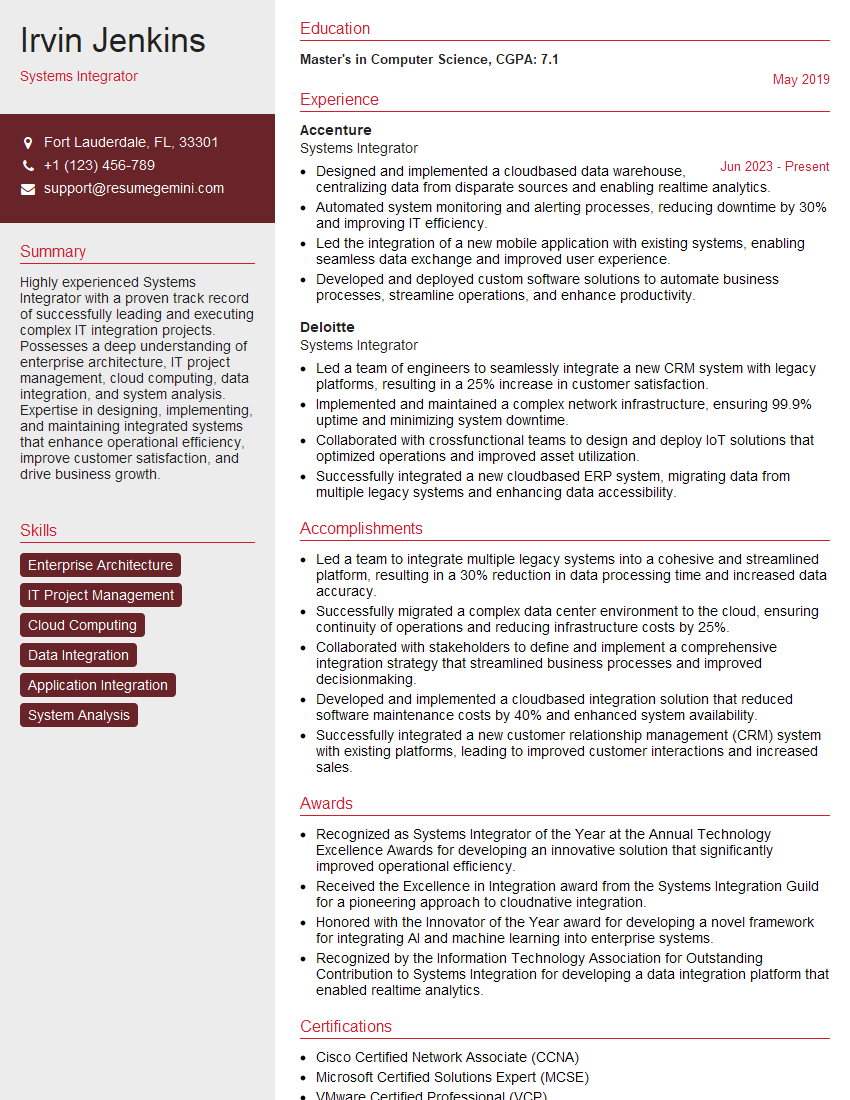

Mastering DCS and PLC systems opens doors to exciting and rewarding career opportunities in various industries. A strong understanding of these technologies is highly sought after, leading to increased earning potential and career advancement. To significantly boost your job prospects, it’s crucial to create a resume that’s both ATS-friendly and highlights your key skills and accomplishments effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to Experience with DCS and PLC systems to help guide you. Use these examples to create a resume that showcases your expertise and lands you your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.