Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Air Compressor Safety interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Air Compressor Safety Interview

Q 1. Describe the different types of air compressors and their safety implications.

Air compressors come in various types, each with unique safety considerations. The primary categories are reciprocating, rotary screw, centrifugal, and scroll compressors.

- Reciprocating compressors use pistons to compress air, creating a pulsating airflow. Safety concerns include high vibration, potential for piston failure, and the risk of hot components causing burns. Think of an old-fashioned bicycle pump – the same basic principle, but on a much larger scale.

- Rotary screw compressors use rotating screws to compress air, offering smoother operation than reciprocating compressors. However, the high-speed rotation poses a risk of catastrophic failure if maintenance is neglected, and lubricating oil poses a fire hazard.

- Centrifugal compressors use rapidly spinning impellers to compress air, generating very high pressures. These are often used in large industrial applications and demand rigorous safety protocols due to the immense power involved and potential for runaway speeds.

- Scroll compressors use two spiral-shaped components to compress air. They are generally quieter and more energy-efficient than other types, but malfunctions can still lead to pressure surges.

Regardless of the type, all air compressors present risks if not properly maintained, operated, and inspected. Understanding these risks is the first step in ensuring a safe working environment.

Q 2. Explain the importance of regular air compressor maintenance and inspection.

Regular maintenance and inspection are paramount for air compressor safety. Think of it like a car – regular servicing prevents major breakdowns. Neglecting maintenance can lead to catastrophic failures, such as explosions, fires, or component malfunctions causing injury.

Regular inspections should include checking for leaks, assessing the condition of belts, hoses, and pressure vessels, lubricating moving parts, and verifying proper pressure relief valve function. A well-maintained air compressor will operate efficiently and reliably, reducing the risk of accidents. A detailed maintenance log is essential for tracking inspections and repairs, ensuring compliance with safety regulations and helping predict potential failures.

Ignoring maintenance could result in reduced lifespan, increased energy consumption, and, most importantly, a significantly heightened risk of serious accidents.

Q 3. What are the common hazards associated with compressed air systems?

Compressed air systems pose several hazards. These include:

- High-pressure bursts: Failure of pressure vessels or hoses can cause projectiles to be launched with significant force, leading to serious injuries or fatalities. Imagine a high-pressure hose failing like a whip, cracking its surroundings.

- Air blasts: Unexpected release of compressed air can knock people over or cause injuries, particularly to eyes. Even relatively low pressure can cause significant damage.

- Fire and explosion: Leaks in compressed air systems carrying flammable materials or lubricated components can lead to ignition, potentially resulting in a fire or explosion.

- Noise pollution: Some air compressor types generate significant noise, exceeding safe levels and requiring hearing protection.

- Moving parts: Exposure to rotating components or belts can cause injuries.

It’s crucial to implement safety measures to minimize these risks, such as using appropriate safety guards and personal protective equipment.

Q 4. How do you identify and mitigate the risks of air compressor explosions?

Air compressor explosions are typically caused by overpressurization or failure of pressure vessels due to corrosion, fatigue, or improper maintenance. Identifying and mitigating these risks involves a multi-pronged approach:

- Regular inspections: Thorough visual inspections of pressure vessels and components for signs of corrosion, damage, or leaks are crucial.

- Pressure relief valves: Ensuring these valves are functioning correctly and are properly sized is vital to prevent overpressurization.

- Proper maintenance: Regular lubrication, cleaning, and replacement of worn-out parts are essential to prevent failures.

- Operator training: Operators need to understand the potential risks and proper operating procedures.

- Safe operating procedures: Establishing and adhering to strict procedures for starting, stopping, and maintaining the system are crucial.

Addressing these points significantly reduces the likelihood of a catastrophic event. Remember, prevention is far cheaper and more effective than dealing with the aftermath of an explosion.

Q 5. What are the OSHA regulations regarding compressed air safety?

OSHA (Occupational Safety and Health Administration) regulations regarding compressed air safety emphasize the need for safe practices to protect workers from hazards associated with compressed air. Specific regulations are found in various sections of the OSHA standards, often related to general industry safety, machine guarding, and personal protective equipment. Key aspects include:

- Proper guarding of machinery: Rotating parts and high-pressure lines need adequate guards.

- Pressure vessel inspections: Regular inspections and testing of pressure vessels are mandated.

- Use of compressed air for cleaning: OSHA strictly limits the use of compressed air for cleaning, forbidding it for blowing dust or debris off a person’s clothing.

- Lockout/Tagout procedures: Clear procedures for de-energizing and locking out equipment during maintenance are required.

- Personal Protective Equipment (PPE): Appropriate PPE, including eye protection, hearing protection, and safety shoes, should be worn.

Compliance with OSHA regulations is non-negotiable and failure to do so can result in significant penalties. Regular training and updated safety procedures are needed to meet these requirements.

Q 6. Explain the procedures for lockout/tagout for air compressor maintenance.

Lockout/Tagout (LOTO) procedures are critical for safe air compressor maintenance. This process ensures the equipment is completely de-energized and isolated to prevent accidental start-up during repair or maintenance. A typical LOTO procedure involves:

- Energy isolation: Shut down the air compressor and isolate all power sources (electric, pneumatic, etc.).

- Lockout: Apply a lockout device (a lock with a unique key) to the main power switch and other critical control points.

- Tagout: Attach a tag indicating that the equipment is locked out and under maintenance, including the worker’s name and date.

- Verification: Verify that the compressor is completely de-energized and incapable of starting.

- Maintenance: Perform the required maintenance tasks.

- Tag removal: The worker who applied the lock removes the tag and lock only after verifying that all maintenance is complete and the system is safe to restart.

- Restart: The equipment is restarted following the established operating procedures.

LOTO procedures are crucial to prevent serious accidents. Proper training and adherence to the established procedures are essential for every worker involved in maintenance tasks.

Q 7. How do you inspect an air compressor for leaks and potential failures?

Inspecting an air compressor for leaks and potential failures involves a systematic approach.

- Visual inspection: Check for any visible signs of damage, leaks, or corrosion on all components (hoses, fittings, pressure vessels, and tanks). Pay close attention to all joints and connections.

- Leak detection: Use soapy water to detect leaks in hoses and fittings. Bubbles will indicate a leak. For larger systems, specialized leak detection equipment might be necessary.

- Pressure testing: If appropriate and within safety guidelines, pressure test the system to verify integrity and identify leaks under pressure.

- Sound analysis: Listen for unusual sounds such as squealing, knocking, or rumbling, which might indicate component failure.

- Vibration analysis: Excessive vibrations might indicate issues with bearings or other moving parts. Use appropriate equipment for vibration analysis.

- Check pressure gauges and safety valves: Verify that pressure gauges are accurate and safety valves function correctly.

Documenting all findings is essential for maintenance records. Addressing identified issues promptly prevents minor problems from escalating into major failures and ensures safe operation.

Q 8. Describe the proper personal protective equipment (PPE) for working with air compressors.

Working with air compressors demands meticulous attention to safety. Proper Personal Protective Equipment (PPE) is paramount to preventing injuries. This includes:

- Safety Glasses or Goggles: These protect your eyes from flying debris, which can be propelled by leaks or component failure. Think of it like wearing a shield against a tiny, high-speed projectile.

- Hearing Protection: Air compressors generate significant noise, especially at higher pressures. Earmuffs or earplugs are essential to prevent hearing damage over time. Prolonged exposure to loud noises can lead to permanent hearing loss, similar to gradual damage from prolonged sun exposure.

- Gloves: Heavy-duty gloves protect your hands from sharp edges, potential cuts from damaged components, or exposure to oil and grease. Think about how much you use your hands—protecting them is crucial.

- Steel-toe Boots: These protect your feet from dropped or falling objects in the workshop environment. A heavy component falling on your foot could result in serious injury. Think of it as adding an extra layer of protection for your most important asset.

- Respiratory Protection (in certain cases): Depending on the application and the environment, a respirator might be necessary if you’re working with dusty or chemically treated air. This protects your lungs from harmful particles and ensures you’re breathing safely.

The importance of consistent PPE use cannot be overstated. It’s the first line of defense against potential hazards.

Q 9. What are the signs of air compressor malfunction and how should they be addressed?

Several signs indicate air compressor malfunction. Early detection is crucial to prevent accidents. Here are some key indicators:

- Unusual Noises: Knocking, squealing, or unusual rattling sounds often indicate internal component wear or damage. This might be like a car making a strange noise – it’s a clear sign that something requires attention.

- Excessive Vibration: Strong vibrations could be due to an imbalance in the rotating components, loose mounting, or bearing failure. It is similar to a washing machine running out of balance—it shouldn’t shake too much.

- Leaks: Air leaks around fittings or connections are not only inefficient but also pose a safety risk. A small leak might appear insignificant, but a large one could lead to serious injury.

- Overheating: If the compressor motor or tank gets excessively hot, it could signify a problem with cooling, excessive load, or internal failure. Think of it like a fever—it shows there’s something wrong that needs addressing.

- Pressure Gauge Inconsistencies: Erratic readings on the pressure gauge, sudden pressure drops, or failure to reach the desired pressure point indicates a potential issue with the pressure regulation system.

Addressing these issues requires immediate action. First, shut down the compressor and isolate it from the power supply. Then, conduct a thorough inspection or call a qualified technician to diagnose the issue and make the necessary repairs.

Q 10. Explain the different types of air compressor safety valves and their functions.

Air compressor safety valves are vital for preventing overpressurization and ensuring safe operation. There are several types:

- Pressure Relief Valve (PRV): This valve automatically releases compressed air if the pressure exceeds a predetermined limit. It’s like a safety fuse, protecting the system from catastrophic failure. They are typically set to a pressure slightly below the tank’s maximum working pressure.

- Unloader Valve: This valve is used to relieve pressure from the system during compressor shut down or during periods of inactivity. It prevents the motor from constantly working against pressure.

- Safety Interlocks: These are switches or mechanisms that prevent the compressor from starting or continuing to operate under unsafe conditions, such as the tank being over-pressurized or a critical component failing. It is like a multiple-fail-safe feature.

- Drain Valves: These allow for the draining of condensation that can build up inside the tank. The accumulation of water and moisture can lead to rust and corrosion within the tank, damaging it over time.

Each valve plays a crucial role in maintaining safe operational parameters. Regularly inspecting and testing these valves is critical for maintaining a safe working environment.

Q 11. How do you handle a compressed air line rupture?

A compressed air line rupture is a serious situation requiring immediate action. The high-velocity air escaping can cause significant injury.

- Step 1: Immediate Evacuation: Clear the immediate area of all personnel to prevent injury from flying debris or the escaping air. This is paramount—safety comes first.

- Step 2: Shut-off Supply: Immediately shut off the main air supply to prevent further release of pressurized air. Locate and close the main shutoff valve.

- Step 3: Secure the Rupture: If possible and safe to do so, try to clamp or block the ruptured line to contain the escaping air. This might involve using heavy-duty clamps, or covering the leak with a suitable material (caution must be taken).

- Step 4: Warning: Place appropriate warning signs around the affected area, preventing unauthorized entry until repairs are completed.

- Step 5: Repair or Replacement: Contact a qualified technician to assess the damage and repair or replace the damaged air line. Do not attempt repairs unless you are properly trained.

Remember, even a seemingly small rupture can be dangerous. Always prioritize safety and follow established emergency procedures.

Q 12. What are the emergency procedures in case of an air compressor accident?

Emergency procedures after an air compressor accident depend on the nature of the accident, but there are common steps:

- First Aid: Immediately provide first aid to any injured personnel. Check for injuries, and seek professional medical assistance if necessary.

- Emergency Services: Call emergency services (911 or your local equivalent) if injuries are severe or require immediate medical attention.

- Isolate the Equipment: Shut down the air compressor and disconnect it from the power supply. If possible, isolate the entire system to prevent further accidents.

- Secure the Area: Restrict access to the accident site, ensuring the safety of others. Use caution tape or other barricades to keep individuals away from the damaged equipment and debris.

- Accident Report: Document the accident thoroughly, including the time, date, location, and nature of the incident, as well as injuries and damages sustained. This documentation is crucial for investigations and safety improvements.

Following a structured emergency response plan is crucial for minimizing the impact of an accident. This could potentially include regular training sessions on accident response, and having designated response personnel within your team.

Q 13. Describe your experience with pressure relief valves and safety interlocks.

Throughout my career, I’ve extensively worked with pressure relief valves and safety interlocks, recognizing their critical role in preventing accidents. I have:

- Inspected and tested pressure relief valves regularly to ensure they function correctly within their specified parameters, preventing build-up of excessive pressure. I’ve witnessed situations where a faulty PRV could have led to catastrophic tank failure if it hadn’t been identified and replaced.

- Configured and maintained safety interlocks on numerous air compressor systems, understanding their function in preventing accidental starts or continued operation under hazardous conditions. I’ve incorporated interlocks for cases like low oil pressure or excessive temperature readings, ensuring a fail-safe mechanism is in place.

- Troubleshooted issues related to malfunctioning safety devices, identifying the root cause of the problem and implementing corrective actions, such as replacing faulty components or adjusting pressure settings.

- Educated colleagues on the importance of proper maintenance and timely inspection of these safety mechanisms, promoting a culture of proactive safety within our team. Through regular walkthroughs and training sessions, we’ve instilled a common understanding of risk and mitigation.

My experience emphasizes the importance of regularly maintaining and inspecting these safety components. A proactive approach is far more cost-effective and safer than reactive repair after a failure.

Q 14. Explain your understanding of compressed air system design and its safety aspects.

Understanding compressed air system design and its safety aspects is critical. A well-designed system minimizes risks and ensures efficient operation. This includes:

- Proper Sizing: The compressor, tank, and piping must be appropriately sized to meet the demands of the application while maintaining safe operating pressures.

- Component Selection: Choosing high-quality, durable components certified to relevant safety standards is crucial. This includes pressure vessels, valves, and fittings rated for the intended pressure and usage.

- Piping Design: The piping system should be designed to minimize pressure drops, avoid sharp bends, and use appropriate materials that can withstand the system’s operating pressure and environmental conditions. Regular inspection for corrosion is key.

- Safety Devices: Incorporating appropriate safety valves, pressure gauges, and safety interlocks is paramount. Redundancy is often recommended to ensure the failure of one device does not lead to a system failure.

- Maintenance Schedule: Establishing a comprehensive maintenance schedule for regular inspection, testing, and repair is vital to maintaining safety and reliability. This includes oil changes, filter replacements, and pressure testing of tanks. Following a pre-determined schedule is critical.

- Emergency Shutdown Mechanisms: Designing the system with readily accessible emergency shutdown mechanisms, like kill switches, is essential for quickly responding to potential emergencies.

A safe design integrates these elements, creating a system that is not only efficient but also prioritizes the safety of the operators and the surrounding environment. Preventive maintenance and adherence to safety protocols are as important as the initial design.

Q 15. How do you perform a risk assessment for compressed air systems?

A thorough risk assessment for compressed air systems involves a systematic evaluation of potential hazards and the likelihood of incidents. It’s like a detective story, where we identify the ‘suspects’ (hazards) and determine how likely they are to ‘commit a crime’ (cause an incident).

- Identify Hazards: This includes pressure vessel failures, leaks, uncontrolled release of compressed air, moving parts, electrical hazards, and improper use of compressed air tools. For example, a faulty pressure relief valve could be a significant hazard.

- Assess Risk: We evaluate the likelihood and severity of each hazard. A high-pressure system in a poorly maintained condition poses a much greater risk than a low-pressure system with regular inspections.

- Implement Controls: Based on the risk assessment, we implement control measures, such as regular inspections, pressure relief valves, emergency shut-off switches, proper training, and personal protective equipment (PPE).

- Document Findings: All findings, including risks, mitigation strategies, and responsibilities are documented in a risk assessment report. This provides a trail of evidence and facilitates proactive maintenance.

For instance, in one project, we identified the risk of a sudden pressure release from a large air receiver. Our risk assessment led to the installation of a secondary pressure relief valve and more frequent pressure testing, significantly reducing the risk of a catastrophic failure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the best practices for storing and handling compressed air cylinders?

Safe storage and handling of compressed air cylinders are paramount to prevent accidents. Think of them as highly pressurized bombs; they demand respect and careful handling.

- Secure Storage: Cylinders should be stored upright and secured to prevent them from falling or rolling. They should be stored away from ignition sources, direct sunlight, and extreme temperatures. I always advocate for designated cylinder storage areas, ideally outdoors or in a well-ventilated space.

- Proper Handling: Always use a cylinder trolley or hand truck when moving them. Never drag or drop them. Protective caps should be in place when not in use to prevent damage to the valve.

- Clear Labeling: Cylinders must be clearly labeled with the gas type, pressure rating, and any relevant warnings. This is vital for quick identification and emergency response.

- Regular Inspection: Check cylinders for any signs of damage, corrosion, or leaks before use. Any cylinder exhibiting damage should be immediately removed from service.

In one instance, a poorly secured cylinder fell, damaging its valve and causing a small leak. Luckily, no one was injured, but it highlighted the importance of secure storage and proper handling.

Q 17. How do you ensure compliance with relevant safety standards and regulations?

Compliance with safety standards and regulations is non-negotiable. It’s not just about following rules; it’s about protecting lives and preventing accidents. The key is proactive compliance, not reactive.

- Identify Applicable Standards: We begin by identifying the relevant national and international standards. This might include OSHA regulations (in the US), or equivalent regulations in other countries. Industry-specific standards often apply as well.

- Implement Procedures: Once we understand the standards, we develop and implement comprehensive safety procedures that cover all aspects of the air compressor system’s lifecycle, from design and installation to operation and maintenance.

- Regular Audits and Inspections: We conduct regular audits and inspections to verify compliance and identify any areas needing improvement. This isn’t just a ‘tick-box’ exercise; it’s a chance to pinpoint and fix potential issues before they escalate.

- Record Keeping: Maintaining detailed records of inspections, maintenance, and any incidents or near misses is critical. This documentation serves as proof of compliance and aids in continuous improvement.

For example, we ensured compliance with ASME Boiler and Pressure Vessel Code for air receivers by implementing regular inspections, pressure testing, and detailed record keeping.

Q 18. Describe your experience with different types of air compressor controls and safety features.

My experience encompasses a range of air compressor controls and safety features, from basic pressure switches to sophisticated PLC-controlled systems.

- Pressure Switches: These are common in smaller systems, providing basic on/off control based on tank pressure. However, they are relatively simple and lack advanced safety features.

- Unloader Valves: These valves are essential for reducing the load on the compressor motor during the ‘off’ cycle, improving efficiency and prolonging lifespan.

- Pressure Relief Valves: These are critical safety devices that release excess pressure and prevent potentially dangerous overpressurization. They’re the ultimate backup for other safety features.

- PLC Controls: Programmable Logic Controllers (PLCs) offer advanced control and monitoring capabilities, including automated shutdown mechanisms and real-time pressure monitoring.

- Safety Interlocks: These prevent operation under unsafe conditions, such as when doors are open or pressure levels are too high. For example, many modern compressors won’t start if a safety guard is removed.

I’ve worked on systems ranging from small, single-phase compressors with basic pressure switches to large, multi-stage systems with sophisticated PLC-based control and interlock systems, each requiring a tailored safety approach.

Q 19. How do you train others on safe air compressor operation and maintenance?

Training is the cornerstone of air compressor safety. It’s not just about reading a manual; it’s about fostering a safety culture.

- Hands-on Training: We conduct hands-on training sessions to familiarize operators with the specific equipment they will be using. This includes demonstrations of correct operating procedures and safety practices.

- Safety Procedures: Comprehensive training manuals cover the emergency shutdown procedures, lockout/tagout protocols, and the proper use of personal protective equipment (PPE).

- Regular Refresher Courses: Regular refresher courses ensure that operators maintain a high level of knowledge and understanding. This is particularly vital with evolving technologies and new safety regulations.

- Practical Assessments: Operators complete practical assessments to demonstrate their competency in safe operation and maintenance procedures.

In a recent training session, we used simulated emergencies to allow trainees to practice shutdown procedures and problem-solving under pressure, enhancing their readiness for real-world scenarios.

Q 20. Explain your experience with troubleshooting common air compressor problems.

Troubleshooting air compressor problems requires a systematic approach and a deep understanding of the system’s components.

- Identify the Problem: Start by accurately defining the problem. Is it a lack of air pressure? Unusual noises? Overheating?

- Check the Basics: Begin by checking simple things, like power supply, air intake filters, and pressure switches. Often, simple issues can be easily resolved.

- Systematic Diagnosis: If the problem is more complex, follow a systematic approach, using diagrams, schematics, and diagnostic tools. I typically check gauges, listen for unusual sounds, and visually inspect components.

- Safety First: Before commencing any troubleshooting, always ensure the compressor is de-energized and depressurized. Lockout/tagout procedures are crucial.

For example, I once encountered a compressor with significantly reduced air output. Through systematic troubleshooting, I identified a clogged air intake filter. Replacing the filter resolved the issue immediately.

Q 21. What are the potential consequences of neglecting air compressor safety procedures?

Neglecting air compressor safety procedures can have severe consequences, ranging from minor inconveniences to catastrophic failures. It’s not worth the risk.

- Injuries: Uncontrolled pressure release, moving parts, and electrical hazards can cause serious injuries, such as lacerations, burns, and even fatalities.

- Equipment Damage: Neglect can lead to premature equipment failure, costly repairs, and production downtime.

- Environmental Damage: Leaks of compressed air containing oil or other contaminants can cause environmental pollution.

- Legal Liability: Failure to comply with safety standards and regulations can result in significant legal penalties and liabilities.

A company I consulted previously had experienced a major air compressor failure due to inadequate maintenance, resulting in significant production downtime and costly repairs. This could have easily been avoided with a proactive safety program.

Q 22. How do you interpret and apply air compressor safety data sheets (SDS)?

Air compressor Safety Data Sheets (SDS), also known as Material Safety Data Sheets (MSDS), are crucial documents that detail the hazards associated with the compressor’s components and the compressed air itself. Interpreting an SDS involves carefully reviewing sections on:

- Hazardous Ingredients: This section lists the potentially harmful substances within the compressor, such as lubricating oils, refrigerants, or materials used in its construction. Understanding these helps in implementing appropriate safety measures.

- Hazards Identification: This section outlines potential health effects (e.g., respiratory irritation, skin sensitization) and physical hazards (e.g., pressure, fire) associated with the compressor and compressed air.

- First Aid Measures: This section is vital in emergency situations and describes the necessary steps in case of exposure or accidents. Knowing this information beforehand is crucial for quick and effective response.

- Handling and Storage: This section details safe practices for using, storing, and handling the compressor and its components. For example, it might specify proper ventilation requirements or storage temperature.

- Personal Protective Equipment (PPE): The SDS will specify the necessary PPE, such as respiratory protection, eye protection, and gloves, to minimize risks.

Applying the SDS involves implementing the recommended safety precautions throughout the compressor’s lifecycle – from initial installation to routine maintenance and eventual disposal. For instance, if the SDS indicates a risk of fire, proper fire suppression systems must be in place. If it highlights respiratory hazards, appropriate ventilation and respiratory protection are mandatory. Regularly reviewing the SDS ensures that safety practices remain aligned with the latest information about potential hazards.

Q 23. Describe your experience with different types of air filters and their importance in safety.

Air filters are paramount for air compressor safety, preventing contaminants from entering the system and potentially causing damage or hazards. I have experience with various types:

- Paper Filters: These are commonly used for general-purpose filtration, removing larger particles and debris. They are cost-effective but may require more frequent replacement.

- Carbon Filters: These filters absorb oil vapors, odors, and other airborne contaminants, crucial in applications where clean, dry air is essential. They improve air quality and extend the life of downstream equipment.

- High-Efficiency Particulate Air (HEPA) Filters: HEPA filters are used when exceptionally clean air is needed, such as in sensitive manufacturing processes. They remove extremely fine particles, protecting both equipment and personnel from contamination. They are more expensive but provide superior filtration.

- Coalescing Filters: These filters remove moisture and liquid contaminants from the compressed air, preventing water damage to tools and equipment. Coalescing filters significantly improve the overall quality of the compressed air.

The importance of air filters in safety stems from several factors. Contaminated compressed air can lead to:

- Equipment Damage: Particles and moisture can clog pneumatic tools, leading to malfunctions or damage.

- Product Contamination: In manufacturing, contaminated air can compromise the quality of the final product.

- Health Hazards: Oil mist and other contaminants can pose respiratory risks to workers.

Therefore, selecting and regularly maintaining the appropriate filter type for a specific application is crucial for ensuring both equipment longevity and worker safety.

Q 24. What is your approach to identifying and addressing potential hazards in an air compressor system?

My approach to identifying and addressing potential hazards in an air compressor system involves a systematic process:

- Hazard Identification: This begins with a thorough walkthrough of the entire system, checking all components: compressor, piping, valves, receivers, and end-use tools. I look for leaks, corrosion, damaged components, inadequate guarding, and improper wiring. I also consider the work environment, evaluating potential trip hazards, electrical hazards, and ergonomic issues.

- Risk Assessment: After identifying potential hazards, I assess the associated risks. This involves considering the likelihood of an accident and the severity of its potential consequences. A risk matrix can be used to prioritize risks.

- Hazard Control: Based on the risk assessment, I implement appropriate controls to mitigate the identified hazards. Controls can be hierarchical: elimination (removing the hazard altogether), substitution (replacing hazardous components), engineering controls (pressure relief valves, safety interlocks), administrative controls (lockout/tagout procedures, training), and PPE (personal protective equipment).

- Regular Inspections: A robust inspection program is crucial. Regular checks for leaks, wear, and tear should be part of the routine maintenance schedule. This proactive approach helps to identify and address potential issues before they become major hazards.

- Documentation: All identified hazards, risk assessments, and implemented control measures must be documented. This record-keeping is critical for tracking progress, complying with regulations, and improving safety over time.

For example, if I identify a significant leak in a compressed air line, the hazard control might involve immediate repair, isolating the section of the line, and implementing a temporary fix until permanent repairs are done. I’d also document the incident, investigation, and corrective actions taken.

Q 25. Explain the importance of using proper ventilation when working with air compressors.

Proper ventilation is critical when working with air compressors, primarily because of the potential for harmful airborne contaminants. These contaminants can include:

- Oil mist: Compressed air systems often use lubricating oils, and some of this oil can be carried in the compressed air stream as an aerosol, causing respiratory problems.

- Water vapor: Moisture in compressed air can create dampness, leading to corrosion and promoting the growth of mold or bacteria.

- Dust and particles: If the air intake isn’t properly filtered, dust and other particles can be drawn into the compressor, eventually entering the compressed air line.

Insufficient ventilation allows these contaminants to accumulate in the air, creating a potentially hazardous environment for workers. This can lead to respiratory illnesses, allergic reactions, or even more serious health problems. Adequate ventilation dilutes these contaminants, ensuring a safer working environment. Proper ventilation should involve:

- Exhaust fans: These remove contaminated air from the work area.

- Air intake placement: Air intake points should be placed in locations with minimal dust and other contaminants.

- Regular air quality monitoring: Periodic testing can help determine the effectiveness of the ventilation system.

Think of it like this: a well-ventilated area is like having an open window in a room; it allows fresh air to circulate and removes stale or contaminated air. Without proper ventilation, working with an air compressor is like being trapped in a room with accumulating fumes – it’s dangerous and can have serious health consequences.

Q 26. How do you ensure the integrity of air compressor piping and connections?

Ensuring the integrity of air compressor piping and connections is crucial for safety. Leaks can lead to pressure loss, reduced efficiency, and more importantly, the potential for serious injury from high-pressure air escaping unexpectedly. My approach focuses on several key areas:

- Regular Inspections: I conduct routine visual inspections to check for signs of corrosion, wear, damage, or leaks. This includes checking all joints, fittings, and valves.

- Proper Installation: Piping should be installed correctly, using appropriate fittings and adhering to pressure rating requirements. This means selecting piping materials and fittings suitable for the pressure and operating conditions.

- Leak Detection: I use various methods to detect leaks, including soapy water tests, pressure gauges, and electronic leak detectors. Even small leaks should be addressed promptly.

- Proper Support and Restraints: Piping should be properly supported to prevent sagging or stress on the connections. Restraints are needed to prevent movement due to vibrations or pressure changes.

- Material Selection: The right piping material is essential. Consider the operating conditions and choose materials that are compatible with the compressed air and are corrosion-resistant. Steel and copper piping are commonly used in many applications.

- Pressure Relief Valves: Pressure relief valves (PRVs) are safety devices that automatically release pressure should the system pressure exceed a set limit, protecting the system from damage and preventing potential hazards. Regular testing of these valves is critical.

Imagine a high-pressure air line with a hidden crack. That crack might go unnoticed, eventually leading to a catastrophic failure, causing injury or significant damage. By following these procedures, we minimize the risks from unexpected failures of the piping and connections.

Q 27. Describe your experience with air compressor system upgrades and modifications from a safety perspective.

Air compressor system upgrades and modifications require a rigorous safety-focused approach. Before any modifications, a thorough risk assessment must be conducted to identify potential hazards arising from the changes. I consider several key factors:

- Pressure Ratings: Any new components or modifications must have pressure ratings appropriate for the system’s operating pressure. Failure to do so can lead to catastrophic failure.

- Material Compatibility: New materials must be compatible with the existing system and any chemicals or substances used. Incompatible materials could react, leading to corrosion or other hazards.

- Lockout/Tagout Procedures: During upgrades or modifications, proper lockout/tagout procedures must be followed to ensure that the compressor is completely isolated and de-energized to prevent accidental start-up.

- Compliance with Regulations: Modifications must meet all applicable safety regulations and codes.

- Testing and Commissioning: After any modifications, the system must be thoroughly tested and commissioned to verify its proper operation and safety.

For instance, if upgrading to a larger compressor, the piping and receivers may need to be upgraded as well. Before doing so, I ensure that the new components are rated for the increased pressure, that correct installation practices are followed, and that a thorough pressure test is performed once installed. Documentation of these changes is essential for future reference and maintenance.

Q 28. How do you stay up-to-date on the latest changes and advancements in air compressor safety?

Staying current on air compressor safety advancements is crucial. I use several methods:

- Professional Organizations: I actively participate in and follow professional organizations like OSHA, and other relevant industry associations. These organizations publish guidelines, best practices, and updates related to compressor safety.

- Industry Publications and Journals: I read trade publications and journals focused on compressed air technology and safety. These resources often feature articles and reports on new safety technologies and regulations.

- Manufacturer Resources: I regularly review safety information provided by air compressor manufacturers. This includes manuals, updates, and safety bulletins.

- Training and Certification: I participate in regular training courses and pursue certifications to stay abreast of the latest safety practices and standards.

- Online Resources: I utilize reputable online resources to access safety information, industry news, and regulatory updates.

Staying informed allows me to adopt best practices, identify potential hazards more effectively, and adapt to evolving safety standards. This ensures that the systems I work with are always safe and compliant.

Key Topics to Learn for Air Compressor Safety Interview

- Compressor Types & Operation: Understanding the differences between reciprocating, rotary screw, and centrifugal compressors, including their operational principles and limitations.

- Pressure Systems & Controls: Knowledge of pressure relief valves, safety interlocks, and pressure gauges; practical experience troubleshooting pressure-related issues.

- Air Purification & Filtration: Understanding the importance of clean, dry air; familiarity with filter types, maintenance schedules, and the consequences of inadequate filtration.

- Safety Regulations & Compliance: Familiarity with relevant OSHA or industry-specific safety regulations and best practices for compliance; ability to identify and mitigate potential hazards.

- Potential Hazards & Risk Mitigation: Identifying potential hazards such as pressure vessel failure, air leaks, and electrical shock; developing and implementing risk mitigation strategies.

- Emergency Procedures & Response: Knowledge of emergency shutdown procedures, first aid protocols for compressor-related injuries, and effective communication during emergencies.

- Preventative Maintenance & Inspection: Understanding routine maintenance schedules, inspection procedures, and the importance of record-keeping for compliance and equipment longevity.

- Troubleshooting & Repair: Practical experience diagnosing and repairing common compressor issues, including identifying faulty components and performing necessary repairs safely.

- Energy Efficiency & Optimization: Understanding techniques to improve compressor energy efficiency and reduce operational costs while maintaining safety standards.

Next Steps

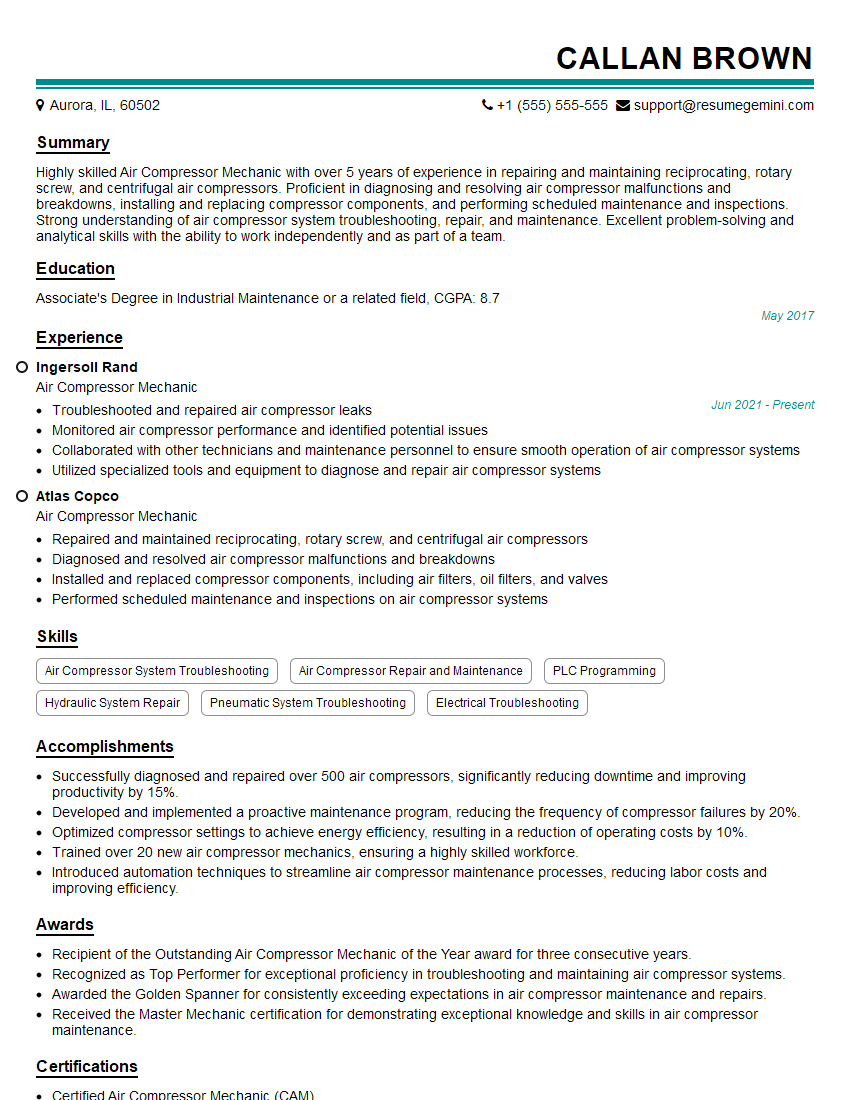

Mastering Air Compressor Safety is crucial for career advancement in this specialized field. A strong understanding of these safety protocols not only demonstrates your commitment to workplace safety but also showcases your technical expertise and problem-solving abilities. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes that will get noticed by recruiters. Examples of resumes tailored to Air Compressor Safety are available to help you showcase your qualifications and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.