Unlock your full potential by mastering the most common Installing and repairing glass interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Installing and repairing glass Interview

Q 1. Describe your experience with different types of glass (e.g., tempered, laminated, insulated).

My experience encompasses a wide range of glass types, each with unique properties and applications. Understanding these differences is crucial for successful installation and repair.

- Tempered Glass: This is heat-treated glass, significantly stronger than annealed glass. It’s commonly used in automotive side and rear windows, shower doors, and storefront applications. Its strength is a major advantage, but it shatters into small, relatively harmless pieces when broken, unlike annealed glass which fragments into sharp shards. I’ve worked extensively with tempered glass, particularly in replacing broken shower doors where safety is paramount.

- Laminated Glass: This consists of two or more layers of glass bonded together with a layer of polyvinyl butyral (PVB) interlayer. This interlayer holds the glass fragments together even when shattered, making it ideal for security and safety glazing. I’ve installed laminated glass in hurricane-prone areas where impact resistance is crucial, and also in vehicle windshields.

- Insulated Glass Units (IGUs): These are double or triple-paned glass units with a sealed air or gas-filled space between the panes. They offer superior insulation, reducing energy costs and noise pollution. My experience includes installing and repairing IGUs in residential and commercial buildings, paying close attention to the proper sealing techniques to prevent moisture ingress.

Choosing the correct glass type is vital; a mismatched selection can compromise safety, energy efficiency, and the overall aesthetics of a project. For instance, using annealed glass where tempered glass is required is a safety hazard.

Q 2. Explain the process of installing a standard double-hung window.

Installing a double-hung window involves careful precision and attention to detail. Here’s a step-by-step process:

- Preparation: Measure the existing window opening accurately to ensure the new window fits perfectly. Remove the old window carefully, taking note of how it was installed.

- Framing: If necessary, adjust or repair the window frame to ensure a snug fit. Ensure the frame is plumb and level.

- Installation: Carefully set the new window into the frame, ensuring it’s level and plumb. Secure it using appropriate fasteners, following the manufacturer’s instructions.

- Glazing: If the window requires glazing, carefully apply glazing compound or sealant to ensure a waterproof and airtight seal.

- Weight Installation: Install the sash weights and cords (if applicable) ensuring proper balance and smooth operation. This requires careful attention to detail.

- Finishing: Caulk around the frame to seal any gaps and prevent air leakage. Install trim and finishing components to complete the installation.

Throughout this process, using the correct tools and materials is crucial. For instance, using a high-quality sealant prevents future drafts and water damage. I always double-check my measurements to avoid costly errors.

Q 3. How do you measure and cut glass accurately?

Accurate glass measurement and cutting is paramount. A slight miscalculation can ruin a whole pane.

- Measuring: Precise measurements are taken using a steel measuring tape, ensuring accuracy to the nearest 1/16th of an inch. I always measure twice and then double-check before cutting to avoid errors.

- Marking: I use a glass cutter to score the glass along the measured lines. A firm, even score is key for a clean break.

- Cutting: Once scored, the glass is carefully broken along the score line using specialized glass-breaking tools. The break should be clean and straight. I’ve refined my technique over many years to achieve precision.

- Finishing: After cutting, the edges are carefully ground and polished to remove any sharp edges or imperfections. Safety glasses and gloves are always used during this step.

A quality glass cutter is essential. A dull cutter will lead to uneven scores and chipped edges. I regularly maintain my tools to ensure accuracy and safety.

Q 4. What safety precautions do you take when working with glass?

Safety is paramount when handling glass. My safety procedures are rigorous and consistent.

- Personal Protective Equipment (PPE): This includes safety glasses, cut-resistant gloves, and closed-toe shoes. I always wear the appropriate PPE, regardless of the size of the job.

- Glass Handling: Glass is always handled with care to avoid chipping or breakage. I use appropriate lifting techniques and tools to prevent injuries.

- Clean-up Procedures: Broken glass is always cleaned up immediately and thoroughly, using a broom and dustpan to avoid accidental cuts. I dispose of the glass properly, following local regulations.

- Work Area: The work area is always kept clean and free of obstructions to minimize the risk of accidents.

One instance where safety was crucial involved a large storefront window repair. We had to utilize specialized suction cups and harnesses to remove and replace the glass safely, avoiding any potential injury to our team or passersby.

Q 5. Describe your experience with different glazing systems.

My experience includes various glazing systems, each with its own advantages and disadvantages.

- Silicone Glazing: This is a common method for setting glass in frames, providing a strong and flexible seal. I prefer high-quality silicone for its durability and weather resistance.

- Butyl Glazing: This involves using butyl tape to seal the glass in the frame. This method is often used in IGUs to create an airtight seal.

- Glazing Beads: These are decorative strips used to hold the glass in place, adding an aesthetic element. They often require additional sealant to provide a proper weather seal.

Selecting the appropriate system depends on the specific application. For example, silicone is versatile, but butyl is crucial for maintaining the integrity of an IGU. I assess each project carefully to determine the best approach.

Q 6. How do you handle broken glass safely and efficiently?

Handling broken glass requires careful and efficient procedures to prevent injuries and ensure proper disposal.

- Safety First: Always wear appropriate PPE, including safety glasses, gloves, and closed-toe shoes.

- Secure the Area: Isolate the area to prevent accidental contact with broken glass. If possible, cordon off the area.

- Clean-up: Use a broom and dustpan to carefully sweep up large pieces of glass. Use a damp sponge or cloth to pick up smaller fragments. Never use your bare hands.

- Disposal: Dispose of the broken glass according to local regulations. It’s often best to use puncture-resistant containers for safe disposal.

I remember once handling a large mirror that had shattered during installation. We had to use specialized equipment and a very methodical approach to collect every piece, ensuring nobody was injured during the clean-up process.

Q 7. What are the common causes of glass breakage and how can they be prevented?

Glass breakage can stem from various causes, many of which are preventable.

- Impact: This is a common cause, ranging from accidental knocks to vandalism. Reinforced glass or protective films can mitigate this.

- Thermal Stress: Sudden temperature changes can cause glass to crack or shatter. Using tempered glass or low-E coatings can reduce this risk.

- Improper Installation: Poorly installed windows or glass can lead to breakage under stress. Careful installation and the use of appropriate sealants are crucial.

- Manufacturing Defects: Occasionally, glass may have inherent defects that lead to breakage. Reputable suppliers can help minimize this risk.

Preventing glass breakage involves careful planning, proper installation, and using appropriate materials. Regular inspections and maintenance can also help identify and address potential problems before they lead to breakage. For instance, I always check for any signs of stress cracks during routine maintenance calls.

Q 8. Explain the process of repairing a cracked windowpane.

Repairing a cracked windowpane depends heavily on the type and extent of the damage. Small, spiderweb cracks, often caused by impact, can sometimes be stabilized with a resin repair kit. Larger cracks or those that compromise the structural integrity of the pane usually require complete replacement.

For resin repairs: This involves injecting a clear, epoxy resin into the crack to bind the broken pieces. It’s crucial to thoroughly clean the crack area, ensuring no dust or debris interferes with the bonding process. The resin is injected using a specialized syringe, and then cured according to the manufacturer’s instructions. Once cured, any excess resin is carefully removed, leaving a smooth surface. This is a cost-effective method for minor cracks but doesn’t restore the pane’s original strength.

For larger cracks or damage: The damaged pane needs to be removed and replaced with a new one of the exact same size and type of glass. This involves carefully removing the old glazing, cleaning the frame thoroughly, and then installing the new pane, ensuring proper sealing to prevent drafts and leaks.

Q 9. How do you ensure a proper seal when installing glass?

A proper seal is paramount for preventing drafts, leaks, and energy loss. It also protects the window from the elements, extending its lifespan. We achieve this using a combination of techniques and materials. A high-quality sealant, such as silicone or polyurethane, is applied around the perimeter of the glass where it meets the frame. Think of it like caulking a bathtub – a continuous, unbroken bead is essential. The sealant needs to be compatible with both the glass and the frame material (wood, vinyl, aluminum). Before applying the sealant, the frame and the glass must be meticulously cleaned to ensure a good bond.

Proper preparation is key! I always clean surfaces with a suitable solvent to remove grease, dirt, and any old sealant residue. After cleaning, I make sure the surfaces are perfectly dry before applying the sealant. This ensures a robust and long-lasting seal. After applying the sealant, I use a smoothing tool to create a neat and even bead. For larger windows, a backer rod might also be used to create a consistent gap for the sealant and limit the amount of sealant needed.

Q 10. What types of tools and equipment are you proficient with?

My tool kit is comprehensive and adaptable to various situations. I’m proficient with:

- Hand tools: Putty knives, glazing tools, utility knives, measuring tapes, chisels, screwdrivers.

- Power tools: Rotary tools (for precision cutting and grinding), handheld drills (for pilot holes and fastening), saws (for cutting wood or other framing materials).

- Specialized glass tools: Suction cups (for handling large panes), glass cutters (for precision cuts), and specialized glazing compounds and sealants.

- Safety equipment: Safety glasses, gloves, dust masks, depending on the specific project and materials used.

I am adept at using this equipment safely and efficiently, ensuring projects are completed to the highest standards.

Q 11. Describe your experience with silicone and other sealants.

Silicone is a workhorse sealant; it’s flexible, waterproof, and adheres well to many surfaces. However, it can be messy and requires precise application to avoid unsightly blemishes. I’ve extensive experience with various silicone types, choosing them based on the specific needs of the job. For example, exterior-grade silicone is essential for windows exposed to harsh weather. It offers UV resistance and greater longevity. Other sealants, like polyurethane, offer superior strength and adhesion in some applications but may have less flexibility than silicone.

Selecting the right sealant is crucial. I always consider factors like the type of glass, frame material, location (interior or exterior), and the level of exposure to the elements. For intricate window designs, I may use a combination of sealants to create a superior and lasting seal.

Q 12. How do you troubleshoot common glass installation problems?

Troubleshooting glass installation problems often involves systematic investigation. Common issues include:

- Leaks: This usually points to improper sealing or gaps in the sealant. The solution involves identifying the gaps and carefully applying more sealant to fill the voids.

- Draughts: Similar to leaks, but might also indicate poor fitting of the glass within the frame. Adjustments might be needed to ensure a snug fit.

- Cracked glass: This can occur during handling or due to faulty glass. Replacing the damaged glass is the solution.

- Difficult glass insertion: This suggests problems with the frame or the pane’s dimensions. Careful measurement and adjustment are needed to ensure a proper fit.

Through systematic checking and careful observation, I can quickly determine the root cause of the problem and implement the appropriate solution. Experience plays a huge role; I’ve seen and solved many unusual issues over the years.

Q 13. Explain the importance of using appropriate spacers during glass installation.

Spacers are crucial during glass installation, particularly in double- or triple-glazed units. They maintain the correct distance between the panes of glass, creating a sealed air or gas-filled cavity. This cavity acts as an insulator, improving energy efficiency and reducing noise. Without proper spacers, the glass panes could touch each other, leading to condensation, heat transfer, and reduced thermal performance.

Think of spacers like tiny pillars supporting the glass panes. They ensure uniform spacing, preventing warping or stress on the glass which could lead to cracking. Different spacer types, like warm-edge spacers, offer enhanced thermal performance compared to older aluminium spacers. The proper choice of spacer affects the energy rating of the window significantly, impacting a building’s overall energy consumption.

Q 14. What is your experience with different types of window frames (e.g., wood, vinyl, aluminum)?

I have extensive experience working with various window frame materials – wood, vinyl, and aluminum – each presenting unique challenges and requiring specific techniques.

Wood frames require careful attention to detail; they need to be properly prepared before installing the glass to ensure a good seal. I make sure to clean the surface thoroughly, address any imperfections, and appropriately caulk or weatherstrip before installing the glass.

Vinyl frames are generally more straightforward to work with, but the material’s flexibility needs to be considered when selecting a sealant to ensure a secure and lasting bond.

Aluminum frames are durable but can be more challenging to work with, sometimes requiring specialized tools or techniques for securing the glass. The material’s thermal properties may also need to be considered, especially in colder climates. I always adapt my techniques based on the specific frame material to ensure optimal results and durability.

Q 15. How do you handle difficult installations, such as curved glass or large windows?

Handling difficult glass installations like curved glass or large windows requires meticulous planning and specialized techniques. Curved glass, for instance, demands precise measurements and careful handling to avoid breakage. We use templates to ensure accurate cutting and often employ suction cups and specialized carriers for safe transport and installation. Large windows necessitate a team approach; we coordinate multiple people to lift and position the glass precisely. Safety is paramount; we always use appropriate safety gear, including gloves, safety glasses, and harnesses for high-reach installations. We also utilize specialized tools, like glass-cutting tools designed for curved surfaces and heavy-duty suction cups capable of managing the weight of the large panes.

For example, I once installed a large, curved storefront window for a boutique. We used a detailed template created from precise measurements, a team of four to lift and position the glass, and heavy-duty suction cups to maneuver it into place. The entire process was carefully choreographed to minimize risk and maximize efficiency. Each step was performed with precision to avoid any damage to the window or potential injury to the team.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with installing insulated glass units (IGUs).

Insulated Glass Units (IGUs), or double-pane windows, are a common installation in my work. My experience encompasses everything from residential to commercial applications. I’m proficient in handling different IGU sizes and configurations, including those with various gas fills (argon, krypton) for enhanced energy efficiency. Installing IGUs requires careful attention to detail, ensuring a perfect seal to prevent moisture or air infiltration. This is usually achieved through the use of high-quality sealant and precise alignment within the window frame. Proper installation is crucial for maintaining the IGU’s energy efficiency and longevity.

I’ve worked on several projects where the proper installation of IGUs was key to improving a building’s energy efficiency rating. In one case, I replaced outdated single-pane windows in an older home with energy-efficient IGUs. This significantly reduced the homeowner’s heating and cooling costs while improving the overall comfort of the home. Another project involved replacing faulty IGUs in a commercial building, preventing further damage from moisture ingress and maintaining the structural integrity of the windows.

Q 17. What are the different methods of securing glass in a frame?

Several methods secure glass within a frame, each with its advantages and suitability based on the type of glass, frame material, and application. Common methods include:

- Mechanical Fasteners: Screws, bolts, or clips directly attach the glass to the frame. This is a robust method, suitable for heavy glass and demanding applications.

- Glazing Beads/Stops: These are small, usually rubber or plastic, pieces that hold the glass in place within a frame. They are compressed to create a tight seal, which is a common method for picture frames and smaller glass panes.

- Adhesive Systems: Silicone or polyurethane sealants create a strong bond between the glass and frame, often used in conjunction with other methods for superior durability and watertight seals.

- Specialty Systems: Certain glass types may require specialized systems like clamps or specific glazing tapes to ensure proper installation and avoid damage.

The selection of the appropriate method depends heavily on the specific project requirements. For instance, a picture frame might use glazing beads, while a storefront window would likely employ a combination of mechanical fasteners and sealant for enhanced security and weather resistance.

Q 18. How do you deal with glass that is warped or bowed?

Dealing with warped or bowed glass is challenging and often requires a careful assessment before attempting any repair or replacement. The extent of the warp and the cause (manufacturing defect, damage, etc.) must be determined. Minor warps can sometimes be mitigated by careful installation and using shims or wedges to compensate for irregularities. However, significant warps usually require replacing the glass. Trying to force a warped pane into a frame can lead to breakage and injury.

In one instance, I inspected a window with slightly warped glass. Careful measurement revealed the distortion was minor, and I was able to compensate by using small shims to ensure a secure and flush fit within the frame. The window functioned perfectly without a full replacement. However, if the warp had been severe, replacement would have been the only practical solution.

Q 19. What is your experience with repairing auto glass?

I have extensive experience in auto glass repair and replacement. This includes chip repair, crack repair, and complete windshield replacements. I’m proficient in using various resin injection systems for chip repair, ensuring a strong, durable, and aesthetically pleasing outcome. I understand the critical safety implications of proper windshield installation, especially in adhering to the manufacturer’s specifications for adhesives and techniques.

For example, I frequently repair minor chips to prevent them from spreading into larger cracks. This not only saves the customer money but also prevents more significant damage and potential safety hazards.

Q 20. What are the different types of glass used in automotive applications?

Automotive applications use various types of glass, each with specific properties and purposes:

- Laminated Glass: This is the most common type used in windshields. It consists of two layers of glass bonded together with a layer of polyvinyl butyral (PVB) interlayer. The PVB interlayer provides strength and holds the glass together in case of impact, preventing shattering and improving safety.

- Tempered Glass: This type of glass is stronger and safer than regular glass. It’s often used in side and rear windows. When broken, tempered glass shatters into small, relatively harmless pieces, unlike regular glass which fragments into sharp shards.

- Solar-Control Glass: This type of glass is designed to reduce heat transfer and glare, improving passenger comfort. It can be either laminated or tempered.

Understanding the differences between these glass types is crucial for choosing the correct replacement glass and ensuring optimal safety and performance.

Q 21. Explain the process of replacing a car windshield.

Replacing a car windshield involves several steps, prioritizing safety and precision throughout the process. First, the old windshield is carefully removed using specialized tools, avoiding damage to the surrounding vehicle components. The old adhesive is then thoroughly cleaned from the frame. Next, a new windshield is positioned, and a high-quality urethane adhesive is applied along the frame’s edge. The new windshield is carefully pressed into place and held securely until the adhesive cures completely. After the adhesive cures, any excess is removed, and the process is complete. Failure to properly adhere to the manufacturer’s instructions regarding adhesive type and curing time can compromise the windshield’s structural integrity, affecting safety.

I always carefully follow manufacturer specifications for adhesive type and curing time, ensuring a safe and secure installation. I’ve replaced countless windshields over the years, always emphasizing safety and precision in each step of the process.

Q 22. Describe your experience with working at heights.

Working at heights is a significant part of glass installation and repair. My experience spans over [Number] years, encompassing various projects involving multi-story buildings, skylights, and high-rise windows. I’m fully proficient in using fall protection equipment such as harnesses, lanyards, and safety nets. I always meticulously inspect this equipment before each job and ensure it’s properly secured. For example, on a recent project replacing a skylight on a three-story building, I utilized a full-body harness, a double-leg lanyard attached to a secure anchor point on the roof, and a safety net below to provide redundancy in case of a fall. Safety is paramount, and I strictly adhere to all relevant OSHA guidelines and company safety protocols when working at heights.

Q 23. How do you adhere to safety regulations when working with glass?

Adhering to safety regulations when handling glass is non-negotiable. This begins with proper personal protective equipment (PPE), including safety glasses, gloves, and cut-resistant clothing. Glass is incredibly sharp and fragile, so I’m meticulous about handling it carefully, avoiding sharp edges and using appropriate tools and techniques to prevent breakage. I always utilize suction cups or specialized glass handling tools to lift and move large sheets. For example, when installing a large storefront window, I employ a team approach with designated roles to prevent accidents. One person operates the suction cups, while another guides the glass into the frame, and a third person offers support. We also cordon off the work area to prevent unauthorized entry and potential injury. We always ensure the area is clear of obstructions that might cause tripping or contact with the glass. Before beginning work, I always assess the area for potential hazards and ensure the safe use of power tools and machinery.

Q 24. What is your understanding of building codes and regulations related to glass installation?

My understanding of building codes and regulations related to glass installation is comprehensive. I am familiar with the International Building Code (IBC) and local ordinances concerning glass type, thickness, strength, safety glazing requirements (especially in areas with potential impact), and the appropriate use of safety films or laminates. I understand the importance of ensuring compliance with energy efficiency standards and the use of appropriately rated glass for specific applications. For example, tempered glass is often mandated for shower enclosures and doors due to its safety features. I’m adept at deciphering building plans and specifications to identify the correct glass type and installation methods required for any given project. Staying updated on code changes is a priority, using resources such as the IBC website and local building departments to ensure compliance in all my work.

Q 25. Describe a time you had to troubleshoot a difficult glass installation problem.

During a recent project involving the installation of a curved glass wall, we encountered a significant challenge. The pre-fabricated frame had slight misalignments that prevented the glass panels from fitting correctly. Initially, attempts to force the glass into place risked breakage. To troubleshoot, I first carefully re-measured the frame and the glass panels, confirming the discrepancy. Then, I consulted the manufacturer’s specifications and schematics. After careful analysis, we identified a minor warping in the frame. We decided to correct the alignment of the frame using precise shimming techniques before attempting to install the glass. This approach, which involved applying carefully calibrated shims to compensate for the discrepancies, allowed us to successfully install the glass panels without any breakage or damage. The solution required patience, attention to detail, and the ability to adapt to unexpected challenges in the field.

Q 26. How do you maintain your tools and equipment?

Maintaining my tools and equipment is a crucial part of my job, both for safety and efficiency. After each job, I thoroughly clean my tools, removing any debris, glass fragments, and adhesive residue. Suction cups are carefully inspected for any cracks or damage. Blades of utility knives are replaced regularly to ensure a sharp and controlled cut. Power tools are inspected for any signs of wear and tear, and I follow the manufacturer’s recommendations for maintenance. I store all tools in a designated, organized manner to prevent damage and facilitate easy retrieval. Regular lubrication and sharpening are part of the routine maintenance, ensuring the tools remain in top condition, prolonging their lifespan, and enhancing safety. This proactive maintenance minimizes downtime and prevents costly tool repairs or replacements.

Q 27. What are your salary expectations?

My salary expectations are in line with my experience and the industry standards for a skilled glass installer and repair specialist with [Number] years of experience. I am open to discussing a competitive compensation package based on the specific requirements and benefits offered.

Q 28. What are your career goals?

My career goals involve continued professional development in the field of glass installation and repair. I aim to expand my expertise in specialized glass types and installation techniques. I am particularly interested in obtaining certifications in advanced glass handling and installation procedures. Ultimately, I envision myself in a leadership role, mentoring newer technicians and contributing to the improvement of safety standards and efficiency within a company.

Key Topics to Learn for Installing and Repairing Glass Interviews

- Glass Types and Properties: Understanding different types of glass (e.g., annealed, tempered, laminated) and their respective strengths, weaknesses, and applications is crucial. This includes knowledge of safety regulations surrounding each type.

- Measurement and Cutting Techniques: Mastering accurate measurements and safe glass cutting techniques is essential for precise installations. Practice different cutting methods and understand the importance of precision to avoid costly mistakes.

- Installation Methods: Familiarize yourself with various installation methods for different glass types and applications (e.g., windows, shower doors, tabletops). Understand the use of sealants, adhesives, and glazing compounds.

- Repair Techniques: Learn to identify and repair common glass damage, such as cracks, chips, and scratches. This includes understanding when repair is feasible versus when replacement is necessary.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of all safety regulations and procedures related to handling, cutting, and installing glass. This includes personal protective equipment (PPE) and safe work practices.

- Troubleshooting and Problem-Solving: Be prepared to discuss how you approach troubleshooting common installation or repair issues. Highlight your ability to identify the root cause of a problem and implement effective solutions.

- Tools and Equipment: Demonstrate familiarity with the various tools and equipment used in glass installation and repair, including their proper use and maintenance.

- Code Compliance: Understand building codes and regulations related to glass installation and repair in your region.

Next Steps

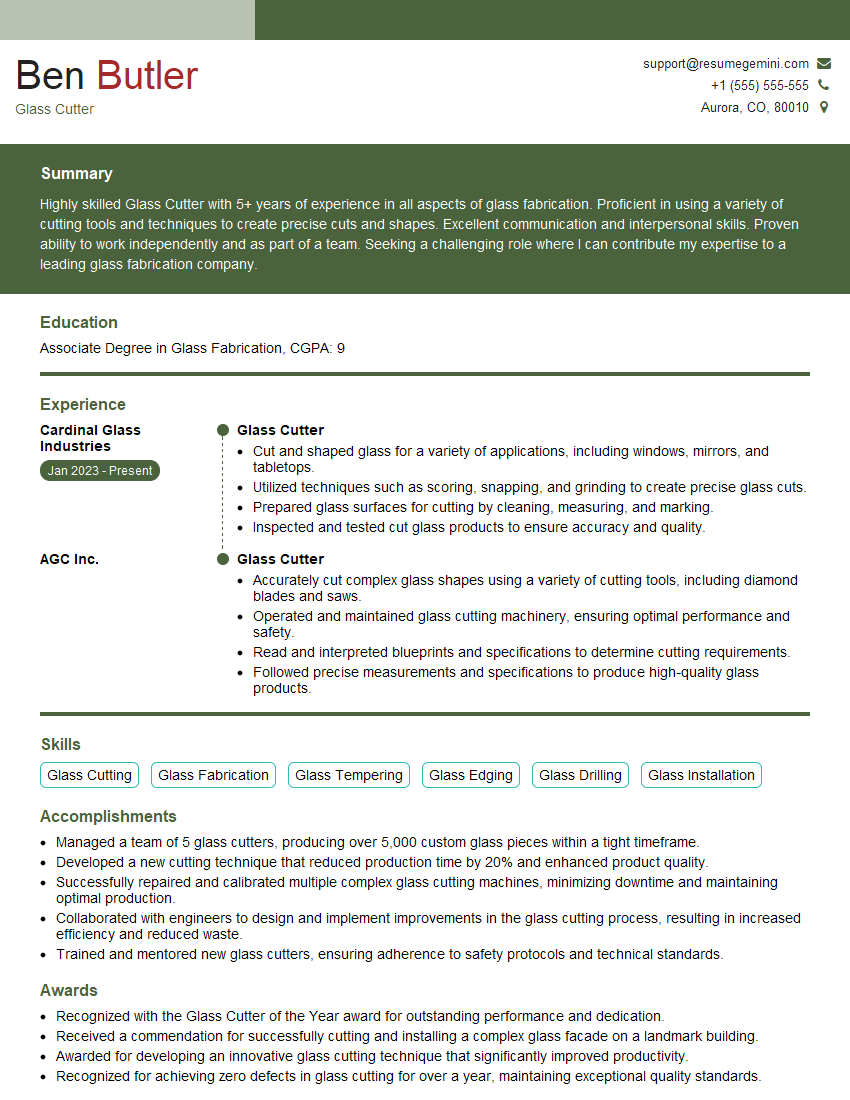

Mastering the skills of installing and repairing glass opens doors to a rewarding career with diverse opportunities for growth. To maximize your job prospects, it’s vital to present your qualifications effectively. Creating an ATS-friendly resume is key to ensuring your application gets noticed by potential employers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specifics of this field. Examples of resumes specifically designed for glass installation and repair professionals are available, providing you with valuable templates and inspiration to showcase your skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.