Cracking a skill-specific interview, like one for Glazing windows and doors, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Glazing windows and doors Interview

Q 1. What types of glass are commonly used in glazing, and what are their properties?

Many types of glass are used in glazing, each offering unique properties. The choice depends on factors like energy efficiency, security, and aesthetic appeal.

- Annealed Glass (Float Glass): This is the most common and least expensive type. It’s relatively easy to cut and shape but shatters into sharp fragments upon breakage. Think of the standard glass in a picture frame.

- Tempered Glass (Safety Glass): Heat-treated to increase strength, tempered glass breaks into small, relatively harmless granules when shattered, making it much safer than annealed glass. Car side windows are a great example.

- Laminated Glass: Two or more layers of glass bonded together with a strong interlayer, typically PVB (polyvinyl butyral). This interlayer holds the glass together even when broken, preventing penetration and reducing noise. Windshields in cars are a prime example of laminated glass.

- Insulating Glass Units (IGUs): Also known as double- or triple-glazed units, these consist of two or more panes of glass separated by a spacer filled with air or inert gas (like argon or krypton). IGUs significantly improve energy efficiency by reducing heat transfer.

- Low-Emissivity (Low-E) Glass: A special coating applied to glass that reflects infrared radiation, reducing heat transfer and improving energy efficiency. This is commonly used in IGUs.

For example, a high-performance window might use a triple-glazed IGU with Low-E coatings for superior insulation and noise reduction.

Q 2. Explain the process of installing a double-glazed window unit.

Installing a double-glazed window unit is a precise process requiring careful attention to detail. Here’s a simplified outline:

- Preparation: Carefully measure the existing window opening to ensure the new unit fits perfectly. Remove the old window frame and any debris.

- Framing (if needed): If the existing frame isn’t suitable, a new frame may need to be installed. This might involve using wood, uPVC, or aluminum.

- Installing the IGU: Carefully position the double-glazed unit into the prepared frame. Ensure it’s level and properly seated.

- Securing the unit: Use appropriate fasteners (screws, nails, or glazing beads) to secure the unit firmly within the frame. Avoid over-tightening, as this could damage the glass.

- Sealing: Apply a high-quality sealant around the perimeter of the IGU to prevent air and water infiltration. This is a crucial step to prevent drafts and condensation.

- Finishing: Install any necessary trim or weather stripping to complete the installation.

Remember to always wear appropriate safety gear during the entire process.

Q 3. Describe different methods for sealing glazing units.

Several methods ensure effective sealing of glazing units, prioritizing water tightness and preventing air leakage. The choice depends on the frame material and unit type.

- Butyl Sealant: A common choice for its excellent adhesion and flexibility. It’s often used as a primary sealant, creating a watertight barrier between the glass and frame.

- Polysulfide Sealant: Another popular choice offering good durability and flexibility. It’s often used as a secondary sealant to further enhance the weather resistance.

- Silicone Sealant: While versatile, silicone sealants are generally less preferred for glazing because they can sometimes shrink over time, compromising the seal’s integrity. They are more often used in the exterior finishing stages.

- Glazing Tape: This is commonly used in conjunction with sealants, providing additional weather resistance and helping to maintain the integrity of the gas fill in IGUs.

- Glazing Beads: These are decorative trim pieces that hold the glass in place, improving the window’s aesthetics while also offering some sealing functionality, although they are not primary seals.

In professional settings, a combination of these methods is often employed to ensure a robust and long-lasting seal. Proper sealant application is crucial for successful glazing.

Q 4. How do you measure and cut glass for a window or door?

Accurate measurement and cutting are vital for a successful glazing project. This usually involves the following steps:

- Precise Measurement: Use a measuring tape to determine the exact dimensions needed for the glass. Account for any required tolerances and frame dimensions.

- Marking the Glass: Mark the glass carefully using a glass marker or chalk to indicate the cutting line. A straight edge is essential for a clean cut.

- Scoring the Glass: Use a glass cutter to score the glass along the marked line, applying firm, even pressure. A single, clean score is crucial.

- Snapping the Glass: Carefully snap the scored glass along the score line. This can be done by hand or with specialized glass-breaking tools.

- Finishing (Optional): Use a glass grinder to smooth any sharp edges after the cut, enhancing safety.

Note that using the correct tools and following safe practices are paramount. Incorrect cutting can easily lead to glass breakage or injury.

Q 5. What safety precautions are crucial when working with glass?

Safety is paramount when handling glass. Always prioritize the following:

- Protective Gear: Wear safety glasses, gloves, and closed-toe shoes to protect yourself from cuts and other injuries.

- Careful Handling: Lift and carry glass sheets with care, avoiding sudden movements or dropping. Use suction cups or other appropriate handling tools for larger or heavier pieces.

- Sharp Edges: Always handle glass with caution, recognizing sharp edges can cause injury. Use protective gear to cover your hands.

- Proper Tools: Use appropriate tools for cutting, measuring, and installing glass to reduce the risk of accidents. Avoid improvised methods.

- Work Area: Maintain a clean and organized workspace to avoid tripping hazards and accidental breakage.

- Disposal: Dispose of broken glass safely. Wrap broken pieces in sturdy cardboard and clearly mark the package as broken glass before disposal.

Remember: A moment’s carelessness can lead to serious injury. Always prioritize safety.

Q 6. What are the common types of window and door frames?

Window and door frames are available in a variety of materials, each with its strengths and weaknesses:

- Wood: Offers a classic look and excellent insulation properties but requires regular maintenance to prevent rot and decay.

- uPVC (Unplasticized Polyvinyl Chloride): A popular choice due to its low maintenance, durability, and energy efficiency. It’s resistant to rot, insects, and moisture.

- Aluminum: A strong and durable material, often chosen for its modern aesthetic and slim profiles. It can be less energy-efficient than wood or uPVC unless thermally broken.

- Composite: These frames combine different materials (e.g., wood and aluminum) to leverage the benefits of each, such as the aesthetics of wood with the durability of aluminum.

- Steel: Very strong and durable; often used for commercial applications but can be susceptible to corrosion without proper finishing.

The best frame material depends on factors such as budget, desired aesthetic, climate, and maintenance considerations.

Q 7. How do you handle different types of glass breakage?

Handling glass breakage requires a methodical approach to ensure safety and efficient cleanup.

- Safety First: Clear the area to prevent further injury and wear appropriate protective gear, such as gloves and safety glasses.

- Assess the Damage: Determine the extent of the damage, identifying any hazardous sharp edges or large shards of glass.

- Secure the Area: If the broken glass poses a safety hazard, cordon off the area to prevent accidental injury.

- Careful Removal: Use a broom and dustpan to carefully collect larger pieces of glass. For small fragments, use a wet cloth or vacuum cleaner with a brush attachment. Never attempt to pick up sharp pieces with bare hands.

- Disposal: Dispose of the broken glass in a sturdy container, clearly marked as broken glass, for safe disposal in accordance with local regulations.

- Replacement: If the broken glass is part of a window or door unit, arrange for professional replacement to ensure proper installation and safety.

Remember, safety is paramount when handling broken glass. Always err on the side of caution.

Q 8. Explain the importance of proper ventilation when installing glazing units.

Proper ventilation during glazing installation is crucial for preventing condensation and ensuring the longevity of the glazing unit. Condensation forms when warm, moist air comes into contact with a cold surface, like a windowpane. This moisture can lead to mold growth, damage to the window frame, and even structural issues over time.

Think of it like this: imagine leaving a cold drink outside on a humid day. The glass will quickly sweat as the moisture in the air condenses on its cold surface. The same principle applies to glazing units. Adequate ventilation helps to regulate the temperature and humidity around the glazing, minimizing the risk of condensation. This often involves ensuring proper air circulation within the building itself, and sometimes incorporating vents or breather channels specifically designed for the glazing system. Failure to do so can lead to costly repairs and potential health hazards.

Q 9. What are the different types of glazings used for energy efficiency?

Several glazing types enhance energy efficiency. The most common include:

- Double Glazing (or Double-Pane): This consists of two panes of glass separated by a spacer filled with air or inert gas (like argon or krypton). The gas reduces heat transfer, improving insulation. It’s a cost-effective and widely used solution.

- Triple Glazing (or Triple-Pane): Similar to double glazing, but with three panes and two gas-filled spaces. Offers even better insulation than double glazing, reducing energy loss significantly. However, it’s generally more expensive and heavier.

- Low-Emissivity (Low-E) Glass: A special coating applied to one or more panes reduces the amount of infrared radiation (heat) that passes through the glass. It reflects heat back into the room during winter and keeps it out during summer, significantly improving energy performance. This coating is often used in conjunction with double or triple glazing.

- Insulating Glass Units (IGUs): These are factory-sealed units that combine multiple panes of glass with spacers and gas fills. They are manufactured to precise tolerances to ensure optimal performance and airtightness.

The choice of glazing depends on factors like climate, budget, and desired level of energy efficiency. In colder climates, triple glazing with Low-E coatings is often preferred, while in milder climates, double glazing with Low-E might suffice.

Q 10. How do you ensure a watertight seal in glazing installations?

Achieving a watertight seal in glazing installations is paramount to prevent leaks, drafts, and structural damage. This involves meticulous attention to detail at every stage of the process. Key steps include:

- Proper Frame Preparation: The window or door frame must be clean, dry, and free of any debris that could compromise the seal. Any imperfections in the frame should be addressed before installation.

- High-Quality Sealants and Adhesives: Using appropriate sealants and adhesives designed for exterior applications is crucial. These materials must be compatible with the frame material and glazing type. We typically use products that are durable, weather-resistant, and offer excellent adhesion.

- Accurate Installation Techniques: The glazing unit must be installed precisely and securely within the frame. This often involves using compression gaskets or other sealing mechanisms to create a tight fit.

- Back Bedding and Glazing Tape: Back bedding (a continuous bead of sealant applied to the frame before the glazing unit) and glazing tape (applied around the perimeter of the unit before the final sealant) enhance the seal’s effectiveness and prevent water penetration.

- Thorough Inspection: After installation, a careful inspection is essential to identify any gaps or imperfections in the seal. Any issues should be addressed promptly to prevent future problems.

Think of it like caulking a bathtub – you wouldn’t leave any gaps! The same principle applies to glazing. A compromised seal can lead to significant damage and costly repairs.

Q 11. What are the common issues encountered in glazing and how do you resolve them?

Common glazing issues include condensation between panes, leaks, broken seals, and cracked or damaged glass.

- Condensation: Usually indicates a failed seal in an IGU. Repair involves replacing the entire unit. Prevention focuses on proper ventilation.

- Leaks: Caused by faulty seals or improper installation. Repair involves identifying the leak source, removing old sealant, and applying new sealant properly.

- Broken Seals: Similar to condensation, this requires replacing the glazing unit.

- Cracked or Damaged Glass: May require replacing the individual pane or the entire unit, depending on the extent of the damage.

Troubleshooting involves careful inspection, identifying the root cause, and employing the appropriate repair technique. Documentation of the problem and repair process is important for future reference and warranty claims.

Q 12. Describe your experience with different types of sealants and adhesives used in glazing.

My experience encompasses a wide range of sealants and adhesives, each chosen based on the specific application and project requirements. I’ve worked extensively with:

- Silicone Sealants: Excellent for exterior applications, offering good adhesion, flexibility, and weather resistance. However, the choice of silicone sealant needs to be compatible with the glazing material and surrounding materials.

- Polyurethane Sealants: Provide strong adhesion and excellent durability. They offer faster curing times compared to some silicone options but require careful application to avoid excessive expansion or contraction.

- Butyl Sealants: Used as primary sealants in many IGUs, known for their excellent adhesion and long-term durability.

- Structural Glazing Adhesives: Used for structurally supporting large glazing panels, these are high-performance adhesives designed to withstand significant stresses.

The selection process involves considering factors such as material compatibility, weather resistance, UV stability, and the specific requirements of the glazing system. I always refer to the manufacturer’s guidelines to ensure proper usage and optimal performance.

Q 13. What are the building codes and regulations related to glazing?

Building codes and regulations related to glazing vary by location but generally focus on safety, energy efficiency, and structural integrity. These regulations often address:

- Impact Resistance: Requirements for glass strength and resistance to impact, especially in areas prone to high winds or potential breakages. This often includes specifying laminated or tempered glass types.

- Energy Efficiency: Minimum standards for U-values (a measure of heat transfer) and solar heat gain coefficient (SHGC, a measure of how much solar heat passes through the glass).

- Safety Glazing: Use of safety glass in specific locations such as doors and low-level windows to minimize injury from breakage.

- Water Resistance: Regulations related to preventing water leakage and condensation.

- Accessibility: Requirements for egress windows, often specifying minimum sizes and opening mechanisms.

Staying up-to-date on local building codes is crucial to ensure compliance and avoid potential legal issues. I always consult the relevant codes before starting any project.

Q 14. How do you ensure the structural integrity of a glazed window or door?

Ensuring the structural integrity of a glazed window or door requires a multifaceted approach that considers:

- Frame Design and Material: The frame must be strong enough to support the weight of the glazing unit and withstand external loads such as wind and snow. The choice of frame material (e.g., aluminum, wood, uPVC) impacts its strength and durability.

- Glazing System Design: The method of glazing installation, including the use of appropriate fasteners, sealants, and supporting elements, is critical. This often includes calculations and engineering considerations, especially for larger or more complex glazing systems.

- Glazing Unit Selection: Choosing glazing units with appropriate strength and resistance to impact is important. Tempered glass is frequently used to meet safety and structural requirements.

- Proper Installation Techniques: Following the manufacturer’s instructions and employing proper installation techniques is crucial to guarantee the structural integrity of the entire system.

- Regular Inspections: Periodic inspections can help identify any potential issues early on, allowing for timely interventions.

Think of it as building a house – a strong foundation and proper construction techniques are essential to withstand the elements. The same principle applies to glazing, where a poorly designed or installed system could lead to structural failure and safety hazards.

Q 15. What tools and equipment are essential for glazing work?

Glazing work requires a specialized toolkit. Safety is paramount, so personal protective equipment (PPE) like safety glasses, gloves, and sturdy work boots are essential. Beyond PPE, the core tools include:

- Measuring tools: Measuring tapes, squares, and levels are crucial for accurate measurements and ensuring a perfect fit.

- Cutting tools: Glass cutters, specifically oil-fed cutters for precise scoring, are essential for cutting glass to size. For intricate shapes, a wet saw may be necessary.

- Installation tools: Putty knives, glazing tools (for applying sealant and bedding), and suction cups or vacuum lifters for safely handling large glass panes are vital.

- Fasteners and Sealants: Appropriate screws, clips, and sealant (silicone, butyl, or polyurethane) are necessary for secure and weatherproof installations. The choice of sealant depends on the application and environmental conditions.

- Power tools (where applicable): Drills, impact drivers, and possibly specialized glass drilling equipment might be used depending on the project.

For example, when installing a custom-sized window, precise measurements are critical. Using a combination of a measuring tape and a square ensures the glass is cut to the exact dimensions, preventing installation issues. Improperly sized glass can lead to leaks, drafts, or even breakage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with working at heights.

I have extensive experience working at heights, having completed numerous glazing projects on multi-story buildings and high-rise structures. My experience includes working on scaffolding, using harnesses and fall protection equipment, and adhering strictly to all safety regulations. I am comfortable and proficient using various fall arrest systems, including full-body harnesses and anchor points.

For instance, during a recent project replacing the glazing on a five-story building, I employed a combination of scaffolding and a harness system. The harness allowed for safe movement on the scaffolding, minimizing the risk of falls. Regular safety checks were conducted, and I ensured that all team members were properly trained and equipped.

Safety is my top priority when working at heights. I always prioritize proper risk assessments, use appropriate safety equipment, and adhere to all relevant safety procedures.

Q 17. How do you handle customer complaints or concerns about glazing installations?

Handling customer complaints is crucial for maintaining positive relationships. My approach involves active listening to fully understand the customer’s concern. I approach each complaint with empathy, acknowledging their frustration and reassuring them that I will address the issue.

I then conduct a thorough investigation to identify the root cause of the problem. This might involve examining the installation, the quality of materials, or the specific conditions of the site. Once I understand the issue, I propose a solution, which may involve repair work, replacement, or a suitable compromise. I keep the customer updated throughout the process and aim to resolve the situation promptly and professionally.

For example, if a customer complains about a leak around a newly installed window, I would carefully inspect the sealant, check for any damage to the frame, and address any potential issues with the installation. I’d communicate all findings clearly, explaining the necessary steps to rectify the problem, and ensure they are satisfied with the resolution.

Q 18. How do you maintain and repair existing glazing systems?

Maintaining and repairing glazing systems involves regular inspections and proactive maintenance. This includes checking for cracks, chips, leaks, and damage to seals and frames. Regular cleaning also helps prevent degradation.

Repairs may range from simple tasks like replacing broken seals or cleaning dirt and debris from tracks to more complex repairs such as replacing damaged glass panes or repairing damaged frames. For example, a cracked pane might require careful removal and replacement with a new pane of the same type and specifications. Leaking windows often require resealing the frame and applying new sealant to ensure weather tightness.

The specific repair techniques will depend on the type of glazing system, the nature of the damage, and the materials used. Using quality materials in repairs is vital for long-term durability and prevents repeat issues. Preventive maintenance, such as regular inspections and cleaning, can significantly extend the lifespan of glazing systems and reduce the need for costly repairs.

Q 19. Explain the process of installing tempered glass.

Installing tempered glass requires careful handling due to its strength and the potential for shattering if mishandled. The process typically involves these steps:

- Accurate Measurements: Precise measurements of the opening are critical to ensure a proper fit.

- Cutting (if necessary): Tempered glass should ideally be ordered pre-cut to the exact dimensions. If cutting is required, specialized tools and techniques are necessary, and it’s usually best left to experienced professionals due to the risk of breakage.

- Preparation: The frame or opening must be clean, level, and free from debris.

- Installation: Using suction cups or vacuum lifters, carefully place the glass into the opening. Avoid any sharp impacts or pressure on the edges.

- Securing: Secure the glass using appropriate fasteners, clips, or sealant, depending on the system’s design. Ensure the glass is firmly held in place without stress.

- Inspection: Thoroughly inspect the installation for any issues, such as gaps or unevenness, before sealing.

- Sealing (if applicable): Apply a suitable sealant around the edges to create a weathertight seal and prevent water infiltration.

Safety is crucial throughout the entire process. Gloves and safety glasses are mandatory to protect against cuts and shattering.

Q 20. What are the differences between annealed and laminated glass?

Annealed and laminated glass differ significantly in their properties and applications:

- Annealed Glass (Float Glass): This is standard glass, produced by cooling molten glass slowly. It’s relatively inexpensive but shatters into sharp shards when broken. It’s commonly used for interior applications where safety isn’t a primary concern.

- Laminated Glass: This consists of two or more layers of glass bonded together with a layer of interlayer, typically polyvinyl butyral (PVB). When broken, the interlayer holds the glass fragments together, preventing sharp shards from scattering. This makes it ideal for safety applications like car windshields, skylights, and areas where impact resistance is crucial.

The key difference lies in their safety features. Laminated glass offers significantly enhanced safety and security compared to annealed glass. The cost of laminated glass is generally higher due to the added layer and manufacturing process.

Q 21. Describe your experience with different types of window and door hardware.

My experience encompasses a wide range of window and door hardware, including:

- Hinges: I’m familiar with various types, including butt hinges, pivot hinges, and concealed hinges, and understand their applications for different door types and weights.

- Handles and Knobs: I’ve worked with various styles and materials, from basic lever handles to sophisticated multi-point locking systems.

- Latches and Locks: My experience includes installing and repairing various types of latches, deadbolts, and multi-point locking mechanisms, understanding the importance of security and weather tightness.

- Sliding Door Hardware: I am experienced with installing and repairing tracks, rollers, and handles for both internal and external sliding doors. This includes understanding the importance of smooth operation and prevention of derailment.

- Window Operators: From simple casement window handles to more complex tilt-and-turn mechanisms, I’m adept at installing, adjusting, and repairing various window operating systems.

For example, when installing a heavy exterior door, I would select robust hinges and a suitable locking mechanism to ensure security and longevity. Understanding the specific requirements of each type of hardware is vital for ensuring a smooth operation and a long-lasting installation.

Q 22. How do you ensure quality control in glazing installations?

Quality control in glazing installations is paramount for ensuring longevity, safety, and aesthetic appeal. It’s a multi-stage process beginning even before the first pane is installed. We meticulously inspect all materials upon delivery, checking for cracks, chips, distortions, and ensuring the correct specifications are met – type of glass, thickness, coatings, etc.

- Pre-Installation Checks: This includes verifying the accuracy of window and door openings against the glazing specifications. Any discrepancies are addressed immediately with the construction team. We also check for proper flashing and weather sealing details.

- Installation Process: During installation, we adhere strictly to manufacturer’s instructions, paying close attention to sealant application, spacer alignment (in insulated glass units), and proper fit within the frame. We use calibrated tools to ensure accurate measurements and consistent installation.

- Post-Installation Inspection: A final thorough inspection is conducted after installation. This includes checking for leaks, proper sealing, operational functionality (opening and closing mechanisms for doors and windows), and overall aesthetic quality. We use specialized tools to detect even minute air leaks.

- Documentation: We maintain comprehensive records throughout the process. This includes material certification, installation photos, and inspection reports, providing a transparent and auditable trail.

For example, on a recent project involving a curved glass facade, we used a laser measurement system to ensure perfect alignment of the individual glass panels, preventing any distortion or stress on the glass.

Q 23. How do you deal with damaged or defective glazing materials?

Dealing with damaged or defective glazing materials is a matter of prompt action and adherence to established procedures. First, we thoroughly document the damage, taking photographs and detailed notes. The extent of the damage dictates the next steps.

- Minor Damage: For minor scratches or blemishes that don’t compromise structural integrity, we may be able to repair the damage using specialized glass repair kits. This is cost-effective and less disruptive.

- Major Damage: In cases of significant cracks, breakage, or damage compromising safety or functionality, immediate replacement is necessary. We contact the supplier to initiate the replacement process, ensuring the new materials meet the original specifications.

- Warranty Claims: We carefully review our warranty agreements with suppliers and immediately initiate claims for defective materials. We document everything thoroughly to support our claims.

- Client Communication: Open and honest communication with the client is essential throughout the process, keeping them informed about the timeline and solutions.

For instance, when a batch of tempered glass arrived with hairline fractures on a large commercial project, we immediately stopped work, documented the issue, and worked with the supplier to expedite a replacement delivery, minimizing project delays.

Q 24. Describe your experience with working on large-scale glazing projects.

I have extensive experience working on large-scale glazing projects, including high-rise buildings, commercial complexes, and museum renovations. These projects often require meticulous planning, coordination, and attention to detail due to their complexity and scale. My experience includes:

- Project Management: Managing teams of installers, coordinating with other contractors, ensuring adherence to strict deadlines and budgets.

- Material Procurement and Logistics: Sourcing and managing the procurement and delivery of large quantities of glazing materials and components, ensuring timely arrivals to avoid delays.

- Safety Management: Implementing and overseeing safety protocols on the worksite, ensuring all personnel adhere to safety regulations, and using appropriate safety equipment.

- Problem-Solving: Effectively resolving challenges that arise during the installation process, such as unforeseen structural issues or material defects.

A particularly challenging project involved the installation of a complex curtain wall system on a 20-story building. This required careful planning of lifting procedures, precise coordination with crane operators, and rigorous quality checks at every stage. Successful completion demonstrated my ability to manage large teams, intricate logistical challenges, and maintain a high standard of quality.

Q 25. How do you manage your time and prioritize tasks in a glazing project?

Time management and task prioritization are critical in glazing projects, which often involve tight deadlines and multiple stakeholders. My approach is multifaceted:

- Project Scheduling: Creating detailed project schedules using software tools like MS Project or similar, identifying key milestones and critical path activities.

- Task Prioritization: Utilizing prioritization techniques like the Eisenhower Matrix (urgent/important), ensuring that critical tasks are tackled first to avoid delays.

- Resource Allocation: Effectively allocating resources (personnel, equipment, materials) to maximize efficiency and minimize downtime.

- Regular Monitoring and Adjustments: Constantly monitoring progress against the schedule, identifying potential roadblocks, and adapting the plan as needed. Daily stand-up meetings are essential for this.

- Communication: Maintaining open communication with the project team and stakeholders to ensure everyone is aligned and informed of any changes or potential issues.

For instance, on a recent project where we faced unexpected delays due to inclement weather, I quickly re-prioritized tasks, focusing on indoor work while waiting for suitable weather conditions to continue exterior work, preventing significant project slippage.

Q 26. What are your strengths and weaknesses as a glazier?

My strengths lie in my meticulous attention to detail, my problem-solving skills, and my ability to work effectively under pressure. I am a highly organized and efficient worker, capable of leading and managing teams. I am also adept at troubleshooting issues and finding creative solutions to unexpected challenges. My experience on complex projects has honed my ability to handle stress and meet deadlines effectively.

One area I’m actively working on is enhancing my project management software skills. While proficient in using existing software, I want to deepen my knowledge of advanced features and explore new technologies to further optimize project efficiency and collaboration.

Q 27. What are your salary expectations?

My salary expectations are in line with my experience and qualifications, and I’m open to discussing a competitive compensation package that reflects the responsibilities and demands of the role. I’m confident that my skills and expertise would contribute significantly to your company’s success.

Q 28. Where do you see yourself in five years?

In five years, I see myself as a highly respected and experienced glazier, possibly in a supervisory or management role, leading and mentoring teams on increasingly complex projects. I am keen to continue expanding my knowledge of new glazing technologies and sustainable building practices. I aspire to contribute to innovative projects that push the boundaries of glazing design and functionality.

Key Topics to Learn for Glazing Windows and Doors Interview

- Window & Door Types: Understanding various materials (uPVC, aluminum, timber), frame designs, and glazing options (single, double, triple glazing). Knowing the strengths and weaknesses of each type is crucial.

- Installation Techniques: Familiarize yourself with best practices for installing windows and doors, including sealing, weatherproofing, and ensuring structural integrity. Be prepared to discuss specific tools and techniques.

- Glazing Techniques: Understand the process of installing glass units, including considerations for size, weight, and safety. Explore different types of glass and their properties (e.g., laminated, tempered).

- Energy Efficiency & Regulations: Discuss energy-efficient glazing options, relevant building codes and regulations, and the importance of thermal performance and sound insulation.

- Problem Solving & Troubleshooting: Be prepared to discuss common issues encountered during installation or maintenance (e.g., leaks, drafts, broken seals) and how to effectively troubleshoot and resolve them.

- Health and Safety: Demonstrate understanding of relevant health and safety regulations and procedures related to working at heights, handling glass, and using power tools.

- Measurements and Calculations: Explain your proficiency in accurately measuring window and door openings and performing necessary calculations for ordering materials and ensuring a precise fit.

- Customer Service & Communication: Highlight your experience in communicating effectively with clients, understanding their needs, and managing their expectations throughout the project.

Next Steps

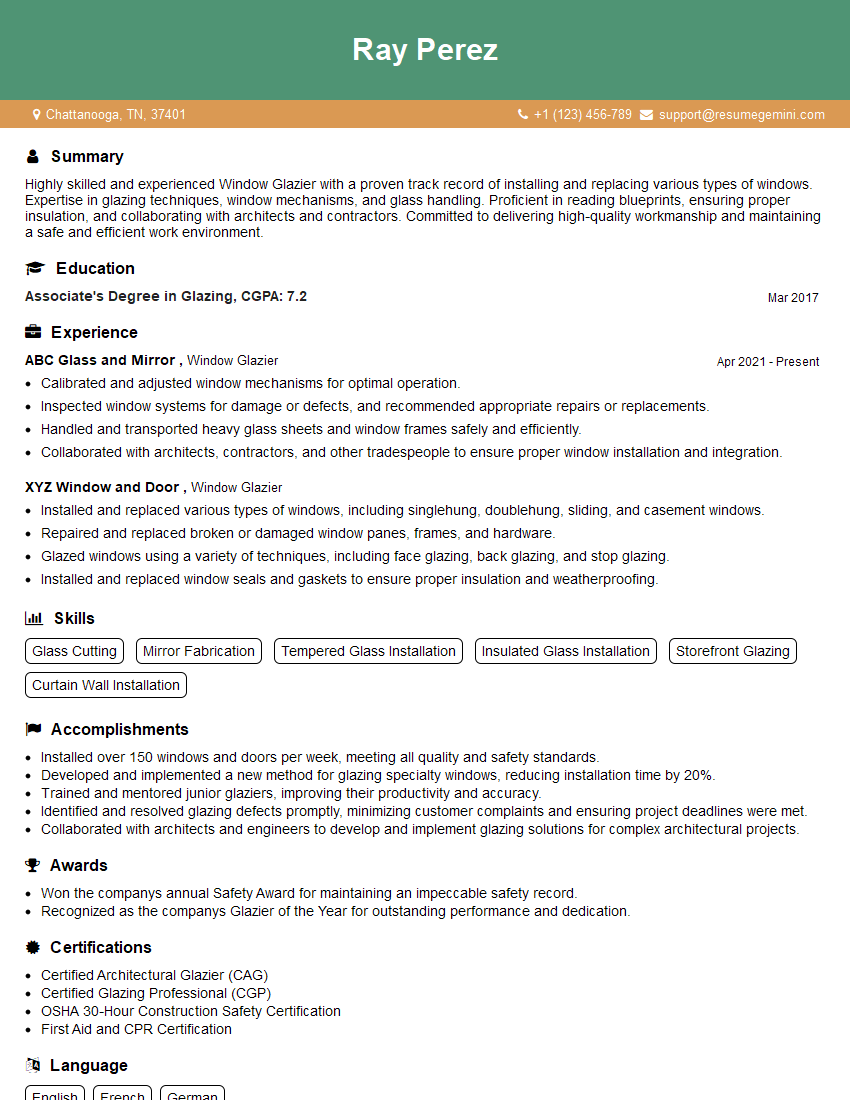

Mastering the intricacies of glazing windows and doors opens doors to exciting career opportunities in the construction and home improvement industries. A strong understanding of these topics showcases your technical expertise and problem-solving skills, making you a highly valuable asset to any employer. To maximize your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the glazing industry. Examples of resumes tailored to Glazing windows and doors are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.