Are you ready to stand out in your next interview? Understanding and preparing for Installing glass tabletops interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Installing glass tabletops Interview

Q 1. What types of glass are commonly used for tabletops?

Several types of glass are suitable for tabletops, each offering different properties and price points. The most common include:

- Tempered Glass (Safety Glass): This is the most popular choice due to its exceptional strength and safety. If it breaks, it shatters into small, relatively harmless pieces, unlike annealed glass which can produce sharp shards. It’s ideal for dining tables and other high-traffic areas.

- Annealed Glass (Float Glass): This is standard glass, less expensive than tempered glass, but significantly more prone to breakage. It’s generally not recommended for tabletops unless it’s a very small, low-use piece.

- Laminated Glass: This glass has a layer of plastic interlayer sandwiched between two sheets of glass. If broken, the glass fragments adhere to the plastic, preventing sharp shards from scattering. It offers good safety and can be aesthetically pleasing with coloured interlayers. It’s a more expensive option.

- Frosted Glass: This offers a degree of privacy and a softer aesthetic. The frosting is applied during manufacturing and isn’t as durable as tempered glass so requires careful handling.

The choice depends on factors like budget, desired aesthetic, and the intended use of the table.

Q 2. Describe the process of measuring for a glass tabletop.

Accurate measuring is crucial for a perfect fit. Here’s the process:

- Prepare the Base: Ensure the base of your table is clean, level, and free from debris. Any imperfections will affect the final fit.

- Measure the Top Surface: Using a metal tape measure, carefully measure the length and width of the tabletop support area. Measure multiple times from different angles to ensure accuracy. Note down the measurements precisely. For round or oval tables, measure the diameter or the longest and shortest diameters.

- Check for Squareness: For rectangular or square tables, check that the corners are perfectly 90 degrees using a square. Any deviations will need to be accounted for during the glass cutting process.

- Account for Overhang: Decide how much overhang you want the tabletop to have. This adds to the overall size of the glass needed. A slight overhang generally enhances the table’s visual appeal, but too much can be unstable.

- Document Everything: Record all measurements clearly, including the desired overhang and any irregularities. If there are complex shapes, take multiple detailed measurements and consider providing a template.

Remember, it’s always better to err on the side of slightly larger measurements to allow for minor adjustments during installation, than to have the glass too small.

Q 3. What safety precautions are necessary when handling glass tabletops?

Safety is paramount when working with glass. Here are crucial precautions:

- Protective Gear: Always wear safety glasses to protect your eyes from flying glass fragments. Gloves are also recommended to protect your hands from cuts.

- Proper Lifting Techniques: Glass tabletops can be heavy and unwieldy. Use proper lifting techniques, avoiding twisting or straining yourself. If the glass is particularly large or heavy, get assistance from another person.

- Controlled Environment: Work in a clean, well-lit area, free from obstacles that could cause the glass to slip or break. Ensure the working surface is clean and dry.

- Careful Handling: Avoid dropping or bumping the glass. Always lift and move the glass from its edges using suction cups or specialized lifting tools, never by the corners.

- Sharp Edges: Be aware that cut glass can have extremely sharp edges. Handle with care to avoid cuts.

If unsure about any step of the installation, it’s always better to seek professional assistance. A broken glass tabletop can be dangerous and expensive to replace.

Q 4. How do you ensure a precise fit for a glass tabletop?

Achieving a precise fit requires meticulous attention to detail throughout the entire process.

- Accurate Measurements: As previously mentioned, extremely accurate measurements are paramount. Multiple measurements from different angles will reduce the chance of errors.

- Professional Templating (if needed): For complex shapes, consider having a professional create a template which the glass supplier will use to cut the glass. This ensures a perfect fit.

- Supplier Communication: Communicate clearly with the glass supplier, providing detailed measurements, desired edge finishing (e.g., polished, beveled), and any specific requirements.

- On-site Adjustments (minimal): Minor adjustments might be necessary during installation, especially with brackets or supports. Use shims or felt pads under the brackets to achieve a level and stable fit. However, significant adjustments usually indicate measurement errors.

A well-fitting glass tabletop enhances both the safety and the aesthetics of the table. A poorly fitted one can be dangerous and look unprofessional.

Q 5. What tools and equipment are essential for glass tabletop installation?

The tools and equipment needed vary depending on the complexity of the installation but typically include:

- Measuring Tape: A metal tape measure for accurate measurements.

- Square: A metal square to check for squareness.

- Suction Cups (or Glass Lifters): For safe and easy handling of the glass.

- Protective Gear: Safety glasses and gloves.

- Support Brackets (as appropriate): Depending on the table design, these are essential for supporting the glass tabletop.

- Drill (if needed): For installing brackets which require drilling into the table base.

- Screws and Fasteners: For securing the brackets.

- Shims/Felt Pads: To adjust for minor discrepancies in the table base and ensure a level tabletop.

- Level: To ensure the tabletop is level.

Investing in quality tools not only ensures safety but also makes the installation process smoother and more efficient. Remember to always follow the manufacturer’s instructions for any tools or equipment used.

Q 6. Explain the process of installing a glass tabletop with support brackets.

Installing a glass tabletop with support brackets involves these steps:

- Prepare the Brackets: Identify suitable locations for the brackets on the table base. This will depend on the size and shape of the tabletop and the bracket design. Ensure you have the correct number of brackets for adequate support.

- Attach the Brackets: Securely attach the brackets to the table base using appropriate screws and fasteners. Ensure they are level and properly aligned to support the glass evenly.

- Position the Glass: Carefully lift the glass tabletop into position using suction cups or glass lifters. Center it on the brackets.

- Adjust for Level: Use a level to ensure the tabletop is perfectly level. If adjustments are needed, use shims or felt pads under the brackets to achieve a perfectly level surface.

- Check Stability: Gently press on the tabletop to check its stability. It should be secure and not wobble.

Different bracket types might have slight variations in their installation, so always consult the manufacturer’s instructions. The number and placement of brackets are crucial for preventing breakage and ensuring the long-term stability of the tabletop.

Q 7. How do you handle glass tabletops with irregular shapes or edges?

Handling irregular shapes or edges requires a more specialized approach:

- Precise Templating: Creating a precise template is essential when dealing with irregular shapes. This template is crucial for ensuring the glass is cut correctly. Using a cardboard template that precisely outlines the support area and a written account of all measurements can prove extremely helpful.

- Specialized Glass Cutters: Specialized glass cutting and edge finishing are often necessary. This requires the services of a professional glass company with experience in handling irregular shapes.

- Custom Brackets: For some irregular shapes, custom brackets might be required to provide adequate support. This frequently requires the expertise of a specialized fabricator.

- Safety Precautions: Handling irregularly shaped glass requires even greater caution due to its potential for unpredictable breakage. Protective gear is absolutely essential.

While technically challenging, installing irregular glass tabletops can add a unique touch. The rewards of a beautifully crafted custom piece can make the extra effort worthwhile, but always prioritize safety and hire professionals when necessary.

Q 8. What are the different types of edging for glass tabletops?

Glass tabletop edging significantly impacts both aesthetics and structural integrity. The choice depends on the desired look and the type of glass used. Popular options include:

- Beveled Edge: A classic choice, this involves a slanted cut, creating a sophisticated, refined look. It’s durable and adds a touch of elegance.

- Pencil Edge: A simple, clean edge, achieved by a narrow, slightly rounded cut. It’s a cost-effective and modern option.

- Ogee Edge: This features a more complex, curved profile, providing a decorative and visually interesting border. It’s often seen in more upscale designs.

- Seamless Edge: This edge is polished to a smooth finish without any visible beveling, providing a clean, almost invisible border. Often used with thicker glass.

- Arris Edge: A sharp, unpolished edge. While visually stark, it is less durable and generally only used for specific, artistic applications.

For example, a modern kitchen might benefit from a seamless or pencil edge, while a more traditional dining room might pair well with a beveled or ogee edge. The selection process involves considering both the overall style and the practical durability needed.

Q 9. How do you deal with potential glass chipping or breakage during installation?

Preventing chipping and breakage during glass tabletop installation is paramount. My process emphasizes careful handling at every stage. This begins with meticulous inspection of the glass upon delivery, checking for any pre-existing flaws. I use specialized soft-tipped suction cups and padded gloves to lift and move the glass, avoiding direct contact with sharp edges. Appropriate padding (like felt or foam) is always placed between the glass and the supporting structure during installation. If working at height, robust safety harnesses and straps are essential. Should a small chip occur during transport (despite precautions), I would assess the severity. Minor chips might be acceptable depending on the client’s tolerance and the location of the chip. However, significant damage necessitates replacing the glass completely to ensure structural integrity and prevent further damage.

For instance, I once had a situation where a small chip appeared during transport due to an unexpected bump in the road. Because the chip was minor and in an inconspicuous location, after informing the customer, we agreed that it was acceptable, and the installation proceeded. However, a crack would absolutely necessitate a replacement.

Q 10. Describe your experience with different types of glass fastening systems.

I’m experienced with a variety of glass fastening systems, each suited for different applications. These include:

- Mechanical Fasteners: These involve using screws, bolts, or clips to secure the glass to the underlying structure. This is common for heavier tabletops and requires precise drilling to avoid cracking the glass. I always pre-drill pilot holes and use appropriate size fasteners.

- Adhesive Systems: Strong structural adhesives are employed to bond the glass directly to the support. This provides a clean, seamless appearance. Careful surface preparation and proper adhesive selection are crucial for a strong bond. I use only high-quality, tested adhesives suitable for glass.

- Clamp Systems: These are ideal for temporary installations or where frequent removal and repositioning are necessary. Clamps securely hold the glass in place. However, this system is usually less robust for permanent tabletop applications.

The choice depends on factors like the tabletop’s weight, the type of supporting structure, and the desired aesthetic. For instance, a heavy glass tabletop on a custom-built wooden base would be most securely fastened with mechanical fasteners, while a lighter glass shelf could utilize adhesive systems for a cleaner look.

Q 11. How do you ensure the glass tabletop is level and stable?

Ensuring a level and stable glass tabletop is critical for both aesthetics and safety. My process involves several steps. First, I carefully check the supporting structure for levelness, using a level tool. Any unevenness must be addressed before glass installation. Next, during the installation of the glass, I utilize shims (small wedges) to create a level surface. This requires precision and patience to ensure a perfect fit. Finally, I recheck the levelness after the tabletop is secured, making any necessary adjustments. For adhesive installations, this requires extra care to ensure the adhesive is applied evenly and the glass settles perfectly level.

A simple analogy is building a house—you need a stable foundation before adding the walls. Similarly, ensuring the supporting structure is perfectly level is essential for a stable and beautiful glass tabletop.

Q 12. What are the common causes of glass tabletop cracks or damage?

Glass tabletop cracks or damage can stem from various causes, often preventable with careful handling and maintenance. These include:

- Impact Damage: Drops or impacts from heavy objects are the most frequent cause of damage. This can range from minor chips to catastrophic cracks.

- Thermal Stress: Sudden temperature changes can cause thermal shock, leading to cracking. Avoiding placing extremely hot or cold items directly on the glass is important.

- Improper Installation: Incorrect fastening, inadequate support, or uneven stress on the glass during installation can lead to cracks. Using the right tools and techniques is critical.

- Manufacturing Defects: While less common, flaws in the glass itself can cause premature cracking.

- Excessive Weight: Overloading the tabletop beyond its weight limit can lead to stress fractures over time.

For instance, placing a hot pan directly on a glass tabletop can cause immediate thermal stress and cracking. Preventing damage is best accomplished through careful use and proper installation.

Q 13. How do you handle customer concerns or complaints regarding installation?

Addressing customer concerns is a crucial part of the job. I approach each situation with empathy and professionalism. First, I actively listen to the customer’s concerns, asking clarifying questions to fully understand the issue. Then, I objectively assess the situation, carefully examining the tabletop and installation. If the issue is related to a flaw in my work, I promptly address the problem, offering a solution such as repair or replacement, depending on the extent of the damage and the client’s preference. If the issue is related to misuse or unintended damage, I patiently explain the proper care and use of the glass tabletop, often providing helpful tips. Throughout the process, I maintain open and clear communication, keeping the customer informed and addressing their questions promptly. Customer satisfaction is my top priority, and I aim to resolve any issues amicably and efficiently. Building trust and providing a positive experience is fundamental to my work.

Q 14. Explain your process for cleaning up after a glass tabletop installation.

Cleaning up after an installation involves meticulous attention to detail. I always remove all protective coverings and packaging materials promptly. Any leftover debris (e.g., dust, shims, adhesive residue) is carefully swept or vacuumed. If adhesives were used, I use appropriate cleaners to remove any excess without scratching the glass. I then thoroughly wipe down the glass tabletop using a microfiber cloth and glass cleaner, ensuring there are no smudges or streaks. The surrounding area is also cleaned to remove any traces of my work. I leave the installation site clean, tidy, and ready for the customer to enjoy their new glass tabletop.

Think of it like leaving a house after completing a renovation—a clean and organized space demonstrates professionalism and respect for the client’s property. The final clean-up is as essential as the installation itself.

Q 15. What is your experience with installing beveled glass tabletops?

Installing beveled glass tabletops adds a touch of elegance. My experience encompasses numerous projects involving various bevel styles, from simple to highly intricate. The key to successful installation lies in meticulous measurement and precise alignment. I always double-check the bevel’s dimensions against the base to ensure a perfect fit. For instance, I recently installed a tabletop with a dramatic, double-beveled edge, requiring extra care to maintain symmetry and prevent any chipping during the process. The use of appropriate adhesive and clamps is crucial to securely hold the glass during the curing period.

Beyond the standard installation, I also have expertise in addressing challenges such as repairing minor chips or scratches on beveled edges before installation, ensuring the finished product is flawless.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate thickness of glass for a tabletop?

Determining the appropriate glass thickness is paramount for safety and aesthetics. It depends on several factors: the tabletop’s size, the anticipated load (e.g., weight of objects placed on it), and the type of support system (e.g., frame, brackets). Generally, larger tabletops need thicker glass for better support and to prevent sagging. For instance, a small coffee table might suffice with 3/8 inch thick glass, while a large dining table might require 1/2 inch or even 3/4 inch for optimal strength.

I always consult with the client to understand their intended use before making a recommendation. I also consider factors like the style of the base and the overall design of the room to ensure the glass thickness complements the overall aesthetic.

Q 17. Describe your experience working with tempered glass.

Tempered glass is my preferred choice for tabletops due to its superior strength and safety. It’s significantly more resistant to breakage and, if it does break, shatters into small, relatively harmless pieces, unlike annealed glass. My experience includes handling various thicknesses and sizes of tempered glass, ensuring proper handling throughout the installation process.

One particularly memorable project involved a large, custom-shaped tempered glass tabletop. This required meticulous planning and precise cutting to ensure a perfect fit and to avoid any damage during the process. Safety is always my top priority, adhering to all safety precautions when handling and installing tempered glass.

Q 18. What are some common mistakes to avoid when installing glass tabletops?

Several common mistakes can compromise the installation of a glass tabletop. The most frequent include:

- Improper Measurement: Inaccurate measurements lead to gaps or an ill-fitting tabletop.

- Inadequate Support: Insufficient or poorly placed support structures can cause sagging or breakage.

- Incorrect Adhesive: Using the wrong type of adhesive can lead to weak bonding and potential failure.

- Neglecting Safety Precautions: Improper handling of glass can result in injury.

- Uneven Application of Adhesive: This can cause stress on the glass and lead to cracking.

To avoid these mistakes, I emphasize meticulous planning, precise measurements, and careful execution at every stage.

Q 19. How do you work with different materials and finishes (e.g., wood, metal) when installing a glass tabletop?

Working with different base materials requires adaptability. Whether it’s wood, metal, or stone, the installation process needs adjustments to ensure a secure and aesthetically pleasing result.

For wood bases, I carefully inspect for any inconsistencies or imperfections before installation, ensuring a stable and level surface. For metal bases, I might use different types of clamps and adhesives depending on the material’s finish. Stone bases require extra attention to prevent scratching and ensuring the adhesive is compatible with the porous nature of the stone. Each material requires a tailored approach to ensure both a secure fit and a visually appealing result. For instance, I once installed a glass tabletop on a handcrafted wooden base, meticulously ensuring the glass seamlessly complemented the wood grain’s natural beauty.

Q 20. Describe your experience with laminated glass tabletops.

Laminated glass tabletops offer enhanced safety and durability. The interlayer between the glass sheets provides added strength and prevents shattering, even if the glass cracks. My experience with laminated glass includes installing tabletops of various designs and sizes.

One key aspect of installing laminated glass is careful handling to prevent damage to the interlayer. I always ensure the use of appropriate tools and techniques to minimize the risk of scratching or compromising the structural integrity of the laminated glass. The added safety features of laminated glass make it an excellent choice for applications where safety is paramount, like families with young children.

Q 21. How do you handle the installation of very large or heavy glass tabletops?

Installing large or heavy glass tabletops demands extra precautions and specialized techniques. I always utilize appropriate lifting equipment, such as suction cups or specialized glass handling tools. A thorough risk assessment is crucial before commencing installation.

Teamwork is essential. Multiple people are needed to handle and maneuver the glass safely. Proper planning of the installation route is essential to avoid obstructions and potential damage to the glass. I always prioritize safety, using appropriate personal protective equipment (PPE) and ensuring the work area is clear and adequately prepared to prevent any accidents.

Q 22. What safety measures do you implement to protect the glass tabletop during transport and installation?

Protecting a glass tabletop during transport and installation is paramount to prevent damage. Think of it like handling a giant, fragile mirror. We use several key methods.

- Specialized Packaging: The glass is meticulously wrapped in protective layers of foam, bubble wrap, and cardboard. This creates a cushion against shocks and vibrations during transit. I’ve even used custom-fit crates for particularly large or irregularly shaped tabletops.

- Secure Strapping: During transport, the packaged tabletop is securely strapped to a pallet to prevent movement. This is especially important for larger pieces to avoid shifting or tipping.

- Careful Handling: On-site, we use suction cups or specialized lifting straps to move the glass. Never lifting from the edges alone. We always use at least two people, ensuring coordinated movements and a steady pace.

- Protective Flooring: We always protect the floor where we will work, whether with cardboard, plywood, or specialized drop cloths. This prevents scratching or accidental breakage.

These measures, combined with a cautious and methodical approach, ensure the glass arrives undamaged and ready for installation.

Q 23. How do you account for potential expansion and contraction of the glass due to temperature changes?

Glass, like most materials, expands and contracts with temperature fluctuations. Ignoring this can lead to cracking or breakage. To account for this, we follow these practices:

- Proper Installation Gaps: When installing the tabletop, we leave small expansion gaps, typically around 1/8th of an inch, between the glass and the surrounding frame or table base. This space allows for thermal movement without causing stress on the glass. Think of it like leaving room for a material to ‘breathe.’

- Choosing the Right Adhesive: We select adhesives specifically designed to accommodate thermal expansion and contraction. These adhesives have flexibility that won’t become brittle and crack under temperature changes.

- Climate Consideration: The climate where the table is installed influences the extent of expansion and contraction. In extreme climates, more attention is paid to these gaps to ensure adequate room for movement.

By considering these factors, we minimize the risk of damage from temperature fluctuations and ensure the long-term integrity of the glass tabletop.

Q 24. What is your experience using specific installation adhesives or sealants?

My experience with adhesives and sealants is extensive. I’ve worked with a variety of products, each with its strengths and weaknesses.

- Silicone Sealants: These are excellent for creating a watertight and durable bond, especially in areas exposed to moisture, offering good flexibility. I frequently use neutral cure silicone to avoid staining the glass.

- Epoxy Adhesives: Epoxies offer superior strength and are ideal for heavy tabletops or where a very strong bond is needed. However, they have a shorter working time, and getting it right is crucial.

- UV-cured Adhesives: These are becoming increasingly popular for their fast curing time and strength, particularly helpful for large projects. But they require specialized equipment and careful application.

The selection depends on the specific needs of the project, including the type of glass, the table base material, and the environmental conditions. Safety Data Sheets (SDS) are always consulted and the correct safety measures followed for handling and application.

Q 25. How do you troubleshoot issues with a glass tabletop installation?

Troubleshooting glass tabletop installations requires a systematic approach. It often starts with careful observation.

- Visual Inspection: Begin by checking for obvious problems like cracks, chips, or loose seals. This often points directly to the issue.

- Check the Level: If the table seems uneven, check the base for proper leveling. Sometimes, an uneven base is the culprit, not a faulty installation.

- Adhesive Issues: If the glass is loose or shifting, the adhesive may have failed to cure properly or wasn’t applied correctly. This requires identifying the adhesive and re-applying it correctly.

- Expansion/Contraction Issues: If cracks appear, especially around the edges, it may be due to insufficient expansion gaps. This may require careful removal and reinstallation with better gap allowances.

Accurate diagnosis and thorough documentation are always important. Taking pictures and detailed notes is very helpful. Remember that safety is always paramount. If the glass is compromised, it’s crucial to replace it rather than attempt a risky repair.

Q 26. How do you ensure the long-term stability of the installed glass tabletop?

Ensuring long-term stability involves attention to detail throughout the installation process and beyond. It’s not just about the initial installation, but about considering ongoing factors.

- Proper Adhesive Selection: Using a high-quality, durable adhesive is fundamental to long-term stability. The adhesive needs to withstand environmental stress such as temperature changes and humidity.

- Appropriate Support: The table base needs to be strong enough to support the weight of the glass. This includes ensuring that the base is securely fastened to the floor and doesn’t flex or wobble.

- Environmental Protection: Protecting the tabletop from harsh conditions (direct sunlight, extreme temperatures) helps prolong its lifespan. This might mean using UV-protective film or placing the table out of direct sunlight.

- Regular Inspection: Periodic inspection of the installation can help to identify any potential problems early on, allowing for timely intervention.

By carefully considering all these aspects, we can significantly extend the life of the glass tabletop and prevent costly repairs or replacements.

Q 27. Describe your experience working with different types of table bases.

I have extensive experience working with a wide variety of table bases, each presenting its unique challenges and opportunities.

- Wood Bases: These require careful preparation to ensure a smooth, level surface for the glass. The wood should be stable and free from warping.

- Metal Bases: Metal bases, whether steel, iron or aluminum, often need to be meticulously cleaned and prepared before applying adhesive, ensuring a clean, dry surface.

- Stone Bases: Stone bases, like marble or granite, require consideration for the porosity of the stone, to ensure proper adhesion. A suitable primer may be required.

- Custom Bases: These often require creative solutions and careful planning. The exact shape and structure of the base needs to be accounted for. Sometimes, special bracing or support structures are necessary.

Adaptability is key. Each base material requires a tailored approach to ensure a safe and secure installation.

Q 28. What is your preferred method for securing glass to a table base?

My preferred method for securing glass to a table base involves a combination of techniques, depending on the specific situation. However, the focus is always on both strength and preventing damage to the glass.

- High-Quality Adhesive: A strong, flexible adhesive appropriate for both the glass and base material forms the foundation of my approach. Careful application is key to a successful bond.

- Mechanical Fasteners (in some cases): For certain applications, especially heavier tabletops or those requiring extra security, I might incorporate discreet mechanical fasteners, but always with extreme care to prevent scratching or chipping the glass. This might involve using specialized clips or brackets designed specifically for glass applications.

- Silicone Sealant (for added protection): To provide added protection and water resistance, I often use a bead of neutral cure silicone sealant around the perimeter of the glass, carefully wiping away any excess to maintain a clean finish.

The goal is always a strong, reliable bond that protects the glass and provides a visually appealing result. Safety is paramount; we always err on the side of caution.

Key Topics to Learn for Installing Glass Tabletops Interview

- Measuring and Templating: Accurately measuring table dimensions and creating precise templates for glass cutting, considering tolerances and potential discrepancies.

- Glass Handling and Safety: Safe handling techniques for different glass types and thicknesses, including lifting, transporting, and preventing breakage. Understanding and adhering to safety regulations and using appropriate PPE.

- Fastening and Attachment Methods: Knowledge of various attachment methods (e.g., clips, adhesives, screws) and their appropriate application based on tabletop design, weight, and material. Understanding the limitations of each method.

- Working with Different Glass Types: Familiarity with common glass types (tempered, annealed, laminated) and their properties, including strength, fragility, and suitability for different applications. Understanding how these properties affect installation methods.

- Troubleshooting and Problem Solving: Identifying and resolving common installation problems such as uneven surfaces, misaligned components, or glass imperfections. Demonstrating practical solutions and problem-solving skills.

- Tools and Equipment: Familiarity with necessary tools and equipment, including measuring instruments, glass cutting tools (if applicable), adhesives, clamps, and safety gear. Understanding proper usage and maintenance.

- Adhesive Selection and Application: Choosing the right adhesive based on the materials involved and environmental conditions. Proper application techniques to ensure a strong and durable bond, avoiding air bubbles or excess adhesive.

- Quality Control and Inspection: Performing quality checks at each stage of the installation process to ensure a secure, aesthetically pleasing, and functional final product. Identifying potential issues before completion.

Next Steps

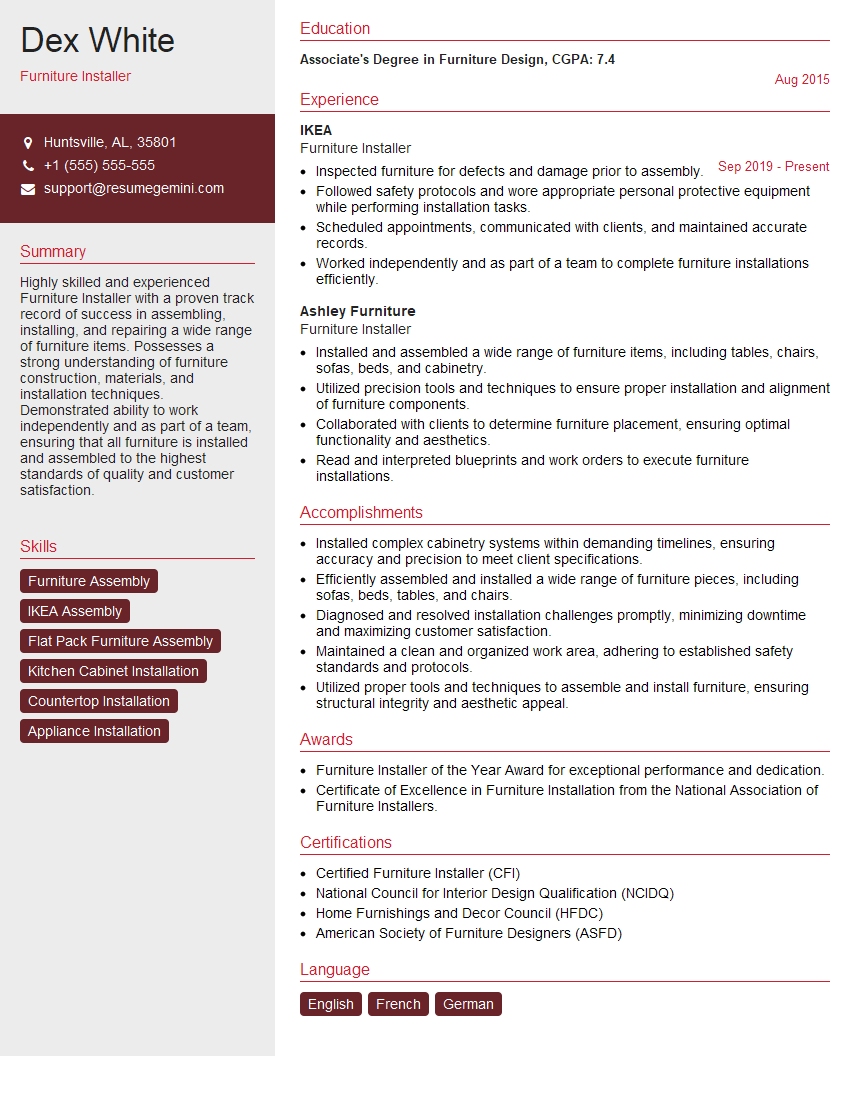

Mastering the art of installing glass tabletops opens doors to a rewarding career with excellent growth potential. This skill is highly sought after in furniture installation, custom fabrication, and interior design fields. To stand out, create a compelling, ATS-friendly resume that highlights your skills and experience. Use ResumeGemini to build a professional resume that showcases your abilities effectively. ResumeGemini provides examples of resumes tailored to the Installing glass tabletops profession, ensuring your application makes a lasting impression.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.