Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Water Meter Installation and Repair interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Water Meter Installation and Repair Interview

Q 1. Describe the different types of water meters.

Water meters come in various types, each with its own mechanism for measuring water flow. The most common are:

- Positive Displacement Meters: These meters use a mechanical mechanism, like a rotating gear or piston, to accurately measure each unit of water passing through. They’re highly accurate, especially at low flow rates, but can be more prone to wear and tear over time. Think of them like a sophisticated odometer in your car, precisely counting each revolution.

- Velocity Meters: These meters measure the speed of water flowing through a pipe. A sensor detects the velocity, and this data is used to calculate the total water volume. They’re often used in larger applications, as they are more cost-effective for high flow rates. They’re less precise than positive displacement meters, particularly at low flows.

- Multi-Jet Meters: A type of velocity meter, these use multiple jets to measure water flow, offering a balance between accuracy and cost-effectiveness across a range of flow rates.

- Smart Meters: These are increasingly common. They integrate electronic components for remote monitoring and data logging, often transmitting consumption data wirelessly. They provide real-time data on water usage, allowing for better leak detection and improved water management practices.

Q 2. Explain the process of installing a residential water meter.

Installing a residential water meter involves several key steps. First, the water supply must be shut off to avoid flooding. Then, the existing pipe needs to be cut to accommodate the meter. The meter is installed, ensuring proper alignment and watertight seals. Then, the pipe is reconnected, and the connections carefully checked for any leaks. Finally, the meter is tested to confirm its functionality, and the water supply is turned back on. It’s crucial to properly size the meter for the expected water usage to prevent inaccurate readings. For example, a small meter in a large household will quickly reach its maximum capacity, leading to inaccurate readings. Furthermore, local building codes must always be followed during installation.

Q 3. How do you troubleshoot a malfunctioning water meter?

Troubleshooting a malfunctioning water meter often involves systematically checking various aspects. Start with a visual inspection: look for any obvious damage, leaks, or obstructions. Check if the meter is spinning freely – if not, there may be a mechanical issue. Verify the meter’s registration – are the numbers advancing consistently? Inconsistent readings could indicate internal problems, a faulty sensor (in the case of velocity meters), or even tampering. If it seems to be registering unusually high usage without a corresponding increase in water consumption, there could be a leak on the customer’s side of the meter. If the problem persists after visual inspection and basic checks, contacting a qualified water meter technician is essential.

Q 4. What are the common causes of water meter inaccuracies?

Water meter inaccuracies can stem from several sources. Mechanical wear and tear, particularly in older meters, is a significant factor. Sediment buildup or debris in the meter can obstruct its internal mechanisms, causing inaccurate readings. Also, improper installation or damage during service can lead to inaccuracies. For positive displacement meters, worn gears or pistons will cause under-registration. For velocity meters, a buildup of scale inside the pipe can affect the accuracy of the flow measurement. Regular maintenance and calibration can mitigate many of these issues. Finally, extreme temperatures or pressure fluctuations can temporarily affect accuracy.

Q 5. Describe the procedure for repairing a leaking water meter.

Repairing a leaking water meter usually requires specialized tools and expertise. The first step is to isolate the leak – pinpoint the source of the water escape. This might involve disassembling parts of the meter, carefully following manufacturer guidelines. Repairing the leak could involve replacing a gasket, tightening a connection, or even replacing a damaged part. After repair, the meter must be thoroughly tested to ensure the leak is fixed and the meter is functioning accurately. In some cases, a complete meter replacement might be necessary if the damage is too extensive.

Q 6. What safety precautions do you take when working with water meters?

Safety is paramount when working with water meters. Always turn off the water supply before working on any meter. Wear appropriate personal protective equipment (PPE), including gloves and safety glasses, to protect against potential hazards. Be mindful of potential hazards like moving parts or sharp edges within the meter casing. If working underground, always use appropriate excavation techniques and be aware of the location of underground utilities to prevent accidents. Remember that water can introduce the risk of electrical shock, so extra care must be taken in wet or damp conditions.

Q 7. How do you calibrate a water meter?

Calibrating a water meter ensures its accuracy. This usually involves a specialized process using calibrated equipment in a controlled environment. The meter is connected to a flow-measuring device that precisely controls and measures the volume of water flowing through the meter. Readings from both the meter and the calibration equipment are compared. Any discrepancies indicate a need for adjustment or repair. This process should only be carried out by trained technicians using appropriate calibration equipment and adhering to manufacturer’s guidelines; it’s not a DIY task.

Q 8. What tools and equipment are essential for water meter installation and repair?

Water meter installation and repair requires a specialized toolkit. The exact contents will vary depending on the type of meter and the specific job, but here are some essentials:

- Pipe wrenches: Various sizes are needed to grip and turn pipes securely during connection and disconnection.

- Screwdrivers (Phillips and flathead): For removing and installing meter covers, mounting brackets, and other components.

- Adjustable wrench: Offers versatility for various bolt and nut sizes.

- Meter key: A specialized tool designed to open and close many types of water meters.

- Pipe cutters or hacksaw: To cut pipes to the correct length for installation.

- Teflon tape or pipe sealant: Crucial for creating watertight connections to prevent leaks.

- Measuring tape: To accurately determine pipe lengths and meter placement.

- Level: Ensures the meter is installed correctly to prevent issues.

- Safety glasses and gloves: Protect against injuries from sharp objects and potential water damage.

- Bucket and towels: To manage any potential water spills during the process.

For more complex repairs, specialized tools like pressure gauges and leak detectors may also be required.

Q 9. Explain the importance of regular water meter maintenance.

Regular water meter maintenance is crucial for several reasons:

- Accuracy: Over time, sediment buildup and mechanical wear can affect the meter’s accuracy, leading to inaccurate billing. Regular checks and cleaning ensure you are paying only for the water you use.

- Leak detection: A regularly inspected meter can quickly reveal unexpected high consumption, potentially indicating a leak on your property, saving you from significant water waste and costly repairs.

- Extended lifespan: Just like a car, preventative maintenance can significantly extend the lifespan of the water meter, delaying the need for costly replacements.

- Preventative measures: Catching minor issues early prevents them from escalating into major problems. For example, a slightly leaky connection can be easily fixed, but left unattended, can lead to significant damage and high water bills.

Think of it like regular car maintenance – oil changes and check-ups prevent bigger problems down the line.

Q 10. How do you handle a water meter that is frozen?

A frozen water meter is a serious issue. Never attempt to thaw a frozen meter with open flame or boiling water. This can damage the meter and potentially cause it to burst. Here’s the proper approach:

- Safety first: Ensure the water supply to the meter is shut off to prevent further water damage.

- Gradual thawing: Use a heating pad, hair dryer set on a low setting, or warm towels to gradually thaw the meter. Be patient; rushing this process can cause cracking.

- Monitor carefully: Watch for signs of thawing and any leaks. If you see cracks or damage, contact a professional immediately.

- Preventative measures: In cold climates, consider insulating the meter to prevent future freezing. This can be done with commercially available meter insulation or even simple foam insulation.

If the meter is severely damaged or you are unsure how to proceed, contacting a qualified plumber is the safest course of action.

Q 11. What are the different types of meter connections?

Water meters can be connected to the water service line in a few ways:

- Flanged connections: These involve large, bolted flanges that create a secure and robust connection.

- Compression connections: A compression fitting uses a nut and ferrule to create a seal around the pipe. This is a common and relatively easy-to-install type.

- Threaded connections: These use threaded pipe and fittings, which are secured by tightening the threads. Teflon tape is essential to create a watertight seal.

- Copper Sweat Connections: These connections use solder to connect the copper fittings and pipes. It requires specialized tools and expertise.

The type of connection used often depends on the material of the service line (copper, PVC, etc.) and the size of the pipe.

Q 12. How do you identify the make and model of a water meter?

Identifying the make and model of a water meter is crucial for ordering replacement parts or seeking technical assistance. The information is usually found on a nameplate located on the meter’s body. This nameplate will typically include:

- Manufacturer’s name: (e.g., Badger Meter, Neptune Technology Group)

- Model number: A specific alphanumeric code identifying the meter’s type and specifications.

- Serial number: A unique identifier for that specific meter.

- Size and flow rate: Indicates the meter’s capacity.

If the nameplate is damaged or illegible, you may need to consult installation records or contact your local water utility for assistance.

Q 13. Describe the process of replacing a water meter.

Replacing a water meter is a fairly involved process that should ideally be done by a qualified professional. The steps generally include:

- Shut off the water: This is the most crucial step; failure to do so could result in significant water damage.

- Drain the line: Open valves downstream of the meter to drain any remaining water.

- Disconnect the meter: Using appropriate tools, carefully disconnect the meter from the service line, paying close attention to the type of connection (flanged, threaded, etc.).

- Install the new meter: Carefully connect the new meter, ensuring all connections are watertight and secure. Use Teflon tape or pipe sealant as needed.

- Turn the water back on: Slowly open the main water supply valve and check for any leaks around the new meter.

- Test for leaks: Thoroughly inspect all connections for leaks. If any leaks are found, immediately turn off the water and address the issue.

- Meter testing (if necessary): Verify the accuracy of the new meter using appropriate testing methods.

Remember, improper installation can lead to leaks and inaccurate readings. If you are not comfortable performing this task, it’s best to hire a qualified professional.

Q 14. How do you test the accuracy of a water meter?

Testing a water meter’s accuracy requires specialized equipment and procedures. There are various methods, but a common approach involves a process called a ‘test flow’ using a known volume of water.

- Precise measurement: A known quantity of water (e.g., using a calibrated container) is carefully measured and passed through the meter.

- Meter reading comparison: The meter’s reading is compared against the known volume. Any significant discrepancy indicates a potential inaccuracy.

- Professional testing: For official accuracy testing and certification, it’s typically necessary to engage a certified professional who possesses the needed calibration equipment and expertise.

Regular checks with a simple visual inspection for obvious defects or unusual readings can indicate a need for more thorough professional testing. Accurate metering is essential for fair billing and water conservation.

Q 15. What are the common problems associated with older water meters?

Older water meters, often mechanical, face several common problems. These include inaccurate readings due to wear and tear on internal components like gears and registers. Sediment buildup within the meter can also hinder its proper functioning, leading to under-reporting or complete failure. Another common issue is leakage from the meter casing, caused by corrosion or damage to seals over time. Finally, the meter itself might become difficult to read due to faded markings or damaged display windows. Imagine an old clock – the gears eventually wear down, affecting its accuracy. The same applies to water meters; prolonged exposure to water pressure and constant operation takes a toll.

- Inaccurate Readings: Leading to billing discrepancies and potential revenue loss for water utilities.

- Leakage: Wasting water and potentially causing damage to surrounding property.

- Difficult Readability: Making meter reading time-consuming and prone to errors.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of reading a water meter.

Reading a water meter involves carefully observing the numbers displayed on the register. Most meters use dials, each representing a different unit of measurement – gallons, cubic feet, or liters. Start by reading the dial with the largest unit of measurement (e.g., hundreds of thousands of gallons) and proceed to the smallest units (e.g., individual gallons). The numbers on the dials rotate backward, and the digit just passed is the reading for that position. For example, if a dial is between 7 and 8, the reading is 7. The total water consumption is calculated by concatenating the readings from all the dials. For digital meters, reading is straightforward, simply noting the displayed number.

Example: If the dials read 1, 2, 7, and 5 from left to right (representing hundreds, tens, units, and tenths), the reading is 127.5 units.

Q 17. How do you manage multiple water meter installations or repairs on a single day?

Managing multiple installations or repairs efficiently requires meticulous planning and organization. I start by prioritizing tasks based on urgency and location, optimizing my route to minimize travel time. I create a detailed schedule, including arrival and departure times for each site. This ensures I’m prepared with the necessary tools and materials for each job and allows me to stick to the schedule and complete all my appointments within the day. Prior to leaving the office, I check my inventory to make sure that I have all the parts and equipment required for each job. When on the job site, I ensure all work is completed quickly and safely.

Example: I’d group jobs in the same neighborhood together, reducing travel time between locations. I also prioritize emergency repairs over routine installations.

Q 18. What is your experience with different types of meter registers?

My experience encompasses various meter registers, including mechanical, electronic, and advanced metering infrastructure (AMI) systems. Mechanical registers, the older type, rely on rotating gears to display water consumption. Electronic registers utilize digital displays for increased accuracy and remote reading capabilities. AMI systems are more complex, utilizing communication networks to transmit meter data wirelessly, allowing for real-time monitoring and improved billing accuracy. I’m proficient in troubleshooting issues specific to each type, from gear replacements in mechanical meters to software updates and communication diagnostics in AMI systems.

Example: I’ve successfully repaired a faulty gear mechanism in an old-style mechanical meter, restoring its accuracy. I also have experience installing and configuring AMI meters, integrating them into the utility’s data management system.

Q 19. How do you ensure proper sealing and waterproofing during installation?

Proper sealing and waterproofing are critical to prevent leaks and ensure the meter’s longevity. During installation, I use approved pipe sealant, specifically designed for water applications, to create a watertight seal between the meter and the pipes. This prevents corrosion and groundwater intrusion. I thoroughly inspect the seals for any gaps or imperfections, and I always ensure that all connections are tightly secured to prevent leakage. Additionally, I use appropriate thread tape and check all joints with soapy water for any leaks.

Think of it like building a dam – every crack or gap must be sealed meticulously to prevent water from escaping or entering where it shouldn’t. This principle applies directly to water meter installation.

Q 20. How do you deal with customer complaints related to water meter issues?

Addressing customer complaints involves a calm and professional approach. I start by actively listening to the customer’s concerns and showing empathy towards their situation. Once I understand the problem, I thoroughly investigate the issue, checking the meter’s readings, inspecting the connections and plumbing, and potentially running tests to identify the root cause. I clearly communicate my findings to the customer, explaining the cause of the problem in simple, understandable terms and outlining the solutions. Whether it’s a simple adjustment, a repair, or a meter replacement, I ensure the customer is well informed and satisfied with the outcome.

Example: If a customer complains about unusually high bills, I might check for leaks in the customer’s plumbing system in addition to inspecting the meter for any malfunctions.

Q 21. Explain your experience with different types of piping and materials used in water meter installations.

My experience includes working with a variety of piping materials, including copper, PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), and polyethylene (PE). Copper pipes are durable and resistant to corrosion, although more expensive. PVC and CPVC are more cost-effective but can be prone to damage from extreme temperatures or impacts. PE pipes are flexible and ideal for certain situations. I understand the specific requirements and limitations of each material, choosing the most suitable option based on factors like water pressure, temperature, and local regulations. I also ensure the piping system is properly sized and supports the expected water flow for accurate meter readings.

Example: In a high-pressure system, I’d likely choose copper or CPVC pipes, while in a low-pressure, buried system, PE pipes might be a more appropriate choice. The correct pipe selection is essential for optimal meter performance.

Q 22. Describe your knowledge of relevant building codes and regulations related to water meter installation.

Building codes and regulations concerning water meter installation vary by location, but some commonalities exist. These codes ensure safe, reliable, and consistent water service. They dictate everything from the type of meter allowed (e.g., mechanical, electronic, smart meters) and its location (accessibility for reading and maintenance, protection from damage) to the materials used for the service line and backflow prevention. For instance, many jurisdictions require meters to be installed within a specific distance of the property line and in easily accessible meter boxes, often made of concrete or plastic to safeguard the meter from damage. Furthermore, the regulations often specify the size and material of the service pipe connecting the main water line to the meter, adhering to standards that ensure sufficient water flow and pressure while preventing leaks. I’m familiar with the International Plumbing Code (IPC) and local variations, and always consult the relevant codes for the specific project location before any installation work begins. Ignoring these codes can lead to significant problems, including system failures, fines, and even legal issues.

For example, during a recent project in a historical district, we had to adhere to strict regulations regarding the aesthetic impact of the meter installation, requiring us to use a specific type of meter box and install it in a discrete location.

Q 23. How do you interpret water meter readings and identify potential leaks or problems?

Interpreting water meter readings involves understanding the units of measurement (typically gallons or cubic meters) and noting the meter’s reading over time. A significant increase in water consumption without a corresponding increase in usage could signal a leak. I routinely analyze meter readings to identify potential problems. This involves comparing current readings with previous readings and analyzing trends over time. For example, a consistent daily increase beyond typical household usage could point to a hidden leak, which I will then investigate further. I’ve also experienced situations where high consumption was actually due to a malfunctioning toilet or other fixture, which were quickly rectified after identifying the culprit through more specific investigation.

Identifying problems often involves using a combination of methods. Visual inspection is critical – looking for signs of obvious leaks, damaged pipes, and malfunctioning fittings. I also utilize more advanced techniques such as pressure testing to detect leaks in underground pipes and utilizing specialized equipment to pinpoint leaks within the plumbing system.

Q 24. What is your experience with using specialized water meter testing equipment?

My experience with water meter testing equipment is extensive. I’m proficient with various tools used to assess meter accuracy and identify malfunctions. This includes using test meters to check the accuracy of installed meters and various flow-testing devices to measure the flow rate under different pressure conditions. I’m also experienced with electronic testing equipment, designed to diagnose problems within smart meters and detect potential data transmission issues. I regularly use these devices during routine maintenance checks and troubleshooting. For example, I recently used a specialized flow-testing device to identify a faulty pressure regulator causing inaccurate readings on several meters in an apartment complex.

The use of these tools is vital for ensuring the reliability and accuracy of water meter readings, which directly impacts billing and water conservation efforts.

Q 25. How do you prioritize and schedule water meter installations and repairs efficiently?

Prioritizing and scheduling water meter installations and repairs efficiently requires a systematic approach. I typically use a combination of factors to prioritize tasks, including urgency (e.g., a burst pipe requires immediate attention), the number of affected customers, and the overall impact on water service. I use a digital scheduling system and maintain a prioritized task list, enabling me to effectively manage multiple jobs and resources. A crucial part of this is clear communication with clients to set realistic expectations and provide updates.

Scheduling is optimized by considering factors such as geographical location to minimize travel time and resource allocation (e.g., assigning teams based on expertise and proximity to the job site). For example, emergency repairs get top priority, followed by planned installations or scheduled maintenance based on a pre-defined schedule.

Q 26. How do you maintain accurate records and documentation of water meter installations and repairs?

Maintaining accurate records is paramount. I utilize a comprehensive database system to track all installations and repairs. This includes detailed information on each meter (type, serial number, installation date), location data (using GPS coordinates), service history (repairs, maintenance), and associated customer details. All work performed is meticulously documented using digital forms that are seamlessly integrated with the database, ensuring accuracy and preventing data loss. The digital records also aid in generating reports which are crucial for billing, regulatory compliance, and asset management.

This detailed record-keeping is crucial for various reasons; it enables easy tracking of meter performance, assists in identifying potential problems and trends, helps with warranty claims, and ensures compliance with regulatory requirements. Furthermore, this data is essential for long-term planning and investment decisions related to water infrastructure.

Q 27. Describe your experience with working in different environments, such as residential, commercial, or industrial settings.

My experience spans a range of settings, including residential, commercial, and industrial environments. Each setting presents unique challenges and considerations. Residential installations often involve working in confined spaces and coordinating with homeowners. Commercial projects might involve larger-scale installations, requiring coordination with contractors and adherence to building codes and safety regulations. Industrial settings often involve high-pressure systems and specialized metering equipment.

For example, installing meters in a large apartment complex differs significantly from installing a meter for a single-family home, both in terms of scale and the logistical considerations involved in coordinating access and service disruption. Similarly, industrial settings may involve specialized equipment and safety protocols that necessitate specific training and experience. Adaptability and a systematic approach are key to success in each context.

Q 28. What is your experience with using GIS mapping and data management systems related to water meters?

I possess significant experience utilizing Geographic Information Systems (GIS) mapping and data management systems for water meter management. This involves integrating meter location data into a GIS platform, creating maps of the water distribution network, and utilizing spatial analysis tools to identify patterns and trends in water consumption and infrastructure performance. Such data is crucial for efficient resource allocation, leak detection, and proactive maintenance planning. I use this technology to analyze water usage patterns to detect potential leaks, forecast future needs, and optimize maintenance schedules.

For example, I recently used GIS mapping to identify a cluster of unusually high water consumption readings in a specific area, suggesting a possible main-line leak. This timely identification helped prevent further water loss and potential damage.

Key Topics to Learn for Water Meter Installation and Repair Interview

- Meter Types and Technologies: Understanding different types of water meters (e.g., mechanical, electronic, smart meters), their functionalities, and limitations is crucial. Be prepared to discuss their installation requirements and maintenance schedules.

- Installation Procedures: Mastering the practical aspects of installing water meters, including proper pipe connections, backflow prevention, and testing for leaks. Be ready to describe the steps involved and potential challenges encountered.

- Repair and Maintenance Techniques: Familiarize yourself with common water meter problems (e.g., leaks, malfunctions, inaccurate readings) and the methods used for their diagnosis and repair. Highlight your experience with troubleshooting and preventative maintenance.

- Safety Regulations and Procedures: Demonstrate a thorough understanding of relevant safety regulations and procedures for working with water lines, including excavation, trench safety, and handling of potentially hazardous materials.

- Reading and Interpreting Meter Data: Explain your proficiency in accurately reading and interpreting water meter readings, including identifying potential issues based on consumption patterns. Discuss your experience with data logging and reporting.

- Troubleshooting and Problem-Solving: Prepare examples showcasing your ability to diagnose and solve complex problems related to water meter installation and repair. Focus on your analytical and problem-solving skills.

- Tools and Equipment: Be familiar with the various tools and equipment used in water meter installation and repair, and their proper use and maintenance. This demonstrates practical experience and attention to detail.

Next Steps

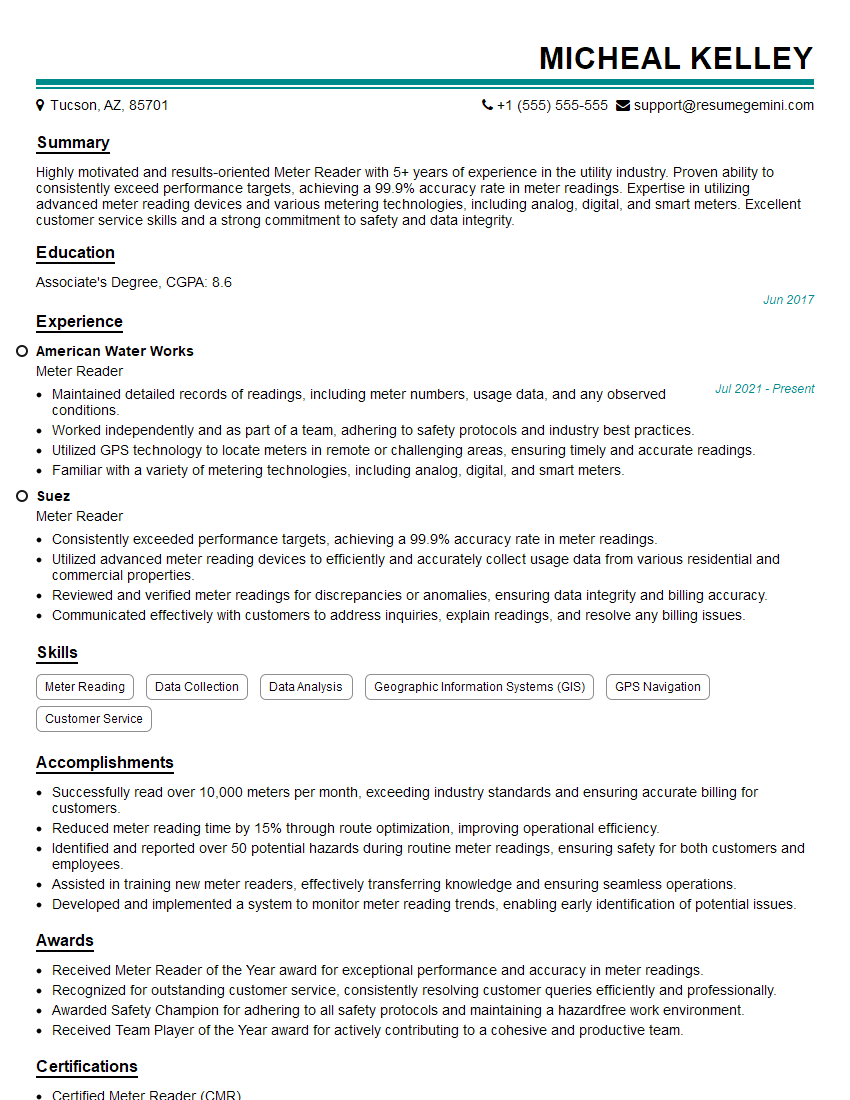

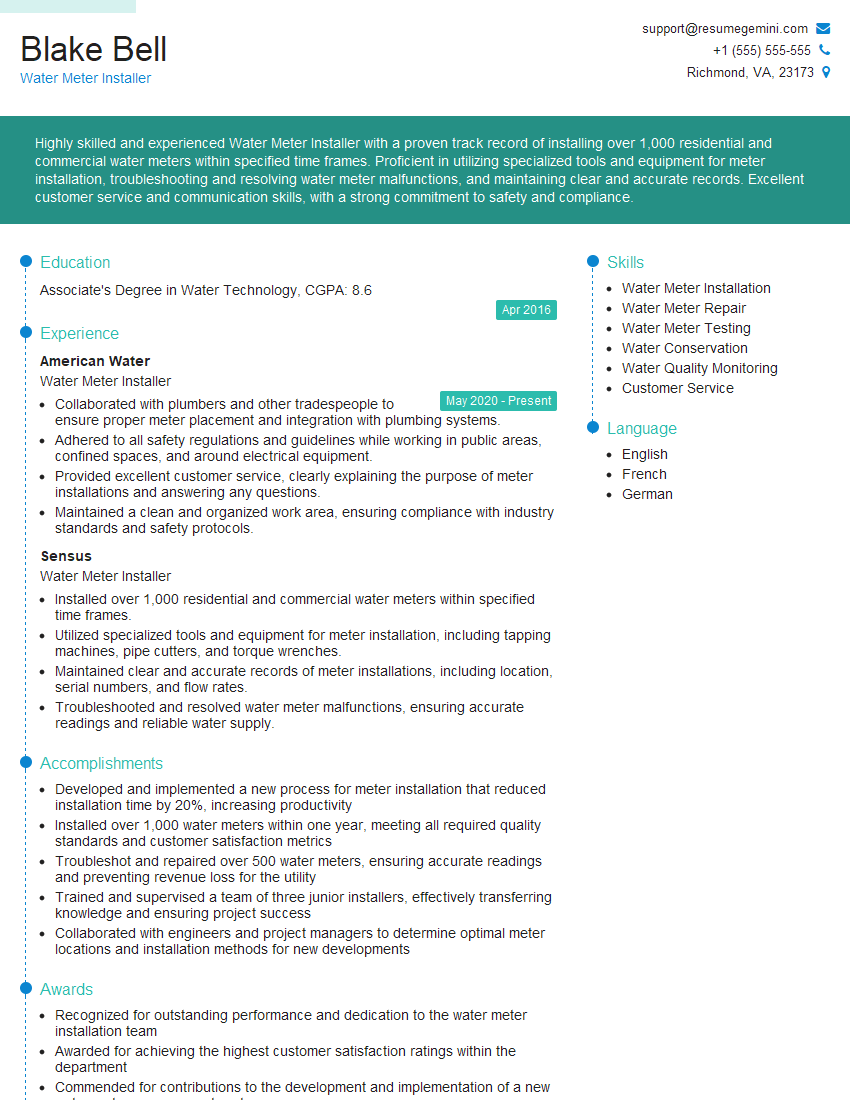

Mastering Water Meter Installation and Repair opens doors to a rewarding career with excellent growth potential. This specialized skillset is highly sought after, offering opportunities for advancement and increased earning potential. To maximize your job prospects, it’s essential to create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific requirements of this field. Examples of resumes tailored to Water Meter Installation and Repair are available, allowing you to create a document that showcases your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.