Are you ready to stand out in your next interview? Understanding and preparing for Sludge Handling and Dewatering interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Sludge Handling and Dewatering Interview

Q 1. Explain the different methods of sludge dewatering.

Sludge dewatering aims to reduce the water content of sludge, making it easier and cheaper to transport and dispose of. Several methods achieve this, each with its own advantages and disadvantages. These can be broadly categorized into mechanical, thermal, and chemical methods.

- Mechanical Dewatering: This involves physically separating water from the solids using equipment like:

- Belt filter presses: These use belts and pressure to squeeze water out of the sludge.

- Centrifuges: High-speed rotation forces the water away from the solids.

- Plate and frame filter presses: These use plates and frames to compress the sludge, removing water.

- Vacuum filters: A vacuum draws water through a filter medium, leaving behind dewatered sludge.

- Thermal Dewatering: This uses heat to evaporate water from the sludge, such as in:

- Incineration: This process burns the sludge, significantly reducing its volume.

- Drying beds: Sludge is spread thinly on beds and allowed to dry naturally.

- Chemical Dewatering: This involves adding chemicals to improve the sludge’s dewatering properties, often used in conjunction with mechanical methods:

- Polymer addition: Polymers act as flocculants, binding sludge particles together, making them easier to dewater.

- Lime addition: Lime increases the pH, affecting the sludge’s properties and improving dewatering.

The choice of method depends on factors like the type of sludge, the desired cake dryness, available space, capital and operating costs, and environmental regulations.

Q 2. Describe the advantages and disadvantages of belt filter presses.

Belt filter presses are a popular choice for sludge dewatering due to their relatively high efficiency and relatively low operating costs compared to some other methods.

- Advantages:

- High solids content in the dewatered cake: They can produce a cake with a relatively high percentage of solids, reducing disposal costs.

- Continuous operation: Unlike batch processes, they operate continuously, providing a steady output.

- Relatively low energy consumption compared to centrifuges: This makes them cost-effective in the long run.

- Ease of operation and maintenance: Relatively simple to operate and maintain compared to more complex dewatering systems.

- Disadvantages:

- High capital cost: The initial investment can be substantial.

- Sensitivity to sludge characteristics: Performance can be affected by variations in sludge properties like solids concentration and particle size.

- Potential for belt clogging: This requires regular cleaning and maintenance.

- Requires pre-treatment: Often requires sludge thickening or conditioning before dewatering to optimize efficiency.

For example, a wastewater treatment plant with a high sludge volume might find belt filter presses cost-effective in the long run despite the initial investment because of their continuous operation and high dewatering efficiency. Conversely, a smaller plant might find other methods more suitable.

Q 3. What are the key parameters to monitor during sludge dewatering?

Effective sludge dewatering relies on careful monitoring of several key parameters. These include:

- Solids content: Measured as Total Solids (TS) and Volatile Solids (VS), this indicates the effectiveness of the dewatering process. Higher solids content in the dewatered cake means successful dewatering.

- Cake dryness: Expressed as a percentage of solids in the dewatered cake. This is crucial for determining transportation and disposal costs.

- Polymer dosage: The amount of polymer added influences flocculation and dewatering efficiency. Careful monitoring prevents unnecessary chemical use.

- pH: The pH of the sludge affects its dewaterability. Maintaining an optimal pH ensures efficient operation.

- Sludge viscosity: High viscosity hinders efficient dewatering. Monitoring viscosity helps optimize the process.

- Filter cloth pressure drop: Increased pressure drop indicates clogging and may require cleaning or replacement.

- Belt speed: Adjusting the belt speed can optimize dewatering efficiency.

- Power consumption: Monitoring energy usage helps identify areas for optimization and cost reduction.

Real-time monitoring systems coupled with data analysis allows operators to make timely adjustments to optimize the process and minimize costs. For instance, if the cake dryness is below target, the polymer dosage or belt speed can be adjusted.

Q 4. How do you optimize sludge dewatering processes for cost-effectiveness?

Optimizing sludge dewatering for cost-effectiveness involves a multifaceted approach. It’s not just about the dewatering technology itself, but also about the entire sludge handling process.

- Sludge Thickening Optimization: Efficient thickening reduces the volume of sludge that needs to be dewatered, minimizing energy and chemical consumption.

- Polymer Selection and Optimization: Choosing the right polymer type and dosage is crucial. Testing different polymers and optimizing the dosage can significantly reduce chemical costs.

- Regular Maintenance: Preventative maintenance on equipment like belt filter presses reduces downtime and extends the lifespan of the equipment, reducing replacement costs.

- Process Control: Implementing automated control systems that monitor key parameters and automatically adjust process variables (e.g., polymer dosage, belt speed) ensures optimal operation and reduces manual labor.

- Energy Efficiency Improvements: Optimizing energy consumption through measures like improving motor efficiency or utilizing renewable energy sources can lead to significant savings.

- Disposal Cost Management: Exploring various disposal options and negotiating favorable contracts with disposal facilities can reduce disposal costs significantly.

For example, a plant might conduct regular trials with different polymer types to find the most cost-effective option for their specific sludge characteristics. They might also invest in an automated control system to ensure consistent optimal operation and reduce labor costs.

Q 5. Explain the concept of sludge thickening.

Sludge thickening is a crucial pre-treatment step before dewatering. It aims to increase the concentration of solids in the sludge, reducing the volume of liquid that needs to be processed during dewatering. This is analogous to squeezing a sponge to remove excess water before wringing it out completely.

Thickening can be achieved using various methods, including:

- Gravity thickening: Sludge is allowed to settle under gravity, concentrating the solids in the bottom of a tank. This is a simple and low-cost method, but it is relatively slow and inefficient for some sludge types.

- Flotation thickening: Air is introduced into the sludge, causing the solids to float to the surface, forming a concentrated layer that can be easily removed.

- Centrifugal thickening: Centrifugal force is used to separate solids from water, resulting in a thickened sludge stream.

The choice of thickening method depends on factors like sludge characteristics, space availability, and cost considerations. Efficient thickening is essential for minimizing the cost and energy required for dewatering.

Q 6. What are the common types of sludge produced in wastewater treatment plants?

Wastewater treatment plants generate various types of sludge, each with different properties and dewatering characteristics. Common types include:

- Primary sludge: Settled solids from the primary sedimentation tanks. This sludge is typically high in organic matter and relatively easy to dewater.

- Secondary sludge: Excess activated sludge from the secondary treatment process. This sludge is typically more difficult to dewater than primary sludge because of its smaller particle size and higher water content.

- Digested sludge: Sludge that has undergone anaerobic digestion. The digestion process stabilizes the sludge, making it less odorous and easier to handle, often improving dewaterability.

- Chemical sludge: Sludge generated from chemical treatment processes used to remove specific pollutants. Its properties depend on the chemicals used.

Understanding the type of sludge generated is vital for selecting the appropriate dewatering method and optimizing the entire sludge management process. For example, secondary sludge might require polymer addition for efficient dewatering, whereas digested sludge might require less.

Q 7. Describe the process of anaerobic digestion of sludge.

Anaerobic digestion is a biological process used to stabilize sludge by breaking down organic matter in the absence of oxygen. This process significantly reduces the volume and mass of the sludge, making it easier and cheaper to handle and dispose of. Think of it as a controlled decomposition process that converts sludge into biogas and a stabilized digestate.

The process typically occurs in large sealed tanks or digesters where the sludge is held for several weeks at a specific temperature and pH. Microbial communities break down the organic matter, producing biogas, a mixture primarily of methane and carbon dioxide, which can be used for energy generation. The remaining material, called digestate, is a stabilized solid that is significantly easier to dewater than raw sludge. The entire process can be broken into these steps:

- Hydrolysis: Complex organic polymers are broken down into simpler molecules.

- Acidogenesis: Simple molecules are fermented into volatile fatty acids.

- Acetogenesis: Volatile fatty acids are converted to acetic acid, hydrogen, and carbon dioxide.

- Methanogenesis: Methane is produced from acetic acid, hydrogen, and carbon dioxide.

Anaerobic digestion is an environmentally friendly and energy-efficient method for sludge treatment, reducing greenhouse gas emissions and providing a renewable energy source.

Q 8. How do you handle sludge with high solids content?

Handling sludge with high solids content requires different approaches than handling low-solids sludge. The key is to minimize energy consumption and optimize dewatering efficiency. Methods typically employed include:

Screw Presses: These are excellent for high-solids sludge, effectively squeezing out water and producing a drier cake. Think of it like a giant, industrial wringer for clothes.

Belt Filter Presses: While generally used for lower solids, certain advanced configurations and polymer conditioning can be effective with higher solids. This method uses belts and vacuum to remove water. The key is careful polymer selection and optimization of the belt speed and tension.

Centrifuges: High-speed centrifuges can handle high-solids content, separating solids from liquids through centrifugal force. This is particularly useful for sludge that’s difficult to dewater using other methods.

Thermal Drying: For very high solids content or when extremely dry sludge is needed, thermal drying techniques are used. This method is energy-intensive but can achieve very low moisture contents. Think of it like drying clothes in a dryer, but on an industrial scale.

The choice of method depends on the specific sludge properties (e.g., viscosity, particle size, chemical composition), the desired dryness of the cake, and the available budget and space.

Q 9. What are the environmental regulations related to sludge disposal?

Environmental regulations concerning sludge disposal vary by location but generally focus on minimizing environmental impact. Key regulations often address:

Pathogen Reduction: Regulations mandate sufficient treatment to eliminate or significantly reduce harmful pathogens like bacteria and viruses before disposal. This often involves processes like digestion or lime stabilization.

Metal Content: Limits are placed on the concentrations of heavy metals like lead, mercury, and cadmium in the sludge to prevent soil and water contamination. Regular testing is crucial to ensure compliance.

Disposal Method Restrictions: Regulations dictate permitted disposal methods (landfilling, land application, incineration). Land application, for example, might have strict requirements on the types of sludge allowed and the application rate to prevent soil contamination. Landfilling often requires specific liners and leachate management systems.

Air Emissions: Incineration requires stringent controls on air emissions to prevent the release of harmful pollutants into the atmosphere.

Staying up-to-date with local and national environmental regulations is crucial for compliance and avoiding penalties. It’s best practice to consult regularly with environmental agencies and legal experts.

Q 10. Explain the role of flocculants in sludge dewatering.

Flocculants play a vital role in sludge dewatering by improving the settling and dewatering characteristics of the sludge. They are chemical polymers that cause small sludge particles to clump together, forming larger, more easily filterable flocs.

Imagine stirring a bowl of sand and water – it’s hard to separate the sand. Adding a flocculant is like adding a glue, binding the sand particles together into larger clumps that settle faster and more completely. This improved settling leads to a higher solids concentration in the sludge, making dewatering processes more efficient.

Different types of flocculants exist, each with varying effectiveness depending on the sludge characteristics. Anionic, cationic, and non-ionic flocculants are common choices. The selection is often based on lab testing to determine the optimal type and dosage for a particular sludge.

Proper dosage is critical; too little is ineffective, while too much can lead to filter blinding or increased costs.

Q 11. How do you troubleshoot a malfunctioning belt filter press?

Troubleshooting a malfunctioning belt filter press requires a systematic approach. Here’s a step-by-step process:

Identify the problem: Is the cake too wet? Is the throughput too low? Are there filter cloth tears? Observe all aspects of the operation carefully.

Check the basics: Ensure proper polymer dosage and mixing, that the belt tension and speed are correctly set, and that the pressure is within the acceptable range. A simple adjustment might solve the issue.

Inspect the filter cloth: Examine the filter cloth for tears, holes, or blinding. Replace or clean the cloth as needed. Blinding can often be addressed by adjusting chemical treatment.

Examine the rollers: Check the condition of the rollers for wear or damage. Uneven roller pressure can cause poor dewatering.

Analyze the sludge: Is there an issue with the feed sludge’s properties? Has something changed in the upstream process that may affect the sludge consistency?

Check the vacuum system: If using a vacuum belt filter press, ensure the vacuum is functioning properly. A leak will cause poor dewatering.

Consider professional help: If the problem persists after addressing these points, it may be necessary to seek assistance from a qualified technician or the manufacturer.

Q 12. Describe the safety procedures associated with sludge handling.

Safety procedures during sludge handling are critical due to potential hazards including:

Infectious diseases: Sewage sludge contains pathogens; appropriate personal protective equipment (PPE) like gloves, boots, and eye protection is essential.

Harmful gases: Anaerobic digestion produces biogas, which can be flammable and toxic. Proper ventilation is paramount, and gas detection equipment might be necessary.

Physical hazards: Moving machinery poses risks of injury. Lockout/tagout procedures must be followed during maintenance.

Chemical hazards: Flocculants and other chemicals present risks; proper handling, storage, and disposal are crucial. Always follow the manufacturer’s safety data sheets (SDS).

Regular safety training for all personnel, implementation of proper emergency procedures (including emergency showers and eye wash stations), and adherence to safety regulations are essential.

Q 13. How do you calculate the solids content of sludge?

The solids content of sludge is typically expressed as a percentage of total solids (TS) or volatile solids (VS). The most common method is the laboratory method of drying a weighted sample of sludge in an oven at 103-105°C until a constant weight is achieved.

The calculation is straightforward:

% Solids = [(Weight of dry solids / Weight of wet sample) x 100]

For example, if a 100g wet sample weighs 20g after drying, the solids content is 20%. Volatile solids are determined by further combusting the dried sample at 550°C and calculating the weight loss, which represents the volatile fraction.

Other methods like using a solids meter or infrared sensors provide faster results but may require calibration and are typically less accurate than the standard laboratory method. Accurate solids content determination is essential for optimizing sludge treatment and dewatering processes.

Q 14. What are the different types of sludge disposal methods?

Various methods exist for sludge disposal, each with its own environmental and economic considerations:

Landfilling: A common method, but stringent regulations are in place to prevent leachate contamination. This is often a last resort.

Land Application: Sludge can be applied to land as a soil amendment, providing nutrients to plants. This requires careful monitoring to avoid soil and water contamination, and is suitable only for certain types of sludge.

Incineration: High-temperature combustion reduces sludge volume significantly, but air emission controls are crucial. Energy can often be recovered from the process.

Composting: Sludge can be composted with other organic materials, producing a stable, nutrient-rich product suitable for soil amendment. This method is environmentally sound and reduces landfill burden.

Anaerobic Digestion: This process breaks down organic matter in the absence of oxygen, producing biogas (renewable energy) and digested sludge, which is easier to dewater.

The optimal choice depends on factors such as sludge characteristics, environmental regulations, available infrastructure, and cost-effectiveness.

Q 15. Explain the importance of sludge conditioning.

Sludge conditioning is a crucial pretreatment step before dewatering that significantly improves the efficiency of the process. Think of it like preparing a sponge for squeezing – a dry, stiff sponge is hard to wring out, but a properly moistened one releases water much more easily. Similarly, sludge conditioning aims to improve the sludge’s physical and chemical properties to make it easier to separate the water from the solids.

This is achieved through various methods, including the addition of chemical conditioners like polymers. These polymers act as flocculants, binding small sludge particles together into larger flocs, increasing the size and settling rate of the solids. Other methods involve adjusting the pH or adding other conditioning agents to enhance the effectiveness of the process. The result is a sludge that is more easily dewatered, resulting in a drier cake and reduced overall costs.

For example, in a municipal wastewater treatment plant, poorly conditioned sludge might require significantly more energy to dewater, leading to increased operational expenses. Effective conditioning translates to less energy consumption, reduced polymer usage, and a smaller final sludge volume.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the impact of pH on sludge dewatering efficiency.

pH plays a vital role in sludge dewatering efficiency, primarily impacting the effectiveness of chemical conditioners, especially polymers. Most polymers function optimally within a specific pH range. Consider it like this: a specific type of glue works best on certain surfaces; an acidic environment may neutralize a particular polymer, significantly reducing its ability to bind sludge particles. The ideal pH is polymer-specific, but generally, a slightly acidic to neutral range is preferred for many anionic polymers.

At the extreme ends of the pH spectrum, problems arise. For example, a highly alkaline pH can cause polymer hydrolysis, rendering it less effective. Conversely, an excessively acidic pH can negatively affect the charge of sludge particles, hindering flocculation. Consequently, poor pH control can lead to a less effective dewatering process, resulting in a less efficient separation of water from solids, a higher moisture content in the dewatered cake, and increased disposal costs.

In practice, pH adjustment is routinely done before polymer addition using chemicals such as lime (to increase pH) or acid (to decrease pH). Regular monitoring of pH is essential to ensure optimal dewatering.

Q 17. How do you determine the optimal polymer dosage for sludge dewatering?

Determining the optimal polymer dosage for sludge dewatering is a crucial aspect of efficient sludge management. It’s a balancing act: too little, and dewatering is inefficient; too much, and costs increase without proportionate benefits. Several methods exist to find this sweet spot.

The most common approach involves jar testing. This laboratory-scale experiment involves mixing various polymer dosages with sludge samples under controlled conditions. The resulting sludge floc characteristics (size, settleability) and the final dewatered cake solids content are then measured and analyzed. This data allows you to establish a clear relationship between polymer dosage and dewatering performance.

Another approach is to utilize a pilot-scale dewatering unit. A small-scale dewatering system mirrors the full-scale system, allowing real-time testing and optimization of polymer dosage at different flow rates and sludge conditions. Data from both jar tests and pilot-scale tests inform the full-scale operation and allow for dynamic adjustments according to fluctuating sludge properties.

Ultimately, the optimal dosage minimizes polymer consumption while maximizing dewatering efficiency, resulting in a cost-effective operation and reduced environmental impact.

Q 18. What is the role of cake moisture content in sludge disposal?

Cake moisture content is the percentage of water remaining in the dewatered sludge (the “cake”). It’s a critical factor in sludge disposal, significantly affecting costs and environmental considerations. A lower moisture content equates to less water to handle and transport, reducing costs associated with transportation, landfill space, and potential leachate management.

High moisture content necessitates larger disposal volumes and potentially increases the risk of odor and leachate generation. Leachate, the liquid that percolates through the sludge in landfills, can be environmentally damaging if not properly managed. Landfills impose strict limits on the moisture content of the disposed sludge, often requiring a predetermined level to be achieved before acceptance. Therefore, optimizing the dewatering process to achieve the lowest feasible moisture content is vital for minimizing costs and environmental impacts.

For instance, a landfill might only accept sludge with a moisture content below 75%. Achieving this target requires careful control of the dewatering process, including proper sludge conditioning and selection of suitable dewatering equipment.

Q 19. Explain the differences between primary, secondary, and tertiary sludge.

The terms primary, secondary, and tertiary sludge refer to the different stages of wastewater treatment where sludge is generated. Each type differs in its composition and characteristics.

- Primary sludge: This is the raw, settled solids removed from the initial stage of wastewater treatment (primary sedimentation). It contains a significant amount of organic matter, grit, and other inorganic materials. It’s typically characterized by a high moisture content and high organic solids load.

- Secondary sludge: This is the biological sludge produced during the secondary treatment stage, commonly using activated sludge processes. This sludge contains a higher proportion of microorganisms (bacteria) that have consumed the organic matter in the wastewater. Secondary sludge is generally more easily dewatered than primary sludge but still has a significant moisture content.

- Tertiary sludge: This is the sludge generated during advanced treatment processes (tertiary treatment) such as filtration or chemical precipitation. It is often less voluminous and with different characteristics depending on the tertiary treatment applied. It might include chemical precipitates or filtered solids.

Understanding the characteristics of each type is crucial for optimizing the dewatering process, as the optimal techniques for primary sludge dewatering, for example, may differ significantly from the methods used for secondary sludge.

Q 20. How do you minimize odor issues associated with sludge handling?

Odor issues are a common concern in sludge handling. These odors are largely caused by the anaerobic decomposition of organic matter within the sludge, releasing volatile organic compounds (VOCs). Several strategies help minimize these issues.

- Proper enclosure and ventilation: Covering sludge storage areas and ensuring proper ventilation helps prevent the build-up of VOCs in the atmosphere. This also minimizes the spread of odors and improves worker safety.

- Chemical treatment: Adding odor-controlling chemicals, such as biocides or odor masking agents, can help reduce or eliminate malodors.

- Rapid dewatering: Quick removal of water from sludge minimizes the time available for anaerobic decomposition to occur, thereby reducing odor formation.

- Proper sludge digestion: Anaerobic digestion processes are designed to break down organic matter, often reducing the odor-causing substances. Effective digestion involves maintaining optimal temperatures and pH levels to enhance the process.

In practice, a combination of these methods is often employed to ensure effective odor control. Regular monitoring and maintenance of equipment are crucial to prevent the development of odor problems.

Q 21. What are the potential health risks associated with sludge handling?

Sludge handling presents various health risks, primarily stemming from exposure to pathogens, hazardous chemicals, and potentially harmful gases. These risks vary depending on the type of sludge, the handling procedures, and the level of personal protective equipment (PPE) used.

- Pathogens: Raw sludge contains numerous pathogenic bacteria, viruses, and parasites. Exposure can cause various infections, depending on the specific pathogens present.

- Hazardous chemicals: Sludge may contain heavy metals, toxins, and other harmful chemicals, posing risks through inhalation, ingestion, or skin contact.

- Harmful gases: Anaerobic decomposition generates gases like hydrogen sulfide (H2S), a highly toxic and flammable gas that can be lethal at high concentrations. Methane (CH4) is another potential hazard.

Mitigation of these risks involves implementing strict safety protocols including proper PPE (gloves, respirators, protective clothing), regular health monitoring of workers, and adherence to safe handling practices. Proper training and the implementation of engineering controls such as enclosed systems are also essential in minimizing health risks associated with sludge handling.

Q 22. How do you ensure compliance with environmental permits during sludge management?

Ensuring compliance with environmental permits during sludge management is paramount. It involves a multi-faceted approach, beginning with a thorough understanding of the specific permit requirements. This includes limits on pollutants like TSS (Total Suspended Solids), BOD (Biochemical Oxygen Demand), and potentially heavy metals. We meticulously track all sludge characteristics – volume, composition, and treatment – through detailed records and regular testing. This data forms the basis of our compliance reports, which are submitted to the regulatory authorities on schedule. For example, if our permit specifies a maximum TSS level of 50 mg/L in the effluent after dewatering, we implement robust monitoring procedures, including regular grab sampling and laboratory analysis, to ensure we consistently stay below that limit. Any deviations trigger immediate investigation and corrective actions, documented thoroughly. Proactive measures, such as optimizing our dewatering processes or implementing preventative maintenance on our equipment, help prevent non-compliance.

Furthermore, we maintain up-to-date knowledge of all relevant regulations and amendments. Regular training for our personnel ensures that everyone understands their role in compliance and is aware of potential risks and penalties. We also work closely with environmental consultants to ensure our practices meet the most stringent standards.

Q 23. Describe your experience with different types of sludge pumps.

My experience encompasses a wide range of sludge pumps, each suited to specific sludge characteristics and application. I’ve worked extensively with positive displacement pumps, such as progressive cavity pumps (PCPs) and diaphragm pumps. PCPs excel at handling high-viscosity and abrasive sludges, often found in wastewater treatment plants. Their ability to pump solids without causing significant shear is a key advantage. Diaphragm pumps offer similar advantages, particularly when dealing with potentially corrosive sludges. On the other hand, centrifugal pumps are often used for less viscous sludges or in situations requiring higher flow rates. While they aren’t ideal for highly concentrated sludge, their reliability and lower maintenance requirements make them suitable for certain applications. For example, we once faced a challenge with highly abrasive sludge causing excessive wear on our PCPs. We switched to a more robust PCP model with hardened components and implemented a more frequent maintenance schedule, dramatically improving the lifespan and efficiency of the pump.

Selection criteria include sludge characteristics (viscosity, abrasiveness, solids content), required flow rate, head pressure, and budget constraints. A thorough understanding of these factors is crucial for optimal pump selection and long-term operational efficiency.

Q 24. Explain the principles of centrifuge dewatering.

Centrifuge dewatering relies on the principle of centrifugal force to separate solids from liquids. Sludge is fed into a rapidly rotating bowl, generating a powerful centrifugal force many times greater than gravity. This force pushes the heavier solids outwards towards the bowl wall, forming a compact cake, while the lighter liquid (centrate) is expelled. The key principle is the difference in density between solids and liquids. Imagine spinning a salad spinner: the water is forced outwards leaving the salad behind. It’s the same principle, but on a larger scale and with much higher G-forces.

Different types of centrifuges exist, including decanter centrifuges and solid-bowl centrifuges. Decanter centrifuges are ideal for high-volume, continuous sludge processing, while solid-bowl centrifuges are better suited for batch processing or sludges with higher solids concentrations. The efficiency of the dewatering process is influenced by factors such as the centrifuge’s speed, bowl geometry, polymer addition (to aid in flocculation), and sludge characteristics. For example, adding a flocculant before the sludge enters the centrifuge can significantly improve the dewatering performance by creating larger, more easily separated solid flocs.

Q 25. How do you manage sludge storage effectively?

Effective sludge storage is vital for minimizing environmental risks and ensuring smooth operation. The design and management of sludge storage facilities depend heavily on the type of sludge and local regulations. Key considerations include capacity, containment, and preventing odor and leachate generation. We typically use enclosed tanks, often with an anaerobic digester integrated, to prevent odors and minimize the risk of environmental contamination. Regular monitoring of the sludge level and its characteristics (pH, temperature, volatile solids) helps prevent issues like overflow and uncontrolled anaerobic decomposition. For example, we implemented a real-time monitoring system for our sludge storage tanks that alerts us to any significant changes in levels or temperature, allowing for proactive intervention and preventing potential issues.

Furthermore, regular maintenance and cleaning of the storage tanks are essential to prevent clogging and ensure longevity. This often involves using high-pressure water jets to remove accumulated solids and prevent the formation of biofilm. Properly designed storage significantly reduces environmental risks and streamlines subsequent sludge treatment and disposal processes.

Q 26. What are the different types of sludge digesters?

Sludge digesters are crucial for the anaerobic stabilization of sludge, reducing volume and producing biogas. There are several types:

- Anaerobic Lagoons: These are simple, low-cost systems suitable for smaller facilities, but their land requirements are significant, and treatment efficiency is relatively lower.

- Covered Digesters: These are enclosed tanks that improve the efficiency of anaerobic digestion by controlling temperature and maintaining an anaerobic environment. They reduce odor emissions and maximize biogas capture.

- High-rate Digesters: These are designed for faster digestion rates using higher temperatures and enhanced mixing. They reduce the footprint of the digester compared to low-rate systems.

- Two-stage Digesters: These systems involve separate digestion and stabilization stages for improved efficiency and biogas production.

The choice of digester type depends on factors like sludge characteristics, available land, budget, and desired biogas production levels. For instance, a larger wastewater treatment plant might opt for a high-rate, covered digester to optimize biogas recovery and minimize environmental impact, whereas a small plant might be more suited to an anaerobic lagoon.

Q 27. How do you address unexpected issues during sludge handling operations?

Unexpected issues during sludge handling are inevitable. Our approach focuses on preparedness, rapid response, and thorough investigation. We have established comprehensive emergency response plans that outline procedures for addressing various scenarios, including pump failures, equipment malfunctions, and spills. These plans detail roles, responsibilities, and contact information for relevant personnel. For example, if a pump fails, we have backup pumps ready and a clear procedure for switching over to prevent prolonged downtime. Regular maintenance and preventative measures significantly reduce the likelihood of unexpected events.

When an issue arises, our first priority is to contain the problem and prevent further escalation. This may involve isolating affected equipment, deploying emergency containment measures, and notifying relevant authorities. Once the immediate threat is addressed, we conduct a thorough investigation to determine the root cause, implementing corrective actions to prevent recurrence. Thorough documentation is maintained throughout the entire process, which enables us to learn from past mistakes and improve our overall operational procedures.

Q 28. Describe your experience with sludge handling automation systems.

I’ve had significant experience with sludge handling automation systems, enhancing efficiency and safety. These systems typically involve Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems. PLCs control the automated operation of pumps, valves, and other equipment, while SCADA systems provide real-time monitoring and data logging, offering a centralized view of the entire process. This allows for optimized control of various parameters like sludge flow rates, levels, and pressures. For example, we implemented a SCADA system that allowed us to remotely monitor and control the operation of our dewatering centrifuges, significantly improving process optimization and reducing manual intervention.

Automation also contributes to improved data management and reporting, facilitating compliance with environmental regulations. The collected data helps in optimizing processes, identifying trends, and predicting potential issues, leading to improved efficiency and reduced operational costs. However, a critical aspect is ensuring robust cybersecurity measures to protect the automation systems from cyber threats and vulnerabilities.

Key Topics to Learn for Sludge Handling and Dewatering Interview

- Sludge Characteristics: Understanding different sludge types (primary, secondary, digested), their physical and chemical properties (solids content, pH, viscosity), and implications for handling and dewatering processes.

- Thickening Technologies: Familiarize yourself with various thickening methods (gravity, dissolved air flotation, centrifugation) and their applications based on sludge characteristics and project requirements. Be prepared to discuss the advantages and disadvantages of each.

- Dewatering Technologies: Gain a comprehensive understanding of dewatering techniques such as belt filter presses, centrifuge dewatering, vacuum filtration, and their suitability for different sludge types. Consider the energy consumption and operational costs of each method.

- Sludge Conditioning: Explore chemical and polymer conditioning methods to optimize dewatering efficiency. Understand how different polymers affect sludge rheology and dewatering performance.

- Process Control and Optimization: Discuss strategies for monitoring and controlling sludge handling and dewatering processes to ensure optimal performance, minimize costs, and meet regulatory compliance requirements. Consider the role of instrumentation and automation.

- Safety and Environmental Regulations: Understand the safety protocols and environmental regulations related to sludge handling and disposal. Be prepared to discuss best practices for minimizing environmental impact and worker safety.

- Troubleshooting and Problem-Solving: Develop your ability to diagnose and solve common problems encountered in sludge handling and dewatering operations, such as filter cake dryness issues, equipment malfunctions, and process inefficiencies.

- Sludge Treatment and Disposal: Be familiar with various sludge treatment and disposal options (land application, incineration, landfilling), and the associated environmental considerations and regulations.

Next Steps

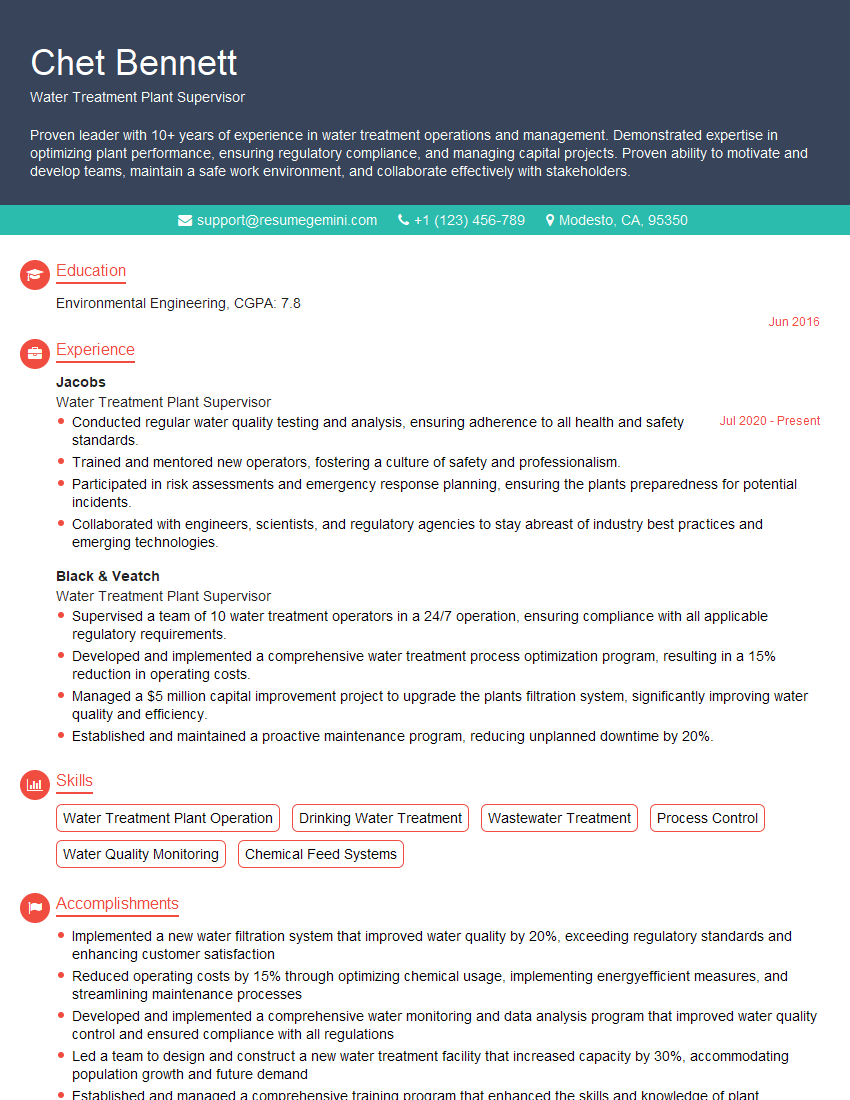

Mastering sludge handling and dewatering opens doors to exciting career opportunities in environmental engineering, wastewater treatment, and industrial process management. To maximize your job prospects, focus on building a strong, ATS-friendly resume that highlights your skills and experience in this specialized field. ResumeGemini is a trusted resource that can help you create a professional and impactful resume, ensuring your application stands out from the competition. Examples of resumes tailored to Sludge Handling and Dewatering are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.