Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Measuring and marking glass for cutting interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Measuring and marking glass for cutting Interview

Q 1. Explain the different types of glass cutters and their applications.

Glass cutters come in various types, each suited for different applications. The most common is the wheel cutter, using a hardened steel wheel to score the glass. This is ideal for straight cuts and is a staple in most glass workshops and DIY projects. Its simplicity and affordability make it a popular choice. Think of it like a really precise pizza cutter for glass.

Oil-fed cutters are similar but incorporate an oil reservoir to lubricate the wheel, resulting in smoother scores and cleaner breaks, especially on thicker glass. They’re a step up from basic wheel cutters in terms of precision and longevity.

Snap cutters are designed for smaller, thinner pieces of glass and use a carbide tip to score the glass. They’re less powerful than wheel cutters but are excellent for delicate work or intricate cuts. Imagine these as miniature, precise glass-cutting tools, perfect for small projects.

Finally, electric glass cutters are power tools offering more control and speed for intricate designs or mass production. These are usually found in professional glass workshops or factories and offer significant efficiency advantages.

- Wheel Cutter: Best for straight cuts and general use.

- Oil-fed Cutter: Offers smoother cuts and better precision.

- Snap Cutter: Ideal for small, thin pieces and detailed work.

- Electric Glass Cutter: Used for large-scale projects and complex designs.

Q 2. Describe the process of measuring glass for a specific project.

Measuring glass accurately is crucial for a successful project. Begin by carefully reviewing your project’s design. This could be a blueprint, sketch, or even a picture of the desired glass piece. Then, use a measuring tape or ruler to take precise measurements. For simple shapes, such as rectangles or squares, measure the length and width.

Remember to account for any tolerances required. For example, if your project calls for a 10cm x 10cm square, you might add a small margin (e.g., 1-2mm) to account for slight inaccuracies during cutting. This prevents ending up with a piece that’s slightly too small.

Mark the measurements directly onto the glass using a grease pencil or marker. Always double-check your measurements to avoid costly mistakes. Think of it like a surgeon double-checking their measurements before an operation – precision is paramount. And always measure twice, cut once!

Q 3. What safety precautions are essential when measuring and cutting glass?

Safety is paramount when working with glass. Always wear safety glasses to protect your eyes from flying shards. Thick gloves can protect your hands from cuts, especially when breaking the glass. Never rush the process, work slowly and deliberately.

Ensure the cutting surface is flat and stable to prevent the glass from shifting mid-cut, causing inaccuracies and potential injuries. After scoring the glass, use a breaking tool or a pair of pliers to snap the glass away from your body. If you’re breaking larger pieces, consider supporting the glass with a suitable base to ensure a clean break and to avoid injury.

Proper disposal of glass shards is also vital. Use a sturdy container to collect the broken pieces and label it appropriately for safe disposal or recycling. Think of this like handling any other hazardous material; careful attention to safety is always the best practice.

Q 4. How do you ensure accurate measurements for complex glass shapes?

Accurate measurements for complex shapes require a more methodical approach. Using a template is the most effective method. For intricate shapes, create a precise template from sturdy material like cardboard or acrylic. Then, carefully trace the template onto the glass using a grease pencil. For irregular shapes, consider using a flexible ruler or curve to follow the outlines precisely.

For very complex shapes, you might consider using CAD software to design the piece digitally and then using a CNC cutter for precise cutting. This is a highly accurate and efficient method, particularly beneficial in mass production.

Remember, the key to accuracy lies in meticulous planning and precise execution. Take your time, carefully review your markings, and don’t hesitate to create several templates until you’re confident in the accuracy of the design before transferring it onto the glass.

Q 5. What are the various methods for marking glass for cutting?

Several methods exist for marking glass for cutting. The most common is using a grease pencil. This creates a visible mark without scratching the glass’s surface, allowing for easy removal once the cut is complete. Grease pencils are widely available and easy to use.

Permanent markers can also be used, particularly for marking multiple lines or complex designs, however it’s essential to use a type that won’t smudge or be washed off during the cutting process. Note that permanent markers may leave a small mark even after the cutting is completed. Alternatively, you could use a fine-tipped dry erase marker which will wipe away easily.

In professional settings, specialized marking tools may be used for enhanced precision, particularly for mass production lines. Regardless of your method, ensure that your markings are clear, consistent, and accurately reflect your measurements.

Q 6. Explain the use of templates in glass cutting.

Templates are indispensable for precise glass cutting, especially for intricate or repetitive shapes. A template acts as a guide, ensuring that each cut is consistent and accurately matches the desired design. This is particularly useful when creating multiple identical pieces, such as for stained glass windows or mosaic work.

To use a template effectively, create it from a durable material like cardboard or acrylic, ensuring its edges are clean and accurately represent the desired shape. Place the template on the glass and trace its outline using a suitable marking tool. This method significantly improves accuracy, reduces errors, and saves time, especially when dealing with complex shapes.

Templates allow for perfect duplication. For example, if you’re making a stained glass window with multiple identical pieces, a template ensures all pieces are precisely the same size and shape, resulting in a flawless and professional-looking final product.

Q 7. How do you handle different types of glass (e.g., tempered, laminated)?

Different types of glass require varying approaches to cutting. Annealed glass (standard float glass) is the easiest to cut and score with standard tools. However, tempered glass (heat-strengthened glass) is significantly harder and more difficult to cut cleanly and safely. Attempting to cut tempered glass can lead to unpredictable shattering, presenting a considerable safety hazard. Therefore, tempered glass should ideally only be cut by professionals using specialized equipment.

Laminated glass (two or more layers of glass bonded with a layer of plastic) is also more challenging to cut. The interlayer of plastic can make scoring more difficult and the cut less precise. The best approach is to carefully score the outer layer of glass, and then use a specialized tool or a diamond blade to cut through the plastic interlayer. Always prioritize safety when working with these specialized glass types.

In summary, while annealed glass is relatively straightforward, specialized techniques and often professional tools are required for tempered and laminated glass to ensure safety and obtain accurate cuts.

Q 8. What are the common errors in glass cutting and how do you prevent them?

Common errors in glass cutting often stem from improper scoring, snapping, or tool maintenance. A poorly scored line can lead to uneven breaks or shattering, while applying too much or too little pressure during snapping results in jagged edges or incomplete cuts. Using a dull cutter also contributes significantly to these problems.

- Preventing Uneven Breaks: Ensure the glass cutter is sharp and applying consistent pressure during scoring. Use a straight edge for accurate marking and maintain a steady hand.

- Preventing Shattering: Use the correct scoring technique for the glass thickness (explained in a later answer). Support the glass adequately to prevent it from flexing during the snapping process. Use running pliers or a breaking tool for thicker glass.

- Preventing Jagged Edges: Use a sharp glass cutter, score deeply, and apply even pressure when snapping. For cleaner breaks, consider using a running pliers or a specialized glass breaker.

- Preventing Dull Cutter Issues: Regularly inspect and maintain your glass cutter (explained in another answer). Replace worn or damaged cutting wheels promptly.

For instance, I once had a client whose project was jeopardized by jagged edges. By carefully analyzing his technique, we discovered he wasn’t applying even pressure during snapping. A quick retraining session, emphasizing consistent pressure, resolved the issue.

Q 9. How do you handle chipped or cracked glass during measurement and cutting?

Handling chipped or cracked glass requires extra caution. Measurement should always begin by assessing the damage. Avoid placing pressure directly on the compromised areas. For measurement, I use a combination of flexible measuring tapes and rulers, carefully maneuvering around the chips. Cutting requires even more care.

- Avoid the Damaged Area: Plan your cuts to avoid the chipped sections altogether if possible. If cutting near a chip is unavoidable, use extra support under and around the damaged area to prevent further cracking.

- Extra Support: Use a stable surface and additional padding to prevent movement and stress on the glass during scoring and snapping.

- Gentle Scoring and Snapping: Apply less pressure during scoring and snapping to minimize the risk of further breakage. Consider using a running pliers even for thinner glass.

Remember, safety is paramount. Always wear safety glasses when handling cracked glass. If the damage is extensive, it’s best to discard the piece and start with a new one.

Q 10. Explain the process of scoring and snapping glass.

Scoring and snapping are the two crucial steps in glass cutting. Scoring creates a controlled fracture line, while snapping propagates that fracture to separate the glass.

- Scoring: Use a sharp glass cutter to score a consistent line along your marked measurement. Apply firm, even pressure, pushing the cutter firmly against the glass. A single, clean score is usually sufficient for thinner glass. Do not go back and forth over the score line.

- Snapping: Support the glass with your fingers or a suitable tool. Position the score line over the edge of a firm surface. Apply downward pressure on the section of glass to be removed, gently pushing away from the scored line. For thicker glass, use running pliers or a glass breaker to ensure a clean break.

Imagine scoring as creating a tiny crack, and snapping as guiding that crack along the desired path to sever the glass.

Q 11. What are the different scoring techniques for various glass thicknesses?

Scoring techniques adjust based on glass thickness. Thicker glass requires a deeper score and potentially different tools for a clean break.

- Thin Glass (under 3mm): A single, firm score is usually sufficient. Snapping is relatively straightforward, often achieved simply by applying downward pressure at the score line over the edge of a table.

- Medium Glass (3-6mm): A deeper score may be necessary, ensuring the cutter penetrates the surface completely. Running pliers are often recommended to control and facilitate the break.

- Thick Glass (over 6mm): Multiple scoring passes are common, ensuring a deep cut along the entire line. Utilizing running pliers, specialized glass breakers, or oil scoring techniques improves the cleanliness of the break and reduces risk of shattering.

Oil scoring is a technique often employed for very thick or particularly fragile glass; it involves lubricating the score line with oil, which allows for a more controlled and smoother fracture, especially beneficial in handling large sheets of specialized glass.

Q 12. How do you clean and maintain glass cutting tools?

Cleaning and maintaining glass cutting tools is essential for accuracy and safety. Dull cutters lead to inaccurate scores and increased risk of breakage.

- Regular Cleaning: After each use, wipe the cutter wheel clean of any glass debris. Use a soft cloth or brush to avoid damaging the wheel.

- Lubrication: Some glass cutters benefit from occasional lubrication of the cutting wheel (check the manufacturer’s instructions). This can extend the life of the wheel and improve the quality of the score.

- Sharpness: Regularly inspect the cutting wheel for damage or dullness. Replace the wheel immediately if it shows significant wear or damage, as a dull wheel will not produce clean cuts.

- Storage: Store your tools in a safe, dry place to prevent rust and corrosion.

I always emphasize proper tool maintenance during training sessions, emphasizing that a well-maintained cutter is an investment in safety and efficiency.

Q 13. What types of measuring tools do you use for accurate measurements?

Accurate measurement is critical for precise glass cuts. I use a combination of tools depending on the project’s complexity and the glass dimensions.

- Steel Rules: These provide precise measurements, particularly useful for smaller pieces or more intricate designs. A good quality steel rule will be sturdy and have clear, sharp markings.

- Measuring Tapes: Flexible measuring tapes are essential for larger sheets of glass, allowing for accurate measurement around curves or irregular shapes.

- Squares and Triangles: For ensuring perfectly square or angled cuts, I rely on precision squares and triangles to mark the glass accurately.

- Digital Calipers: For extremely precise measurements, especially for smaller or more complex cuts, digital calipers provide a high degree of accuracy.

I typically prefer a combination of these; For example, a steel rule to measure smaller components and then a measuring tape to ensure the larger sheet is correctly aligned prior to cutting.

Q 14. Describe your experience with different types of glass cutting equipment.

My experience encompasses various glass cutting equipment, from basic hand tools to more advanced machinery.

- Hand Glass Cutters: I have extensive experience using different types of hand glass cutters, ranging from simple oil-fed wheels to more sophisticated diamond-tipped cutters. The choice depends on the type of glass being cut and the desired level of precision.

- Electric Glass Cutters: I’ve also used electric glass cutters, which offer increased speed and consistent scoring for high-volume work, particularly when dealing with thicker or more challenging glass.

- Automated Glass Cutting Systems: I have some familiarity with computer-controlled glass cutting systems used in industrial settings. These systems are typically employed for mass production, offering exceptional precision and efficiency.

Each tool has its strengths and weaknesses, and my ability to select and proficiently use the appropriate equipment is crucial for the success of any glass-cutting project. The choice of equipment is dictated by the project at hand; for delicate work, hand tools might be preferable; for mass production, an automated system provides increased efficiency and repeatability.

Q 15. How do you calculate the amount of glass needed for a given project?

Calculating the amount of glass needed involves meticulous planning and precise measurements. It’s not just about the final piece; you must account for waste during cutting and potential errors. The process typically begins with detailed drawings or blueprints of the project. From these, I determine the dimensions of each individual glass piece needed.

For example, if a project requires ten rectangular pieces, each measuring 12 inches by 18 inches, the total area would be 10 x (12 inches x 18 inches) = 2160 square inches. However, this doesn’t account for the cutting process. I usually add a percentage, typically 10-15%, to compensate for waste from cutting, especially for intricate shapes or when working with multiple pieces.

In practice, I often use specialized software to create cutting patterns that minimize waste. This software allows me to input the dimensions of available glass sheets and the required pieces, and it generates optimized cutting plans. This minimizes material usage and cost, crucial for managing a project’s budget.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of accurate marking in achieving precise cuts.

Accurate marking is paramount in glass cutting; it’s the foundation of a precise and clean cut. An imprecise mark directly translates to an imprecise cut, leading to wasted materials, flawed aesthetics, and potentially, safety hazards. Think of it like baking a cake – if your measurements are off, the cake won’t turn out right.

I utilize various marking tools depending on the project’s complexity. For simple, straight cuts, a ruler and a quality glass marker or scribe are sufficient. More intricate designs may require templates, stencils, or even specialized software-guided laser marking systems for unparalleled accuracy. Always ensuring a firm, stable surface and a consistent pressure while marking are key to achieving precise lines.

Q 17. How do you manage waste materials during glass cutting?

Managing waste during glass cutting is an environmental and economic responsibility. It’s about more than just throwing away scraps; it’s about responsible resource management. I have established a system for segregating glass waste based on type and thickness. Smaller pieces suitable for mosaic work or other crafting applications are set aside. Larger, usable pieces are stored for future projects, preventing unnecessary waste and saving on material costs. The remaining unusable glass is disposed of according to local regulations, often through specialized recycling facilities that can handle glass responsibly.

Furthermore, I minimize waste through optimized cutting patterns, as mentioned earlier. Using software to plan cuts reduces the number of offcuts produced. This is a continual learning process—as I become more proficient and experienced, I improve my waste management techniques further, always striving for greater efficiency and sustainability.

Q 18. How do you ensure the safety of yourself and others in a glass cutting environment?

Safety is the absolute top priority in any glass cutting environment. Glass shards are incredibly sharp and dangerous. I always start by ensuring I have the appropriate personal protective equipment (PPE), including safety glasses, cut-resistant gloves, and a closed-toe work area. The workspace itself is organized and clutter-free, reducing the risk of accidental cuts or trips.

Beyond PPE, proper techniques are crucial. I use a cutting tool designed for glass, applying even pressure and avoiding excessive force, which can lead to cracks and potential injury. After cutting, pieces are handled carefully, and any sharp edges are immediately smoothed or processed to reduce the risk of injury. I also regularly inspect my tools and replace damaged or worn-out equipment promptly. It’s not just about my safety; I ensure all around me are aware of the hazards and follow the same safety protocols.

Q 19. Describe your experience with quality control measures in glass cutting.

Quality control is an integral part of my work. It’s not enough to simply cut the glass; the final product must meet exacting standards. My quality control measures begin with meticulous initial planning and precise marking. Throughout the cutting process, I regularly inspect the work for any imperfections. This includes checking for cracks, chips, or inconsistencies in the cut.

After cutting, each piece undergoes a thorough inspection for size accuracy and edge quality. I use measuring tools to verify dimensions against the plans, and I check for any sharp edges or irregularities. Any pieces that do not meet my standards are rejected, and the process is repeated to ensure a high-quality finished product. Maintaining detailed records of each project also ensures traceability and enables me to identify and address any recurring quality issues.

Q 20. What are the different types of glass edges and how are they achieved?

Glass edges can be finished in various ways, each offering unique aesthetic and functional properties. The most common are:

- Straight Cut Edge: This is the simplest, produced directly by a glass cutter. It’s sharp and requires further processing for safety.

- Seamed Edge: Created by grinding, this edge is smoother and safer than a straight cut but still leaves a visible seam.

- Beveled Edge: Achieved by grinding at an angle, this creates a sloped edge, often used for decorative purposes.

- Polished Edge: This is the smoothest and safest edge, obtained through a meticulous polishing process after grinding. It provides a polished and refined finish.

- Fire-Polished Edge: Created by reheating the edge, melting the surface for a smooth finish. It’s particularly suitable for certain glass types.

The method used depends on the project requirements and desired aesthetic. A simple frame might only need a seamed edge, while high-end furniture might require polished edges for a premium look and feel.

Q 21. How do you adapt your techniques to various glass thicknesses and types?

Adapting to different glass thicknesses and types is essential. Thicker glass requires more force and a sharper cutting tool, and different glass compositions (e.g., tempered, laminated, annealed) necessitate adjustments in techniques.

For instance, tempered glass, due to its strength, requires a diamond-tipped scoring tool and a controlled snapping technique to prevent shattering. Laminated glass, with its multiple layers, requires a more precise cut to avoid damaging the layers. Furthermore, the scoring depth needs to be adjusted for varied thicknesses; a shallow score for thinner glass and a deeper score for thicker glass. Experience helps me determine the optimal pressure, cutting angle, and post-cutting processes to ensure consistent results across diverse glass types and thicknesses.

Q 22. Describe your experience using CAD software for glass cutting patterns.

CAD software is indispensable for precise glass cutting patterns, especially in complex projects. My experience spans several years using programs like AutoCAD and Vectorworks. I’m proficient in creating detailed drawings, incorporating dimensions, and generating cut lists. For instance, I recently used AutoCAD to design a custom glass mosaic for a hotel lobby. The software allowed me to accurately plan the placement of hundreds of individually cut pieces, ensuring perfect alignment and minimizing waste. I’m also comfortable importing and exporting files in various formats (DXF, DWG) to seamlessly integrate with other design and manufacturing processes.

Beyond simple shapes, I’m adept at using CAD to design intricate curves and bevels. For example, when designing a curved glass shower enclosure, I utilize the software’s spline tools to create precise representations of the curves, ensuring the glass pieces fit together flawlessly. This ensures the final product is accurate and efficient to manufacture.

I regularly use the software’s dimensioning and annotation tools to create clear and unambiguous instructions for the cutting and fabrication team, including detailed notes about tolerances and critical dimensions.

Q 23. What are the common challenges in measuring and marking curved glass?

Measuring and marking curved glass presents unique challenges compared to flat glass. Accuracy is paramount, and traditional measuring tools can be less effective. The primary difficulty lies in achieving consistent and precise measurements along the curve’s radius. Slight inaccuracies can lead to significant errors when cutting.

One common challenge is compensating for the curve’s changing dimensions. A simple straight ruler won’t capture the true length of a curved edge. Instead, we use flexible measuring tapes, or, for extremely precise work, a combination of flexible rulers and digital calipers to take multiple measurements at intervals along the curve.

Marking the glass itself also requires specialized techniques. Instead of straight lines, we often use flexible templates made from thin, pliable materials like plastic or metal. These templates are carefully shaped to conform to the curve, providing an accurate guide for the glass cutter.

Finally, the curvature itself can complicate the cutting process. Consistent pressure and technique are crucial to avoid fracturing the glass during cutting.

Q 24. How do you handle large and heavy glass sheets during measurement and cutting?

Handling large and heavy glass sheets requires safety and efficiency. My approach prioritizes safety first and foremost. I utilize specialized equipment like vacuum lifters or suction cups to safely move and position the glass. These tools allow for single-person handling of even the largest sheets, minimizing the risk of injury.

For smaller, manageable sheets, I employ techniques like using multiple people for lifting with proper lifting techniques. The use of wheeled carts or dollies makes transportation easier. Proper supports, such as wooden blocks, are crucial during the measuring and marking process to prevent accidental breakage or damage.

Before starting any work, I ensure the workspace is clean and clear of any obstructions to avoid trips or falls. The proper use of safety glasses is mandatory to protect against any potential flying debris. I also meticulously inspect each sheet for pre-existing damage before undertaking any measuring or cutting. For example, any stress marks are noted to inform the cutting plan, minimizing the chance of the glass cracking during the cut.

Q 25. Describe your experience with different types of glass cutting oils or lubricants.

Different glass cutting oils or lubricants significantly impact the cutting process, affecting the smoothness of the cut and minimizing chipping or cracking. My experience includes using various types, each suited to different glass types and cutting methods.

Mineral oil is a common and cost-effective choice for general-purpose glass cutting. It provides adequate lubrication and helps reduce friction. However, for thicker or harder glasses, I often opt for specialized cutting oils formulated for increased lubrication and chip reduction. These oils often contain additives designed to improve the scoring process and create cleaner, smoother cuts.

I also have experience using water-based lubricants which are environmentally friendlier and generally safer to handle. The choice of lubricant often depends on the job at hand, the type of glass being worked with, and the specific cutting tools being utilized. For example, intricate cutting requires a lubricant that provides exceptional lubrication to prevent chipping, while mass production might prioritize a cheaper, more readily available option.

Q 26. How do you interpret and follow complex glass cutting blueprints or diagrams?

Interpreting complex glass cutting blueprints or diagrams requires careful attention to detail and a thorough understanding of architectural and engineering drawings. I approach this systematically by first reviewing the entire blueprint to understand the overall design and the relationships between different glass pieces.

Next, I meticulously examine each individual piece, noting its dimensions, shape, and any special features like bevels, curves, or holes. I cross-reference these dimensions with the overall design to ensure consistency and accuracy. Any ambiguities or inconsistencies are flagged and clarified with the design team or client before proceeding.

To aid in understanding, I often create annotated sketches or digital models to visualize the complex assembly and to ensure a clear understanding of the task at hand. For instance, when working with large-scale projects involving multiple glass panels, I create a numbered sequence, clearly marking each piece to help streamline the production process and reduce potential errors.

Q 27. Explain your experience with troubleshooting problems encountered during glass cutting.

Troubleshooting problems during glass cutting requires a methodical approach and a good understanding of the process. Common issues include chipping, cracking, or inaccurate cuts.

Chipping often arises from excessive pressure during scoring or improper lubrication. To address this, I adjust my cutting technique, ensuring consistent pressure and using the correct lubricant. If the problem persists, I might try a different type of cutting wheel or oil.

Cracking can be caused by pre-existing flaws in the glass, excessive pressure during cutting, or improper handling. Careful inspection of the glass before cutting is crucial, and using appropriate support during cutting helps minimize the risk. In cases of persistent cracking, I would recommend checking the glass’s overall quality and exploring alternative solutions.

Inaccurate cuts typically result from imprecise measurements or marking. To address this, I double-check all measurements and markings and use precision tools. If the inaccuracy persists, I investigate the measuring tools and equipment to rule out any calibration issues. For particularly intricate cuts, I utilize digital measuring instruments to guarantee precision.

Key Topics to Learn for Measuring and Marking Glass for Cutting Interview

- Understanding Glass Types and Properties: Learn the characteristics of different types of glass (e.g., annealed, tempered, laminated) and how these properties influence cutting techniques and measurement accuracy.

- Precise Measurement Techniques: Master using various measuring tools (e.g., rulers, tape measures, calipers) to ensure accurate measurements for cutting. Understand the importance of precision and potential sources of error.

- Marking Techniques for Clean Cuts: Explore different marking methods (e.g., using pencils, markers, scribes) and understand how to create clear, precise marks that guide the cutting process effectively. Consider the impact of different marking tools on various glass types.

- Safety Procedures and Precautions: Familiarize yourself with safety regulations and best practices for handling glass, including the use of personal protective equipment (PPE) and safe disposal of waste.

- Cutting Tools and Their Applications: Understand the operation and maintenance of various glass cutting tools (e.g., glass cutters, scoring tools) and their suitability for different glass thicknesses and types.

- Troubleshooting Common Cutting Issues: Develop problem-solving skills to identify and rectify common issues encountered during the glass cutting process, such as chipping, cracking, or inaccurate cuts. This includes understanding the causes of these problems and implementing corrective actions.

- Quality Control and Inspection: Learn the procedures for inspecting cut glass for quality and identifying defects. This includes understanding tolerance levels and the importance of adhering to quality standards.

Next Steps

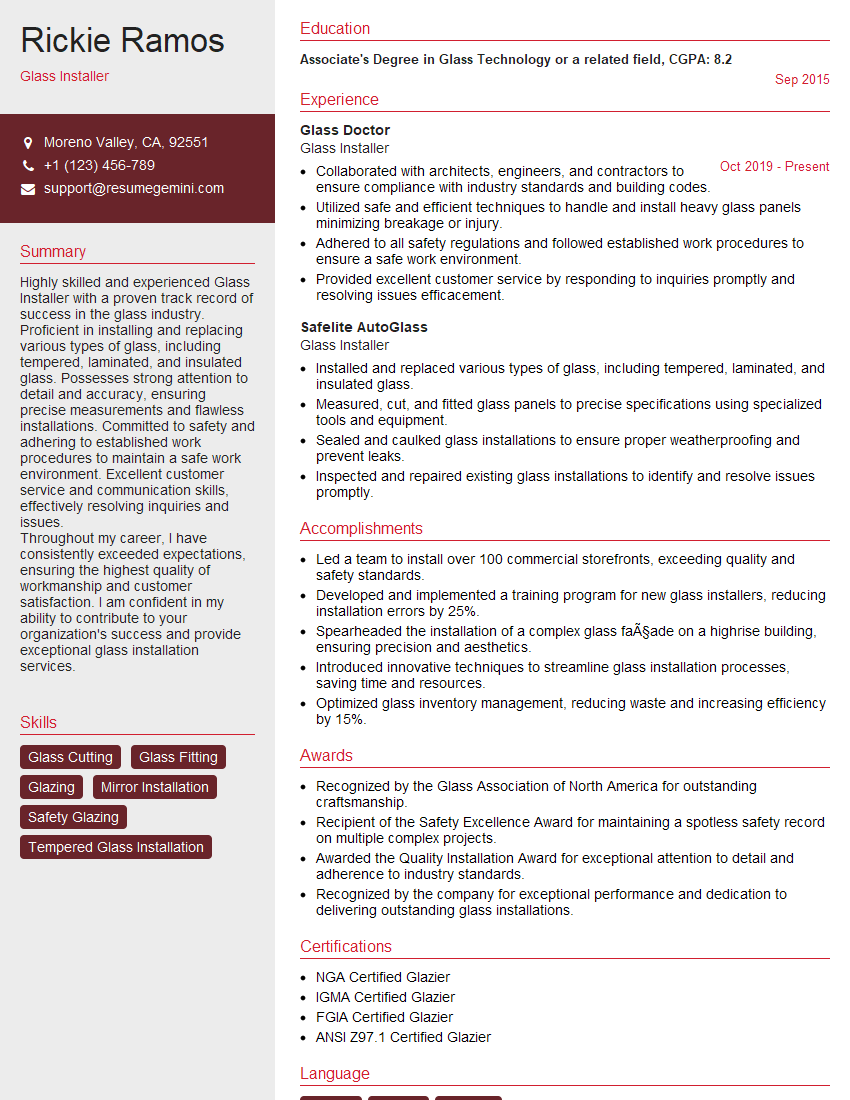

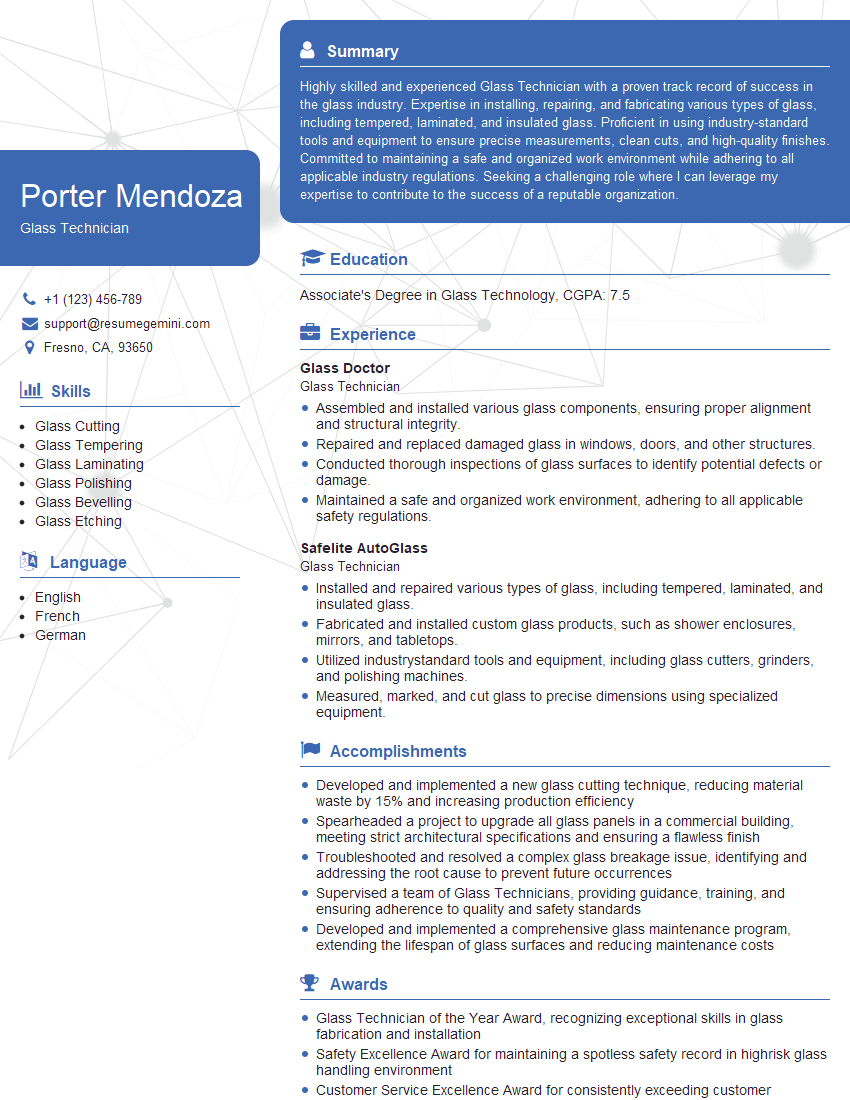

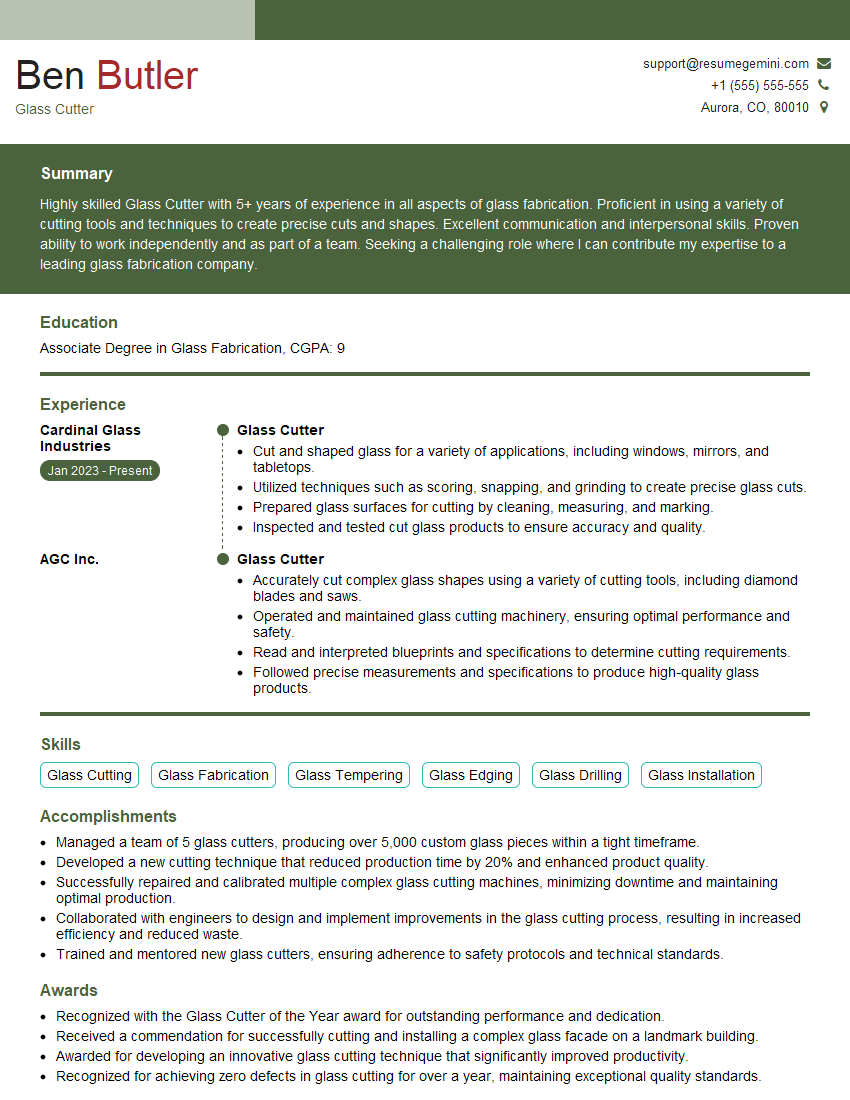

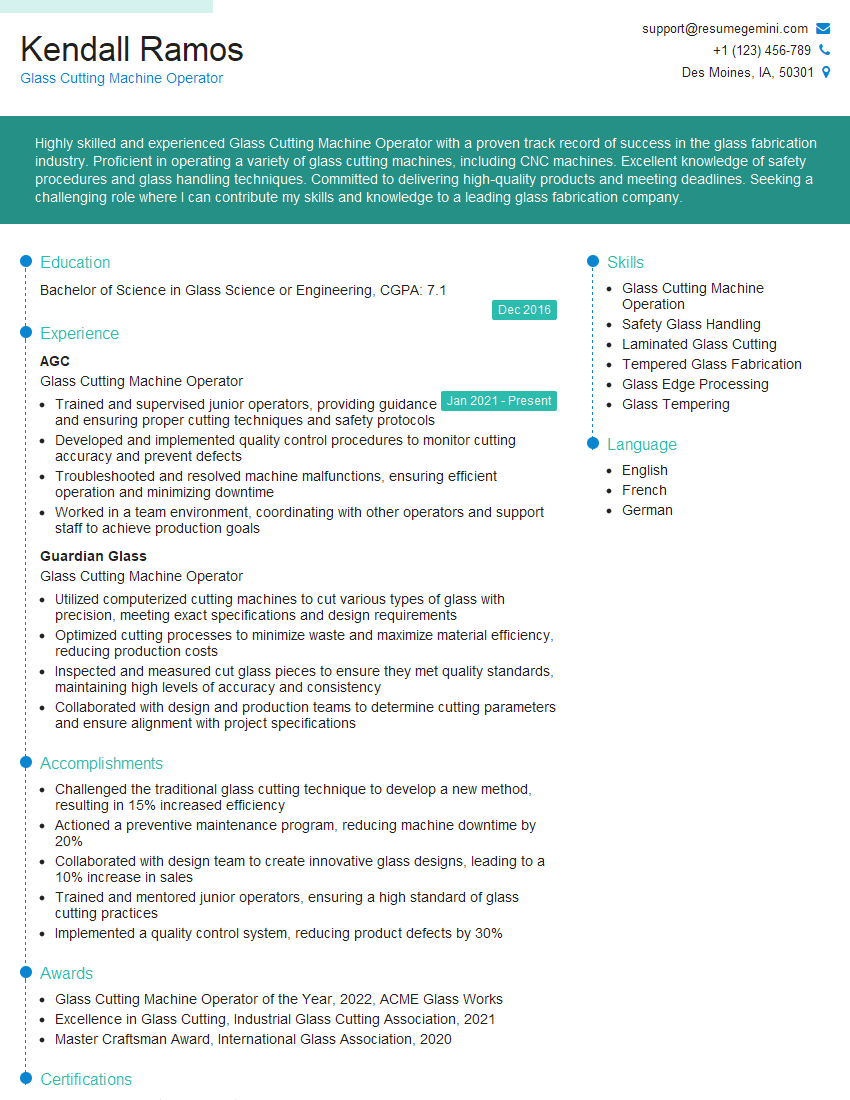

Mastering the art of measuring and marking glass for cutting is crucial for success in many manufacturing and construction roles. It demonstrates precision, attention to detail, and a commitment to safety – highly valued skills in today’s job market. To significantly improve your job prospects, focus on crafting a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that showcases your abilities. We provide examples of resumes tailored to the Measuring and marking glass for cutting field to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.