Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Biosolids Transportation and Disposal interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Biosolids Transportation and Disposal Interview

Q 1. Describe the different methods of biosolids transportation.

Biosolids transportation methods depend heavily on the volume, distance, and the final disposal or beneficial use destination. The most common methods include:

- Tank Trucks: These are the workhorse of biosolids transport, particularly for shorter distances. They’re versatile and can handle various biosolids consistencies, from liquid to thickened sludge. Think of them as the ‘delivery trucks’ of the wastewater treatment world.

- Pneumatic Transport: This method uses air pressure to move dry or dewatered biosolids through pipelines. It’s efficient for long distances and minimizes the need for numerous truck trips, reducing transportation costs and environmental impact. It’s like a high-speed, enclosed conveyor belt for biosolids.

- Belt Conveyors: Used primarily in wastewater treatment plants for moving biosolids between different processes or to loading points for other transportation methods. They are efficient for short distances within a plant setting.

- Rail Cars: For large volumes and long distances, rail transport becomes cost-effective. Specialized tank cars are employed to handle the material safely and securely. This is especially useful for plants located far from disposal or beneficial use sites.

- Barges: Ideal for transporting large quantities of biosolids across waterways, offering a cost-effective solution for long distances where water transport is feasible. Think of them as ‘biosolids ships’ moving across rivers and canals.

The choice of transportation method is crucial for efficient operations and regulatory compliance. Factors like cost, distance, environmental impact, and the nature of the biosolids themselves all play a significant role in this decision.

Q 2. What are the key regulatory requirements for biosolids transportation and disposal?

Biosolids transportation and disposal are stringently regulated to protect human health and the environment. Key regulations often stem from the Environmental Protection Agency (EPA) in the US, and equivalent agencies in other countries. These regulations address various aspects, including:

- Proper labeling and manifest tracking: All shipments must be accurately documented, including the quantity, origin, and destination of the biosolids. This ensures traceability and accountability throughout the entire process. Think of it like a ‘passport’ for the biosolids.

- Vehicle and equipment requirements: Transportation vehicles must meet specific standards regarding leak prevention, spill containment, and cleaning procedures to prevent accidental releases. Imagine these as ‘biosolids-safe’ vehicles, designed to prevent spills and leaks.

- Personnel training and certification: Drivers and handlers must undergo proper training to understand the hazards associated with biosolids and handle them safely. This ensures that those handling the material are knowledgeable and capable.

- Disposal site permits and regulations: Land application, incineration, or other disposal methods must adhere to strict regulations concerning site selection, application rates, and monitoring of environmental impacts. It’s akin to selecting and managing a ‘biosolids safe haven’.

- Pollution prevention and emergency response plans: Wastewater treatment plants must have plans in place to prevent spills and leaks during transport and disposal, and to respond effectively in case of an emergency. These serve as a ‘biosolids emergency kit’ for handling accidents.

Non-compliance can lead to significant penalties, including fines and legal action. Therefore, rigorous adherence to all relevant regulations is paramount.

Q 3. Explain the process of biosolids land application.

Biosolids land application, also known as beneficial reuse, is a sustainable disposal method that returns valuable nutrients to the soil. The process involves several key steps:

- Site selection and assessment: Suitable sites are chosen based on soil type, topography, proximity to water bodies, and potential impact on groundwater. Thorough analysis ensures environmentally safe application.

- Biosolids processing and quality control: Biosolids are often processed to meet specific quality standards regarding pathogen levels and nutrient content before land application. This ensures proper nutrient levels and minimizes health risks.

- Application method: Methods include surface spreading, injection, and incorporation. The chosen method depends on factors such as soil type, climate, and equipment availability. Each method has advantages and disadvantages depending on the situation.

- Application rate and monitoring: Biosolids are applied at rates that prevent nutrient overload and comply with regulations. Regular monitoring of soil conditions, groundwater quality, and vegetation health helps assess the effectiveness and environmental impact of application. This safeguards against negative effects on the environment.

- Post-application management: Following application, soil testing and monitoring are undertaken to ensure that nutrient levels remain within acceptable limits and potential environmental impacts are mitigated. This is vital for long-term sustainability and environmental protection.

Successful land application requires careful planning, strict adherence to regulations, and continuous monitoring to ensure its environmental and economic benefits are maximized while minimizing any risks.

Q 4. How do you ensure the safety of biosolids transportation personnel?

Ensuring the safety of biosolids transportation personnel is a critical aspect of responsible biosolids management. This involves a multi-faceted approach:

- Comprehensive training programs: Training should cover safe handling procedures, emergency response protocols, and awareness of potential health hazards associated with biosolids exposure. This ensures everyone knows how to handle the materials correctly.

- Personal protective equipment (PPE): Providing and mandating the use of appropriate PPE, such as respirators, gloves, protective clothing, and eye protection, is essential to reduce the risk of exposure to pathogens and hazardous materials. This is the primary defense against potential hazards.

- Regular health monitoring: Periodic medical checkups and health monitoring of personnel involved in biosolids handling can help identify any potential health issues resulting from exposure. Early detection enables timely intervention.

- Emergency response plans and equipment: Access to emergency showers, eye wash stations, and well-defined emergency response plans are crucial in case of accidental spills or exposure incidents. This ensures quick and effective response to incidents.

- Safe vehicle operation and maintenance: Regular vehicle inspections and maintenance ensure that transport vehicles are in good working condition and equipped with safety features like spill containment systems. Regular inspections reduce the risk of accidents and breakdowns.

A proactive approach to safety, combining training, equipment, and monitoring, is vital for protecting the health and well-being of personnel involved in biosolids transportation and disposal.

Q 5. What are the environmental risks associated with improper biosolids disposal?

Improper biosolids disposal poses significant environmental risks, potentially leading to:

- Water pollution: Runoff from improperly managed biosolids application sites can contaminate surface water and groundwater with pathogens, nutrients, and heavy metals, harming aquatic life and potentially affecting drinking water sources. This can have devastating effects on ecosystems.

- Air pollution: Incineration of biosolids, if not properly controlled, can release harmful air pollutants, contributing to respiratory problems and acid rain. Proper control and monitoring are critical in preventing air pollution.

- Soil contamination: Excessive application of biosolids or application to unsuitable sites can lead to soil contamination with heavy metals and pathogens, impacting soil health and agricultural productivity. Careful site selection and application rates are paramount.

- Odor issues: Improperly managed biosolids can generate unpleasant odors, impacting nearby communities and causing nuisance complaints. Proper handling and management reduce unpleasant smells.

- Vector attraction: Improperly stored or disposed-of biosolids can attract disease vectors like rodents and insects, increasing the risk of disease transmission. Proper storage and disposal are critical.

These risks highlight the critical importance of adhering to stringent regulations and best practices in biosolids management to protect the environment and public health.

Q 6. Describe your experience with biosolids handling and storage.

Throughout my career, I’ve been extensively involved in various aspects of biosolids handling and storage. This includes:

- Experience with different biosolids handling technologies: I’ve worked with various technologies, including belt presses, centrifuges, and anaerobic digestion, to process biosolids to suitable consistencies for transportation and disposal. This broad experience allows for adaptable solutions.

- Storage facility design and management: I’ve been involved in the design, construction, and management of biosolids storage facilities, ensuring they meet regulatory requirements for containment, odor control, and environmental protection. Safety and environmental protection are my top priorities.

- Implementation of best management practices: I have a proven track record of implementing best management practices to minimize environmental impacts and ensure efficient biosolids handling. This has resulted in efficient and sustainable practices.

- Oversight of biosolids inventory and tracking: I’ve overseen systems for accurate tracking of biosolids quantities, movement, and ultimate disposal. This ensures efficiency and traceability.

- Troubleshooting and problem-solving: I possess strong problem-solving skills, adept at handling issues related to equipment malfunction, unexpected influent changes, and regulatory compliance challenges. This ensures smooth operational efficiency.

My experience has equipped me with a comprehensive understanding of the challenges and best practices associated with biosolids handling and storage, emphasizing safety, environmental protection, and regulatory compliance.

Q 7. How do you maintain compliance with EPA regulations for biosolids?

Maintaining compliance with EPA regulations for biosolids requires a proactive and multi-faceted approach:

- Regular monitoring and testing: Routine monitoring of biosolids characteristics, including pathogen levels, nutrient content, and heavy metals, ensures they meet regulatory standards before transportation and disposal. This ensures the biosolids meet the regulations.

- Record-keeping and documentation: Meticulous record-keeping of all aspects of biosolids handling, transportation, and disposal is crucial for demonstrating compliance. Detailed records are crucial for regulatory compliance.

- Internal audits and inspections: Regular internal audits and inspections of facilities and processes help identify any potential compliance issues and address them proactively. This is a preventative measure.

- Training and education of personnel: Continuous training and education of personnel ensure they are aware of the regulations and best practices, enhancing compliance. Training ensures everyone is up-to-date.

- Collaboration with regulatory agencies: Open communication and collaboration with regulatory agencies ensure that any changes in regulations or guidelines are quickly implemented. This fosters a positive relationship with regulators.

- Contingency planning for emergencies: Develop a robust contingency plan that outlines procedures for handling spills, accidents, or emergencies, ensuring a rapid response to minimize environmental impacts. This minimizes environmental damage in case of accidents.

A commitment to continuous improvement and a culture of compliance are essential for successful biosolids management and maintaining EPA regulatory compliance.

Q 8. What are the different types of biosolids and their respective disposal methods?

Biosolids, the semi-solid byproduct of wastewater treatment, come in various forms, each requiring a tailored disposal approach. The primary types include:

- Digested sludge: This is the most common type, resulting from the anaerobic digestion process, which stabilizes the sludge, reducing pathogens and odor. Disposal methods include land application (agriculture, landscaping), incineration, and landfilling.

- Anaerobically digested biosolids: Similar to digested sludge but with a higher level of stabilization. Often used for land application due to its lower pathogen count and improved odor control.

- Aerobically digested biosolids: Produced through aerobic digestion, requiring more oxygen and resulting in a less stable product compared to anaerobic digestion. It typically requires more stringent handling and disposal methods like landfilling or incineration.

- Dewatered biosolids: Biosolids that have undergone dewatering processes to reduce their water content, making them easier to transport and handle. This can then be disposed of through various means depending on local regulations and the specific characteristics of the dewatered material.

The choice of disposal method depends on factors like biosolids characteristics (e.g., pathogens, heavy metals, solids content), environmental regulations, cost, and land availability. For instance, land application is a cost-effective option for suitable biosolids and land, but requires careful monitoring to prevent environmental contamination. Incineration, while more expensive, effectively reduces volume and eliminates pathogens, but produces ash that requires safe disposal. Landfilling is often the last resort, due to its high cost and environmental impact.

Q 9. Explain the role of a manifest in biosolids transportation.

A manifest in biosolids transportation is crucial for tracking and documenting the movement of biosolids from origin to final disposal. Think of it as a detailed ‘shipping invoice’ but specifically for biosolids. It ensures compliance with environmental regulations and provides accountability throughout the entire transportation process.

The manifest typically includes information such as:

- Generator’s name and address

- Transporter’s name and address

- Recipient’s name and address

- Quantity and type of biosolids

- Date and time of transport

- Transportation route

- Signature of parties involved

Having a properly completed manifest allows regulatory agencies to trace the biosolids throughout the transportation chain, investigating potential spills or unauthorized disposal. Missing or incomplete manifests can result in significant fines and legal repercussions. For example, if a spill occurs, the manifest provides critical information to help with clean-up efforts and to determine liability.

Q 10. How do you manage biosolids transportation in emergency situations?

Emergency situations involving biosolids transportation require immediate and decisive action. My approach prioritizes safety and environmental protection. This includes:

- Immediate containment: In case of a spill, immediately secure the area to prevent further spread and protect personnel and the environment. This might involve deploying absorbent materials, diverting traffic, and notifying emergency services.

- Notification: Report the incident to appropriate authorities (environmental protection agencies, local emergency responders) as quickly as possible. Provide details about the location, type and quantity of spilled biosolids, and any potential hazards.

- Clean-up and remediation: Implement a clean-up plan in accordance with local and federal regulations. This could involve vacuum trucks, specialized equipment for hazardous materials, and potentially soil remediation.

- Documentation: Thoroughly document all aspects of the incident, including the containment, notification, clean-up procedures, and any environmental impact assessments. This documentation is vital for insurance claims, regulatory reporting and future incident prevention.

A pre-planned emergency response plan, including designated personnel, equipment, and communication protocols, is crucial for efficient and effective handling of these situations. Regular training exercises help ensure readiness and competence.

Q 11. What are the common challenges in biosolids transportation and how do you overcome them?

Biosolids transportation faces several challenges, including:

- Odor control: Biosolids can have strong and unpleasant odors. This requires specialized equipment and techniques to minimize odor release during transportation and storage.

- Regulatory compliance: Strict environmental regulations govern biosolids transportation and disposal, demanding precise record-keeping and adherence to permit requirements. Failure to comply can result in significant penalties.

- Transportation logistics: Finding suitable transportation routes and infrastructure can be challenging. Certain roads may be restricted, requiring careful route planning.

- Public perception: Negative public perception of biosolids can lead to resistance from communities along transportation routes. Public education and transparent communication can help address such concerns.

To overcome these, proactive strategies are key. Odor control is addressed through the use of enclosed tanker trucks, specialized biofilters, and regular maintenance. Effective communication with regulatory authorities and local communities ensures compliance and manages public perception. Implementing robust GPS tracking and reporting systems allows for efficient logistics management and better incident response. Using advanced technologies, such as sensor systems to continuously monitor conditions within transport vehicles and ensure immediate alerts in the case of leaks, are also important.

Q 12. Describe your experience with different types of biosolids transportation equipment.

My experience encompasses a wide range of biosolids transportation equipment, including:

- Vacuum trucks: These are commonly used for collecting and transporting sludge from treatment plants. I’ve worked with models ranging from smaller trucks for localized collection to larger, high-capacity units for long-distance transport.

- Pneumatic transfer systems: These systems move biosolids through pipelines using air pressure, offering a cleaner and more efficient method for transferring biosolids over longer distances. My experience includes overseeing the maintenance and operation of such systems, ensuring optimal performance and preventing blockages.

- Tanker trucks: Used for liquid or semi-liquid biosolids, these require specific materials to be resistant to corrosion and biodegradation. I’ve managed the selection and maintenance of these vehicles, ensuring their suitability for different biosolids types.

- Specialized containers: These are used for storing and transporting dewatered or solidified biosolids, often employed for long-distance transport or when dealing with higher solid concentrations. Selecting containers that maintain the integrity of the biosolids during transportation was always a focus.

Each type of equipment requires specific operational procedures and maintenance to ensure safe and efficient transportation. Regular inspections, driver training, and adherence to safety protocols are critical aspects of my responsibilities.

Q 13. How do you ensure the accuracy of biosolids tracking and record-keeping?

Accuracy in biosolids tracking and record-keeping is paramount for compliance and accountability. My approach involves a multi-faceted strategy:

- Barcoding and RFID tagging: These technologies offer precise identification and tracking of biosolids throughout the transport chain. This reduces errors and ensures that records accurately reflect the actual movement of material.

- Automated data logging: Integrating sensors and GPS tracking systems into transport vehicles provides real-time data on location, temperature, and other critical parameters. This data is automatically logged, eliminating manual data entry errors.

- Database management: Using specialized software for managing biosolids data ensures data integrity and facilitates reporting to regulatory agencies. I’m proficient in several widely used software programs in the industry.

- Regular audits and reconciliation: Regular internal audits and reconciliation of records ensures data accuracy and identifies any discrepancies. The goal is to close any gaps between the reported amount and the actual amount of biosolids.

A robust and well-maintained system is crucial, emphasizing both technological solutions and rigorous procedural controls. Any discrepancy is investigated thoroughly, providing feedback that continually improves the overall accuracy of tracking.

Q 14. What are the best practices for minimizing the odor associated with biosolids transportation?

Minimizing odor associated with biosolids transportation is crucial for public acceptance and environmental protection. Strategies include:

- Enclosed transport vehicles: Using sealed tanker trucks or specialized containers prevents odor release during transport. These vehicles often include ventilation systems with odor control technology.

- Odor control agents: Adding odor control agents (e.g., biofilters or chemical treatments) to biosolids can significantly reduce odors. The choice of treatment must be compatible with the biosolids composition and disposal method.

- Regular cleaning and maintenance: Thorough cleaning of transport vehicles and equipment after each use is essential to prevent odor buildup. Regular maintenance of any odor control systems also plays a vital role.

- Proper biosolids processing: Pre-treatment of biosolids at the wastewater treatment plant to reduce odor-producing compounds can significantly minimize odors during transport. This includes steps such as adjusting pH, adding chemicals to reduce odor-causing microbes, and proper dewatering.

- Route optimization: Choosing routes that minimize travel time and proximity to residential areas helps mitigate odor impacts on communities.

A holistic approach combining proper vehicle selection, effective odor control technologies, rigorous cleaning procedures, and thoughtful route planning is most effective. Monitoring feedback from communities along transportation routes and adjusting strategies based on this feedback ensures proactive odor management.

Q 15. Explain your understanding of biosolids dewatering techniques.

Biosolids dewatering is crucial for reducing transportation and disposal costs. It involves removing excess water from the biosolids, creating a more manageable and less bulky material. Several techniques exist, each with its advantages and disadvantages.

- Belt filter presses: These use belts and vacuum to squeeze out water, producing a cake-like material. They are efficient and relatively low-maintenance but can be expensive to purchase and operate.

- Centrifuges: High-speed spinning separates solids from water. These are very efficient at water removal but might require pre-treatment and are less suitable for all types of biosolids.

- Gravity Thickening: A simpler, less energy-intensive method that relies on gravity to settle solids. It’s inexpensive but less efficient in water removal compared to other techniques.

- Anaerobic digestion: This biological process breaks down organic matter and produces biogas. As a byproduct, it thickens the biosolids, reducing the water content significantly.

- Thermal drying: High temperatures evaporate water, producing a dry, easily manageable product. This method requires significant energy input and is usually reserved for specialized situations where a very dry product is needed.

The choice of dewatering technique depends on factors like biosolids characteristics (e.g., sludge type, solids content), budget constraints, available space, and environmental regulations. For instance, a smaller wastewater treatment plant might opt for gravity thickening due to its simplicity, while a large facility might invest in belt filter presses for higher efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate the transportation costs associated with biosolids?

Calculating biosolids transportation costs involves several factors. It’s not a simple formula, but rather a multifaceted estimation.

- Volume and weight: The amount of biosolids to be transported directly impacts costs. Dewatering significantly reduces volume and weight, leading to lower costs.

- Distance: Longer distances translate to higher fuel costs and driver expenses.

- Transportation method: Truck transport is common, but rail or barge transport may be more economical for large volumes and longer distances. The type of truck (e.g., tanker, enclosed) also affects costs.

- Hauling fees: These vary based on the contractor, distance, and fuel prices. Negotiating contracts is essential to secure favorable rates.

- Permits and fees: Various permits and associated fees will increase the overall transportation costs.

- Disposal fees at the receiving site: These must be factored into the total cost. Costs vary widely depending on the disposal method (land application, incineration, etc.).

A practical approach involves creating a detailed spreadsheet or using specialized software that takes into account all these factors. Often, multiple bids are solicited from transportation contractors to ensure cost-effectiveness. For example, if we are transporting 100 tons of biosolids 50 miles, the cost would be significantly lower than transporting the same amount 500 miles. Regular monitoring and adjustment of these costs is crucial for budgetary management.

Q 17. What are the different types of permits required for biosolids handling and transportation?

Permits required for biosolids handling and transportation vary by jurisdiction but generally include:

- NPDES permit (National Pollutant Discharge Elimination System): This permit regulates wastewater discharges, including biosolids, into waterways. It sets limits on pollutants and requires monitoring and reporting.

- State and local permits: These may cover aspects like transportation, storage, and land application of biosolids. Specific requirements vary significantly based on location.

- Hazardous waste permits: If biosolids contain hazardous materials, additional permits will be needed, following stricter guidelines.

- Transportation permits: These usually apply to the vehicles transporting biosolids. They may include vehicle registration, specific placarding requirements, and driver qualifications.

It is crucial to check with the relevant environmental agencies at the state and local levels to understand the specific permitting requirements and ensure full compliance. Failure to obtain the necessary permits can result in significant fines and legal repercussions. For instance, a permit might specify the maximum allowable solids concentration or the route a biosolids truck can take.

Q 18. Describe your experience with biosolids quality control and testing.

Biosolids quality control and testing are vital to ensure they meet regulatory standards and are safe for disposal or beneficial reuse. This includes regular monitoring of various parameters.

- Pathogen testing: This checks for harmful bacteria, viruses, and parasites. Common tests include E. coli, Salmonella, and fecal coliform counts.

- Nutrient analysis: This determines the levels of nitrogen, phosphorus, and other nutrients, important for land application.

- Heavy metal analysis: This assesses the presence of heavy metals like lead, cadmium, and mercury, which can be harmful to the environment and human health.

- Solids content determination: This measures the percentage of solids in the biosolids, a key parameter for dewatering and transportation.

- pH measurement: This determines the acidity or alkalinity of the biosolids, which impacts their handling and environmental impact.

Testing is conducted at various stages—from the wastewater treatment plant to the final disposal or application site. Results are documented and used to adjust treatment processes if necessary. For example, if pathogen levels are too high, additional treatment like heat or lime stabilization might be implemented. Regular, meticulous record-keeping is crucial for demonstrating compliance and ensuring public safety.

Q 19. How do you select the appropriate disposal method for different types of biosolids?

Selecting the appropriate disposal method depends on several factors, including biosolids characteristics, environmental regulations, and cost-effectiveness.

- Land application: Biosolids rich in nutrients are often used as fertilizer in agriculture or forestry. This requires careful consideration of soil types, crop suitability, and potential environmental impacts (e.g., nutrient runoff).

- Incineration: This method reduces volume significantly and destroys pathogens but produces air emissions. Energy recovery is sometimes possible.

- Composting: Biosolids are mixed with other organic materials to produce a compost product suitable for soil amendment. This requires controlled conditions and careful monitoring.

- Landfilling: This is a less environmentally friendly option, usually reserved for biosolids that are not suitable for other disposal methods. This requires specific landfill permits and often entails higher disposal costs.

- Beneficial reuse in construction: Biosolids can be used in certain construction materials, like lightweight fill or soil stabilization. This offers an environmentally friendly alternative to landfills.

A cost-benefit analysis, considering environmental impacts, should be performed before selecting a disposal method. For example, land application might be preferred if the biosolids quality is high and suitable agricultural land is available. Otherwise, incineration or landfilling might be more appropriate, though potentially less sustainable.

Q 20. Explain your understanding of biosolids pathogen reduction techniques.

Biosolids pathogen reduction is crucial for protecting public health and the environment. Several techniques are employed, often in combination.

- Heat treatment: High temperatures effectively kill pathogens. This can be achieved through processes like aerobic digestion or thermal drying.

- Lime stabilization: Adding lime raises the pH, creating an alkaline environment that inhibits pathogen growth. This is a cost-effective and commonly used method.

- Anaerobic digestion: The anaerobic environment and the resulting heat contribute to pathogen reduction.

- UV irradiation: Ultraviolet light can inactivate pathogens, but its effectiveness may be limited depending on the biosolids’ characteristics.

The effectiveness of each method depends on several factors, including the type and concentration of pathogens, temperature, exposure time, and pH. Regulations often dictate minimum pathogen reduction requirements that must be achieved before biosolids can be land applied or used for beneficial reuse. Combining multiple methods often enhances pathogen reduction efficacy. For example, anaerobic digestion followed by lime stabilization significantly reduces the pathogen load and improves biosolids’ suitability for land application.

Q 21. How do you prevent and manage spills during biosolids transportation?

Preventing and managing spills during biosolids transportation is crucial for environmental protection and public safety. A multi-pronged approach is necessary.

- Proper vehicle maintenance: Regular inspection and maintenance of transport vehicles, including leak detection and repair, are essential. This includes checking the integrity of tanker trucks and ensuring proper sealing mechanisms.

- Appropriate loading and unloading procedures: Following established procedures, using proper equipment, and training personnel can prevent spills during loading and unloading.

- Driver training: Drivers should be trained to handle biosolids safely, recognizing potential hazards and following emergency procedures.

- Emergency response plan: A detailed plan should be in place for responding to spills, including procedures for containment, cleanup, and notification of authorities.

- Spill kits: Appropriate spill kits should be readily available in transport vehicles for immediate response to minor spills.

Regular monitoring during transport, secure fastening mechanisms, and appropriate speed limits minimize the risk of accidents. In the event of a spill, immediate action is critical to minimize environmental damage and prevent potential health risks. This includes containing the spill, contacting the appropriate authorities, and initiating the cleanup process according to the emergency response plan.

Q 22. What are the key safety procedures for handling and transporting biosolids?

Safe biosolids handling and transportation hinge on minimizing environmental and health risks. This involves rigorous adherence to regulations and best practices at every stage, from source to disposal.

Personal Protective Equipment (PPE): Workers must always wear appropriate PPE, including respirators, gloves, and protective clothing, to prevent exposure to pathogens and hazardous materials. This is crucial, especially when dealing with potentially infectious biosolids.

Vehicle Maintenance and Containment: Transport vehicles need regular inspections and maintenance to ensure leaks are prevented. Proper sealing and containment systems are essential to avoid spills during transit. Imagine a tanker truck—it needs airtight seals to stop any accidental release.

Emergency Response Planning: A robust emergency response plan is necessary. This includes procedures for handling spills, accidents, and other unexpected events. For instance, a designated spill response team should be ready to act swiftly in case of a leak.

Proper Labeling and Documentation: All containers and vehicles must be clearly labeled with the contents, potential hazards, and handling instructions. Comprehensive documentation, including manifests and transport records, is mandatory for tracking and auditing purposes.

Driver Training: Drivers responsible for biosolids transport must receive thorough training on safe driving practices, emergency procedures, and handling of hazardous materials. Regular refresher courses reinforce these vital safety skills.

Q 23. Describe your experience with biosolids incineration.

My experience with biosolids incineration spans over ten years, encompassing both project management and operational oversight. I’ve worked on several projects involving the design, construction, and commissioning of modern incineration facilities. These facilities utilize advanced combustion techniques to reduce the volume of biosolids significantly while simultaneously generating energy from the process.

One notable project involved a state-of-the-art facility that incorporated flue gas cleaning technologies to minimize air emissions. The facility was designed to meet stringent environmental standards and produced a residual ash that was suitable for beneficial reuse as a construction material. I was directly responsible for ensuring the facility met regulatory compliance throughout its operation. This involved careful monitoring of emissions, maintaining comprehensive records, and collaborating with regulatory agencies.

Q 24. How do you ensure the security of biosolids transportation against theft or vandalism?

Securing biosolids transportation requires a multi-layered approach, combining physical security measures with robust tracking and monitoring systems.

GPS Tracking and Monitoring: Real-time GPS tracking allows for constant monitoring of vehicle location, speed, and route adherence. This helps deter theft and allows for immediate response to any deviations from the planned route.

Sealing and Locking Mechanisms: Secure locking mechanisms and tamper-evident seals are essential for preventing unauthorized access to the biosolids. These must be regularly inspected and documented.

Security Personnel (where applicable): For high-value or high-risk shipments, the use of security personnel to escort the transport vehicle can be a crucial measure. This adds a strong deterrent against theft or vandalism.

Regular Audits and Inspections: Routine security audits and inspections of vehicles, storage facilities, and procedures help identify and address vulnerabilities promptly.

Improved Communication: Maintaining clear lines of communication between the transportation team and monitoring personnel enables quick response in the event of suspected theft or vandalism.

Q 25. How do you communicate effectively with regulatory agencies regarding biosolids transportation?

Effective communication with regulatory agencies is paramount for ensuring compliance and maintaining a positive working relationship. This involves proactive engagement, clear and concise reporting, and a commitment to transparency.

Proactive Reporting: Submitting all required reports and permits on time and accurately is fundamental. This includes detailed information on transportation routes, volumes, and any incidents.

Open Communication Channels: Maintaining open and clear communication channels with the relevant agencies is essential. This includes attending meetings, responding promptly to queries, and providing clear explanations of any issues or deviations from standard practices.

Documentation and Record-Keeping: Maintaining meticulous records of all biosolids transportation activities is crucial. This helps support any communication with regulatory agencies and demonstrates compliance.

Collaboration and Consultation: Consulting with regulatory agencies before initiating significant changes to biosolids transportation practices demonstrates a commitment to collaboration and compliance.

Q 26. What are your strategies for optimizing biosolids transportation routes and schedules?

Optimizing biosolids transportation routes and schedules involves a strategic approach combining logistical planning with technological tools.

Route Optimization Software: Using route optimization software can help identify the most efficient routes, minimizing transportation time and fuel consumption. This software considers factors such as traffic patterns, road conditions, and distance.

Scheduling and Load Planning: Careful scheduling and load planning ensure efficient use of vehicles and minimize the number of trips required. Consolidating loads whenever possible reduces transportation costs and environmental impact.

Real-time Traffic Data: Integrating real-time traffic data into the transportation planning process helps avoid delays and disruptions caused by congestion or accidents.

Regular Route Evaluation: Regular evaluation and adjustment of transportation routes are essential to respond to changing conditions and identify potential improvements. This might include considering alternative routes or adjusting schedules to avoid peak traffic times.

Q 27. Describe your experience with implementing and maintaining a biosolids management plan.

Implementing and maintaining a comprehensive biosolids management plan is a crucial aspect of my work. It requires a detailed understanding of regulatory requirements, best practices, and technological options.

My experience includes developing and implementing plans that encompass all stages of biosolids management, from collection and processing to transportation and final disposal. A successful plan requires clear objectives, defined responsibilities, detailed procedures, and robust monitoring and evaluation mechanisms. For example, one plan I developed included a detailed risk assessment, emergency response procedures, and a system for tracking and reporting key performance indicators (KPIs) such as transportation costs, compliance rates, and environmental impacts. Regular reviews and updates ensure the plan remains relevant and effective in the face of changing regulations or operational needs.

Key Topics to Learn for Biosolids Transportation and Disposal Interview

- Regulations and Compliance: Understanding federal, state, and local regulations governing biosolids transportation and disposal, including permits and reporting requirements. This includes familiarity with relevant environmental protection agencies and their guidelines.

- Transportation Methods and Equipment: Knowledge of various transportation methods (e.g., tanker trucks, pneumatic transport, pipelines) and the associated equipment, including their maintenance and safety protocols. Be prepared to discuss the pros and cons of each method.

- Disposal Methods: Familiarity with different biosolids disposal techniques such as land application, incineration, composting, and anaerobic digestion. Understanding the environmental impact and cost-effectiveness of each method is crucial.

- Quality Control and Monitoring: Knowledge of procedures for monitoring biosolids quality throughout the transportation and disposal process, including testing methodologies and compliance with quality standards. This also involves understanding how to address potential quality issues.

- Safety Procedures and Risk Management: Demonstrate understanding of safety protocols related to handling and transporting biosolids, including personal protective equipment (PPE), emergency response plans, and hazard communication. Be ready to discuss risk assessment and mitigation strategies.

- Environmental Impact Assessment: Ability to assess the environmental impacts of biosolids transportation and disposal methods, considering factors such as soil contamination, water pollution, and greenhouse gas emissions. This includes understanding environmental impact statements and relevant assessments.

- Cost Analysis and Budgeting: Understanding the cost factors involved in biosolids transportation and disposal, including transportation, treatment, disposal, and potential penalties for non-compliance. This also covers budget planning and resource allocation.

- Sustainability and Best Practices: Familiarity with sustainable biosolids management practices and innovative technologies aimed at minimizing environmental impact and maximizing resource recovery. Discuss examples of environmentally responsible approaches.

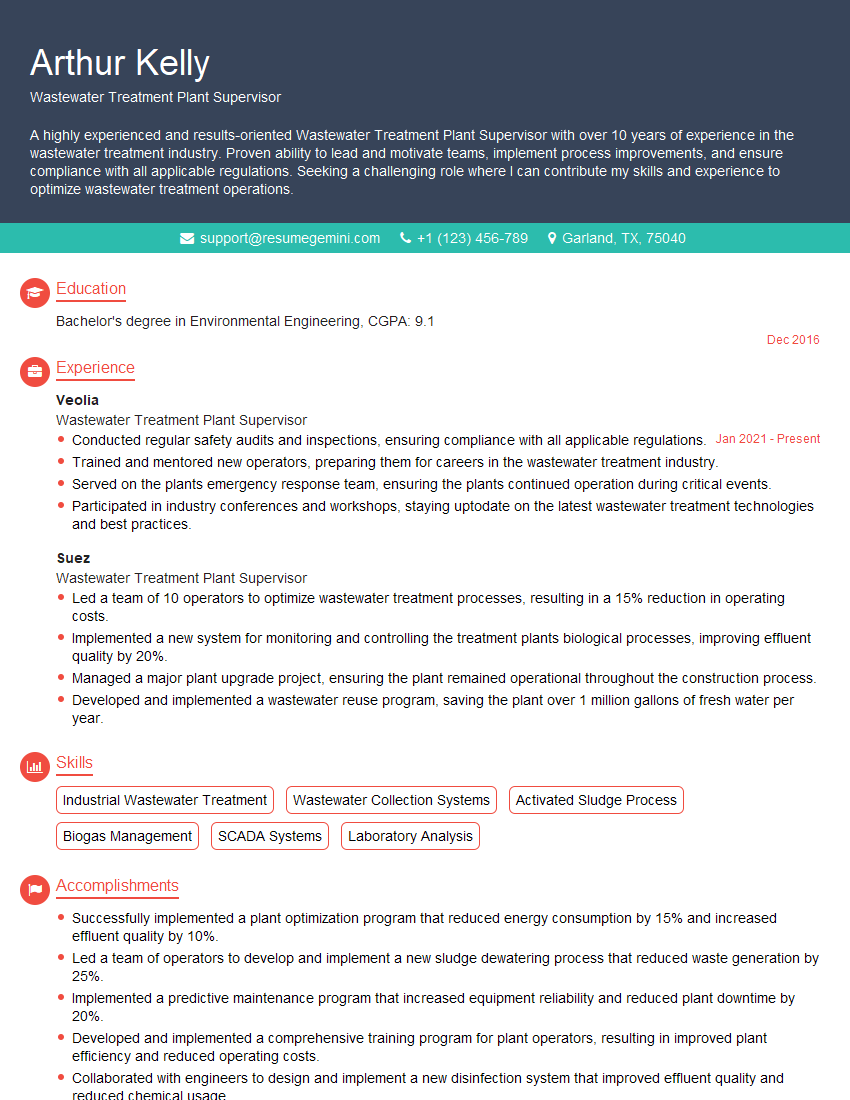

Next Steps

Mastering Biosolids Transportation and Disposal opens doors to rewarding careers in environmental management and engineering. A strong understanding of these concepts is highly sought after by employers. To significantly improve your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to Biosolids Transportation and Disposal to guide you through the process. Invest time in crafting a compelling resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.