Preparation is the key to success in any interview. In this post, we’ll explore crucial Installing glass hardware interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Installing glass hardware Interview

Q 1. What types of glass are you experienced in installing?

My experience encompasses a wide range of glass types commonly used in residential and commercial installations. This includes annealed glass (standard float glass), tempered glass (safety glass, much stronger than annealed), laminated glass (two or more layers bonded together for enhanced safety and sound insulation), and insulated glass units (IGUs) which are double or triple-paned for improved energy efficiency. I’m also familiar with patterned glass, textured glass, and specialty glasses like low-E glass (low emissivity, reducing heat transfer). Knowing the properties of each type is crucial for selecting the right hardware and ensuring a safe and successful installation.

Q 2. Describe your experience with different types of glass hardware.

I’ve worked extensively with a variety of glass hardware, including hinges (both traditional and concealed), handles, clamps, channel systems, shower door rollers, and various types of fasteners. For example, I’m proficient with different hinge styles – full mortise hinges, half mortise hinges, and surface-mounted hinges – each requiring specific installation techniques and considerations. My experience also extends to working with different materials in the hardware itself, such as stainless steel, brass, and aluminum, each requiring different care to prevent corrosion or damage. Understanding the compatibility between the hardware and the type of glass is essential for a long-lasting and safe installation. For example, using the wrong type of clamp on tempered glass could lead to breakage.

Q 3. Explain the process of installing a shower door.

Installing a shower door is a multi-step process requiring precision and attention to detail. First, I carefully measure the opening to ensure a precise fit for the door and frame. Next, I prepare the frame for installation, ensuring it’s level and plumb. Then, I install the hinges on the door and the frame, making sure they’re properly aligned and securely fastened. The door is then hung on the hinges. Shower door rollers require careful adjustment to ensure smooth and effortless operation. Finally, I install any handles or other hardware and thoroughly seal all the seams to prevent water leakage using high-quality silicone sealant. Throughout the process, I regularly check for levelness and alignment to ensure the door operates correctly and safely.

Q 4. How do you ensure the proper sealing of glass installations?

Proper sealing is critical to prevent water damage and ensure the longevity of the glass installation. I use high-quality silicone sealant, specifically designed for wet environments in the case of shower doors or similar applications. The sealant is applied in a continuous bead, ensuring complete coverage of all joints and seams. Before applying the sealant, I ensure the surfaces are clean and dry to maximize adhesion. For larger gaps or more complex configurations, backer rods might be used to control the sealant bead and reduce the amount of sealant needed. I allow the sealant to fully cure according to the manufacturer’s instructions before testing the installation.

Q 5. What safety precautions do you take when installing glass?

Safety is paramount when working with glass. I always wear safety glasses to protect my eyes from flying debris. When handling tempered glass, extra caution is needed, as it shatters into small, relatively harmless pieces, but these pieces can still cause eye injuries. Gloves are used to protect my hands from cuts and abrasions. I use appropriate lifting techniques to avoid injury from heavy glass panels. I also ensure the work area is clear of obstructions to prevent accidents. Proper personal protective equipment (PPE) and safe work practices are non-negotiable for any glass installation project.

Q 6. How do you handle different types of glass breakage?

Glass breakage can occur due to various reasons, from improper installation to accidental damage. If a small crack develops, depending on its location and severity, repair might be possible. However, if the damage is significant, particularly in tempered glass (which cannot be repaired safely), the entire glass panel needs replacement. I always follow safe disposal procedures for broken glass, carefully sweeping up all fragments and disposing of them in appropriate containers to avoid injury. When dealing with a breakage, determining the cause is important to prevent similar incidents in the future.

Q 7. What are the common challenges in installing glass hardware?

Some common challenges include working with uneven surfaces, which require careful adjustments to ensure proper alignment and sealing. Another challenge is dealing with difficult-to-reach areas, demanding creative solutions for installation. Precise measurements are crucial; even a slight inaccuracy can lead to issues with fit and functionality. Finally, coordinating with other trades, like plumbers or electricians, is important to ensure a seamless overall installation. Overcoming these challenges requires experience, problem-solving skills, and a dedication to precision and safety.

Q 8. Explain your experience with measuring and cutting glass.

Measuring and cutting glass requires precision and safety. I begin by carefully measuring the required dimensions, accounting for any tolerances needed for the specific installation. This usually involves using a high-quality measuring tape and a square to ensure accuracy. For example, when installing a glass shower door, even a slight miscalculation can lead to gaps or a poor fit. After measuring, I use a glass cutter, scoring the glass lightly before snapping it along the score line using specialized pliers or a snapping tool. This process demands a steady hand and a keen understanding of the glass type to avoid shattering. I always wear safety glasses and gloves to prevent injuries from glass shards. Finally, I carefully grind and polish the edges to ensure a smooth, safe finish. Experienced handling allows for efficient cutting, reducing waste and ensuring a perfect fit.

Q 9. How do you ensure the structural integrity of glass installations?

Structural integrity is paramount in glass installations. I achieve this through several key methods. First, I select the appropriate type of glass for the application, considering factors like strength, thickness, and the intended load. Tempered glass is ideal for applications requiring high strength and impact resistance, while laminated glass offers superior safety in case of breakage. Second, I meticulously ensure proper frame selection and installation. The frame must be sturdy and correctly sized to provide adequate support for the glass. Secure fasteners, using appropriate torque values, are critical for maintaining the integrity of the connection. Third, I utilize high-quality sealants and adhesives, carefully following manufacturer’s instructions. This ensures a watertight and durable bond, preventing movement or breakage of the glass. Regular inspection during the process is vital to catch any potential issues early, reinforcing structural integrity.

Q 10. What tools and equipment are essential for glass hardware installation?

A range of specialized tools and equipment are necessary for safe and effective glass hardware installation. These include:

- Glass cutter: For precise scoring and cutting of glass.

- Glass pliers/snapping tool: For cleanly breaking the glass along the score line.

- Grinding wheel/polisher: For smoothing and finishing cut edges.

- Measuring tape and square: For accurate measurements.

- Safety glasses and gloves: Essential safety equipment.

- Silicone sealant and caulk gun: For sealing and creating watertight connections.

- Drill with appropriate bits: For drilling pilot holes in frames or glass (if necessary).

- Screwdrivers and fasteners: Matching the type of frame and hardware.

- Level: For ensuring accurate and plumb installations.

- Suction cups/glass handling tools: To safely maneuver large or heavy glass panels.

The specific tools needed may vary based on the complexity of the project and the type of glass and frame involved.

Q 11. Describe your experience with installing tempered glass.

I have extensive experience installing tempered glass, recognizing its unique properties and the necessary precautions. Tempered glass, also known as safety glass, is significantly stronger than annealed glass, but it’s crucial to handle it carefully. Once tempered, it cannot be cut or modified. Therefore, precise measurements are absolutely essential. I always ensure that the tempered glass is installed correctly within its frame to prevent any stress or pressure points that could lead to spontaneous breakage. I carefully inspect the glass for any imperfections or damage before installation, rejecting any compromised pieces. I am very familiar with the specific safety guidelines required, including appropriate personal protective equipment (PPE) throughout the entire process.

For example, I once installed a large tempered glass window for a homeowner. I meticulously measured the opening and ordered the glass to fit perfectly. Using suction cups and careful handling, I positioned the glass within the frame, ensuring proper alignment before securing it. The final result was a beautiful and secure installation.

Q 12. How do you work with different types of glass frames?

Different glass frames present unique installation challenges. I have experience working with various types, including aluminum, wood, vinyl, and metal frames. Each material requires a slightly different approach. For instance, aluminum frames may require specific fasteners and techniques to avoid damaging the frame. Wood frames often require pre-drilling pilot holes to prevent splitting. Vinyl frames are typically more flexible, requiring careful attention to ensure a secure and watertight seal. Metal frames may require specialized tools to achieve proper fastening. Understanding the strengths and weaknesses of each frame material allows me to select the correct tools and techniques to ensure a secure and long-lasting installation. I always double-check manufacturer’s specifications for the frame and glass to ensure compatibility.

Q 13. Explain your knowledge of building codes related to glass installations.

I am thoroughly familiar with building codes related to glass installations, particularly concerning safety and structural integrity. These codes vary by location, but they generally address issues such as glass type, thickness requirements for different applications (e.g., windows, doors, shower enclosures), and the appropriate use of safety glazing materials in high-risk areas. I consistently adhere to these regulations, ensuring my work meets or exceeds the required safety standards. For instance, I know the specific requirements for using laminated or tempered glass in certain applications, such as near doorways or in areas prone to impact. Staying updated on local building codes and best practices is essential for creating safe and compliant installations.

Q 14. What is your experience with installing laminated safety glass?

Laminated safety glass is a key component in many of my installations, especially where safety is paramount. Laminated glass consists of two or more layers of glass bonded together with a layer of interlayer, usually polyvinyl butyral (PVB). This interlayer holds the glass fragments together in case of breakage, significantly reducing the risk of injury from sharp shards. I’m proficient in installing this type of glass, understanding its unique properties and handling requirements. The installation process is similar to other types of glass, but extra care must be taken to avoid damaging the interlayer during handling and installation. I always follow manufacturer’s guidelines for proper installation and cleaning to maintain its integrity and safety features.

Q 15. How do you ensure a watertight seal around shower doors?

Achieving a watertight seal around shower doors is crucial for preventing leaks and maintaining a clean, functional bathroom. It’s a multi-step process that relies on careful preparation and the right materials. First, you must ensure the frame is perfectly level and plumb – any inconsistencies will compromise the seal. Then, we use a high-quality silicone sealant, specifically designed for wet areas and resistant to mold and mildew. Before applying the sealant, the surfaces must be thoroughly cleaned and dried to ensure proper adhesion. I typically use a primer to further enhance the bond. The sealant is applied in a continuous bead, ensuring complete contact with both the glass and the frame. Finally, a smoothing tool helps create a neat, even bead, minimizing the risk of gaps. Think of it like caulking a bathtub – a continuous, even bead is key. I often use a combination of sealant and a rubber gasket for an extra layer of protection. We then allow the sealant to cure completely according to the manufacturer’s instructions before testing the seal by running a shower.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of glass sealants you are familiar with?

There’s a range of glass sealants, each with its own properties. Silicone sealant is the workhorse; it’s flexible, durable, and water-resistant, making it ideal for shower enclosures and other wet areas. But different silicones exist – some are specifically formulated for bathrooms (mildew-resistant), others for exterior applications (UV-resistant). I also use polyurethane sealants for some applications; they offer superior strength and adhesion but require more precision during application. Finally, there are specialized sealants designed for specific types of glass, like tempered glass, which needs a sealant that can withstand the stress and strain. Choosing the right sealant is crucial; the wrong one can lead to cracking, leaks, or premature failure.

Q 17. How do you troubleshoot common installation problems?

Troubleshooting is a significant part of glass installation. Common issues include leaks, which usually stem from poor sealant application or an uneven frame. I systematically check the sealant beads for gaps or inconsistencies, and I carefully inspect the frame for levelness using a level and plumb bob. Another common problem is glass that doesn’t fit properly, usually caused by inaccurate measurements or improper preparation of the opening. In such cases, we may need to readjust the frame or even make minor adjustments to the glass itself (within safe limits). Cracked glass is the most serious issue and usually indicates a problem with the handling, installation process, or stress on the glass. We need to determine the cause – was it improper support, impact damage, or a defect in the glass itself? A systematic approach helps us identify and correct the problem quickly and efficiently.

Q 18. Describe your experience with installing large glass panels.

I have extensive experience installing large glass panels, often in commercial settings and high-end residential projects. This involves specialized techniques and safety precautions. Because of the weight, we utilize suction cups and specialized lifting equipment to ensure safe handling and prevent damage. Furthermore, extra support structures are often required to distribute the load evenly and prevent stress on the glass. Precise measurements and careful planning are critical. For example, a recent project involved a large glass wall for a conference room. We used a crane to hoist the panels into place and then secured them with heavy-duty hardware and multiple layers of sealant. Safety is paramount, so we always follow stringent safety protocols and use appropriate personal protective equipment (PPE).

Q 19. What is your experience with installing glass in high-traffic areas?

Installing glass in high-traffic areas requires selecting highly durable materials and using robust installation methods. Tempered glass is almost always the choice due to its exceptional strength and resistance to impact. The hardware used must also be of superior quality, able to withstand constant stress and wear. In areas with high foot traffic, for instance, we might use stronger frame materials and reinforced sealant systems. Proper maintenance is also important in these settings – regularly inspecting the installation for signs of wear and tear and addressing any issues promptly. For example, we recently installed a tempered glass partition in a busy office reception area, opting for extra strong fittings and regularly checking the installation to ensure ongoing safety and longevity.

Q 20. How do you deal with uneven surfaces during installation?

Uneven surfaces present a major challenge. Before installation, it’s crucial to assess the surface irregularities. Minor imperfections can often be addressed by using shims or fillers to create a level plane. For more significant discrepancies, we sometimes need to adjust the frame itself, making sure it is properly secured and level before installing the glass. Precision is critical here. Incorrect adjustments can lead to stress points and cracking. Using a laser level and plumb bob helps maintain accuracy throughout the process. Each shim or filler should be carefully measured and precisely positioned to prevent gaps and ensure an even distribution of weight. Remember, the goal is a perfect, stable base for the glass.

Q 21. What is your experience with using different types of adhesives for glass?

My experience spans several adhesive types for glass. Silicone is again the most frequently used, offering a flexible bond suitable for various substrates. But for specialized applications, other adhesives come into play. For instance, structural adhesives (like epoxy) offer incredibly strong bonds, but require precise application and careful surface preparation. Urethane adhesives provide a strong, durable bond, especially in applications where movement and vibration might be present. The choice of adhesive depends entirely on the project requirements, the type of glass, the substrate material, and the environmental conditions. Each adhesive has its own curing time and requires adherence to the manufacturer’s instructions to ensure the integrity of the bond.

Q 22. How do you maintain the quality and precision of your work?

Maintaining quality and precision in glass hardware installation is paramount. It’s a blend of meticulous preparation, precise execution, and a commitment to using the right tools for the job.

- Precise Measurements: I always double-check and even triple-check measurements before drilling or cutting. A millimeter off can ruin the entire installation. I use digital calipers for extremely accurate measurements, especially with intricate designs.

- Proper Tool Selection: Using the correct drill bits, saws, and fasteners is crucial. For instance, using a diamond-tipped drill bit for glass prevents chipping and ensures a clean hole. The wrong bit can lead to cracks and necessitate replacement of expensive glass panels.

- Cleanliness: Maintaining a clean workspace minimizes the risk of scratching the glass. I use protective films and masking tape to safeguard the surfaces.

- Quality Materials: I exclusively use high-quality hardware from reputable suppliers. Cheap, poorly-made hardware can fail quickly, leading to safety concerns and customer dissatisfaction.

- Testing and Inspection: Before declaring a job complete, I thoroughly test all hardware functionality, ensuring smooth operation and secure fitting. I always do a final visual inspection to ensure everything is perfectly aligned and free from defects.

Q 23. Describe your experience with working from heights.

I have extensive experience working at heights, having completed numerous installations involving large glass panels and high-rise buildings. Safety is my top priority.

- Proper Training and Certification: I hold all necessary certifications and undergo regular safety training, including fall protection techniques and the safe use of harnesses and scaffolding.

- Equipment: I always utilize appropriate safety equipment, including harnesses, lanyards, and safety lines, complying with all relevant OSHA regulations. I regularly inspect this equipment before commencing work at height.

- Risk Assessment: Before starting any project involving heights, I conduct a thorough risk assessment to identify potential hazards and develop a safe work plan. This includes assessing weather conditions and structural integrity.

- Teamwork: When working at heights, I always work with a qualified team member to act as a spotter and provide assistance, ensuring a safe and efficient workflow.

- Communication: Clear communication with my team is essential to coordinate movements and actions safely and effectively.

Q 24. What are your preferred methods for cleaning up after installation?

Cleaning up after installation is as important as the installation itself. It shows professionalism and respect for the client’s property.

- Immediate Cleanup: I clear away debris (glass shards, packaging materials, etc.) immediately after each step of the installation process. This prevents accidents and keeps the workspace organized.

- Vacuuming and Dusting: After completing the installation, I thoroughly vacuum and dust the area, removing all traces of construction materials. I pay special attention to glass surfaces to avoid smudges.

- Waste Disposal: All waste is disposed of properly, following all local regulations regarding glass recycling and hazardous waste disposal.

- Final Inspection: A final walk-through with the client is conducted to ensure they are satisfied with the cleanliness and the installation itself.

Q 25. How do you handle customer concerns or complaints?

Handling customer concerns is crucial. My approach is based on open communication, understanding, and finding effective solutions.

- Active Listening: I actively listen to the customer’s concerns without interrupting. I let them fully explain their issue.

- Empathy and Understanding: I show empathy and understand their frustration. Putting myself in their shoes helps me address their concerns more effectively.

- Problem Solving: I systematically investigate the problem, identifying the root cause. This might involve re-examining the installation or hardware used.

- Proposed Solutions: I propose clear, actionable solutions, outlining the steps involved and the timeframe for resolution. I make sure the customer is fully informed.

- Follow-up: I always follow up with the customer to confirm the problem has been resolved and to ensure their satisfaction.

Q 26. Describe a time you had to troubleshoot a challenging glass installation.

I once encountered a challenging installation involving a large, irregularly shaped piece of glass for a custom shower enclosure. The angles were difficult, and the existing framework wasn’t perfectly square.

Troubleshooting Steps:

- Precise Measurement and Adjustment: I used precision measuring tools and made small adjustments to the frame to accommodate the irregular glass shape. This involved careful cutting and sanding of the wooden supports.

- Custom Hardware Solutions: Standard hinges wouldn’t work, so I sourced custom-made hinges that could adapt to the unique angles. I had to consult with a specialist hardware supplier to find the right solution.

- Reinforcement: To ensure structural integrity, I added additional support structures to distribute the weight of the glass evenly, preventing stress points and potential breakage.

- Patient Approach: The process took longer than expected, but by patiently working through each step, I completed the installation successfully, delivering a beautiful and functional shower enclosure. The client was extremely pleased.

Q 27. What is your experience working with various types of glass hardware (hinges, handles, etc.)?

I have extensive experience with a wide variety of glass hardware, including hinges, handles, clamps, and other specialized fasteners.

- Hinges: I’m proficient with various hinge types—from standard butt hinges to more complex pivot hinges and concealed hinges, designed for different glass thicknesses and applications.

- Handles: I have experience installing a range of handles, including knobs, pulls, and integrated grab bars. This includes different materials like stainless steel, brass, and glass.

- Clamps: I frequently work with various clamping systems for securing glass panels to frames or walls, including channel systems and point-fix systems.

- Specialty Hardware: I’m familiar with specialized hardware such as shower door rollers, frameless glass door hardware, and custom-designed solutions.

- Understanding Material Compatibility: It’s critical to understand the compatibility of different hardware materials with various types of glass to prevent corrosion and ensure longevity.

Q 28. How do you ensure the longevity and durability of your installations?

Ensuring the longevity and durability of my installations involves using high-quality materials and implementing best practices throughout the process.

- High-Quality Materials: I select hardware and sealant made from durable materials like stainless steel, tempered glass, and high-grade silicone.

- Proper Installation Techniques: Precise measurements, appropriate drilling techniques, and correct fastener selection prevent premature wear and tear.

- Weatherproofing: For exterior installations, I ensure proper weather sealing and protection from the elements, preventing corrosion and water damage.

- Regular Maintenance: I advise clients on regular maintenance, such as cleaning and lubrication of moving parts, which extends the life of the installation.

- Professional Service: Addressing customer concerns promptly and making necessary adjustments shows a dedication to long-term performance.

Key Topics to Learn for Installing Glass Hardware Interview

- Understanding Glass Types and Properties: Learn the characteristics of different glass types (tempered, laminated, annealed) and how these properties influence hardware selection and installation techniques.

- Hardware Selection and Compatibility: Master the process of choosing appropriate hardware (hinges, clamps, clips, etc.) based on glass thickness, weight, and application (e.g., shower doors, tabletops, shelves).

- Measurement and Precision Techniques: Practice accurate measurements and understand the importance of precise drilling and cutting for a secure and aesthetically pleasing installation.

- Installation Methods and Best Practices: Familiarize yourself with various installation methods for different hardware types and learn best practices for ensuring safety and preventing damage to the glass.

- Safety Procedures and Regulations: Understand and adhere to relevant safety regulations and procedures, including the use of personal protective equipment (PPE) and proper handling of glass.

- Troubleshooting Common Installation Issues: Develop problem-solving skills to address common issues like misaligned hardware, cracked glass, or loose fittings. Practice diagnosing and resolving these problems efficiently.

- Understanding Building Codes and Regulations: Become familiar with relevant building codes and regulations pertaining to glass installation in various applications.

- Tools and Equipment Familiarity: Demonstrate knowledge of the tools and equipment used in glass hardware installation, including their proper use and maintenance.

Next Steps

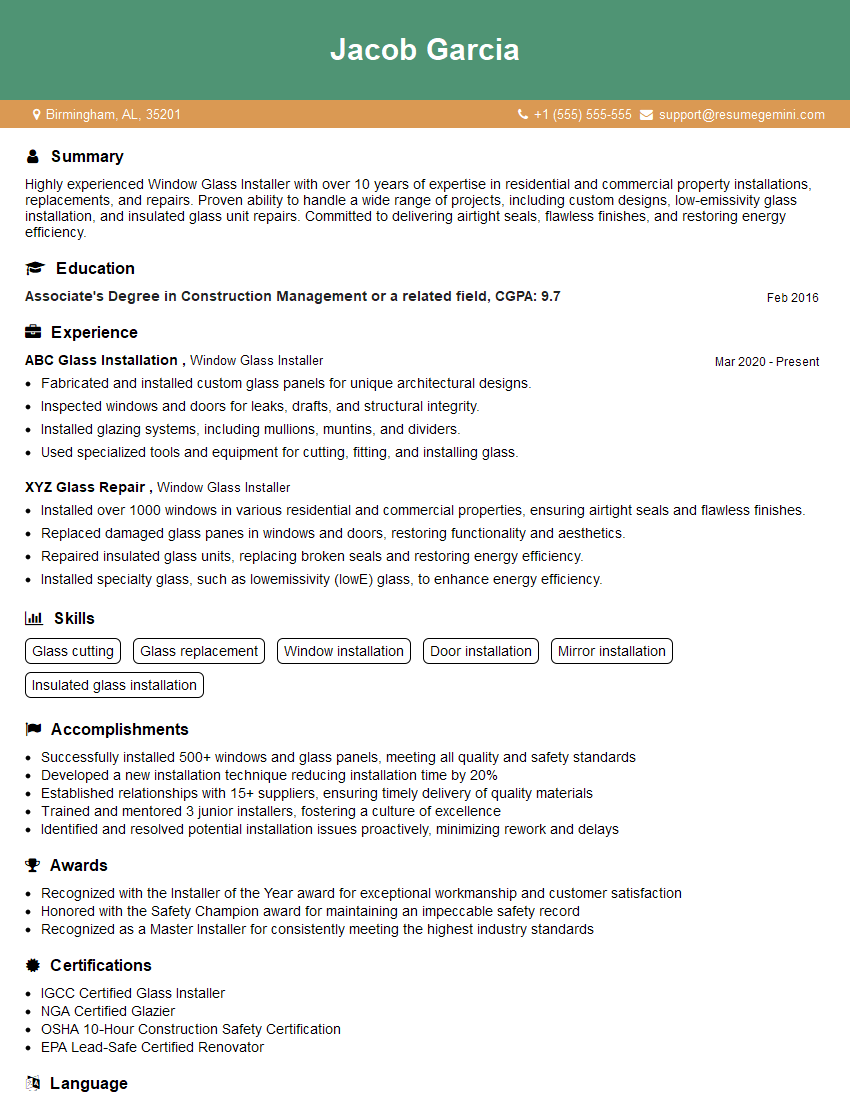

Mastering the art of installing glass hardware opens doors to exciting career opportunities in construction, renovation, and specialized glasswork. A strong understanding of these techniques will significantly enhance your employability and earning potential. To further strengthen your job search, focus on creating a professional and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a compelling resume tailored to the specific demands of the Installing glass hardware field. Examples of resumes optimized for this industry are available, providing valuable templates and guidance to help you stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.