Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Insulating Glass Unit Installation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Insulating Glass Unit Installation Interview

Q 1. Describe the different types of insulating glass units (IGUs).

Insulating Glass Units (IGUs), also known as double- or triple-glazed windows, come in various types, primarily differentiated by the number of glass panes and the gas fill between them.

- Standard IGUs: These typically consist of two panes of glass separated by a spacer bar containing desiccant to absorb moisture, and filled with air or an inert gas like argon or krypton. They offer improved insulation compared to single-pane windows.

- Triple-Glazed IGUs: These feature three panes of glass and two spacer bars, providing even greater insulation and noise reduction. The added layer significantly reduces heat transfer.

- Low-Emissivity (Low-E) IGUs: These incorporate a special coating on one or more glass panes that reflects infrared radiation, reducing heat transfer and improving energy efficiency. Think of it like a tiny mirror for heat.

- Laminated IGUs: These use a layer of interlayer (like PVB) between the glass panes, enhancing safety and security by holding the glass together in case of breakage. They’re often used in areas where impact resistance is crucial.

- Specialty IGUs: This category encompasses IGUs designed for specific applications, such as sound insulation (using thicker glass or specialized gas fills), sun control (with tinted glass), or even self-cleaning glass.

The choice of IGU type depends on factors like climate, budget, and desired performance characteristics. For instance, a triple-glazed, Low-E IGU might be ideal for a cold climate to minimize energy loss, while a laminated IGU would be appropriate for a storefront in a high-traffic area.

Q 2. Explain the process of installing an IGU in a new window frame.

Installing an IGU in a new window frame is a precise process requiring care and attention to detail. Here’s a breakdown:

- Preparation: Ensure the frame is clean, dry, and properly sized to accommodate the IGU. Any debris or imperfections can compromise the seal.

- Setting Blocks/Shims: Use setting blocks or shims to ensure the IGU is perfectly centered and sits evenly within the frame. This prevents stress on the glass and ensures proper drainage.

- Sealant Application: Apply a bead of high-quality, weather-resistant sealant (typically polyurethane) around the perimeter of the frame where the IGU will sit. This creates a watertight seal.

- IGU Placement: Carefully lower the IGU into the frame, ensuring it rests squarely on the sealant bed. Avoid touching the glass surface directly.

- Glazing Tape (Optional): Some installers use glazing tape to further enhance the seal, particularly in high-wind areas or climates with extreme temperature variations.

- Final Sealant Application: Apply a second bead of sealant over the glazing tape (if used) and the IGU perimeter, ensuring complete coverage.

- Inspection: Carefully inspect the installation for any gaps, irregularities, or sealant deficiencies.

It’s crucial to follow the manufacturer’s instructions for both the IGU and the sealant to guarantee a long-lasting and effective installation. Think of this as building a small, perfectly sealed box to protect the glass from the elements.

Q 3. How do you ensure proper sealant application during IGU installation?

Proper sealant application is paramount for preventing IGU failure. Several factors contribute to this:

- Choosing the Right Sealant: Use a high-quality, weather-resistant sealant specifically designed for exterior applications. Polyurethane sealants are common due to their durability and elasticity.

- Surface Preparation: Ensure the frame and IGU surfaces are clean, dry, and free of dust or debris. Contamination can weaken the bond.

- Even Bead Application: Apply a continuous, even bead of sealant around the entire perimeter of the IGU. Avoid gaps or inconsistencies.

- Tooling: Use a sealant gun designed for consistent bead application. Using the correct nozzle size is essential for a uniform bead.

- Curing Time: Allow sufficient curing time for the sealant to fully dry and achieve maximum bond strength according to the manufacturer’s specifications. Don’t rush the process.

- Protection: Once the sealant is applied, protect the newly installed IGU from debris, direct sunlight, and extreme temperatures during the curing process.

Think of the sealant as the glue holding everything together. A rushed or improperly applied seal is a recipe for future problems.

Q 4. What are the common causes of IGU failure?

IGU failure can stem from several factors, often leading to fogging or leaks:

- Seal Failure: The most common cause is deterioration of the sealant over time due to UV exposure, extreme temperatures, or mechanical stress.

- Spacer Bar Degradation: The spacer bar can corrode or degrade, allowing moisture to enter the IGU.

- Manufacturing Defects: Imperfections in the manufacturing process, such as inadequate sealant application or insufficient desiccant, can contribute to early failure.

- Physical Damage: Impact or other physical damage can compromise the seal or crack the glass.

- Improper Installation: Incorrect installation techniques, such as inadequate sealant application or improper shimming, can lead to stress and premature failure.

Regular inspections and preventative maintenance can help identify potential issues early on and prolong the lifespan of your IGUs.

Q 5. How do you diagnose and troubleshoot IGU leaks?

Diagnosing IGU leaks requires careful observation and investigation:

- Visual Inspection: Carefully examine the IGU for signs of fogging, condensation, or visible water stains. These are clear indicators of a leak.

- Sealant Examination: Inspect the sealant around the perimeter of the IGU for cracks, gaps, or deterioration.

- Dye Test (if necessary): A dye test can pinpoint the source of a leak by introducing a colored dye into the IGU and observing where it emerges. This is usually done by a specialized professional.

- Pressure Test (if necessary): A pressure test can detect leaks by applying pressurized air to the IGU and measuring pressure loss over time.

Troubleshooting involves identifying the root cause of the leak and addressing it appropriately. This might involve resealing the unit, replacing the sealant, or even replacing the entire IGU. Always consult a professional for complex leak detection and repair.

Q 6. What safety precautions do you take when handling IGUs?

Safety is paramount when handling IGUs, given their size and fragility:

- Proper Lifting Techniques: Always use appropriate lifting equipment, such as suction cups or lifting straps, to prevent breakage and injury.

- Protective Gear: Wear gloves and safety glasses to protect against cuts and debris.

- Careful Handling: Avoid dropping or jarring the IGU during transportation and installation.

- Work Area Safety: Ensure the work area is clear of obstacles to prevent tripping or accidental damage to the IGU.

- Disposal: Follow proper disposal procedures for broken glass and sealant materials.

IGUs can be heavy and easily damaged; prioritizing safety ensures the wellbeing of workers and the integrity of the product.

Q 7. Explain the importance of proper spacer bar selection in IGU construction.

The spacer bar plays a critical role in IGU performance and longevity. Its function goes beyond simply separating the glass panes:

- Maintaining the Air/Gas Space: The spacer bar defines the airtight cavity where the insulating gas (argon, krypton, etc.) is contained. A poorly designed or damaged spacer bar compromises insulation performance.

- Desiccant Holding: The spacer bar houses the desiccant, which absorbs moisture from the air during the IGU manufacturing process. Without a proper seal, this moisture can lead to fogging.

- Structural Integrity: The spacer bar contributes to the overall structural integrity of the IGU. It helps maintain the spacing between the glass panes and prevents warping or bowing.

- Material Selection: Spacer bars are typically made of materials like aluminum, stainless steel, or composite materials. The choice of material affects the IGU’s thermal performance, durability, and cost.

Selecting an appropriate spacer bar is crucial for optimizing the IGU’s performance, energy efficiency, and lifespan. A high-quality spacer bar with a proper seal is an investment in long-term energy savings and comfort.

Q 8. What are the different types of gas fills used in IGUs and their properties?

Insulating Glass Units (IGUs) utilize different gases to maximize their insulating properties. The most common are argon, krypton, and xenon. Each gas offers varying levels of thermal performance.

- Argon: This is the most widely used gas due to its cost-effectiveness and excellent insulating capabilities. It’s heavier than air, so it tends to stay within the IGU for a longer time. Think of it like a fluffy blanket – it traps heat and prevents it from escaping.

- Krypton: More expensive than argon, krypton offers significantly better insulation. It’s denser, leading to even lower thermal conductivity. Imagine this as a thicker, more luxurious blanket, providing superior insulation.

- Xenon: The most expensive and best-performing gas, xenon offers exceptional insulation but its cost often makes it impractical for widespread use. It’s the equivalent of a high-tech, thermal-regulating space blanket, offering ultimate warmth retention.

The choice of gas depends on the desired level of performance and budget. For residential applications, argon is often sufficient. High-performance buildings or areas with extreme climates might benefit from krypton.

Q 9. How do you measure for and cut IGUs to fit a specific opening?

Precise measurement is crucial for a proper IGU fit. I start by carefully measuring the rough opening, accounting for any variations in the frame. I use a combination of tools – a tape measure, a level, and possibly a digital caliper for high precision. For instance, I always check for squareness to ensure the unit sits correctly.

After obtaining accurate measurements, I transfer them to the IGU, allowing for the necessary spacer for the frame. If the IGU needs cutting (which is less common with pre-fabricated units but sometimes necessary with custom jobs), I use a specialized glass cutter designed for the thickness of the IGU. This requires steady hand and precision. I always practice a test cut on a scrap piece before cutting the actual unit.

Post-cutting, I carefully inspect the edges for any chips or imperfections and smooth them if needed. The goal is a perfect fit that minimizes gaps and maximizes insulation.

Q 10. Describe your experience with different types of window frames (e.g., wood, vinyl, aluminum).

My experience encompasses various window frame materials, each presenting unique challenges and advantages during IGU installation.

- Wood Frames: Wood frames require careful preparation to ensure a stable and secure installation. I need to check for rot, warping, and proper sealant application. Wood’s natural expansion and contraction needs to be accommodated to avoid issues.

- Vinyl Frames: Vinyl frames are generally easier to work with. They are less prone to warping and offer good insulation themselves. However, precise measurement is still critical as expansion and contraction can be a factor, though generally less significant than wood.

- Aluminum Frames: Aluminum frames conduct heat more readily, so careful attention to thermal bridging is necessary. The IGU’s thermal break design plays a vital role in mitigating this. Aluminum can be more challenging to work with due to its potential for bending or warping during installation if not properly supported.

Regardless of the material, understanding the frame’s properties and potential limitations is critical to ensure a successful IGU installation that maximizes performance and longevity.

Q 11. How do you handle damaged or defective IGUs?

Handling damaged or defective IGUs requires a systematic approach. First, I carefully document the damage – taking photos and noting the extent of the defect. This information is crucial for warranty claims or supplier communication.

Depending on the nature of the damage, I may attempt a repair (if minor) or recommend replacement. Minor scratches or sealant issues may be addressed with specialized sealants or coatings. However, significant damage – such as cracked glass or compromised seals – necessitates a complete replacement to maintain the IGU’s integrity and insulation properties.

I always communicate transparently with the client regarding the repair or replacement options, explaining the costs and timelines involved.

Q 12. What tools and equipment are essential for IGU installation?

Successful IGU installation requires a range of specialized tools and equipment.

- Measuring Tools: Tape measure, level, square, digital caliper.

- Cutting Tools: Glass cutter (specifically designed for IGU thickness), diamond blade wet saw (for more substantial cutting or frame modification).

- Installation Tools: Putty knife, sealant gun, spacers, shims, suction cups or lifting equipment (for larger units), utility knife.

- Safety Equipment: Safety glasses, gloves, dust mask.

The specific tools may vary depending on the project’s complexity and the types of frames being used. For example, a pneumatic nail gun may be useful with certain types of window frames.

Q 13. Explain the process of cleaning and preparing the window frame before IGU installation.

Thorough cleaning and preparation of the window frame are paramount for a successful IGU installation. This involves several steps.

- Removal of old sealant and debris: Carefully remove any old sealant, paint, or debris from the frame’s surface using a putty knife or scraper. This ensures a clean surface for proper adhesion.

- Cleaning the surface: Clean the frame thoroughly with a suitable cleaning agent to remove dirt, grease, and other contaminants that might interfere with the sealant’s bond. I usually use a specialized window cleaner. A clean and dry surface is crucial for optimal adhesion.

- Priming (if necessary): Depending on the frame material and the type of sealant used, a primer might be required to improve adhesion and prevent reactions between the sealant and the frame material.

- Inspection: Inspect the frame for any damage, cracks, or warping that could compromise the installation. Address any issues before proceeding.

This meticulous preparation phase is essential for creating a secure and airtight seal, maximizing the IGU’s performance and longevity. Skipping these steps can lead to leaks, poor insulation, and premature failure.

Q 14. How do you ensure proper alignment and level of the IGU during installation?

Ensuring proper alignment and level is crucial for a successful and aesthetically pleasing IGU installation. I use a combination of techniques to achieve this.

- Precise measurements and marking: I carefully mark the frame where the IGU will be installed. This ensures consistent spacing and accurate placement.

- Shims and spacers: Shims and spacers are used to level the IGU and ensure proper alignment within the frame opening. This is particularly important if the frame is not perfectly square or level.

- Level and plumb checks: Throughout the installation process, I use a level and a plumb bob to verify vertical and horizontal alignment. Regular checks are done throughout the process.

- Temporary support: For larger units, temporary support is necessary to prevent slippage or damage during the installation. This often involves suction cups or specialized lifting equipment.

- Final checks: Before permanently securing the IGU, a final check is conducted to confirm perfect alignment and level. Any adjustments are made at this stage.

These steps ensure the IGU sits correctly, preventing problems like water leakage, pressure imbalances, and unsightly misalignment.

Q 15. Describe your experience with different types of sealants used in IGU installation.

My experience encompasses a wide range of sealants used in Insulating Glass Unit (IGU) installation, each with its own strengths and weaknesses. The choice of sealant depends heavily on the application and the specific requirements of the project.

- Butyl Sealant: This is a primary sealant, creating the initial airtight and watertight seal between the glass panes and the spacer. It’s known for its excellent adhesion and flexibility, crucial for withstanding thermal expansion and contraction. I’ve used butyl extensively in various projects, ensuring a consistent bead thickness is applied for optimal performance. For example, on a recent high-rise project, we meticulously applied butyl sealant to ensure the IGUs would withstand extreme weather conditions.

- Polyisobutylene (PIB) Sealant: PIB is a secondary sealant applied over the butyl, providing an added layer of protection against moisture ingress. It’s often more flexible than butyl, accommodating movement better. I’ve found PIB to be particularly useful in high-humidity environments where extra protection is needed.

- Silicone Sealant: While less common as the primary sealant in IGU construction, silicone is frequently used for exterior applications or as a structural sealant for the IGU frame in the window assembly. Its flexibility and weather resistance are key advantages, although careful application is crucial to avoid any dripping or inconsistent sealant.

Understanding the properties of each sealant—its adhesion, flexibility, curing time, and compatibility with other materials—is crucial for a successful installation. Improper sealant application can lead to premature IGU failure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with using specialized IGU installation tools (e.g., suction cups, spacers)?

Specialized tools are essential for efficient and accurate IGU installation. My experience includes using a variety of tools, significantly enhancing both speed and precision.

- Suction Cups: I’ve used various sizes of suction cups, from small ones for handling individual glass panes to larger ones for managing entire IGUs. Proper technique is crucial to avoid damage to the glass. For instance, ensuring the suction cups are evenly distributed across the glass surface prevents uneven pressure and possible breakage.

- Spacers: Accurate spacer placement and consistent gap width are critical for the IGU’s thermal and acoustic performance. I’m proficient in handling both warm-edge spacers (offering superior insulation) and traditional metal spacers. The correct spacer selection is paramount, depending on the IGU’s size and desired performance characteristics. For example, warm-edge spacers are preferred for energy efficiency.

- IGU Assembly Machines (for larger projects): While not always used on smaller projects, I’ve worked with automated IGU assembly machinery on larger jobsites, increasing productivity and ensuring consistency in the assembly process.

Beyond the specifics, a keen understanding of the tools’ limitations and appropriate safety procedures is vital to prevent accidents and ensure the quality of the work.

Q 17. How do you maintain the quality and consistency of IGU installations?

Maintaining quality and consistency in IGU installations involves a multi-faceted approach focusing on precision, adherence to standards, and meticulous attention to detail.

- Proper Training and Certification: I prioritize ongoing training and professional certification to stay updated on best practices and industry advancements. This ensures I’m applying the latest techniques and adhering to the most current standards.

- Quality Control Checks: At every stage, from sealant application to final installation, I implement rigorous quality control checks. This includes visual inspections, checking for proper sealant application and confirming the absence of any debris within the IGU.

- Accurate Measurements and Planning: I meticulously measure and plan each IGU installation. Precise measurements prevent any misalignment or gaps, significantly affecting the IGU’s performance and longevity. Even minor inaccuracies can lead to seal failure over time.

- Use of Appropriate Materials: Using high-quality materials is paramount. Choosing the right type of glass, sealants, and spacers is critical for the IGU’s intended purpose and environmental exposure.

Ultimately, consistent high-quality installation leads to increased customer satisfaction and minimizes the likelihood of future problems and warranty claims.

Q 18. What are the building codes and regulations related to IGU installation in your area?

Building codes and regulations related to IGU installation vary depending on location and often address energy efficiency, safety, and structural integrity. In my area, we adhere to the International Energy Conservation Code (IECC) which often dictates minimum performance standards for windows and IGU’s. Specific requirements may also relate to wind load resistance, impact resistance (particularly for areas prone to severe weather events), and even sound transmission. Furthermore, local regulations might include specific permits or inspections required before and after installation. I am familiar with all relevant codes and ensure every installation is compliant. This includes maintaining detailed records of materials used and installation procedures for future reference or audits. For example, I regularly consult the local building department for any updates on codes or permit requirements to ensure compliance.

Q 19. How do you manage your time and prioritize tasks during IGU installation projects?

Time management during IGU installation projects involves effective planning, prioritization, and efficient execution. I typically begin with a thorough project assessment, breaking down the tasks into smaller, manageable units.

- Detailed Project Schedule: Creating a detailed schedule with deadlines for each phase, such as material procurement, IGU assembly (if applicable), and on-site installation, is crucial for efficient workflow.

- Prioritization: I prioritize tasks based on their urgency and importance, focusing on critical path activities first. This ensures the project stays on schedule and prevents delays.

- Resource Allocation: I efficiently allocate resources—personnel, tools, and materials—to optimize the workflow and prevent bottlenecks. This minimizes downtime and keeps the installation process running smoothly.

- Regular Monitoring and Adjustment: I constantly monitor progress against the schedule, making adjustments as needed. This involves identifying and addressing potential delays or issues proactively, preventing them from escalating. For instance, if a material delivery is delayed, I might shift priorities to focus on other tasks that don’t depend on that material.

Effective time management leads to on-time project completion and keeps the project within budget.

Q 20. Describe your experience working with different types of glass (e.g., tempered, laminated).

My experience includes working with various types of glass commonly used in IGU construction, each with its own properties and handling requirements.

- Tempered Glass: Known for its strength and resistance to breakage, tempered glass is a frequent choice for IGU applications, especially in high-traffic areas or applications requiring enhanced safety. However, its handling requires extra care, as it can shatter into small, relatively harmless pieces if damaged.

- Laminated Glass: Laminated glass consists of two or more layers of glass bonded together with a polymer interlayer. Its strength and safety features, such as reducing the risk of penetration, make it suitable for various locations. This type is often used in locations where security is a priority.

- Low-E Glass: Low-emissivity (Low-E) glass reduces heat transfer, enhancing energy efficiency. I have significant experience installing IGUs with Low-E coatings, paying close attention to handling and installation techniques to prevent coating damage.

- Specialty Glasses: In addition to common types, I’ve also worked with specialty glasses like tinted glass, patterned glass, or those with acoustic properties, each requiring specific handling and installation considerations.

Understanding the unique properties of each glass type is vital for successful installation, preventing damage during handling and ensuring the IGU meets the specified performance requirements.

Q 21. How do you address issues with condensation within an IGU?

Condensation within an IGU indicates a seal failure, allowing moisture to penetrate the air space between the glass panes. Addressing this requires careful diagnosis and remediation.

- Identify the Cause: The first step is to pinpoint the source of the seal failure. This might involve visual inspection of the IGU for any visible signs of sealant degradation or cracks.

- Remediation: Depending on the severity and location of the condensation, several remediation options are possible. For minor condensation, sometimes simply letting the unit dry out might suffice. However, for significant or persistent condensation, the affected IGU likely needs replacement. In some cases, resealing might be an option, but this needs to be carefully evaluated.

- Preventative Measures: Proper installation and use of high-quality sealants are key to preventing IGU condensation. Regular inspection of IGUs, particularly in high-humidity environments, can detect issues early.

Addressing condensation issues promptly not only restores the aesthetic appeal of the window but also prevents further damage, ensuring the long-term performance of the IGU and preventing the growth of mold or mildew.

Q 22. Explain the process of removing and replacing a faulty IGU.

Removing and replacing a faulty Insulating Glass Unit (IGU) requires precision and care to avoid damaging the window frame or the new IGU. The process generally involves these steps:

- Careful Removal of the Old IGU: Begin by carefully removing any existing sealant or glazing material around the perimeter of the IGU. This often involves using a utility knife or specialized sealant removal tools. It’s crucial to avoid scratching the window frame. I’ve found that a heat gun can be helpful in softening stubborn sealant, making removal easier and cleaner.

- Removal of the Old IGU: Once the sealant is removed, gently pry the old IGU out of the frame, taking care not to break the glass. Depending on the type of frame, this might involve using suction cups or specialized tools. A damaged IGU is often fragile, requiring extra caution.

- Preparation of the Frame: Thoroughly clean the window frame to remove any remaining sealant, debris, or old glazing compound. This is vital for a secure and weathertight seal for the new IGU. I usually use a solvent cleaner to remove any residue, followed by a thorough cleaning with a tack cloth.

- Installation of the New IGU: Carefully insert the new IGU into the window frame. Ensure it is properly seated and aligned. This step requires precision. A slightly oversized IGU will require adjustment and careful positioning to fit correctly.

- Glazing and Sealing: Apply a high-quality glazing compound around the perimeter of the new IGU, ensuring a complete and even seal to prevent air and water infiltration. The type of sealant will depend on the application and local climate. For instance, silicone-based sealants are common, but polyurethane is also used for its flexibility.

- Finishing and Cleanup: Once the sealant has cured, clean up any excess material and inspect the installation to ensure a watertight seal. A good IGU installation should have no gaps, and the IGU should be securely fixed in the frame. It should also be aesthetically pleasing.

Remember, safety glasses and gloves are essential throughout this process.

Q 23. How do you handle challenging installation situations (e.g., irregular window openings)?

Challenging installation situations, such as irregular window openings, require creative problem-solving and specialized tools. For instance, I’ve encountered windows with warped frames or unusual shapes. Here’s how I handle such situations:

- Precise Measurements: Thorough and accurate measurements are crucial. I use digital calipers and laser measuring devices to capture every detail of the irregular window opening. Template creation might also be necessary.

- Custom Fabrication (if necessary): In some cases, I may need to fabricate custom shims or spacers to accommodate the irregularities. This ensures the IGU sits properly and avoids stress on the glass.

- Flexible Glazing Materials: I choose glazing compounds that are flexible enough to accommodate minor irregularities in the frame, ensuring a weathertight seal.

- Additional Support: In cases of severely warped or damaged frames, I may recommend reinforcement or repair before IGU installation. This prevents future problems and ensures a long-lasting installation.

- Careful Planning: Careful planning and visualization are key to success. I often create detailed drawings or mock-ups to ensure the installation will go smoothly.

For example, I once installed an IGU in a window with a severely bowed frame. By carefully measuring the bow, creating custom shims, and using a flexible sealant, I was able to successfully install the IGU with a perfect seal.

Q 24. What is your experience with different types of caulking and weatherstripping?

My experience encompasses a variety of caulking and weatherstripping materials, each suited to different applications and environments. I’m proficient with:

- Silicone Sealants: Excellent adhesion, durability, and flexibility; ideal for many IGU installations. However, some types are not paintable.

- Polyurethane Sealants: High strength and adhesion, excellent for filling gaps, though often require more specialized cleanup.

- Butyl Sealants: Excellent for primary glazing, providing a strong and lasting seal but less flexible than silicone.

- EPDM Weatherstripping: Durable, weather-resistant, and commonly used to create a weathertight seal between the IGU and the window frame.

- Neoprene Weatherstripping: Another good option offering flexibility and resilience to the elements, but usually less long-lasting than EPDM.

The choice of material depends on factors such as the type of frame, the climate, and the specific requirements of the installation. For example, in extremely cold climates, I might prefer a sealant that remains flexible even at low temperatures.

Q 25. Describe your experience with different types of glazing systems.

My experience with various glazing systems is extensive, encompassing different frame materials and IGU types. I’ve worked with:

- Aluminum Frames: These are common for commercial applications, requiring careful consideration of thermal bridging and sealant compatibility.

- Vinyl Frames: Popular for residential applications, often requiring specific sealant types to maintain a good bond.

- Wood Frames: Require careful handling and sealing to prevent moisture damage. Different wood types require different approaches.

- Laminated Glass IGUs: Offer enhanced safety and security features.

- Low-E Glass IGUs: Improve energy efficiency by reducing heat transfer.

- Gas-Filled IGUs: Enhance energy efficiency through reduced heat transfer compared to air-filled IGUs (Argon, Krypton are common fills).

Understanding the properties of each glazing system is vital for selecting appropriate sealants and installation techniques to ensure optimal performance and longevity. For example, aluminum frames, being a good heat conductor, may require a sealant that is resistant to thermal expansion and contraction.

Q 26. How do you ensure the long-term performance and durability of the IGU installation?

Ensuring long-term performance and durability involves meticulous attention to detail throughout the installation process. Key aspects include:

- Proper Selection of Materials: Choosing high-quality, weather-resistant sealants and glazing compounds appropriate for the climate and frame material. I always carefully research the properties of each material.

- Precise Installation Techniques: Accurate measurements, proper seating of the IGU, and consistent application of sealant are crucial for preventing leaks and premature failure.

- Thorough Inspection: A thorough inspection after installation identifies and addresses any potential problems before they escalate. This includes checking for air leaks and ensuring the IGU is securely fixed.

- Protection from the Elements: Taking steps to protect the newly installed IGU from extreme weather conditions during the curing process is crucial for the longevity of the sealant.

- Adherence to Manufacturer’s Guidelines: Always following the manufacturer’s recommendations for installation and material usage ensures optimal performance and avoids voiding warranties.

For example, on a recent project, I used a specialized sealant with UV protection to prevent degradation of the sealant over time, extending the life of the IGU installation.

Q 27. What are your salary expectations for this IGU Installer position?

My salary expectations are commensurate with my experience and skills, and are in line with the industry standard for experienced IGU installers in this region. I’m open to discussing a competitive salary range based on the specifics of the position and benefits package offered. I am confident I can provide significant value to your company.

Key Topics to Learn for Insulating Glass Unit Installation Interview

- Understanding IGU Components: Thoroughly familiarize yourself with the different components of an Insulating Glass Unit (IGU), including glass panes, spacers, sealants, and gas fills. Understand their individual functions and how they interact.

- IGU Installation Techniques: Master various installation methods, including the use of different sealants, proper glazing techniques, and adherence to manufacturer specifications. Practice explaining your approach to different installation scenarios.

- Quality Control and Inspection: Learn how to identify defects in IGUs, both before and after installation. Understand the importance of quality control measures and how to perform thorough inspections to ensure a high-quality final product.

- Safety Procedures and Regulations: Demonstrate a strong understanding of relevant safety regulations and procedures for handling glass, using tools, and working at heights. Be prepared to discuss your experience with safe work practices.

- Troubleshooting and Problem-Solving: Be ready to discuss how you would approach common problems encountered during IGU installation, such as sealant failure, glass breakage, or air leakage. Highlight your analytical and problem-solving skills.

- Material Knowledge: Develop a strong understanding of different types of glass, spacers, and sealants used in IGU construction. Be able to discuss the properties and applications of each material.

- Tools and Equipment: Familiarize yourself with the various tools and equipment used in IGU installation. Be able to explain their proper usage and maintenance.

Next Steps

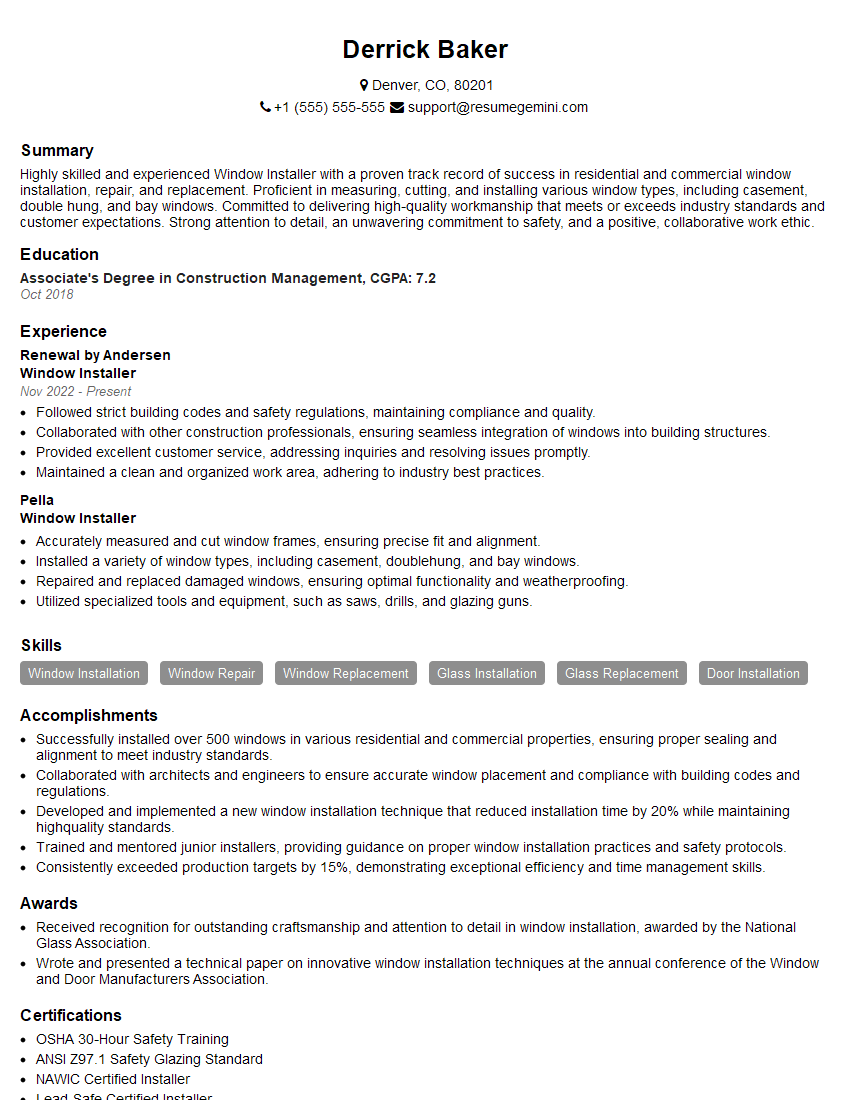

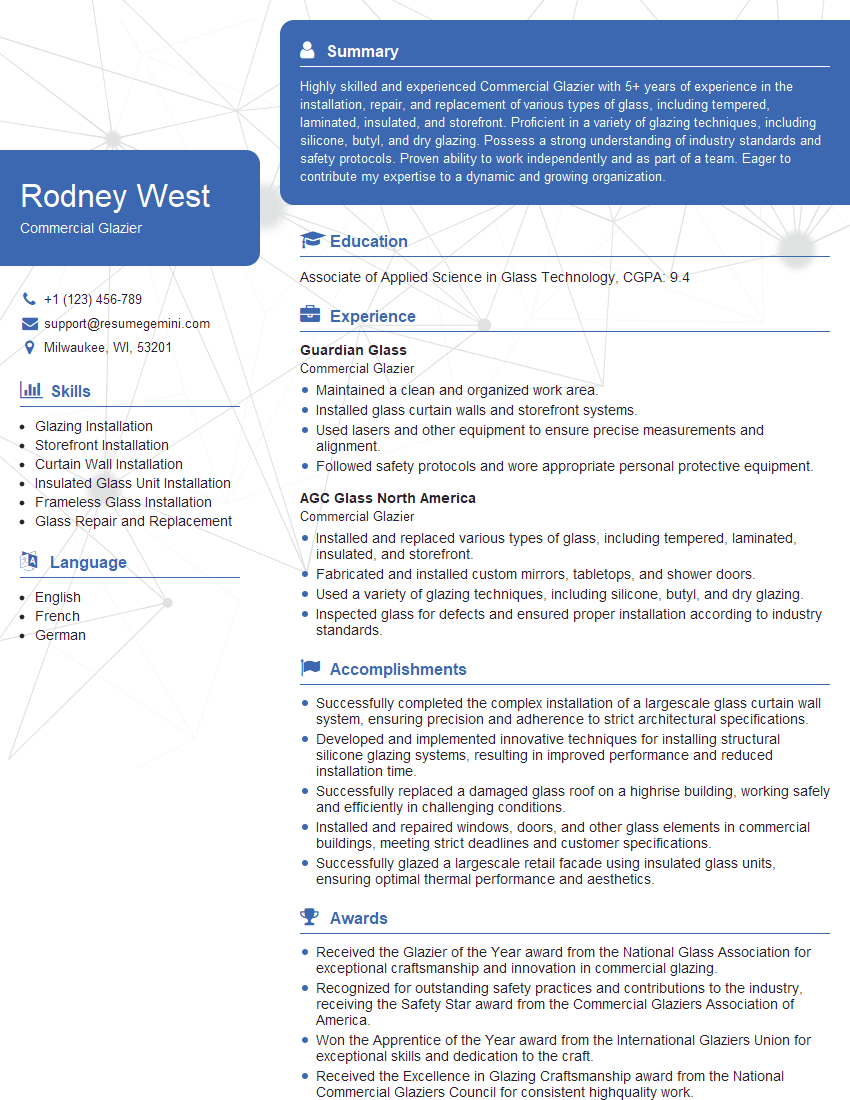

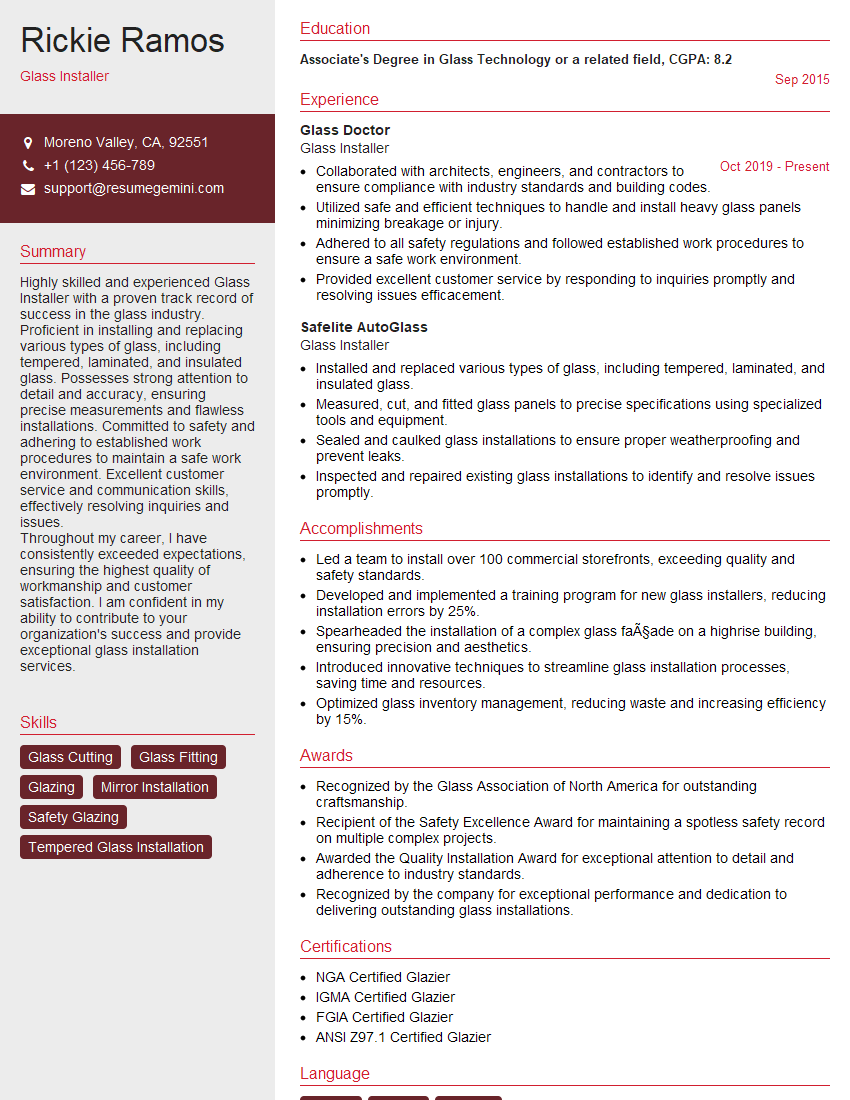

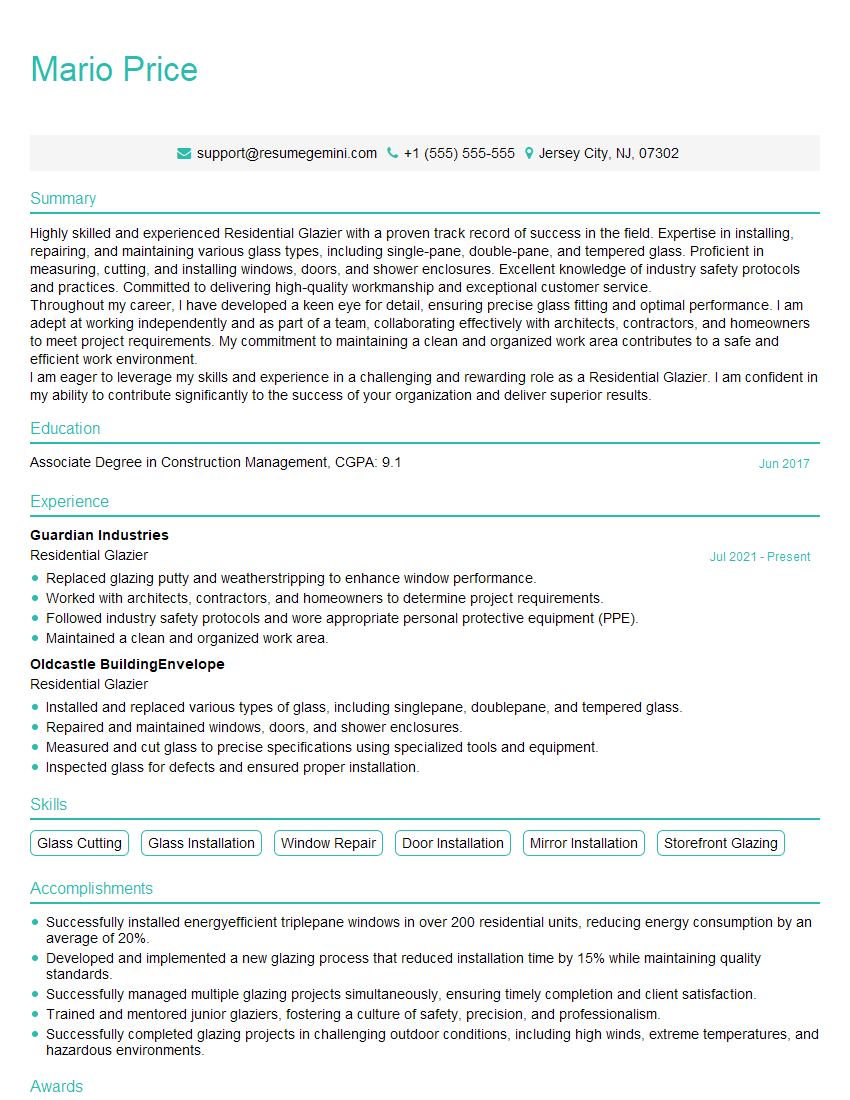

Mastering Insulating Glass Unit Installation opens doors to a rewarding career with excellent growth potential. The demand for skilled installers is consistently high, leading to competitive salaries and opportunities for advancement. To maximize your chances of landing your dream job, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, designed to get noticed by recruiters. We provide examples of resumes tailored to the Insulating Glass Unit Installation field to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.