Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Odor Control Techniques interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Odor Control Techniques Interview

Q 1. Explain the different types of odor sources and their characteristics.

Odor sources are incredibly diverse, ranging from biological processes to industrial emissions. Understanding their characteristics is crucial for effective odor control. We can broadly categorize them as follows:

- Biological Sources: These are often associated with decomposition. Think of landfills, wastewater treatment plants, or even overflowing bins. The odors stem from the breakdown of organic matter by microorganisms, releasing volatile organic compounds (VOCs) like methane, hydrogen sulfide, and various amines. These odors are often pungent and complex, varying with the type of decomposing material and environmental conditions.

- Industrial Sources: Factories and industrial processes generate a wide spectrum of odors, depending on their operations. For example, rendering plants (processing animal byproducts) produce strong, fatty odors, whereas chemical plants might emit sulfurous or acrid smells. These sources often involve specific VOCs or other gases related to the manufacturing process. Pinpointing the exact odorant requires targeted analysis.

- Agricultural Sources: Livestock farms, manure storage areas, and composting facilities produce characteristic odors primarily from ammonia, hydrogen sulfide, and various volatile organic acids. The intensity of these odors depends heavily on factors such as animal density, manure management practices, and weather conditions.

- Domestic Sources: These encompass everyday sources like cooking, pets, and even improperly maintained drainage systems. While generally less intense than industrial or agricultural sources, they can still accumulate and cause significant nuisance in densely populated areas.

Understanding the specific source is the first step in choosing the right control strategy. For example, controlling odors from a landfill will differ significantly from controlling those from a chemical plant.

Q 2. Describe various odor control technologies (e.g., biofiltration, activated carbon).

Numerous technologies exist for odor control, each with its strengths and limitations. Here are some prominent examples:

- Biofiltration: This is a biological method using microorganisms to break down odor molecules. Air containing odors is passed through a bed of compost or other suitable media, where microorganisms metabolize the odorants. It’s highly effective for various VOCs and is environmentally friendly, but it requires significant space and careful monitoring of the media’s moisture and nutrient levels.

- Activated Carbon Adsorption: This physical method utilizes activated carbon, a porous material, to adsorb odor molecules onto its surface. Air passes through a bed of activated carbon, trapping the odors. This technology is effective for many VOCs and is relatively simple to operate. However, it requires regular regeneration (heating to release trapped odorants) or replacement of the carbon, and it isn’t suitable for all types of odors equally.

- Scrubbers (Wet Scrubbing): These systems use a liquid solution to absorb or react with odor molecules. The air is passed through a contact chamber where it comes into contact with the scrubbing liquid. Different scrubbing liquids are used depending on the target odorants. For example, alkaline solutions can neutralize acidic odors. This is effective for many odors and is often used for high-volume applications, but it requires careful handling of the waste liquid and the cost can be significant.

- Thermal Oxidation: This method involves burning the odor molecules at high temperatures. This is highly effective for many VOCs, but it requires significant energy and can generate other pollutants if not properly managed. This is particularly relevant for highly concentrated streams of odorous gases.

- Chemical Oxidation: This involves using chemical oxidants, such as ozone or hydrogen peroxide, to break down odor molecules. This is effective for various odors but might produce byproducts that need to be managed. Ozone is a particularly potent oxidant but can be hazardous if not handled properly.

Q 3. What are the limitations of each odor control technology?

Each technology has its own set of limitations:

- Biofiltration: Ineffective for some very persistent or toxic compounds, can be sensitive to temperature fluctuations, requires significant space.

- Activated Carbon Adsorption: Can become saturated requiring regeneration or replacement, not effective against all odors, and expensive to replace the carbon.

- Scrubbers: Requires careful management of wastewater, can be expensive to operate and maintain, less effective against some VOCs.

- Thermal Oxidation: High energy consumption, potential for byproduct formation, requires substantial capital investment.

- Chemical Oxidation: Can produce secondary pollutants, potentially hazardous chemicals involved, and requires specialist knowledge for operation.

The choice of technology needs to carefully weigh its effectiveness against its cost and environmental impact in the context of the specific odor and application.

Q 4. How do you determine the appropriate odor control method for a specific application?

Selecting the right odor control method involves a systematic approach. It’s not a one-size-fits-all solution.

- Identify the odor source and its characteristics: What is the source of the odor? What are the main odor compounds involved? How concentrated are the odors? This may involve chemical analysis.

- Quantify the odor: Employ techniques like olfactometry (described below) to determine the odor concentration and its impact.

- Assess the available technologies: Considering factors like cost, effectiveness, space constraints, regulatory requirements, and environmental impact, we narrow down potential methods.

- Conduct pilot studies: Small-scale tests with different technologies often provide valuable information on performance and optimization.

- Optimize the selected method: Fine-tuning parameters like airflow rates, media type (in biofiltration), or chemical concentrations are often necessary.

- Monitor and maintain the system: Regular monitoring ensures the system operates at peak efficiency and meets environmental standards.

For instance, a small restaurant might opt for a simple activated carbon filter, whereas a large rendering plant would require a more complex multi-stage system potentially incorporating scrubbing and thermal oxidation.

Q 5. Explain the concept of odor thresholds and their significance in odor control.

Odor thresholds represent the lowest concentration of an odorant that can be detected by a human nose. They are crucial in odor control because they dictate the level of treatment required to make an odor imperceptible. Different substances have different odor thresholds; some are detectable at extremely low concentrations (e.g., hydrogen sulfide), while others require much higher concentrations to be smelled.

The significance in odor control is that achieving a concentration below the odor threshold ensures the odor is no longer a nuisance. Regulations often set odor limits based on these thresholds, expressed as odor units per cubic meter (ouE/m³). These units are determined through olfactometry.

Consider a composting facility. If the odor threshold for the dominant odorant is 10 ouE/m³, the odor control system needs to reduce the odor concentration to below this level to meet regulatory standards and prevent complaints.

Q 6. Describe different odor measurement methods (e.g., olfactometry, gas chromatography).

Several methods exist for measuring odor concentration:

- Olfactometry: This is the most widely accepted method for determining odor concentration. A panel of trained assessors sniffs diluted samples of air until they can no longer detect the odor. The dilution required to reach the detection threshold is used to calculate the odor concentration in odor units (ouE).

- Gas Chromatography-Mass Spectrometry (GC-MS): This sophisticated analytical technique identifies and quantifies individual volatile organic compounds present in the air. It provides precise chemical composition but doesn’t directly measure the perceived odor intensity, as the human nose responds to a complex mixture in a way that isn’t easily predicted by individual compound concentrations.

- Electronic Noses: These instruments utilize arrays of sensors to detect a range of volatile organic compounds. They offer a rapid screening method but are still under development and need to be carefully calibrated for accurate quantification.

Olfactometry offers a direct measure of the perceived odor strength, whereas GC-MS provides the detailed chemical composition of the odorous air. Often, a combination of both methods is used for a comprehensive assessment.

Q 7. How do you interpret odor concentration data?

Interpreting odor concentration data is vital for evaluating the effectiveness of odor control measures. The data, usually expressed as odor units (ouE/m³), indicates the strength of the odor at a particular location. For example, a reading of 20 ouE/m³ means that the air sample needed to be diluted 20 times for a trained panel to no longer detect the odor.

Lower odor concentrations indicate more effective odor control. By comparing data before and after implementing control measures, we can quantify the improvement achieved. Data trends over time also reveal system performance and may point to the need for maintenance or adjustments.

Regulatory compliance is another key aspect of interpretation. Comparing measured odor concentrations against regulatory limits allows us to assess whether the system meets legal requirements. For example, if the regulatory limit is 10 ouE/m³, and measured concentrations consistently exceed this value, it means corrective action is required.

Spatial variations in odor concentration data help to pinpoint odor sources or areas where the control system is less effective. This information aids in optimizing the system’s design or placement.

Q 8. How do you develop an odor control strategy?

Developing an effective odor control strategy requires a systematic approach. Think of it like solving a detective mystery – you need to identify the ‘culprit’ (the odor source), understand its ‘modus operandi’ (the odor generation mechanism), and then devise a plan to neutralize or eliminate it. This involves several key steps:

- Source Identification and Characterization: This is paramount. We use techniques like odor mapping, gas chromatography-mass spectrometry (GC-MS) to pinpoint the source and identify the specific odor compounds. For example, a rendering plant might have different odor profiles at different stages of processing, requiring targeted solutions.

- Odor Quantification: We use olfactometry, a standardized sensory test, to quantify odor intensity. This helps us establish baseline levels and measure the effectiveness of our interventions. Think of it as measuring the ‘strength’ of the smell.

- Technology Selection: Based on the source, odor compounds, and environmental context, we select appropriate control technologies. Options range from simple solutions like improved ventilation and scrubbing to more complex systems such as biofiltration, activated carbon adsorption, or thermal oxidation.

- Implementation and Monitoring: The chosen technology is implemented, followed by continuous monitoring to ensure effectiveness. This is where regular olfactometry measurements and ongoing assessments are crucial.

- Optimization and Adjustment: Odor control is an iterative process. We continuously monitor performance and adjust strategies as needed, adapting to changing conditions and refining our approach for optimal results.

Q 9. Describe the regulatory framework surrounding odor control in your region.

The regulatory framework for odor control varies significantly by region, but generally involves environmental agencies setting odor concentration limits and establishing permitting processes for facilities that may generate odors. For instance, in many jurisdictions, there are specific regulations concerning permitted odor concentrations near residential areas, and industries like landfills and wastewater treatment plants are subject to strict permitting requirements based on best available technologies. These regulations often include procedures for odor complaint investigations, enforcement actions for non-compliance, and possibly community engagement initiatives.

Specific regulations are often defined in terms of odor concentration units (e.g., odor units per cubic meter, OUM/m³), and might incorporate specific odor thresholds for different industries. Penalties for non-compliance can include fines, operational restrictions, or even legal action.

It’s critical for businesses to stay informed about and compliant with the relevant regulations in their area to avoid potential legal issues and environmental damage.

Q 10. Explain the importance of risk assessment in odor control projects.

A thorough risk assessment is the cornerstone of any successful odor control project. Imagine building a house without a blueprint – it’s unlikely to be structurally sound! Similarly, a risk assessment identifies potential hazards and vulnerabilities related to odor generation, impact, and mitigation. This helps determine:

- Potential Odor Impacts: This involves identifying sensitive receptors (residential areas, schools, hospitals) and assessing the potential impact of odors on human health, comfort, and property values.

- Source Characterization: This helps determine the nature, intensity, and variability of odor emissions. A detailed understanding is needed to choose the right solution.

- Technology Suitability: The risk assessment helps select the most appropriate and effective odor control technology based on cost-effectiveness and potential risks associated with different options (e.g., energy consumption, chemical usage).

- Compliance Risks: This identifies potential non-compliance with environmental regulations and helps develop mitigation strategies.

- Economic Risks: This involves evaluating the potential financial implications of implementing control measures, including initial investment costs, ongoing maintenance expenses, and potential penalties for non-compliance.

A comprehensive risk assessment minimizes potential problems and ensures a cost-effective and compliant solution.

Q 11. How do you address odor complaints from the public?

Addressing odor complaints involves a systematic and empathetic approach. The first step is to acknowledge the complaint and show that we take it seriously. We then follow these steps:

- Investigation: We investigate the complaint thoroughly, determining the time, location, and nature of the odor. This may involve on-site inspections, odor monitoring, and interviews with residents.

- Verification: We use objective methods, such as olfactometry, to verify the presence and intensity of the odor. This provides factual data to support our findings.

- Communication: We communicate our findings to the complainant, clearly explaining the investigation’s results and the steps we are taking to address the issue. Transparency builds trust.

- Corrective Action: We implement corrective actions, which may include adjusting equipment operation, implementing additional odor control measures, or enhancing existing systems. This step may involve collaborating with regulatory agencies.

- Follow-up: We follow up with the complainant to ensure the problem has been resolved and the situation has improved. Continuous monitoring helps ensure that the issue doesn’t recur.

This approach is vital for maintaining positive community relations and complying with regulations.

Q 12. What are the safety precautions associated with odor control technologies?

Odor control technologies present various safety hazards that require careful consideration. Safety measures depend on the specific technology employed, but common precautions include:

- Personal Protective Equipment (PPE): This includes respirators, gloves, and eye protection, particularly when handling chemicals or working in confined spaces.

- Chemical Handling: Safe handling and disposal of chemicals used in odor control processes are essential. This necessitates adherence to safety data sheets (SDS) and proper training for personnel.

- Ventilation and Confined Space Entry: Adequate ventilation is crucial to prevent oxygen depletion and accumulation of hazardous gases, especially when working in confined spaces. Strict adherence to confined space entry protocols is necessary.

- Fire and Explosion Hazards: Some odor control technologies, such as thermal oxidizers, involve high temperatures and flammable materials, demanding robust fire safety measures.

- Electrical Hazards: Proper grounding and electrical safety precautions are needed to prevent electrical shocks and fires.

Regular safety training and risk assessments are vital for minimizing hazards associated with odor control equipment and operations.

Q 13. Explain the economic aspects of implementing odor control systems.

Implementing odor control systems involves significant economic considerations. The initial investment can be substantial, depending on the technology selected and the scale of the problem. Costs include:

- Equipment Purchase and Installation: This is often the most significant expense, varying widely based on the technology chosen (biofilters, activated carbon systems, thermal oxidizers, etc.).

- Engineering and Design: Professional engineering services are needed to design and optimize the system for effectiveness and efficiency.

- Operation and Maintenance: Ongoing operational costs include energy consumption, replacement of consumables (e.g., activated carbon), and regular maintenance. These can be significant over the system’s lifespan.

- Permitting and Regulatory Compliance: Obtaining necessary permits and ensuring compliance with environmental regulations may involve additional costs.

However, the economic benefits can be substantial. Reduced odor complaints improve community relations, avoid potential fines for non-compliance, and may enhance property values. A cost-benefit analysis is crucial to justify the investment and compare different solutions.

Q 14. Discuss the maintenance requirements for odor control equipment.

Regular maintenance is crucial for the effective and efficient operation of odor control equipment and for maximizing its lifespan. The specific maintenance requirements vary greatly depending on the technology used. However, common practices include:

- Regular Inspections: Regular visual inspections are vital for identifying potential problems early on. This might include checking for leaks, corrosion, or signs of malfunction.

- Filter/Media Replacement: Filters or adsorbents (such as activated carbon) used in many odor control systems require periodic replacement to maintain their effectiveness. This frequency depends on the system’s capacity and the concentration of odor compounds.

- Cleaning and Sanitization: Many systems require periodic cleaning and sanitization to prevent biofouling and maintain optimal performance. This is especially important for biofilters and scrubbers.

- Equipment Calibration: Regular calibration of sensors and control systems ensures accurate operation and monitoring of the odor control process.

- Preventative Maintenance: Following a schedule of preventive maintenance tasks helps to prevent equipment failures and extends the lifespan of the system.

A comprehensive maintenance plan, often including a preventive maintenance schedule and regular inspection reports, is essential for maximizing system performance and minimizing operational disruptions.

Q 15. How do you ensure the effectiveness of odor control measures?

Ensuring the effectiveness of odor control measures requires a multi-faceted approach. It starts with a thorough understanding of the odor source – identifying the specific compounds responsible for the unpleasant smell is crucial. This often involves using gas chromatography-mass spectrometry (GC-MS) for detailed analysis. Once the source is identified, we select appropriate control technologies. This might involve a combination of strategies. For example, we might implement source control measures such as modifying processes to reduce odor generation, coupled with treatment technologies like biofiltration or activated carbon adsorption to remove odorous compounds from the air stream.

Effectiveness is then monitored using both instrumental and sensory methods. Instrumental methods include using electronic noses and gas detectors to measure odor concentrations. Sensory methods, like olfactometry (measuring odor intensity using trained panelists), provide a human perception perspective. Regular monitoring, coupled with data analysis and adjustments to the control strategy, ensures optimal and continuous odor reduction.

For instance, I once worked with a rendering plant facing community complaints. After GC-MS analysis showed a high concentration of volatile organic compounds (VOCs), we implemented a combination of source control (process modifications) and a biofilter system. Regular olfactometry testing showed a significant reduction in perceived odor intensity, successfully resolving the issue.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the potential environmental impacts of odor control technologies?

Odor control technologies, while crucial for mitigating nuisance and public health risks, can have environmental impacts. For example, the disposal of spent activated carbon, a common adsorbent, needs careful management to avoid secondary pollution. Improper disposal could lead to landfill space issues and potential leaching of contaminants. Similarly, biofilters, while environmentally friendly in principle (using microbial action to break down odorants), can generate secondary waste streams like sludge which require proper treatment and disposal. The energy consumption associated with some technologies, like thermal oxidizers, needs to be considered in terms of greenhouse gas emissions.

A crucial aspect is the selection of environmentally friendly technologies and sustainable practices in disposal. Life cycle assessments (LCAs) of different odor control technologies can help us compare their overall environmental impacts and make informed decisions. For instance, we might prioritize technologies with low energy consumption and minimal waste generation, focusing on resource efficiency and waste minimization.

Q 17. How do you manage unexpected odor events?

Managing unexpected odor events demands a rapid response protocol. This begins with immediate identification of the source and magnitude of the odor release. We often utilize mobile odor monitoring equipment to assess the impact area and direction of plume movement. Based on the nature of the event (equipment failure, accidental release, etc.), we deploy appropriate emergency control measures. This could include the temporary shutdown of the odor source, the immediate activation of backup odor control systems, or the use of temporary odor masking agents.

Effective communication is also critical. We need to promptly inform affected parties (neighbors, regulatory agencies) and keep them updated on the situation and mitigation efforts. Post-incident, a thorough investigation is crucial to identify root causes and prevent future occurrences. This involves analyzing data from the monitoring equipment and potentially reviewing operational procedures. Corrective actions and improved safety protocols are implemented to improve resilience against future odor events.

Q 18. Explain your experience with different types of odor control equipment.

My experience encompasses a wide range of odor control equipment. I’ve worked extensively with biofilters, which use microorganisms to break down odorous compounds. These are environmentally friendly but require careful management of media and moisture content. I’ve also used activated carbon adsorption systems, which are effective for a variety of odorants but generate spent carbon requiring disposal. I have experience with scrubbers, which utilize liquid absorption to remove odorous gases, and thermal oxidizers, which use high temperatures to destroy odorous compounds – these are effective but energy intensive. I’ve also explored newer technologies like plasma oxidation and catalytic oxidation, which offer potential advantages in certain applications.

Choosing the right equipment depends on many factors, including the type and concentration of odorants, the air volume to be treated, and economic and environmental considerations. For example, in a small-scale application, a biofilter might be cost-effective and environmentally friendly; however, for large industrial operations, a thermal oxidizer might be necessary. My experience allows me to assess the specific needs and select the most appropriate and efficient technologies.

Q 19. How do you perform odor impact assessments?

Odor impact assessments aim to quantify the extent to which odors affect the surrounding environment and community. This involves both objective and subjective measurements. Objective measurements involve using gas chromatography-mass spectrometry (GC-MS) or electronic noses to quantify odorant concentrations. Subjective measurements rely on olfactometry – trained panelists assess the intensity and character of the odor.

The assessment typically includes meteorological data (wind speed, direction, stability), which are crucial for understanding odor dispersion patterns. We also map the location of odor sources and receptors (residential areas, businesses, etc.). Data analysis then helps determine the frequency, intensity, and duration of odor impacts at different locations. The results are typically presented as odor concentration maps or isopleths which show areas with similar odor levels.

In a real-world example, I performed an odor impact assessment for a wastewater treatment plant. We used a combination of GC-MS, olfactometry and dispersion modeling to establish the extent of odor impact within the surrounding neighborhood. This data informed the design and implementation of an effective odor control strategy.

Q 20. What software or tools do you use for odor modeling and prediction?

For odor modeling and prediction, I use various software packages including AERMOD, CALPUFF, and other specialized atmospheric dispersion models. These models utilize meteorological data and information about odor source characteristics (emission rates, stack height, etc.) to predict odor concentrations at various locations downwind.

Example input parameters for AERMOD might include: emission rate (g/s), stack height (m), wind speed (m/s), atmospheric stability class. The software then uses these data and complex algorithms to calculate the concentration of pollutants in the air at different distances and directions from the source. The output typically includes concentration maps, showing the predicted odor impact in the surrounding area. The software facilitates visualization and analysis of predicted odor plumes, enabling informed decision-making about odor control measures.

Q 21. Describe your experience with odor dispersion modeling.

Odor dispersion modeling is a crucial tool in predicting the spatial and temporal distribution of odors released into the atmosphere. It involves using specialized software (as mentioned above) to simulate how meteorological factors like wind speed, direction, and atmospheric stability influence odor plume movement and dilution. Accurate modeling requires detailed information about the odor source (location, emission rate, composition), as well as high-quality meteorological data.

My experience includes using these models to assess odor impacts from various sources, ranging from industrial facilities to agricultural operations. We use the model predictions to design effective odor control strategies and to comply with regulatory requirements. For example, by inputting different control scenarios into the model, we can compare the effectiveness of various control technologies in reducing odor impacts. This allows us to optimize our choices, ensuring the most efficient and cost-effective odor control solutions are implemented.

Q 22. How do you design and implement odor control systems for industrial facilities?

Designing and implementing odor control systems for industrial facilities is a multifaceted process that begins with a thorough understanding of the odor source. We start with a comprehensive site assessment, identifying the type and quantity of odorous compounds being emitted. This involves analyzing the process involved, identifying potential emission points, and measuring the concentration and composition of the odors using specialized equipment like gas chromatographs and olfactometers.

Based on this assessment, we select the most appropriate control technology. Options range from simple methods like improved ventilation and enclosure of odor sources, to more complex systems such as scrubbers (wet and dry), biofilters, thermal oxidizers, and carbon adsorption systems. The choice depends on factors including the type of odor, its concentration, the volume of air to be treated, and regulatory requirements and budget constraints.

For example, a rendering plant might benefit from a combination of anaerobic digestion to reduce odor at the source, followed by a biofilter to treat the remaining emissions before release. A chemical plant emitting volatile organic compounds (VOCs) might require a thermal oxidizer to combust the VOCs and render them odorless. The system design also includes considerations for safety, maintainability, and energy efficiency. Finally, we monitor the system’s performance to ensure it’s meeting the desired reduction in odor levels.

Q 23. How do you troubleshoot malfunctioning odor control equipment?

Troubleshooting malfunctioning odor control equipment requires a systematic approach. We begin by reviewing operating logs and performance data to pinpoint the potential problem area. This could indicate issues like pressure drops in scrubbers, reduced airflow in biofilters, or a decrease in carbon adsorption efficiency.

Next, we conduct a visual inspection of the equipment, checking for leaks, blockages, or signs of damage. This might involve inspecting piping, valves, pumps, filters, and other components. We’ll also analyze the odor itself – has the character or strength of the odor changed? This can help us narrow down the source of the malfunction.

For example, a reduction in scrubber efficiency might point to a problem with the scrubbing solution, such as low pH or depletion of active ingredients. A clogged biofilter could be the result of insufficient maintenance or an overload of organic compounds. Instrument readings such as pressure, temperature, and flow rate are crucial in diagnosing and solving such problems. Using specialized diagnostic tools and tests such as gas chromatography, we can obtain detailed chemical information of the treated air to further aid in pinpoint the issue. The ultimate goal is to restore the system’s functionality and ensure compliance with regulatory limits.

Q 24. How do you ensure compliance with relevant environmental regulations?

Ensuring compliance with environmental regulations is paramount. We begin by thoroughly researching all applicable local, regional, and national regulations regarding air quality and odor control. These regulations often specify allowable emission limits for various pollutants and odor concentrations, typically measured in odor units (OU). We incorporate these regulations into the design of the odor control system from the very beginning.

Throughout the project lifecycle, we conduct regular monitoring and testing to demonstrate compliance. This involves collecting air samples at designated points and analyzing their odor concentration using olfactometry, a sensory test that measures odor intensity through human panelists. We also use instrumental techniques such as gas chromatography-mass spectrometry (GC-MS) to identify and quantify specific odorous compounds. We maintain detailed records of all monitoring data, and prepare comprehensive reports to demonstrate ongoing compliance with all applicable regulations. We also work closely with regulatory agencies to ensure transparency and proactively address any concerns.

Q 25. How do you communicate technical information about odor control to non-technical audiences?

Communicating technical information about odor control to non-technical audiences requires clear, concise, and relatable language. I avoid using jargon as much as possible, preferring simple analogies to explain complex concepts. For example, instead of saying “the biofilter exhibits reduced efficiency due to microbial inhibition,” I might say, “Think of the biofilter as a garden – if the soil becomes unhealthy, the plants won’t grow as well. Similarly, if the microorganisms in the biofilter are stressed, they won’t break down the odors effectively.”

I use visual aids like diagrams, charts, and photographs to enhance understanding. I also tailor my communication style to the audience’s level of knowledge and their primary concerns. For example, when communicating with plant managers, I would emphasize cost-effectiveness and compliance; when communicating with community members, I would highlight public health and environmental protection. Ultimately, effective communication is crucial for building trust and ensuring successful implementation of odor control projects.

Q 26. Describe your experience with project management in odor control projects.

My experience in project management for odor control projects encompasses all phases, from initial client consultation to system commissioning and ongoing maintenance. I’m proficient in developing detailed project plans, managing budgets, and scheduling tasks to ensure projects are completed on time and within budget. I have experience working with multidisciplinary teams, including engineers, contractors, and regulatory personnel. I employ project management methodologies like Agile and Waterfall, adapting them based on the specific project needs.

For example, in one recent project involving a large-scale poultry farm, I successfully managed the design, procurement, and installation of a comprehensive odor control system involving a combination of biofiltration and activated carbon adsorption. This involved coordinating with numerous stakeholders, including the farm owners, contractors, and environmental regulators. I meticulously tracked progress using project management software and held regular meetings to ensure everyone was informed and aligned. My leadership and ability to handle unforeseen challenges were instrumental in completing the project successfully, and on time.

Q 27. What are the key performance indicators (KPIs) for successful odor control?

Key Performance Indicators (KPIs) for successful odor control projects vary depending on the specific context, but some common ones include:

- Odor Concentration Reduction: Measured in odor units (OU) or parts per billion (ppb) of specific odorous compounds. This shows the system’s effectiveness in reducing odor intensity.

- Compliance with Regulatory Limits: Demonstrates adherence to environmental regulations and permits.

- System Uptime: Measures the percentage of time the system operates without malfunctions. High uptime indicates system reliability.

- Operational Costs: Includes energy consumption, maintenance costs, and replacement of consumables like scrubbing solutions or activated carbon.

- Community Feedback: Surveys and complaints can gauge public perception of odor levels and overall project success.

These KPIs are tracked continuously and used to fine-tune the system’s performance and optimize operational efficiency. Regular reporting ensures transparency and informs decision-making related to maintenance, upgrades, or further improvements.

Q 28. How do you stay up-to-date with the latest advancements in odor control technology?

Staying updated with the latest advancements in odor control technology is critical. I accomplish this through several channels:

- Professional Organizations: Active membership in organizations like the Air & Waste Management Association (AWMA) provides access to conferences, publications, and networking opportunities.

- Industry Publications and Journals: Regularly reading trade magazines and scientific journals keeps me abreast of new technologies and research findings.

- Conferences and Workshops: Attending industry conferences and workshops allows me to learn about cutting-edge technologies and best practices from experts in the field.

- Online Resources and Databases: Utilizing online databases and resources provides access to a wealth of information on odor control technologies, regulations, and research.

- Collaboration and Networking: Maintaining connections with colleagues and industry experts fosters the exchange of knowledge and insights.

This continuous learning ensures that I am always equipped with the most up-to-date knowledge and techniques to design, implement, and manage the most effective and efficient odor control systems.

Key Topics to Learn for Odor Control Techniques Interview

- Source Identification and Characterization: Understanding the origin and chemical composition of odors is crucial for effective control. Learn methods for odor source identification and sampling techniques.

- Odor Control Technologies: Familiarize yourself with various odor control methods, including absorption, adsorption, biofiltration, thermal oxidation, and masking agents. Understand the principles behind each technology and their respective applications.

- Air Pollution Control Regulations and Standards: Know the relevant environmental regulations and industry standards related to odor control. This includes permissible emission limits and compliance procedures.

- Odor Dispersion Modeling: Learn about atmospheric dispersion modeling and its role in predicting odor impact and designing effective control strategies. Understand the factors that influence odor plume behavior.

- Practical Application and Case Studies: Review case studies of successful odor control projects in various industries (e.g., wastewater treatment, landfills, agriculture). Analyze the challenges faced and solutions implemented.

- Troubleshooting and Problem Solving: Develop your ability to diagnose odor problems, identify the root causes, and propose effective solutions. Practice analyzing scenarios and designing mitigation strategies.

- Instrumentation and Monitoring: Understand the various instruments and techniques used for odor monitoring and measurement, such as olfactometry and gas chromatography-mass spectrometry (GC-MS).

- Economic and Sustainability Considerations: Explore the economic aspects of odor control, including cost-benefit analysis and life-cycle assessments. Understand the importance of sustainable and environmentally friendly practices.

Next Steps

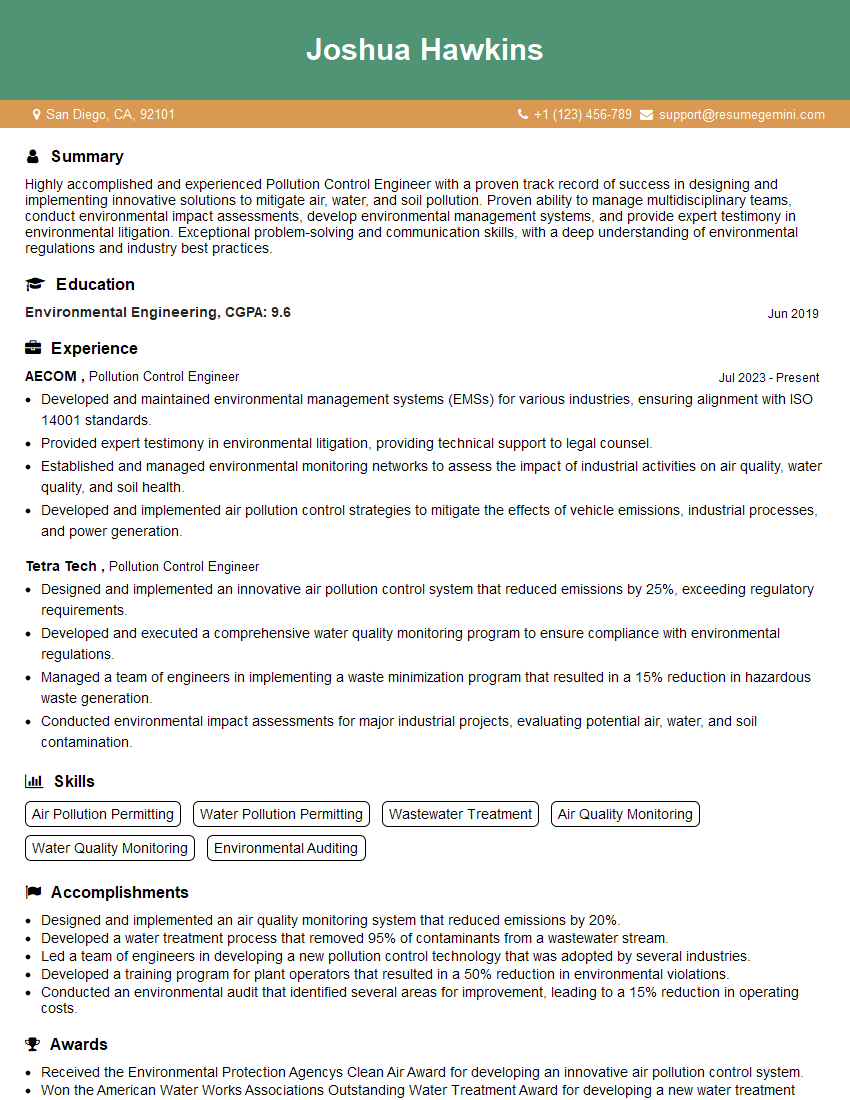

Mastering Odor Control Techniques opens doors to exciting career opportunities in environmental engineering, industrial hygiene, and related fields. A strong understanding of these principles is highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored specifically to Odor Control Techniques to give you a head start. Invest in crafting a compelling resume—it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.