The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Use of Glazing Equipment and Tools interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Use of Glazing Equipment and Tools Interview

Q 1. What types of glazing tools are used for cutting glass?

Several tools are used for cutting glass, each suited for different thicknesses and types of glass. The most common is the glass cutter, a handheld tool with a hardened steel wheel that scores the glass. For thicker glass, a wet saw or circular saw with a diamond blade provides a cleaner, more precise cut. Specialized tools like nippers are used to break glass along a scored line, and glass grinders smooth rough edges after cutting.

- Glass Cutter: Uses a rotating wheel to score the glass, allowing it to break cleanly along the score line.

- Wet Saw: Uses a water-cooled diamond blade for precise cutting of thicker glass, minimizing chipping and cracking.

- Nippers: Handheld tools that apply pressure to the scored line, snapping the glass cleanly.

- Glass Grinder: Used for smoothing and refining the edges of cut glass for safety and aesthetics.

Q 2. Describe the safety procedures for using a glass cutter.

Safety is paramount when working with glass. Always wear safety glasses to protect your eyes from flying debris. Use a cutting mat or firm, flat surface to support the glass and prevent slipping. Score the glass firmly with a single, even stroke, avoiding multiple passes. When snapping the glass, use gloves to protect your hands and apply pressure evenly to avoid shattering. Never apply excessive force. After cutting, carefully handle the sharp edges with gloves or use a grinder to smooth any rough edges. Dispose of glass fragments responsibly in a sturdy container marked for sharp objects.

Imagine you’re handling a delicate antique – care and precision are essential for preventing injury and maintaining the integrity of your work.

Q 3. Explain the process of installing a window with insulating glass units (IGUs).

Installing insulating glass units (IGUs) requires precision and care. First, carefully measure the window opening to ensure a snug fit. Next, prepare the frame, ensuring it’s clean, level, and properly sealed. The IGU, which is a sealed unit containing two or more panes of glass with a spacer in between for insulation, is then carefully positioned in the frame. Use appropriate shims to maintain levelness and prevent stress on the IGU. Apply glazing sealant around the perimeter of the IGU to seal it into the frame and ensure weather resistance. Finally, install the interior and exterior trim to complete the installation.

Think of it like assembling a high-precision puzzle: each step must be executed precisely to ensure a long-lasting, energy-efficient installation.

Q 4. How do you measure and cut glass for a specific window opening?

Accurately measuring and cutting glass requires meticulous attention to detail. Measure the window opening’s height and width precisely, noting any existing frames or other constraints. Add allowances for the glazing material, frame depth, and desired spacing around the edges. Always measure twice and cut once! Transfer these measurements to your glass sheet. Using the appropriate glass cutting tools (as described previously), score the glass along the marked lines and carefully snap it. Double-check your cut against your measurements to ensure accuracy before proceeding with installation.

Precision is key here. A small error in measurement can lead to a misfit that compromises the window’s integrity and aesthetics. An example scenario would involve measuring a window opening of 36 inches by 24 inches; you may need to add an inch or more to each dimension for glazing material and frame depth.

Q 5. What are the different types of glazing systems?

Several glazing systems exist, each with unique properties. Single glazing uses a single pane of glass, while double glazing (or double-pane) incorporates two panes separated by an air or gas-filled space. Triple glazing has three panes with two spaces for enhanced insulation. Laminated glass combines multiple layers of glass with an interlayer of polyvinyl butyral (PVB) for increased strength and safety. Tempered glass is heat-treated to enhance its strength and shatter resistance. Curtain wall systems are used in large buildings to create large glass facades.

The choice of system depends on factors such as energy efficiency needs, safety requirements, aesthetic preferences, and budget.

Q 6. What are the common causes of glass breakage during installation?

Several factors can contribute to glass breakage during installation. Improper handling, such as dropping or applying excessive force, can cause cracks or shattering. Uneven support during cutting or installation can lead to stress and breakage. Excessive pressure on the glass during installation from improperly fitted frames or shims can cause cracking. Impact damage from tools or other objects can also break the glass. Temperature fluctuations can stress the glass, making it more susceptible to breakage. Finally, using the wrong cutting tools or techniques can lead to chipping and cracking.

Careful planning and execution are vital to prevent any mishap. The most common causes stem from haste or neglect of necessary safety measures.

Q 7. How do you handle different types of glass, such as tempered or laminated glass?

Handling different types of glass requires different approaches. Tempered glass is extremely strong but shatters into small, relatively harmless pieces when broken. Avoid scoring tempered glass, as this can weaken it and make it prone to spontaneous shattering. Laminated glass, when broken, holds together due to the interlayer, preventing sharp fragments from scattering. This requires extra care during cutting to prevent delamination. Special scoring techniques and tools might be needed for both types. For both, protective eyewear is essential during cutting and handling.

Think of it like handling different types of materials – some are more delicate and require gentler handling than others.

Q 8. Explain the importance of proper sealant application in glazing.

Proper sealant application is paramount in glazing because it forms the crucial weatherproof barrier, preventing water ingress, air leakage, and the ingress of pollutants. Think of it as the glue that holds the entire system together, ensuring longevity and performance. A poorly applied sealant compromises the structural integrity, leading to potential failure and costly repairs.

For example, a gap left unsealed around a window pane can lead to drafts, condensation, and eventually, damage to the window frame and surrounding building materials. It also impacts the energy efficiency of the building as heat escapes and conditioned air leaks out.

Q 9. What types of sealants are used in glazing, and what are their properties?

Several types of sealants are employed in glazing, each with unique properties suitable for specific applications. The choice depends on factors such as the material being sealed, the environmental conditions, and the desired performance characteristics.

- Silicone Sealants: These are highly versatile, offering excellent adhesion to various substrates, including glass, metal, and stone. They are flexible, weather-resistant, and durable, making them ideal for exterior applications. However, they can be more challenging to clean up.

- Polyurethane Sealants: Known for their high strength and elasticity, polyurethane sealants are also commonly used. They provide a robust seal and offer good resistance to UV degradation. They come in various hardnesses to suit different needs.

- Butyl Sealants: These are particularly good for applications requiring high adhesion and moisture resistance. They are often used as primary seals in insulated glass units (IGUs). They are also very durable, offering excellent long-term performance.

- Polysulfide Sealants: These are renowned for their excellent flexibility and movement capability, making them suitable for applications with significant structural movement, like large curtain walls.

Selecting the wrong sealant can lead to premature failure, leaks, and costly repairs. It’s essential to consult technical data sheets and follow manufacturer’s instructions for optimal performance.

Q 10. Describe the process of installing a curtain wall system.

Installing a curtain wall system is a complex process requiring precision and expertise. It typically involves several stages:

- Fabrication: The frames and panels are manufactured off-site to precise specifications.

- Framing Installation: The primary structural frame is anchored to the building’s structure. This stage requires careful surveying and precise measurements to ensure alignment and plumbness.

- Panel Installation: The prefabricated glass panels are carefully lifted into place and secured within the framework. Specialized lifting equipment and harnesses are commonly used for larger panels.

- Sealant Application: Sealants are applied to all joints and seams to create a weatherproof barrier. This requires meticulous attention to detail to avoid gaps and ensure a complete seal.

- Inspection and Testing: The entire system is thoroughly inspected to verify proper installation, alignment, and sealing. Air leakage testing may be performed to confirm the system’s air tightness.

The process necessitates a coordinated team of skilled professionals, including engineers, fabricators, and installers. Any errors during any stage can compromise the structural integrity, performance, and safety of the system.

Q 11. What are the challenges in working with large glass panels?

Handling large glass panels presents unique challenges. Their sheer size and weight necessitate specialized equipment and techniques. Some key challenges include:

- Transportation and Handling: Moving and positioning large glass panels requires specialized equipment like vacuum lifters and cranes to avoid breakage.

- Installation Precision: Aligning and installing large panels accurately is crucial to prevent stress and potential cracking. This necessitates precise measurements and careful coordination.

- Safety Risks: The risk of injury from dropped glass is significant, demanding strict adherence to safety protocols and the use of personal protective equipment.

- Wind Loads: In tall buildings, wind loads can exert significant pressure on large glass panels, requiring the use of robust framing and anchoring systems.

For example, I once worked on a project where a large panel cracked during installation due to an unforeseen slight misalignment. This led to costly delays and replacements, emphasizing the importance of precision and careful planning.

Q 12. How do you ensure proper alignment and levelness during installation?

Ensuring proper alignment and levelness is crucial for both aesthetics and structural integrity. This is achieved through a combination of careful planning, precise measurements, and the use of specialized tools:

- Precise Measurements: Laser levels, plumb bobs, and measuring tapes are used to establish reference points and ensure accuracy during installation.

- Leveling Systems: Adjustable shims and wedges are employed to fine-tune the alignment of panels and frames.

- Frame Anchoring: Proper anchoring of the framework to the building structure is essential for long-term stability and to prevent movement that could lead to misalignment.

- Regular Inspections: Throughout the installation process, regular inspections are conducted to verify alignment and make any necessary adjustments.

The use of advanced leveling systems and regular checks minimizes the risks of misalignment, ensuring the long-term durability and performance of the glazing system.

Q 13. What safety equipment is essential when working with glass?

Safety is paramount when working with glass. Essential safety equipment includes:

- Safety Glasses or Goggles: To protect the eyes from flying debris.

- Gloves: To protect hands from cuts and abrasions.

- Hard Hats: To protect the head from falling objects.

- Safety Harness and Fall Protection: Essential when working at heights.

- Cut-Resistant Clothing: Provides an additional layer of protection against cuts from broken glass.

- Vacuum Lifters and Suction Cups: Safe handling of glass panels.

Regular safety briefings and adherence to established safety procedures are equally crucial to ensure a safe working environment. Ignoring safety protocols can result in serious injuries.

Q 14. How do you troubleshoot common glazing problems?

Troubleshooting glazing problems requires a systematic approach. Common issues and solutions include:

- Leaks: Examine sealant joints for gaps or cracks. Repair or replace damaged sealant. Check for issues with the flashing system.

- Condensation: Investigate the integrity of insulated glass units (IGUs). Check for air leaks that allow moisture ingress.

- Cracked Glass: Determine the cause (impact, thermal stress, improper installation). Replace the damaged panel.

- Misalignment: Check the framing system for proper alignment and make adjustments using leveling shims or wedges.

A thorough inspection is the first step. Knowing the type of glazing system, materials used and the building’s environment helps pinpoint the root cause and facilitates effective solutions. It’s crucial to maintain detailed records during installation to help in troubleshooting later.

Q 15. What are the different types of glazing beads and their applications?

Glazing beads are the small, decorative strips that hold the glass in place within a window or door frame. They come in various materials and styles, impacting both the aesthetic and functional aspects of the glazing.

- PVC Glazing Beads: These are the most common type, offering a balance of affordability and durability. They’re easy to install and come in a wide range of colors to match different frames. Think of them as the workhorses of the glazing bead world.

- Wooden Glazing Beads: These offer a more traditional and aesthetically pleasing look, often used in period properties or where a more rustic feel is desired. They’re usually more expensive and require more careful handling to prevent damage.

- Aluminum Glazing Beads: Often used in commercial settings or where durability and weather resistance are paramount. They are strong and less prone to warping or cracking compared to wood or PVC.

- Rubber Glazing Beads: These provide a great seal, particularly useful in applications where soundproofing or weatherproofing is crucial. However, they’re less common in standard window installations.

The application of glazing beads depends heavily on the type of frame, the desired aesthetic, and the specific requirements of the project. For instance, a historic building restoration might call for wooden beads to maintain authenticity, while a modern commercial building might opt for durable aluminum beads for longevity and low maintenance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper ventilation when working with sealants.

Proper ventilation when working with sealants is absolutely crucial for both health and safety reasons and to ensure proper sealant cure. Sealants often contain volatile organic compounds (VOCs) that can be harmful if inhaled in poorly ventilated spaces. Inadequate ventilation can lead to headaches, dizziness, and in severe cases, more serious health problems.

Furthermore, some sealants require specific temperature and humidity levels to cure properly. Poor ventilation can affect the humidity levels, potentially leading to poor adhesion, cracking, and a shorter lifespan for the sealant. Think of it like baking a cake; you need the right environment for it to rise properly. Similarly, sealants need the right environment to cure correctly.

In a professional setting, we always ensure adequate ventilation, often using exhaust fans or opening windows, especially when working with large quantities of sealant in enclosed spaces. Wearing appropriate respiratory protection is also a must.

Q 17. How do you calculate the amount of sealant needed for a specific project?

Calculating sealant quantity requires careful measurements and consideration of several factors. It’s not simply a case of filling the gaps! We need to accurately measure the bead size (width and depth of the sealant joint), the length of the joint, and then account for any waste or overlaps.

For example, if we are sealing a window frame with a 10mm wide by 5mm deep bead around a perimeter of 2 meters, we calculate the volume:

Volume = Width x Depth x Length = 10mm x 5mm x 2000mm = 100,000 mm³

Then convert mm³ to ml (1 mm³ = 10⁻³ ml): 100,000 mm³ = 100 ml. However, this is an idealized calculation. We always add an extra 10-20% to account for waste during application and ensure we have sufficient material to complete the job properly.

More complex projects, such as larger glass panels or intricate designs, may require more sophisticated calculations and the use of specialized software or industry standards to ensure accurate estimations.

Q 18. What are the different methods for cleaning glass after installation?

Cleaning glass after installation is crucial to maintain its pristine appearance and prevent damage. Different cleaning methods are suitable for different types of glass and sealants.

- For newly installed glass: Use a soft, lint-free cloth and a solution of warm water and mild detergent. Avoid abrasive cleaners or harsh chemicals that could scratch the surface. After washing, rinse thoroughly with clean water and dry with a clean, soft cloth to prevent water spots.

- For stubborn residue: A glass scraper may be necessary to remove excess sealant or paint. However, exercise caution and use the scraper gently to avoid scratching the glass. Isopropyl alcohol can effectively remove some types of adhesive residue.

- For specific sealant types: Some sealants require a specific cleaner to ensure they’re removed without damaging the glass. Consult the sealant manufacturer’s instructions.

It’s essential to allow sufficient drying time for the sealant before cleaning. Premature cleaning can damage the curing process and lead to issues in the long run.

Q 19. Describe the process of repairing a cracked or broken window pane.

Repairing a cracked or broken window pane depends heavily on the extent of the damage and the type of glass. Small chips or cracks might be manageable, while large breaks usually necessitate replacement.

For minor cracks: Specialized glass repair kits are available that inject a resin into the crack to fill it and restore structural integrity. This is a temporary solution and won’t restore the glass’s original strength, but it can prevent further cracking and enhance the aesthetic appeal. It’s crucial to follow the manufacturer’s instructions precisely for best results.

For major breaks: Replacement is the only viable option. This involves carefully removing the broken pane, measuring the dimensions precisely, ordering a replacement pane (matching thickness and type), and then carefully reinstalling it using the appropriate glazing techniques and materials. Safety is paramount during this process, so using appropriate safety glasses and gloves is crucial.

Q 20. How do you handle waste materials during a glazing project?

Responsible waste management is a cornerstone of any professional glazing project. We must adhere to local regulations and environmental best practices.

- Segregation: Different waste materials need to be separated. Glass should be disposed of separately for potential recycling. Excess sealant, packaging materials, and other debris should be sorted accordingly.

- Recycling: Glass is readily recyclable in many regions. Properly disposing of the glass in designated recycling bins is crucial for environmental responsibility.

- Hazardous Waste: Some sealants and cleaning agents may be considered hazardous waste and require special handling and disposal methods. Always consult local regulations and safety data sheets (SDS).

- Disposal: Follow all local ordinances related to construction and demolition waste disposal. This might involve using licensed waste removal services for specific types of materials.

Proper waste management not only protects the environment but also ensures compliance with legal requirements and reduces the risk of fines or penalties.

Q 21. What are the building codes and regulations related to glazing?

Building codes and regulations related to glazing are extensive and vary depending on location (national, regional, and local). These regulations are primarily focused on safety and energy efficiency.

- Safety Glass: Many jurisdictions mandate the use of safety glass (e.g., tempered or laminated glass) in certain applications, particularly those involving high-impact risks or areas where shattering could cause injury. Think of shower enclosures or storefront windows.

- Energy Efficiency: Regulations often dictate minimum performance standards for glazing to ensure energy efficiency. This might include requirements for U-values (heat transfer coefficient) and solar heat gain coefficient (SHGC).

- Wind Load Resistance: Glazing must be able to withstand the expected wind loads in the specific region. This is especially important in areas prone to high winds or hurricanes.

- Impact Resistance: Building codes often specify impact resistance requirements for glazing in areas prone to vandalism or other impacts.

It’s absolutely essential for glazing professionals to be fully aware of the relevant building codes and regulations in their area to ensure compliance and protect both the occupants and the structural integrity of the building. Failing to comply can result in significant penalties and legal issues.

Q 22. What experience do you have with different types of glazing equipment?

My experience with glazing equipment spans a wide range, encompassing both manual and automated systems. I’m proficient in using suction cups, glazing tools, and various types of sealant applicators for smaller projects. For larger-scale installations, I’m experienced with automated glazing robots and cranes used for lifting and positioning large glass units. This includes experience with equipment specifically designed for handling different glass types, such as insulated glazing units (IGUs) and curved glass. I’ve also worked extensively with specialized equipment for cutting, grinding, and polishing glass to precise specifications. For instance, I’ve utilized CNC glass cutting machines to achieve intricate designs and ensure consistent accuracy.

- Suction Cups: Essential for handling individual glass panes safely and efficiently.

- Glazing Tools: Includes spacers, wedges, and sealant guns for precise installation.

- Automated Glazing Robots: Increase efficiency and precision, especially on large projects.

- CNC Glass Cutting Machines: Allow for precise and intricate cuts in various glass types.

Q 23. Describe a situation where you had to troubleshoot a glazing problem. What was the solution?

During a recent high-rise building project, we encountered a problem with consistent sealant adhesion on an IGU installation. We noticed inconsistent bead formation, leading to potential air leakage and compromised energy efficiency. After eliminating issues with surface preparation (cleaning and priming), we investigated the sealant itself and the application technique. The problem wasn’t the sealant’s quality, but its temperature. The sealant had been stored in a location exposed to direct sunlight, causing it to thicken and become less adhesive. The solution involved moving the sealant to a climate-controlled storage area and adjusting the application gun settings to ensure proper flow and consistency. We also implemented a more rigorous quality check process on each IGU before installation.

Q 24. What are the pros and cons of different glazing materials?

Different glazing materials offer a unique blend of advantages and disadvantages. Let’s compare two common examples: laminated glass and annealed glass.

- Laminated Glass:

- Pros: Superior safety due to its interlayer, which holds the glass together during breakage; improved sound insulation; higher resistance to impact and penetration; UV protection.

- Cons: More expensive than annealed glass; can be more difficult to cut and work with; may delaminate over time under certain conditions.

- Annealed Glass (float glass):

- Pros: Inexpensive; readily available; easily cut and shaped.

- Cons: Shatters into sharp fragments upon breakage; offers less sound and UV protection; relatively weak compared to other types of glass.

The best choice depends heavily on the project’s specific requirements and budget.

Q 25. How do you ensure the structural integrity of the glazing system?

Ensuring structural integrity in a glazing system is paramount. This involves several key considerations:

- Proper Frame Design: The frame must be adequately sized and strong enough to support the weight of the glass and withstand environmental loads (wind, snow, seismic activity).

- Appropriate Fasteners and Sealants: High-quality fasteners, correctly installed, are crucial for holding the glass securely. Suitable sealants are essential to prevent water ingress and maintain a strong bond.

- Accurate Measurements and Installation: Precise measurements are vital to avoid gaps or stress concentrations in the system. Careful installation techniques ensure proper alignment and stability.

- Load Calculations and Engineering: For larger projects, structural engineering calculations are necessary to ensure the system can handle anticipated loads.

- Regular Inspections: Routine checks for signs of damage, deterioration, or movement are critical for proactive maintenance and safety.

Imagine building a house – a weak foundation will eventually cause problems, no matter how nice the rest of the building looks. Similarly, if any of these steps are skipped, the entire glazing system will be at risk.

Q 26. Explain the importance of using the right type of glazing for different climates.

Climate plays a significant role in glazing material selection. In hot climates, low-E glass (low-emissivity) helps reduce solar heat gain, keeping interiors cooler and reducing energy costs. In cold climates, the same low-E glass can help retain heat and lower heating costs. Consider the U-value (thermal transmittance) and solar heat gain coefficient (SHGC) when selecting glass for different climates. For coastal regions, impact-resistant glass may be needed to withstand strong winds and potential debris. High altitudes may necessitate glass with greater resistance to UV radiation.

For instance, selecting a single-pane annealed glass in a cold, snowy region is inefficient and could lead to excessive heat loss. Choosing laminated glass with a high U-value would be a far better option.

Q 27. How do you maintain and clean glazing equipment to ensure optimal performance?

Maintaining and cleaning glazing equipment is crucial for optimal performance and longevity. Regular cleaning removes debris, sealant residue, and other contaminants that can interfere with operation or damage equipment. Suction cup systems need regular inspection and cleaning to ensure they maintain their grip. Automated equipment should be inspected according to manufacturer recommendations, and any necessary lubrication or adjustments should be performed by qualified personnel. Proper storage in a clean, dry environment will help to prevent corrosion and premature wear. Always refer to the manufacturer’s manual for specific cleaning and maintenance guidelines.

Think of it like maintaining your car; regular maintenance prevents costly repairs and keeps it running smoothly for longer.

Q 28. Describe your experience with different types of glass and their applications.

My experience encompasses a variety of glass types, each suitable for different applications:

- Annealed Glass (Float Glass): The most common type, used for windows, doors, and general glazing applications due to its low cost and ease of fabrication.

- Tempered Glass (Heat-Strengthened Glass): Stronger than annealed glass, often used in safety-critical applications like shower enclosures, automotive windshields, and storefront windows.

- Laminated Glass: Composed of two or more layers of glass bonded with an interlayer (typically PVB), offering increased safety and security, sound insulation, and UV protection. Ideal for high-traffic areas or security applications.

- Insulated Glass Units (IGUs): Composed of two or more panes of glass separated by a spacer containing desiccant, maximizing energy efficiency by reducing heat transfer. Common in modern windows.

- Curved Glass: Used for architectural features, providing aesthetic appeal and sometimes improved structural performance. Requires specialized equipment for fabrication.

The choice of glass type depends on the specific needs of the application, considering factors such as safety, energy efficiency, aesthetics, and cost.

Key Topics to Learn for Use of Glazing Equipment and Tools Interview

- Safety Procedures and Regulations: Understanding and adhering to all safety protocols when operating glazing equipment and handling tools. This includes personal protective equipment (PPE) usage and emergency procedures.

- Types of Glazing Equipment: Familiarizing yourself with various types of glazing equipment, such as glass cutters, suction cups, sealant applicators, and glazing beads. Understanding their functionality and limitations is key.

- Glazing Techniques: Mastering different glazing techniques, including cutting, measuring, fitting, and sealing glass units. Practical experience and theoretical understanding are both crucial.

- Material Properties and Selection: Knowledge of different types of glass (e.g., annealed, tempered, laminated) and their appropriate applications. Understanding sealant types and their compatibility with various substrates.

- Troubleshooting and Maintenance: Identifying and resolving common issues with glazing equipment and tools. Performing routine maintenance and recognizing signs of wear and tear to ensure optimal performance and safety.

- Quality Control and Inspection: Understanding quality control procedures for glazing installations. Knowing how to inspect completed work for defects and ensuring it meets industry standards.

- Reading and Interpreting Blueprints/Specifications: Accurately interpreting technical drawings and specifications to ensure correct installation of glazing units.

Next Steps

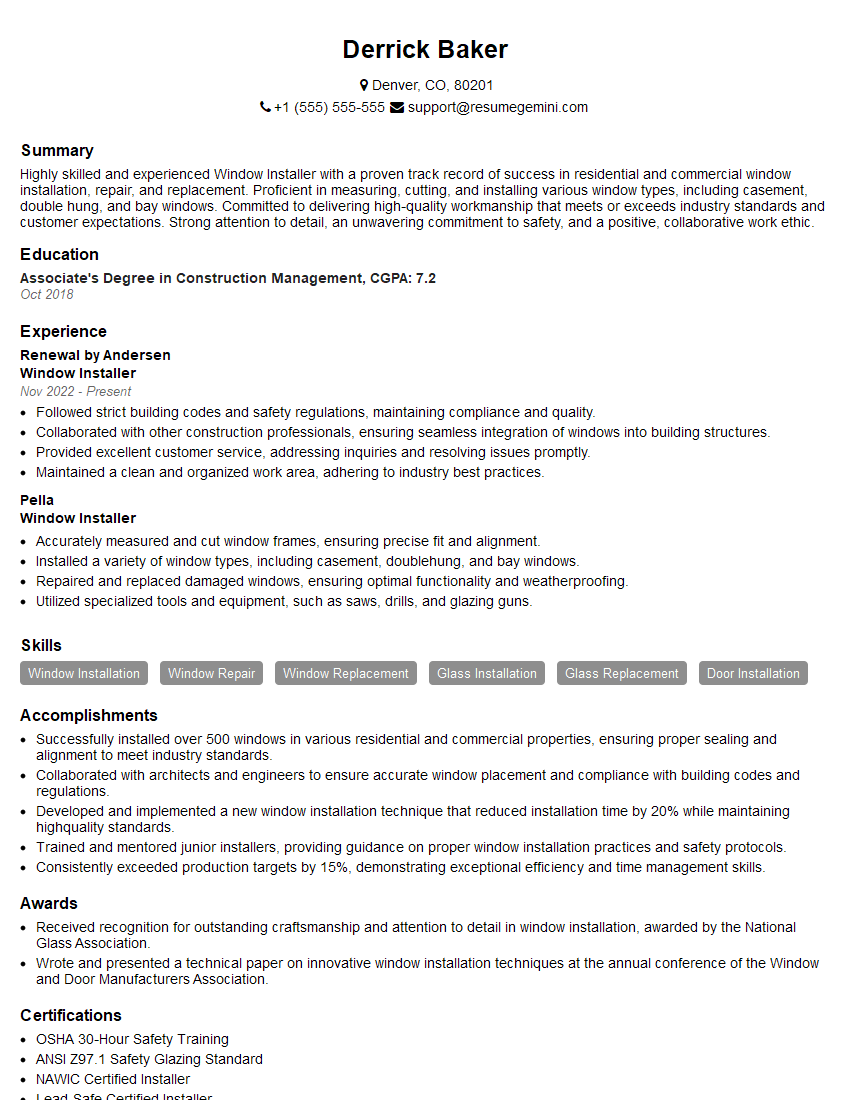

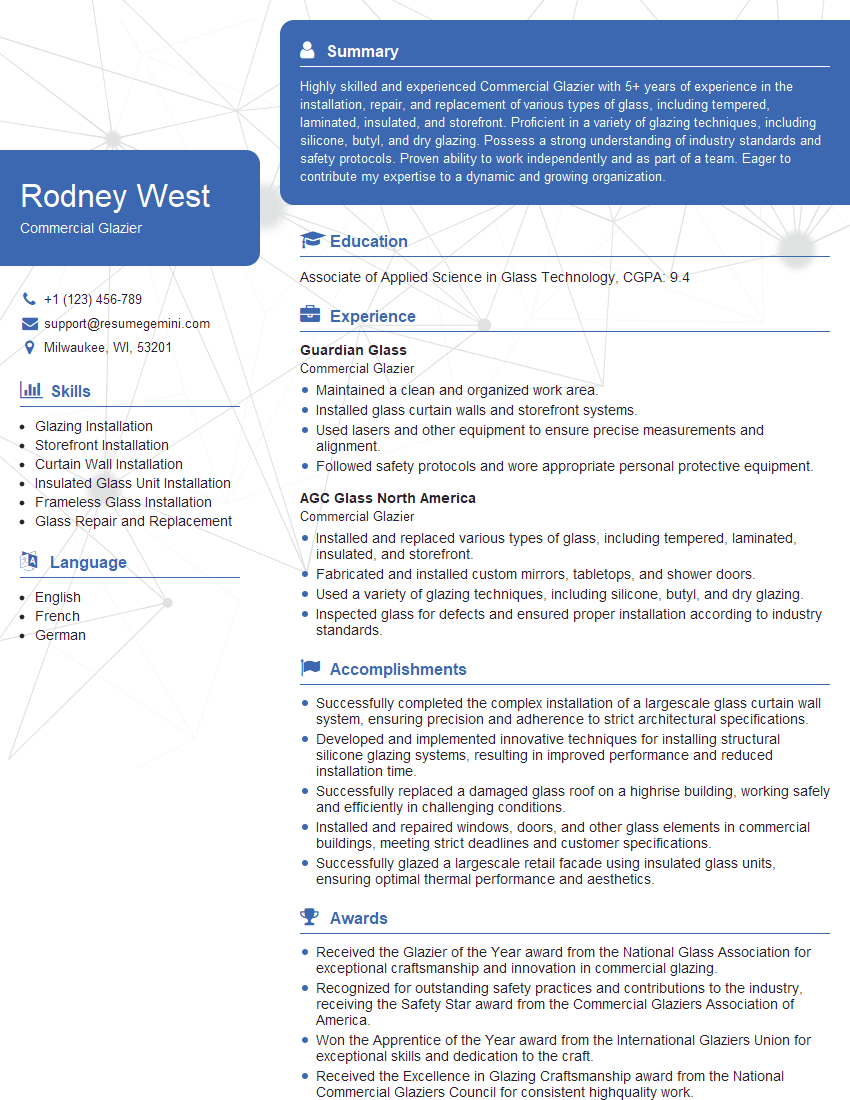

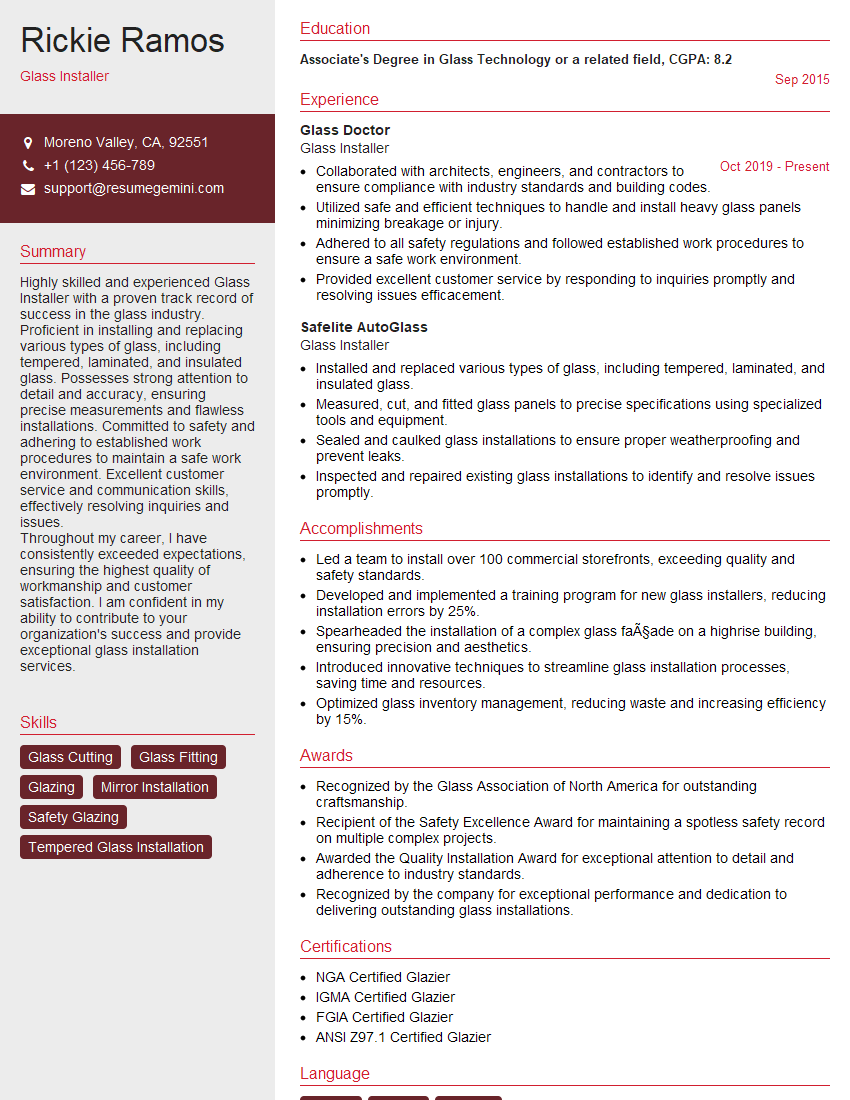

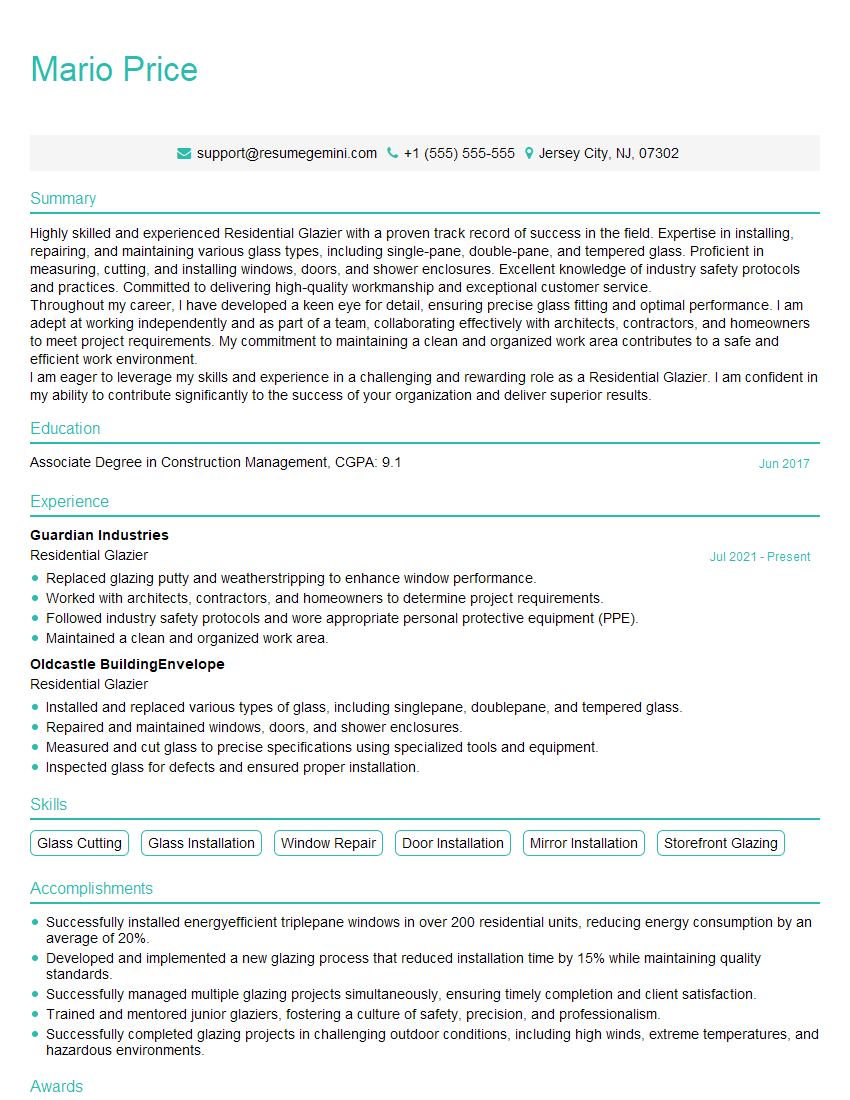

Mastering the use of glazing equipment and tools is essential for career advancement in the construction and glazing industries. A strong understanding of these skills demonstrates competence, efficiency, and a commitment to safety, opening doors to more challenging and rewarding opportunities. To maximize your job prospects, it’s vital to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes that get noticed by recruiters. We offer examples of resumes tailored to showcasing expertise in Use of Glazing Equipment and Tools, to help you present yourself in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.