Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Ductwork Sealing interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Ductwork Sealing Interview

Q 1. What types of sealants are commonly used in ductwork sealing?

Selecting the right sealant is crucial for effective ductwork sealing. The choice depends on the duct material, the environment, and the specific application. Commonly used sealants include:

- Mastics: These are rubber-based, easy-to-apply sealants ideal for most ductwork materials. They offer good adhesion and flexibility, accommodating minor movements in the ductwork.

- Sealants with foil backing: These are particularly useful for sealing seams in flexible ductwork or for applications where a more robust, vapor barrier is needed. They are often self-adhesive, simplifying the installation.

- Butyl rubber sealants: These are durable and weather-resistant, often chosen for outdoor ductwork or areas with extreme temperature fluctuations.

- Polyurethane foam sealants: While effective for filling gaps, these need careful application to avoid over-expansion and damage to the ductwork. They’re best for larger gaps or irregular surfaces.

- Acrylic latex caulk: This is a relatively inexpensive option, best suited for smaller gaps and non-critical applications. It’s less durable than other options and may not be suitable for high-temperature environments.

Think of choosing a sealant like choosing the right glue – you wouldn’t use superglue to mend a delicate piece of fabric; similarly, choosing the right sealant ensures longevity and performance.

Q 2. Explain the importance of proper ductwork sealing in energy efficiency.

Proper ductwork sealing is paramount for energy efficiency. Unsealed ducts leak conditioned air, forcing your HVAC system to work harder to maintain the desired temperature. This leads to increased energy consumption and higher utility bills. Imagine your house as a thermos – if the thermos has cracks, the hot or cold liquid inside will escape quickly, requiring more energy to keep it at the desired temperature. Similarly, leaky ducts reduce the efficiency of your HVAC system by up to 30%, costing you significant money annually.

By sealing the ducts, you minimize air leaks, improving the system’s effectiveness and reducing the strain on your HVAC equipment. This leads to lower energy consumption, reduced wear and tear on the system, and significant cost savings over time.

Q 3. Describe different methods for sealing various ductwork materials (e.g., galvanized steel, fiberglass).

Sealing methods vary depending on the duct material:

- Galvanized Steel: Seams in galvanized steel ducts are typically sealed using mastic sealant applied with a caulking gun. For larger gaps, a backer rod can be inserted before applying the mastic to ensure a proper seal. Metal tape can also be used to reinforce the seal, especially in high-vibration areas.

- Fiberglass: Fiberglass ductwork often uses foil-backed sealants or specialized tapes designed for flexible ductwork. These are applied by pressing firmly onto the seams to ensure a tight bond. For larger gaps or connections, mastic sealant can be used in conjunction with the tape.

- Flexible Ductwork: Flexible ductwork requires careful attention to sealing connections and seams. Mastics, foil tapes, or self-adhesive sealants are commonly used, ensuring a strong and airtight seal to prevent air leakage.

Remember, thorough surface preparation is crucial before applying any sealant. Cleaning the surfaces to remove dust, debris, and any existing sealant ensures optimal adhesion.

Q 4. How do you identify and address air leaks in a ductwork system?

Identifying air leaks requires a systematic approach. One common method is using a duct blaster or smoke pencil. This involves introducing a non-toxic smoke into the ductwork. Leaks will be visible as the smoke escapes from the openings. Another method uses a thermal imaging camera to detect temperature differences caused by escaping air. These visual methods can precisely locate the leaks.

Addressing leaks involves cleaning the area thoroughly, then applying the appropriate sealant according to the duct material and the size of the gap. For larger leaks, reinforcement with metal tape or additional mechanical fasteners might be necessary. Always allow the sealant to cure completely before testing the repair.

Q 5. What are the common causes of ductwork leaks?

Ductwork leaks often result from:

- Improper installation: Inadequate sealing during the initial installation is a common culprit.

- Poor workmanship: Gaps, cracks, and loose connections are often caused by insufficient attention to detail during installation.

- Damage: Physical damage from rodents, pests, or accidental impacts can create leaks over time.

- Vibration and movement: Repeated vibrations or shifting of the ductwork can compromise the seals, leading to leakage.

- Age and deterioration: Over time, sealants can lose their elasticity and effectiveness, requiring resealing or replacement.

Regular inspections and preventive maintenance significantly reduce the risk of ductwork leaks.

Q 6. What safety precautions should be taken during ductwork sealing?

Safety is paramount during ductwork sealing. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator, especially when working with sealants or in confined spaces. Adequate ventilation is also crucial to prevent inhalation of sealant fumes. If working at heights, proper fall protection measures should be in place. Always follow the manufacturer’s instructions for handling and applying sealants, and be aware of potential fire hazards when using certain materials. Working with a partner ensures safety and efficiency, especially in challenging situations.

Q 7. What tools and equipment are essential for effective ductwork sealing?

Essential tools and equipment include:

- Caulking gun: For applying liquid sealants.

- Putty knife or scraper: For preparing surfaces and removing old sealant.

- Duct sealant: Choosing the appropriate sealant is critical.

- Duct tape (metal or foil): For reinforcing seals.

- Backer rod: To fill larger gaps before applying sealant.

- Smoke pencil or duct blaster: For leak detection.

- Thermal imaging camera (optional but helpful): For precise leak identification.

- Ladder or scaffolding (if needed): For reaching high areas.

- Safety glasses and gloves: Essential PPE.

- Respirator (if needed): To avoid inhaling sealant fumes.

Investing in quality tools and equipment ensures accurate and efficient ductwork sealing, minimizing time and material waste.

Q 8. How do you determine the appropriate amount of sealant needed for a job?

Determining the correct amount of sealant for a ductwork sealing job requires careful planning and measurement. It’s not a guess; it’s a precise calculation based on several factors. First, I meticulously measure the total linear footage of seams and joints requiring sealing. Then, I consider the width of the sealant being used – for example, a 2” mastic bead will require more material than a 1” bead. Finally, and critically, I account for the type of sealant. Mastics have different application rates and coverage, while tapes have their own specified widths and overlaps. For instance, a project involving 100 feet of seams with a 2” mastic application might need approximately 200 linear inches of sealant, but the exact amount depends on the mastic’s specific application rate stated by the manufacturer. I always add a 10-15% buffer to compensate for waste and unevenness. Think of it like painting a room; you wouldn’t buy paint based on a rough estimate; precise calculations based on square footage are crucial, and the same applies to sealant.

Q 9. Explain the difference between mastic and foil tape in duct sealing.

Mastic and foil tape are both commonly used in duct sealing, but they differ significantly in their properties and applications. Mastic is a sealant applied in a thick bead, typically using a caulking gun. It’s flexible, offering good adhesion to a variety of surfaces including sheet metal, fiberglass, and galvanized steel. It’s effective at filling gaps and creating an airtight seal. However, mastic can be messy, requires precise application, and may need more curing time. Foil tape, on the other hand, is a self-adhesive tape with a foil backing for superior vapor barrier properties. It’s easier and faster to apply, especially in tight spaces, and offers a clean finish. But it’s less forgiving in bridging large gaps, and its effectiveness can be reduced by uneven surfaces. I often choose mastic for larger gaps or irregular seams where superior sealing is needed. For smaller gaps and for applications where a neat, quick seal is preferable, foil tape is my go-to choice. The best approach often involves a combination, using mastic for primary sealing and tape for reinforcing or covering small imperfections. Think of it like building a house: a solid foundation (mastic) is crucial, and then cosmetic touches and reinforcement (tape) are added.

Q 10. Describe your experience with different types of ductwork construction.

Throughout my career, I’ve worked extensively with a variety of ductwork constructions. This includes galvanized steel, which is the most common and durable; fiberglass ductwork, offering flexibility and often used in residential applications; and spiral-spun galvanized steel, which is efficient for large-diameter ducts. I also have experience with flexible ductwork (usually aluminum foil), primarily employed for short runs or in less accessible spaces. Each material presents unique sealing challenges. Galvanized steel requires careful attention to ensure the sealant adheres properly to its smooth surface. Fiberglass, while easier to seal, demands a sealant that can penetrate its porous texture. Flexible ductwork needs a sealant that can accommodate its expansion and contraction. My experience allows me to tailor my sealing techniques to the specific material and its inherent characteristics, leading to superior, long-lasting results. Selecting the right sealant for each type of duct material is akin to choosing the right tools for a carpentry project – using the wrong one will only lead to frustration and poor results.

Q 11. How do you ensure a durable and long-lasting ductwork seal?

Creating a durable and long-lasting duct seal requires attention to detail at every stage. Surface preparation is paramount; cleaning the surfaces of dust, debris, and any existing sealant is crucial for optimal adhesion. The right sealant is key; I always opt for high-quality mastics and tapes designed for ductwork applications and suited to the material type, taking into account factors like temperature fluctuations and potential exposure to moisture. Proper application techniques are also vital; this includes ensuring full coverage of all seams and joints, avoiding gaps or thin spots. And finally, post-application inspection is critical to verify that the seal is complete and the ductwork is airtight. A thorough inspection can identify any minor imperfections that can be rectified before they become major issues later. This multi-stage approach ensures that the seal lasts the life of the ductwork system, and is akin to building a strong brick wall – a solid foundation, quality materials, and careful construction techniques all ensure lasting strength and stability.

Q 12. How do you handle sealing around difficult-to-reach areas?

Sealing difficult-to-reach areas demands ingenuity and specialized tools. For tight spaces, I use flexible sealants like mastics in conjunction with applicator tools designed for narrow gaps and corners. For areas where access is completely restricted, I employ mirror inspection to verify the sealant’s application, and might use specialized long-reach caulking guns or even apply sealant through access holes, taking great care to avoid damaging other parts of the ductwork system. In certain situations, I will utilize a combination of mastic and foil tape to make the process of sealing easier while ensuring a sufficient seal. Sometimes, using a small mirror with a strong light source to check coverage in tight areas can be particularly helpful. The key is meticulous planning and adaptability; I always look for creative solutions that ensure complete sealing, without compromising the integrity of the system, while remembering that safety is always the top priority.

Q 13. What is your experience with pressure testing ductwork systems?

Pressure testing is an essential part of ensuring the airtightness of a ductwork system. My experience encompasses both positive and negative pressure tests, depending on the specific system and requirements. I am proficient in setting up the testing equipment, monitoring pressure gauges, and identifying leak points through observation and specialized tools like smoke pencils or pressure-sensitive leak detectors. I understand the importance of following established procedures and industry standards (like SMACNA guidelines) to ensure accurate and reliable test results. It’s all about finding any and all air leaks within the entire ductwork system before placing it into operation.

Q 14. How do you interpret pressure test results?

Interpreting pressure test results requires a keen understanding of the system’s design and the limitations of the testing method. A successful test shows minimal pressure drop over a specified period, indicating an airtight system. Conversely, significant pressure loss points to leaks. My interpretation goes beyond simply identifying leaks; I analyze the rate of pressure drop to determine the severity of leaks and their possible location. I then use smoke pencils and/or pressure leak detectors to pinpoint the exact locations of the leaks, even those that are subtle and hard to spot. This methodical approach, combining quantitative data with qualitative assessment, ensures that all identified leaks are correctly addressed to ensure the air handler system operates at its optimal performance level. Thinking of it like a medical diagnosis, the pressure test is like a general checkup, while further investigation pinpoints the specific problem.

Q 15. What are the implications of improper ductwork sealing?

Improper ductwork sealing has significant implications for both the efficiency and health of a building’s HVAC system. Think of your ductwork as a network of arteries carrying conditioned air; leaks are like holes in those arteries, causing significant blood (air) loss.

- Energy Loss: Leaky ducts allow conditioned air to escape into unconditioned spaces (attics, crawl spaces), forcing your HVAC system to work harder to maintain the desired temperature. This leads to higher energy bills and reduced system efficiency. Imagine trying to inflate a balloon with holes – it’s a losing battle.

- Reduced Air Quality: Unsealed ducts can suck in dust, pollen, and other contaminants from these unconditioned spaces, compromising indoor air quality. This is especially problematic for allergy sufferers or those with respiratory conditions. It’s like trying to drink from a straw that’s partially submerged in dirt.

- Increased Noise: Leaks can create whistling sounds, especially noticeable when the HVAC system is running. This can be annoying and disruptive to occupants.

- Inadequate Heating or Cooling: Leaks lead to uneven temperature distribution throughout the building. Some rooms might be too hot, while others are too cold, rendering your climate control system less effective.

- Potential for Mold Growth: Leaky ducts can create areas of moisture buildup, especially in the presence of condensation. This can promote the growth of mold and mildew, which presents significant health risks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with various duct sealing regulations and codes.

Throughout my career, I’ve worked extensively with various duct sealing regulations and codes, including those set by ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers), SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association), and local building codes. These codes often specify the type of sealant, application methods, and acceptable leakage rates for different duct systems and applications. For instance, I’ve been involved in projects adhering to ASHRAE Standard 110 for testing and balancing, ensuring the ductwork meets the specified leakage limits and overall system performance. I’m familiar with the specific requirements for different materials like mastic sealants, foil tapes, and metal tapes, and understand the selection criteria based on factors such as duct material, location, and environmental conditions. My experience has encompassed both residential and commercial projects, allowing me to adapt my sealing techniques to various scenarios and regulatory frameworks.

Q 17. How do you maintain proper hygiene and cleanliness during ductwork sealing?

Maintaining hygiene and cleanliness is paramount during ductwork sealing. We utilize several strategies to ensure a clean and safe work environment. Before starting any work, we thoroughly inspect the area, remove any debris or obstructions, and protect the surrounding space with drop cloths and plastic sheeting. We wear appropriate personal protective equipment (PPE), including respirators, safety glasses, and gloves, to prevent dust inhalation and skin irritation. During the sealing process, we carefully apply sealants, minimizing excess material to prevent messy spills or drips. After completing the sealing, we carefully clean up any leftover sealant, debris, or dust, ensuring the area is left clean and tidy. Proper waste disposal of materials is also strictly followed, adhering to all environmental regulations.

In projects involving extensive duct cleaning before sealing, we employ specialized HEPA-filtered vacuum systems to contain dust and prevent its spread. A post-sealing inspection is always conducted to ensure a neat and thoroughly sealed system.

Q 18. How do you manage time effectively on a ductwork sealing project?

Effective time management on ductwork sealing projects involves meticulous planning and execution. Before commencing the job, we conduct a thorough site assessment to estimate the scope of work, materials needed, and potential challenges. We create a detailed project schedule, breaking down the work into smaller tasks, and allocate specific timeframes for each phase. This helps us stay on track and identify any potential delays. We utilize efficient tools and techniques, which streamlines the sealing process. Regular communication with the client and the project team is crucial to maintain transparency and address any unforeseen issues promptly. We maintain a checklist for each project to ensure all steps are followed, further improving efficiency and preventing oversights. Experience allows me to accurately estimate project duration and adjust the schedule based on the actual progress, keeping the client informed of any changes.

Q 19. How do you handle unexpected challenges or problems during a job?

Unexpected challenges are inevitable in any construction project. For example, I once encountered a situation where the existing ductwork was far more deteriorated than initially assessed. My approach involves a calm, methodical assessment of the problem. First, I carefully document the issue, identifying the nature and extent of the problem with photographs and notes. I then consult with the client and project team to discuss potential solutions and their implications. I explore alternative sealing methods or materials to address the specific issue, ensuring we maintain compliance with relevant codes and regulations. In this instance, we had to reinforce some sections of the ductwork before proceeding with sealing, adjusting the project timeline accordingly. Open communication and collaborative problem-solving are key to successfully handling unexpected challenges without significant delays or cost overruns.

Q 20. Explain your experience with working in confined spaces or at heights.

I have extensive experience working in confined spaces and at heights, adhering strictly to safety protocols. When working in confined spaces, we ensure proper ventilation, use appropriate respiratory protection, and have a safety observer present. We utilize confined-space entry procedures, including pre-entry checks and atmospheric monitoring. When working at heights, we use appropriate fall protection equipment, such as harnesses and safety lines, ensuring that all work platforms are stable and secure. We also follow all relevant OSHA regulations and company safety guidelines, participating in regular safety training to stay updated on the latest best practices. Safety is non-negotiable; we always prioritize it above all else.

Q 21. Describe your understanding of HVAC system operation and its relation to ductwork integrity.

Understanding HVAC system operation is crucial for effective ductwork sealing. The entire HVAC system relies on the integrity of the ductwork to deliver conditioned air efficiently. Leaks in the ductwork compromise the system’s ability to maintain consistent temperatures and humidity levels, leading to energy waste and reduced performance. I have a deep understanding of airflow dynamics, pressure drops, and the overall system balance. My experience allows me to identify potential issues within the system that might be exacerbated by inadequate sealing. For instance, a poorly sealed duct system can cause excessive back pressure on the blower, increasing energy consumption and potentially shortening the lifespan of the equipment. A thorough knowledge of HVAC principles allows me to perform sealing work in a way that supports optimal system performance and longevity. This holistic approach goes beyond just sealing the ducts; it’s about optimizing the entire system’s efficiency.

Q 22. What is your experience working with different HVAC system designs?

Throughout my career, I’ve worked extensively with various HVAC system designs, from simple residential systems to complex commercial and industrial setups. This includes experience with both low-velocity and high-velocity systems, utilizing various duct materials like galvanized steel, flexible duct, and fiberglass. I’m familiar with different duct configurations—rectangular, round, and spiral—and understand the implications of each on sealing requirements. For instance, rectangular ducts often present more sealing challenges due to the presence of numerous seams and joints compared to round ducts. My experience also encompasses systems incorporating different ventilation strategies, including variable air volume (VAV) systems, which necessitate particularly precise sealing to maintain proper pressure differentials.

- Residential: I’ve worked on numerous single-family homes, mastering the intricacies of sealing smaller ductwork systems often located in attics or crawl spaces.

- Commercial: My experience with larger commercial buildings included meticulous sealing of extensive duct networks within ceilings and plenums, paying careful attention to noise reduction and energy efficiency.

- Industrial: I’ve worked on industrial projects that presented unique challenges, such as sealing ductwork in high-temperature or corrosive environments, requiring specialized sealants and techniques.

Q 23. How do you assess the condition of existing ductwork before sealing?

Assessing the condition of existing ductwork before sealing is crucial for a successful project. It’s a multi-step process that begins with a visual inspection, checking for obvious leaks, damage, and deterioration. I use a combination of tools and techniques to conduct a thorough evaluation. This includes:

- Visual Inspection: Looking for gaps, holes, cracks, and loose connections. I pay close attention to seams, joints, and transitions between different duct sections.

- Smoke Testing: Using a smoke machine to identify air leaks, pinpointing the exact location of compromised seals. This is especially important in identifying leaks that aren’t visually apparent.

- Pressure Testing: Measuring the pressure drop across the ductwork system to quantify the extent of leakage. This provides quantitative data to support the sealing plan.

- Infrared Thermography: Employing an infrared camera to detect temperature differences indicative of air leaks. This is particularly useful for identifying leaks in hard-to-reach areas.

Once the assessment is complete, I compile a detailed report that documents the findings, including photographs and measurements of all identified leaks. This report serves as the basis for developing a comprehensive sealing plan.

Q 24. How do you calculate the total material costs for a ductwork sealing project?

Calculating material costs involves a detailed breakdown of all necessary components. It starts with accurately measuring the linear footage of ductwork requiring sealing. Then, I determine the type and quantity of sealant needed based on the type of duct material and the severity of the leaks. My cost estimations include:

- Sealant: This is the main cost driver, and the choice depends on the application (e.g., mastic, foil tape, etc.). I carefully consider factors like temperature and humidity resistance.

- Access Equipment: Costs associated with scaffolding, ladders, or other equipment needed for access to the ductwork.

- Protective Gear: Costs for personal protective equipment (PPE), including respirators, gloves, and eye protection.

- Labor Costs: This accounts for the time and expertise needed to complete the sealing project. I’ll factor in my hourly rate and the estimated time for the job.

- Contingency: A percentage is added to account for unforeseen challenges or additional materials.

I typically create a detailed spreadsheet outlining each cost component, providing a clear and transparent cost breakdown for the client. For example, if a project needs 100 feet of duct sealed with a specific mastic sealant costing $X per foot, this is explicitly shown in the estimate.

Q 25. How do you create and submit accurate job reports?

Accurate job reports are critical for maintaining transparency and demonstrating accountability. My reports always include:

- Project Overview: A summary of the project scope, including the date, location, and client information.

- Pre-Sealing Assessment: A detailed description of the initial ductwork condition, including photographs and measurements of identified leaks.

- Materials Used: A list of all sealants, tapes, and other materials used, along with their quantities.

- Sealing Procedures: A detailed description of the steps taken to seal the ductwork, adhering to industry best practices.

- Post-Sealing Assessment: A verification of the completed work, again using visual inspection, smoke testing, or pressure testing as needed. This section should show that all identified leaks have been successfully sealed.

- Photographs: Before-and-after photographs illustrating the completed work. This provides visual confirmation of the improvement.

These reports are professionally formatted and easy to understand. They’re often accompanied by electronic copies for easy access and archiving.

Q 26. Describe your teamwork experience and how this helps you perform efficiently.

Teamwork is integral to efficient and successful ductwork sealing projects. My experience collaborating on various projects has demonstrated the importance of clear communication, mutual respect, and shared responsibility. On one project, for example, coordinating with electricians and HVAC technicians ensured seamless integration of sealing work with other ongoing renovations, minimizing downtime.

- Communication: I believe in proactive communication, ensuring that everyone on the team is informed about the project’s progress, challenges, and any necessary adjustments. This prevents misunderstandings and delays.

- Collaboration: I value the expertise of my colleagues and actively seek their input and insights. This collective approach leads to better solutions and a more efficient workflow.

- Problem-Solving: When faced with unexpected challenges, I collaborate with the team to find creative and effective solutions, always prioritizing safety and quality.

Effective teamwork allows for a smoother, faster, and more efficient project completion, ultimately leading to greater client satisfaction.

Q 27. What are your plans for professional development in ductwork sealing?

My commitment to professional development in ductwork sealing is ongoing. I aim to stay abreast of the latest industry advancements, techniques, and technologies. This includes:

- Continuing Education: Regularly attending industry conferences, workshops, and training sessions to learn about new sealants, methods, and best practices.

- Industry Certifications: Pursuing relevant certifications to demonstrate my competence and adherence to industry standards.

- Professional Networking: Engaging with other professionals in the field to exchange knowledge, share experiences, and learn from best practices.

- Staying Updated: Following industry publications, journals, and online resources to keep my knowledge current and relevant.

This continuous learning ensures I remain at the forefront of the field, capable of delivering the highest quality of work and exceeding client expectations.

Q 28. What are your salary expectations for this role?

My salary expectations are commensurate with my experience, skills, and the requirements of this role. I am open to discussing a competitive salary range based on the specifics of the position and the overall compensation package.

Key Topics to Learn for Your Ductwork Sealing Interview

- Ductwork Materials & Properties: Understanding different materials used in ductwork (galvanized steel, aluminum, fiberglass) and their respective properties (strength, flexibility, resistance to corrosion) is crucial. Consider how material choice impacts sealing techniques and long-term performance.

- Sealing Techniques & Methods: Mastering various sealing methods, including mastic sealants, tapes, and mechanical fasteners. Be prepared to discuss the advantages and disadvantages of each, considering factors like cost, durability, and application suitability for different duct materials and sizes.

- Leak Detection & Diagnostics: Familiarity with methods for identifying air leaks in ductwork systems, such as pressure testing, smoke testing, and infrared thermography. Understand how to interpret test results and recommend appropriate sealing solutions.

- Health & Safety Regulations: Demonstrate understanding of relevant safety regulations and best practices related to working with sealing materials (e.g., proper ventilation, PPE usage, handling hazardous materials). This shows responsibility and commitment to a safe work environment.

- HVAC System Integration: Discuss how proper ductwork sealing contributes to the overall efficiency and performance of HVAC systems. Be prepared to explain the impact on energy consumption, air quality, and system longevity.

- Troubleshooting & Problem Solving: Describe your approach to diagnosing and resolving common sealing challenges, such as sealant failure, improper application, or leaks around penetrations. Highlight your problem-solving skills and ability to find practical solutions.

- Industry Standards & Codes: Familiarize yourself with relevant industry standards and building codes related to ductwork sealing. Knowing these demonstrates professionalism and attention to detail.

Next Steps

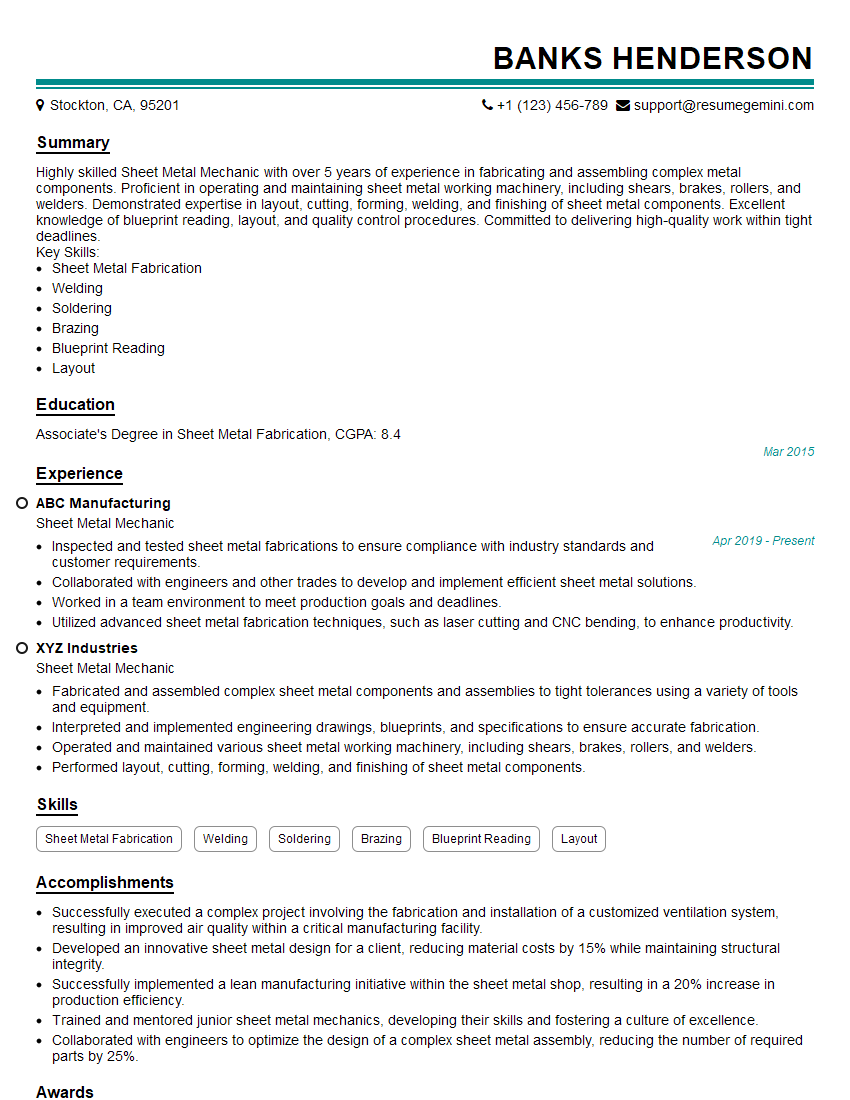

Mastering ductwork sealing techniques opens doors to rewarding and well-compensated careers in the HVAC industry. Your expertise in this critical area is highly valuable. To maximize your job prospects, crafting a compelling, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored specifically to the Ductwork Sealing field are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.