Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Laboratory Analysis for Wastewater interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Laboratory Analysis for Wastewater Interview

Q 1. Describe your experience with various wastewater analysis methods.

My experience encompasses a wide range of wastewater analysis methods, both classical and instrumental. I’m proficient in techniques for determining physical parameters like temperature, pH, turbidity, and conductivity, using standard meters and sensors. For chemical analysis, I’m skilled in titrations (e.g., for alkalinity, hardness), spectrophotometry (measuring absorbance at specific wavelengths to quantify various substances like nitrates and phosphates), and various forms of chromatography (HPLC and GC for analyzing complex organic compounds like pesticides and pharmaceuticals). I also have experience with microbiological methods such as colony counting for determining bacterial populations and membrane filtration techniques for detecting specific pathogens.

For example, in one project, I used HPLC to analyze a wide range of pharmaceuticals in a municipal wastewater treatment plant effluent, helping to assess the effectiveness of the treatment process in removing these emerging contaminants. In another project, I used a spectrophotometer to monitor daily nutrient levels in an industrial wastewater stream, allowing for timely adjustments to the treatment process to meet discharge permits.

Q 2. Explain the process of sample collection and preservation for wastewater analysis.

Proper sample collection and preservation are crucial for obtaining reliable analytical results. The process begins with selecting the appropriate sampling location and time, considering factors like flow rate and mixing within the wastewater stream. Samples are collected using sterile containers to prevent contamination, and the volume collected depends on the tests to be performed.

Preservation methods are critical to prevent changes in sample composition before analysis. For example, refrigeration at 4°C is often used to slow down biological activity. The addition of chemical preservatives, such as sulfuric acid to prevent volatilization of ammonia or zinc acetate to preserve sulfides, may also be necessary, depending on the target analytes. The choice of preservation method depends heavily on the parameters being measured and the time delay before analysis.

Accurate documentation, including the date, time, location, and preservation methods used, is essential for maintaining the chain of custody and ensuring data integrity. For instance, using a chain-of-custody form ensures traceability and accountability throughout the sampling and testing process.

Q 3. How do you ensure the accuracy and precision of your laboratory results?

Ensuring accuracy and precision in laboratory results is paramount. We utilize a multi-pronged approach to achieve this. First, meticulous attention to detail is crucial during sample handling, preparation, and analysis. We follow strict Standard Operating Procedures (SOPs) for all methods. Second, we regularly calibrate and maintain our instruments to ensure their accuracy. Calibration curves are generated using certified reference materials and checked against control charts to detect any drift from the expected values.

We employ quality control (QC) samples, including blanks, duplicates, and spiked samples, throughout the analysis to monitor the performance of the method. Blanks detect contamination in reagents or glassware; duplicates assess the precision of the method; and spiked samples assess the accuracy and recovery of the method. Out-of-control results trigger investigations, and corrective actions are implemented to resolve any identified issues. Regular participation in proficiency testing programs provides external validation of our laboratory’s performance and helps us to identify areas for improvement.

Q 4. What are the common parameters analyzed in wastewater and their significance?

Many parameters are analyzed in wastewater, each offering insights into its quality and potential environmental impact. Common parameters include:

- pH: Indicates the acidity or alkalinity of the water, affecting aquatic life and corrosion.

- BOD (Biochemical Oxygen Demand): Measures the amount of oxygen consumed by microorganisms during the decomposition of organic matter, indicating the level of organic pollution.

- COD (Chemical Oxygen Demand): Measures the total amount of oxygen required to chemically oxidize organic and inorganic matter, providing a quicker assessment of pollution than BOD.

- SS (Suspended Solids): Represents the total amount of solid particles suspended in the water, impacting water clarity and treatment processes.

- Nutrients (Nitrogen & Phosphorus): Excessive levels can lead to eutrophication, algal blooms, and oxygen depletion in receiving waters.

- Metals (e.g., lead, cadmium, mercury): Toxic heavy metals can bioaccumulate in the food chain, posing significant health risks.

- Oil and Grease: Indicate industrial discharge and affect aquatic life and water quality.

- Pathogens (bacteria, viruses): Presence indicates fecal contamination and potential health risks.

The significance of each parameter varies depending on the source and intended use of the wastewater. For example, high levels of BOD in a river could lead to fish kills, while the presence of pathogens in drinking water could cause serious health issues. Analyzing these parameters allows for efficient monitoring, treatment, and environmental protection.

Q 5. Explain your understanding of quality control and quality assurance in a wastewater laboratory.

Quality Control (QC) and Quality Assurance (QA) are the cornerstones of a reliable wastewater laboratory. QA encompasses all activities ensuring the quality of the analytical process, while QC involves specific techniques to monitor the process and identify deviations from quality standards. In our laboratory, QA includes regular instrument calibration and maintenance, staff training and competency assessment, review of SOPs, and participation in proficiency testing programs. QC involves the analysis of QC samples (blanks, duplicates, spikes, and standards) with each batch of samples. Statistical process control (SPC) charts are used to monitor the performance of the analytical methods, and out-of-control results trigger corrective actions.

We maintain a comprehensive quality manual outlining all procedures, guidelines, and responsibilities to ensure adherence to national and international standards (e.g., ISO 17025). We also implement a robust documentation system, recording all results, QC data, and corrective actions. This comprehensive approach ensures that our laboratory produces reliable, accurate, and defensible results.

Q 6. Describe your experience with different analytical instruments used in wastewater analysis (e.g., Spectrophotometer, Chromatography).

I have extensive experience with various analytical instruments used in wastewater analysis. Spectrophotometers are routinely used for determining the concentration of various substances based on their absorbance of light at specific wavelengths. For example, we use a UV-Vis spectrophotometer to measure the concentration of nitrates and phosphates in wastewater samples. Gas chromatography (GC) and High-Performance Liquid Chromatography (HPLC) are indispensable for separating and quantifying complex mixtures of organic compounds, such as pesticides and pharmaceuticals present in wastewater. I’m also proficient in using Ion Chromatography (IC) for determining the concentrations of anions and cations, such as chloride, sulfate, and various metals.

In addition to these, I have experience using more specialized equipment like Inductively Coupled Plasma Mass Spectrometry (ICP-MS) for trace metal analysis and Total Organic Carbon (TOC) analyzers for measuring the total amount of organic carbon present in the water. The choice of instrument is carefully made based on the specific analytes being measured and the required detection limits.

Q 7. How do you troubleshoot instrument malfunctions and maintain equipment?

Troubleshooting instrument malfunctions and ensuring proper equipment maintenance are crucial for reliable results. My approach involves a systematic troubleshooting process. When an instrument malfunctions, I first check the obvious things, like power supply, connections, and reagent levels. If the problem persists, I consult the instrument’s manual, error codes, and the laboratory’s maintenance logs. I also utilize my experience to identify potential problems. For instance, a drift in the calibration curve of a spectrophotometer may indicate a need for cleaning the cuvettes or recalibration of the instrument.

Preventive maintenance is crucial to minimize downtime and maintain instrument accuracy. We adhere to regular maintenance schedules, including cleaning, calibration, and replacement of parts as recommended by the manufacturer. We keep detailed logs of all maintenance activities, including dates, actions taken, and any observed issues. This proactive approach minimizes instrument downtime and ensures that our results are reliable and accurate.

Q 8. What are the safety protocols you follow in a wastewater laboratory?

Safety is paramount in a wastewater laboratory, where we handle potentially hazardous materials. Our protocols are comprehensive and strictly adhered to. They include:

- Personal Protective Equipment (PPE): This is the cornerstone of our safety. We always wear lab coats, gloves (nitrile or other appropriate material depending on the analysis), safety glasses, and sometimes face shields, depending on the procedure. For example, when handling concentrated acids or performing digestions, additional protective measures are taken.

- Chemical Handling and Storage: We follow strict guidelines for the handling, storage, and disposal of chemicals. Chemicals are stored according to their compatibility and hazard class, with proper labeling and safety data sheets readily available. Spills are immediately addressed using appropriate neutralization and cleanup procedures, and all waste is disposed of according to regulations.

- Biological Safety: Wastewater can contain pathogens. We follow biosafety protocols, including using biological safety cabinets when necessary (especially for handling samples suspected of high pathogen content) and practicing aseptic techniques to prevent contamination.

- Sharps Disposal: Needles, broken glassware, and other sharps are disposed of in designated puncture-resistant containers to prevent injuries.

- Emergency Procedures: We have well-defined emergency procedures in place for spills, fires, and other incidents. All personnel receive regular safety training and know the locations of safety equipment such as eyewash stations and safety showers.

- Regular Maintenance and Calibration: Equipment maintenance and calibration schedules are rigorously followed to ensure accurate results and prevent equipment malfunctions that could lead to accidents.

Think of it like this: Our lab is a mini-industrial facility where safety is not an afterthought, but a foundational element integrated into every process.

Q 9. How do you interpret and report wastewater analysis results?

Interpreting and reporting wastewater analysis results involves several key steps. First, we ensure the data’s quality by checking for outliers and inconsistencies. Then, we compare the results to regulatory limits (e.g., permitted discharge limits set by the Environmental Protection Agency or similar bodies) and to historical data from the same source. The report includes:

- Sample Information: Date, time, location, and sample type (e.g., influent, effluent, stormwater).

- Analytical Results: Values for each parameter tested (e.g., BOD, COD, TSS, ammonia, nitrates, phosphates, metals, etc.). Units are clearly specified (e.g., mg/L, µg/L).

- Methodologies: A clear statement of the analytical methods used to obtain the results, conforming to standard methods like those published by the American Public Health Association (APHA).

- Quality Control (QC) Data: This includes details of the QC samples analyzed alongside the actual samples (blanks, duplicates, spikes) to assess the accuracy and precision of the analyses. This section verifies the reliability of our data. For example, the percent recovery of a spiked sample shows our accuracy.

- Interpretation and Compliance Status: This section indicates whether the results meet regulatory limits. Non-compliance is clearly highlighted, and potential causes are sometimes discussed, based on available data and experience.

- Graphs and Charts: Visual representations of the data can aid in understanding trends and patterns over time.

A clear, concise, and factual report is crucial for effective decision-making by wastewater treatment plant operators, regulatory agencies, and other stakeholders. We aim for a report that’s easily understandable even to non-scientists, with clear explanations of any technical terms.

Q 10. Explain your understanding of regulatory compliance regarding wastewater analysis.

Regulatory compliance is paramount in wastewater analysis. Our work directly supports compliance with environmental regulations designed to protect water quality. We must adhere to stringent guidelines set by various agencies, which vary by location and the type of wastewater. For example, the Clean Water Act in the US dictates permitted levels of various pollutants in wastewater discharges. These regulations specify acceptable limits for numerous parameters (e.g., BOD, COD, nutrients, heavy metals, pathogens).

Compliance involves:

- Method Selection: Employing standardized, validated analytical methods as specified by the regulatory body (EPA methods, for instance).

- Data Quality Assurance/Quality Control (QA/QC): Maintaining rigorous QA/QC protocols to ensure data accuracy and reliability, including appropriate sample preservation and handling.

- Record Keeping: Meticulous documentation of all aspects of the analysis, from sample collection to data interpretation and reporting, including chain of custody.

- Reporting: Accurate and timely submission of analysis reports to the relevant regulatory agencies in the specified format. Any deviations from standard methods or expected results are clearly documented.

- Audits and Inspections: We are prepared for regular audits and inspections by regulatory agencies to verify compliance and the integrity of our processes.

Non-compliance can lead to significant penalties, so staying abreast of the latest regulations is crucial. We routinely update our procedures and training to reflect the current standards.

Q 11. How do you handle discrepancies in laboratory results?

Discrepancies in laboratory results are addressed systematically and thoroughly. The first step is to identify the source of the discrepancy. This could stem from various sources such as:

- Sampling Error: Improper sample collection or preservation.

- Analytical Error: Equipment malfunction, incorrect procedure application, or human error in calculations.

- Matrix Effects: Interferences from components within the sample matrix affecting the analysis.

Our investigation involves:

- Reviewing the raw data: Checking calculations, instrument readings, and QC data.

- Repeating the analysis: Using a fresh aliquot of the original sample or a new sample to confirm the result. If there’s an apparent error, this should be addressed first.

- Investigating equipment calibration and maintenance records: To rule out instrumentation issues.

- Analyzing QC data: Checking the performance of controls to identify if it might be responsible for the discrepancy.

- Consulting with colleagues: To gain expert opinions and alternative perspectives.

Once the source is identified, corrective actions are taken, and the discrepancy is documented. The corrected results and a detailed explanation of the discrepancy are included in the final report. This ensures transparency and allows for effective follow-up. For example, if we find an equipment malfunction, we would document the repair and recalibration, ensuring future results are reliable.

Q 12. Describe your experience with data analysis and interpretation in wastewater analysis.

My experience with data analysis in wastewater analysis is extensive. It goes beyond simple reporting. I utilize statistical software (such as R or SPSS) and spreadsheet software (Excel) to analyze trends, patterns, and correlations in wastewater data. This helps in:

- Identifying seasonal variations: For example, observing higher BOD levels in warmer months due to increased microbial activity.

- Tracking treatment plant performance: Monitoring key indicators like BOD removal efficiency and identifying areas for improvement.

- Assessing the impact of industrial discharges: Correlating specific pollutants with industrial inputs to pinpoint sources of contamination.

- Developing predictive models: Using historical data to predict future pollutant concentrations and optimize treatment plant operations.

- Creating visualizations: Using graphs and charts to effectively communicate complex data to stakeholders.

For instance, in one project I used statistical process control (SPC) charts to monitor the performance of a wastewater treatment plant. By identifying outliers and trends in the data, we were able to proactively address issues before they escalated and impacted effluent quality.

Q 13. What is your experience with different types of wastewater (industrial, municipal, etc.)?

I have experience analyzing various types of wastewater, including:

- Municipal Wastewater: This encompasses wastewater from residential, commercial, and institutional sources. Analysis focuses on parameters like BOD, COD, TSS, nutrients, and pathogens.

- Industrial Wastewater: This is more complex and varies greatly depending on the industry. Analysis needs to account for specific pollutants associated with the industry (e.g., heavy metals from electroplating, organic solvents from manufacturing, etc.). I have experience with industrial wastewater from food processing, manufacturing, and other sectors. We must adapt our analysis to the specific industry.

- Stormwater Runoff: This type of wastewater contains pollutants washed from streets, parking lots, and other surfaces. Analysis often focuses on suspended solids, heavy metals, and oil and grease.

The analytical methods and parameters tested vary depending on the type of wastewater and the regulatory requirements. My expertise lies in adapting my approach to the specific characteristics of each type of wastewater to ensure accurate and reliable results.

Q 14. How familiar are you with different wastewater treatment processes?

My familiarity with wastewater treatment processes is quite comprehensive. I understand the various stages involved, including:

- Preliminary Treatment: Processes like screening, grit removal, and flow equalization.

- Primary Treatment: Physical processes such as sedimentation and clarification to remove solids.

- Secondary Treatment: Biological processes such as activated sludge and trickling filters to remove dissolved organic matter. I’m also familiar with membrane bioreactors (MBR).

- Tertiary Treatment: Advanced treatment methods like filtration, disinfection (UV, chlorination), and nutrient removal to further improve effluent quality.

- Sludge Treatment: Processes for managing the biosolids generated during treatment (e.g., thickening, digestion, dewatering, and disposal).

Understanding these processes is essential for interpreting wastewater analysis results. For example, knowing the efficiency of the activated sludge process helps us interpret the BOD and COD values in the effluent. Furthermore, I can use my knowledge to suggest potential improvements in treatment processes based on the analytical data. For example, consistently high ammonia levels in the effluent might indicate a problem with the nitrification process in the secondary treatment stage.

Q 15. Explain your understanding of the different types of water pollutants.

Water pollutants can be broadly categorized into several types. Think of a river – anything that shouldn’t be there is a pollutant. These can be:

- Physical pollutants: These are visible contaminants like plastics, sediment, and suspended solids that affect water clarity and aquatic life. For instance, a construction site near a river can lead to increased sediment levels.

- Chemical pollutants: These encompass a wide range, including heavy metals (lead, mercury, cadmium), pesticides, herbicides, industrial chemicals, and nutrients (nitrogen and phosphorus). Industrial discharge is a major source of chemical pollutants, leading to toxicity and eutrophication.

- Biological pollutants: These are mainly microorganisms like bacteria, viruses, and parasites that can cause diseases. Untreated sewage is a significant source of this type of pollution, potentially leading to waterborne illnesses.

- Thermal pollutants: These are changes in water temperature, often due to industrial cooling water discharge. A drastic temperature change can disrupt the delicate balance of the aquatic ecosystem.

- Radioactive pollutants: These are radioactive materials originating from nuclear power plants or accidents, posing serious health risks. These are often tightly regulated.

Understanding these categories is crucial for effective wastewater treatment and environmental protection. Different pollutants require different treatment methods.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate BOD and COD?

BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) are both measures of the amount of oxygen required to decompose organic matter in water. The difference lies in *how* they measure it.

BOD measures the oxygen consumed by aerobic microorganisms while decomposing organic matter over a specific period (usually 5 days at 20°C). It reflects the *biodegradable* organic matter. We measure the dissolved oxygen (DO) levels at the beginning and end of the incubation period. The difference represents the BOD.

BOD = (Initial DO - Final DO) mg/L

COD, on the other hand, measures the oxygen required for chemical oxidation of *all* organic matter, regardless of biodegradability. A strong oxidizing agent, typically potassium dichromate, is used in a reflux process. The amount of dichromate consumed is directly proportional to the COD.

Imagine BOD as a natural process – microorganisms ‘eating’ organic matter. COD is a forced, faster process – chemically ‘burning’ everything. Both tests are vital for assessing the pollution load and effectiveness of treatment.

Q 17. What are the limitations of different analytical methods used in wastewater analysis?

Every analytical method has its limitations. For instance:

- BOD test: It’s time-consuming (5 days minimum), can be affected by the presence of toxic substances that inhibit microbial activity, and may not accurately reflect the total organic matter present because it only considers biodegradable substances.

- COD test: It’s relatively faster than BOD but is susceptible to interference from certain inorganic substances, and it doesn’t differentiate between biodegradable and non-biodegradable organic matter. It also uses harsh chemicals.

- Spectrophotometry: While versatile and widely used for measuring various parameters, it requires calibration and can be prone to interference from other substances present in the sample matrix.

- Gas Chromatography-Mass Spectrometry (GC-MS): This is a powerful technique for identifying and quantifying specific organic pollutants, but it’s expensive and requires specialized training and expertise.

- Microbiological methods: These techniques often require sterile conditions and specific incubation times and can be affected by sample storage and handling.

Understanding these limitations is key to selecting the most appropriate method for a particular analysis and interpreting the results accurately. We often use multiple methods to get a comprehensive picture.

Q 18. How do you ensure the chain of custody for wastewater samples?

Maintaining the chain of custody is paramount to ensuring the integrity and admissibility of wastewater samples. This involves meticulously documenting every step of the sample handling process from collection to analysis. It’s like a relay race – every handoff must be accounted for.

Our chain of custody procedures typically include:

- Unique sample identification: Each sample is given a unique identification number that remains consistent throughout the process.

- Detailed documentation: A chain of custody form is completed at each stage, recording who collected the sample, the date and time, the location, the analysis requested, who handled the sample at each transfer, and the date and time of each transfer. Signatures and dates are essential at each step.

- Secure storage: Samples are stored in secure, temperature-controlled conditions to prevent degradation or contamination.

- Proper sealing and labeling: Samples are sealed with tamper-evident seals and labeled clearly with the unique ID number.

- Audit trail: The entire process is regularly audited to ensure compliance with quality control protocols.

Failing to maintain a proper chain of custody can compromise the reliability of the analytical results, leading to inaccurate conclusions and potentially invalidating legal proceedings.

Q 19. Explain your experience with microbiological analysis of wastewater.

My experience with microbiological analysis of wastewater is extensive. I’m proficient in various techniques, including:

- Total coliform counts: Using membrane filtration or multiple tube fermentation methods to determine the presence of coliform bacteria, indicating fecal contamination.

- Fecal coliform counts: Quantifying fecal coliforms like E. coli, which are more specific indicators of fecal contamination and potential health risks.

- Heterotrophic plate counts (HPC): Assessing the overall microbial load in wastewater by counting colony-forming units (CFUs) on nutrient agar plates.

- Pathogen detection: Using techniques like PCR (polymerase chain reaction) or ELISA (enzyme-linked immunosorbent assay) for detecting specific pathogens like Salmonella or Giardia. These tests are crucial in assessing public health risks.

I have a solid understanding of microbiological principles, including growth media preparation, quality control measures, and interpretation of results. I’ve worked extensively with wastewater samples from various sources, ensuring proper sample handling and preventing contamination.

Q 20. Describe your proficiency with specific laboratory software and data management systems.

I am proficient in several laboratory software and data management systems. My experience includes:

- LIMS (Laboratory Information Management System): I’ve used LIMS extensively for managing samples, tracking results, generating reports, and ensuring data integrity. It’s the backbone of our laboratory operations.

- Spreadsheet software (e.g., Microsoft Excel): I’m adept at using spreadsheets for data analysis, generating graphs, and creating customized reports.

- Statistical software (e.g., R or SPSS): I’ve employed statistical software for advanced data analysis, including quality control charting, trend analysis, and regression modeling.

- Chromatography software (e.g., Empower, Chromeleon): I am experienced in using various chromatography data systems for instrument control, data acquisition, and analysis of complex samples.

My familiarity with these systems allows me to efficiently manage large datasets, automate data analysis, and maintain the highest level of data accuracy and integrity.

Q 21. How would you address a situation where a deadline is missed in the lab?

Missing a deadline in a laboratory setting is serious, particularly when it involves time-sensitive analysis. My approach would involve immediate action:

- Assess the situation: Identify the reason for the delay – was it due to instrument malfunction, unexpected sample volume, an unforeseen complication in analysis, or staff shortages?

- Communicate promptly: Inform the relevant parties – supervisor, clients – immediately and transparently about the delay, explaining the reason. Proactive communication is critical in mitigating damage to reputation and trust.

- Develop a recovery plan: Prioritize tasks, allocate additional resources if necessary (e.g., overtime, additional personnel), and adjust the workflow to expedite the analysis without compromising data quality.

- Implement corrective actions: Once the immediate crisis is handled, investigate the root cause of the delay to prevent recurrence. This may involve preventative maintenance, improved scheduling, or additional training for staff.

- Document everything: Maintain thorough documentation of the delay, including the reason, the recovery plan, and any corrective actions implemented. This documentation is valuable for quality control and continuous improvement.

My focus would always be on delivering accurate results, even if it means working outside of normal hours. The integrity of the data is paramount.

Q 22. Describe your experience with method validation and verification in the wastewater lab.

Method validation and verification are critical in ensuring the reliability and accuracy of our wastewater analysis. Validation confirms that a method is suitable for its intended purpose, while verification ensures ongoing performance. In my experience, this involves meticulously following guidelines like those from Standard Methods for the Examination of Water and Wastewater. For example, validating a new method for measuring total phosphorus might involve assessing its linearity, accuracy (recovery studies using spiked samples), precision (repeatability and reproducibility), and detection limits. We’d analyze different concentration levels of phosphorus, including blanks and replicates, and statistically evaluate the results. Verification, on the other hand, is an ongoing process involving regular checks against control charts and the periodic analysis of certified reference materials to confirm the method remains accurate and precise. Any deviations trigger investigation and potential corrective actions, such as recalibration of instruments or retraining of personnel.

- Linearity: Assessing the method’s ability to produce results proportional to the analyte concentration over a specified range.

- Accuracy: Determining how close the measured values are to the true values through recovery experiments.

- Precision: Evaluating the reproducibility and repeatability of the method through multiple analyses of the same sample.

- Detection Limit: Establishing the lowest concentration of the analyte that can be reliably detected by the method.

Q 23. How do you handle unexpected results or outliers in your data?

Unexpected results or outliers demand a systematic approach. First, I meticulously review the entire analytical process, starting from sample collection and preservation. Did any procedural deviations occur? Were there any equipment malfunctions? Was there a potential contamination issue? Then, I’d examine the raw data for any obvious errors in transcription or calculation. Statistical analysis, such as Grubbs’ test, helps to identify outliers formally. If the outlier persists after thorough investigation and cannot be attributed to procedural errors, I explore the possibility of matrix effects – interferences from other substances in the sample. I might run the sample through a different validated method as a confirmation. If the discrepancy remains, I’d document the findings thoroughly, flagging the result and explaining the investigations performed. Depending on the nature of the outlier and its potential impact on the overall conclusion, it might be excluded from the final report with justification. Each instance is treated uniquely, balancing the need for data integrity with an understanding of the practical challenges of wastewater analysis.

Q 24. Explain your knowledge of different types of wastewater treatment technologies.

Wastewater treatment involves a sequence of processes to remove pollutants. I’m familiar with several technologies, including:

- Primary Treatment: Physical processes like screening and sedimentation to remove larger solids.

- Secondary Treatment: Biological processes, such as activated sludge and trickling filters, that use microorganisms to break down organic matter. Activated sludge is like a mini-ecosystem in a tank where microorganisms consume pollutants, and the resulting sludge is separated. Trickling filters employ a bed of media where the microorganisms live and wastewater trickles through.

- Tertiary Treatment: Advanced processes, such as filtration, disinfection (chlorination, UV, ozonation), and nutrient removal (biological nutrient removal using enhanced biological phosphorus removal and nitrification/denitrification processes). This stage aims to remove remaining pollutants and ensure compliance with discharge standards.

Understanding these processes is crucial for interpreting wastewater analysis results, as the choice of treatment influences the types and concentrations of pollutants remaining. For instance, a plant using enhanced biological phosphorus removal will show lower phosphorus levels in the effluent compared to one without this technology.

Q 25. How do you stay updated with the latest advancements in wastewater analysis techniques?

Staying current in wastewater analysis requires a multi-pronged approach. I regularly attend conferences and workshops, such as those organized by professional organizations like the WEF (Water Environment Federation). I actively subscribe to relevant journals, such as ‘Environmental Science & Technology’ and ‘Water Research’. Participation in professional networks and online communities allows for discussions and exchanges of knowledge with other experts. I regularly check websites of instrument manufacturers for updates on software and instrumentation developments. Moreover, I seek out and participate in training courses to maintain proficiency in new techniques and regulatory updates. Continuous learning is essential to keep pace with the rapid advancements in this dynamic field.

Q 26. Explain your understanding of the impact of wastewater on the environment.

Untreated or inadequately treated wastewater poses significant environmental threats. It can contaminate surface water bodies, leading to eutrophication (excessive nutrient enrichment causing algal blooms that deplete oxygen, killing aquatic life). Pathogens in wastewater can cause waterborne diseases. Toxic chemicals and heavy metals can bioaccumulate in the food chain, impacting human and animal health. The release of organic matter increases the biological oxygen demand (BOD), depleting oxygen levels in water bodies. The impact extends to groundwater contamination as well, compromising drinking water sources. Effective wastewater treatment is therefore crucial to mitigating these risks and protecting environmental health. A good analogy is to consider our water systems as arteries and veins of our environment: if they are clogged, the whole system suffers.

Q 27. What is your experience with using standard operating procedures (SOPs)?

Standard Operating Procedures (SOPs) are the backbone of a well-functioning laboratory. My experience involves developing, revising, and adhering to SOPs for various analytical methods. We have SOPs covering everything from sample collection and preservation to instrument calibration, data analysis, and quality control. Following SOPs ensures consistency, reproducibility, and traceability of results. They also contribute significantly to maintaining quality assurance and regulatory compliance. A well-written SOP should be clear, concise, and unambiguous, leaving no room for misinterpretation. I’ve been involved in drafting SOPs for new methods and reviewing and updating existing ones to reflect new technologies or regulatory changes. Using SOPs enables not only high quality results but also consistency across a team and easy training of new analysts. A deviation from the SOP is a serious matter, necessitating immediate documentation and investigation.

Q 28. How do you prioritize tasks in a busy laboratory environment?

Prioritization in a busy lab is crucial. I employ a combination of strategies. First, I identify urgent tasks based on deadlines, sample turnaround times, and regulatory requirements. Tasks that directly impact public health or environmental compliance typically take precedence. I use tools like task management software to list and organize tasks. I also consider the complexity and resource requirements of each task, prioritizing simpler tasks that can be completed quickly to free up time for more complex ones. Collaboration and communication are key; I discuss task priorities with my colleagues to ensure efficient resource allocation and avoid bottlenecks. Regular review and adjustment of priorities are necessary to respond effectively to unexpected events and changing workload demands. Think of it like a conductor of an orchestra, ensuring each instrument section plays its part harmoniously and efficiently.

Key Topics to Learn for Laboratory Analysis for Wastewater Interview

- Water Quality Parameters: Understanding key indicators like pH, turbidity, dissolved oxygen, BOD, COD, and nitrogen/phosphorus levels. Knowing the significance of each parameter and the methods used for their determination.

- Analytical Techniques: Familiarity with various laboratory techniques including titrations, spectrophotometry, chromatography (e.g., HPLC, GC), and electrochemical methods. Be prepared to discuss the principles behind these techniques and their applications in wastewater analysis.

- Quality Control and Assurance (QA/QC): Understanding the importance of accuracy, precision, and reliability in laboratory results. This includes proficiency in calibration procedures, standard operating procedures (SOPs), and data analysis to ensure the validity of results.

- Wastewater Treatment Processes: A basic understanding of different wastewater treatment stages (primary, secondary, tertiary) and how laboratory analysis informs the effectiveness of each stage. This includes knowledge of relevant effluent discharge standards and regulations.

- Microbial Analysis: Depending on the role, familiarity with microbiological testing methods for detecting indicator organisms (e.g., E. coli) and pathogens is crucial. Understanding the implications of microbial contamination and relevant safety protocols.

- Data Interpretation and Reporting: Ability to analyze laboratory data, draw conclusions, and prepare clear and concise reports. This includes understanding statistical analysis methods and presenting findings effectively.

- Troubleshooting and Problem-Solving: Be prepared to discuss experiences in identifying and resolving issues encountered during laboratory analysis, demonstrating your analytical and problem-solving skills.

- Safety and Regulations: Demonstrate awareness of laboratory safety protocols, handling of hazardous materials, and relevant environmental regulations concerning wastewater analysis.

Next Steps

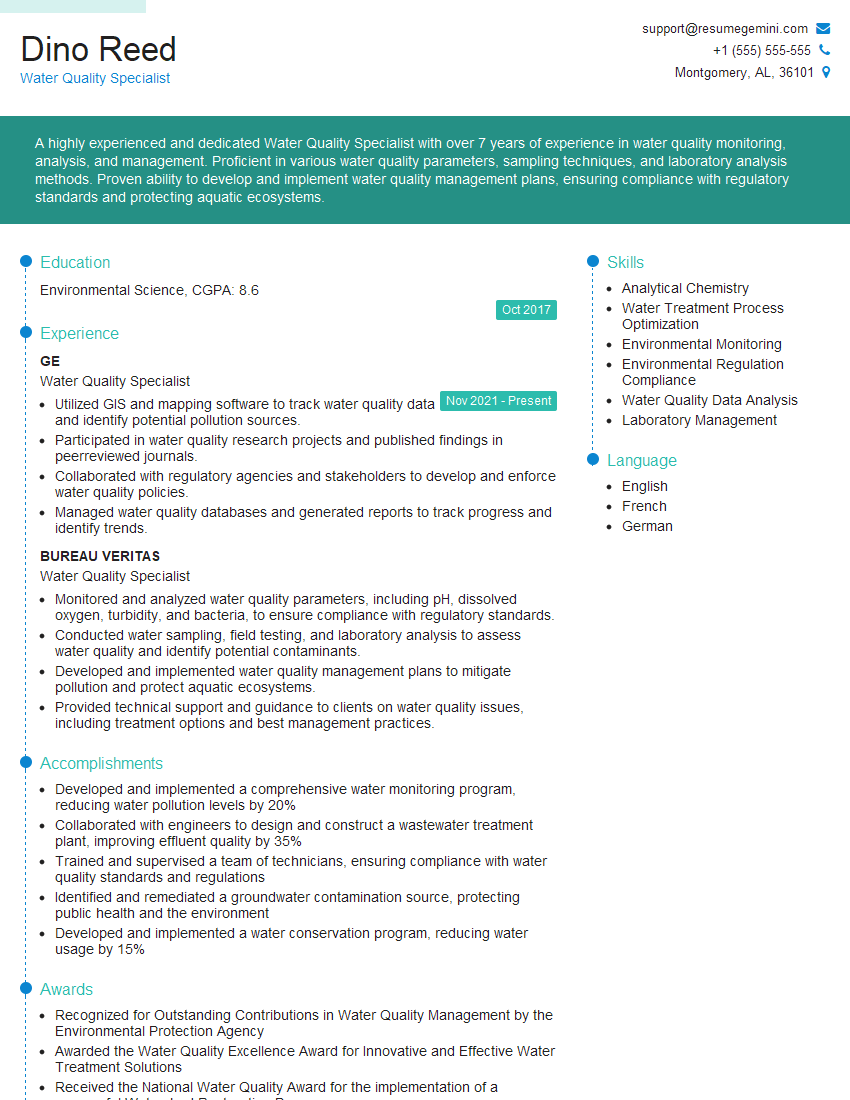

Mastering laboratory analysis for wastewater opens doors to a rewarding career with excellent growth potential in environmental science and engineering. Advancement opportunities abound in roles with increased responsibility, specialized testing, and project management. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that stands out. They provide examples of resumes tailored to Laboratory Analysis for Wastewater positions to guide you through the process. Invest time in crafting a strong resume – it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.