Cracking a skill-specific interview, like one for Roofing Repair and Maintenance, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Roofing Repair and Maintenance Interview

Q 1. Describe your experience with different roofing materials (e.g., asphalt shingles, tile, metal).

My experience spans a wide range of roofing materials, each with its own unique characteristics and challenges. Asphalt shingles, the most common type, are relatively inexpensive and easy to install, but their lifespan is shorter than other options. I’m proficient in all aspects of their installation, repair, and replacement, including understanding different shingle profiles and nailing patterns to ensure optimal performance. Tile roofs, while more durable and aesthetically pleasing, require specialized techniques due to their weight and fragility. My experience includes working with both clay and concrete tiles, understanding their susceptibility to cracking and the importance of proper underlayment. Finally, metal roofing – including standing seam and corrugated – offers exceptional longevity and weather resistance. I’m well-versed in its installation, knowing the critical importance of proper sealing and flashing to prevent leaks. I’ve worked on numerous projects involving each of these materials, from small repairs to complete roof replacements, allowing me to develop a deep understanding of their strengths, weaknesses, and the best practices for their maintenance.

Q 2. Explain the process of identifying and repairing roof leaks.

Pinpointing a roof leak requires a systematic approach. First, I’ll conduct a thorough visual inspection, looking for obvious signs like damaged shingles, missing flashing, or cracks in the chimney. If the leak isn’t immediately apparent, I’ll use a variety of methods: I might employ a moisture meter to detect hidden water damage within the roof structure. Alternatively, during rainfall, I’ll carefully observe the interior of the building, noting where water is entering. For hidden leaks, a thermal imaging camera can often reveal temperature differences indicating the presence of moisture. Once the source is identified, repair involves addressing the underlying problem. This could be anything from replacing a few damaged shingles to extensive repairs involving flashing or even structural elements. It’s crucial to ensure proper drainage and ventilation during the repair process to prevent future problems.

For example, if a leak is found near a chimney, the flashing around it may need to be replaced or resealed. If a shingle is damaged, it needs to be removed and replaced with a new one, matching the existing ones as closely as possible for aesthetic consistency. After the repair is complete, I always test the repair for effectiveness and check for any remaining leaks.

Q 3. How do you assess the condition of a roof and determine the necessary repairs?

Assessing a roof involves a multifaceted inspection. I start by visually inspecting the entire roof surface from the ground and then proceed to a close-up examination from the roof itself (with appropriate safety measures in place). I look for signs of damage such as missing or damaged shingles, cracked or curling shingles, rust on metal roofs, broken or missing tiles, and damaged flashing around chimneys, vents, and skylights. I check for proper drainage, examining gutters and downspouts for blockages and ensuring water flows away from the foundation. I’ll also evaluate the overall condition of the underlayment, looking for deterioration or damage that could compromise the roof’s integrity. Furthermore, I consider the age of the roofing material, as this is a key factor in determining its remaining lifespan and the need for potential repairs or replacement. Finally, I consider environmental factors such as extreme weather conditions which may have accelerated deterioration. Based on this comprehensive evaluation, I’ll create a detailed report outlining the necessary repairs, their urgency, and associated costs, providing homeowners with all the information to make informed decisions.

Q 4. What safety measures do you employ when working on a roof?

Safety is paramount when working on a roof. I always adhere to OSHA safety regulations and utilize appropriate personal protective equipment (PPE), including a safety harness with a lanyard anchored to a secure point on the roof, hard hat, safety glasses, and sturdy work boots with slip-resistant soles. I use fall protection equipment, such as safety nets, when working at heights. Before starting work, I inspect the roof to identify any potential hazards, such as damaged sections, loose materials, or slippery surfaces. I also ensure proper access and egress points. I never work alone, and always have a spotter or partner to assist and ensure my safety. If necessary, I utilize scaffolding or ladders which are properly secured, inspected regularly, and designed to support the weight of the equipment and personnel involved.

Q 5. Describe your experience with different types of roofing repairs (e.g., shingle replacement, flashing repair, gutter cleaning).

My experience encompasses a broad spectrum of roofing repairs. Shingle replacement is a common task, ranging from replacing a few damaged shingles to a complete re-roofing. I am skilled in properly matching shingle types and colors for seamless repairs. Flashing repair is crucial for preventing leaks. I’m adept at identifying and replacing or sealing damaged flashing around chimneys, vents, and skylights, using appropriate materials like aluminum or copper to ensure watertight seals. Gutter cleaning is essential for preventing water damage and ice dams. I clean and repair gutters, removing debris and ensuring proper drainage. In addition to these, I handle more complex repairs like repairing structural damage under the roofing, replacing damaged roof sheathing, and addressing issues with underlayment. I’ve tackled various challenges, from fixing minor leaks to resolving complex water damage problems, always prioritizing a meticulous and thorough approach.

Q 6. How familiar are you with building codes and regulations related to roofing?

I’m very familiar with local building codes and regulations pertaining to roofing. I understand the requirements for slope, materials, flashing, ventilation, and snow load, ensuring all my work complies with these standards. I regularly update my knowledge to keep abreast of any changes or new regulations. Before undertaking any project, I always check local building codes and obtain the necessary permits, ensuring legal compliance. This includes understanding specific requirements related to fire safety, wind resistance, and energy efficiency, all crucial aspects of responsible roofing practices.

Q 7. Explain your experience using specialized roofing tools and equipment.

I’m proficient in using a wide array of specialized roofing tools and equipment. This includes various types of hammers, nail guns, utility knives, roofing shovels, and measuring tools for accurate cutting and placement of materials. I’m experienced with using power tools such as circular saws, reciprocating saws, and drills for efficient and precise work. My experience also includes using specialized equipment for more complex tasks such as roof jacks and scaffolding for safe and efficient work at heights, and thermal imaging cameras for detecting hidden moisture problems. I am also comfortable using various types of roofing sealants, adhesives, and underlayment materials to ensure a durable and watertight roof.

Q 8. Describe your problem-solving skills related to unexpected challenges on a roofing project.

Unexpected challenges are par for the course in roofing. My approach is systematic. First, I assess the situation calmly, identifying the root cause of the problem. This often involves a visual inspection, sometimes using specialized tools like moisture meters or thermal cameras. Then, I brainstorm potential solutions, weighing their feasibility and cost-effectiveness. For example, if I discover unexpected rot during a shingle replacement, I wouldn’t just patch it; I’d determine the extent of the damage, explain it to the client, and propose options: localized repair, sheathing replacement, or even a more extensive overhaul if necessary. Prioritizing safety is paramount; if a structural issue is discovered, I immediately halt the work and consult with an engineer before proceeding.

I document all unexpected findings meticulously, including photographs and detailed notes, which aids in communication with clients and allows for accurate cost adjustments if needed. One time, I encountered a hidden wasp nest during a roof inspection – safety first! I immediately secured the area, contacted a pest control professional, and resumed the project once it was safe. This illustrates my proactive approach to problem-solving, emphasizing both technical expertise and safety consciousness.

Q 9. How do you prioritize multiple roofing repair projects or tasks?

Prioritization is crucial for efficient project management. I use a combination of methods. First, I assess the urgency of each project, considering factors like the severity of damage (a leaking roof takes precedence over a minor cosmetic repair), the client’s needs (an elderly homeowner needs faster service), and potential weather impacts (storm damage needs immediate attention). Then, I schedule projects based on urgency and availability of resources – materials, crew, and equipment. I often use a Kanban-style board or a digital project management tool to visualize the workflow and track progress. This allows for easy re-prioritization as new, more urgent requests come in.

For instance, if I have a critical leak repair and a smaller gutter cleaning job, the leak repair takes priority. I communicate clearly with clients about scheduling, managing their expectations and providing realistic timelines. This transparent approach ensures client satisfaction and helps to prevent conflicts or delays.

Q 10. Explain your understanding of roof ventilation and its importance.

Roof ventilation is critical for the longevity and performance of a roof. It’s essentially the roof’s respiratory system. Proper ventilation prevents moisture buildup, which is the root cause of many roofing problems, such as mold, rot, and ice dams. A well-ventilated roof allows for the escape of hot, moist air from the attic, preventing condensation and reducing the potential for structural damage. It also helps regulate attic temperature, making the home more energy-efficient.

There are three key components to a good ventilation system: intake vents at the soffits (low points), exhaust vents at the ridge or peak (high points), and proper insulation. Imagine your attic as a room: you need to bring in fresh air and let stale air out for proper air circulation. Insufficient ventilation can lead to a host of problems, from shortened roof lifespan to increased energy bills and even structural issues. I always assess a roof’s ventilation during an inspection and recommend improvements where needed.

Q 11. How do you estimate the cost of roofing repairs or projects?

Estimating roofing repair costs involves a detailed breakdown of several factors. First, a thorough inspection is crucial to accurately assess the extent of damage. Then, I consider the type of roofing material, the area to be repaired or replaced, the labor costs (including the crew size and the time required), the cost of materials (including disposal fees), and any permits or other potential expenses. I always factor in a contingency for unexpected issues that might arise during the project.

For example, a simple shingle repair might cost significantly less than a complete roof replacement, which could involve removing old materials, installing underlayment, installing new shingles, and potentially repairing or replacing fascia and flashing. I provide clients with a detailed, itemized estimate to ensure transparency and avoid any surprises. I also provide a range of options, allowing clients to choose the solution that best fits their budget and needs.

Q 12. Describe your experience working with clients or homeowners.

Building strong relationships with clients is paramount. I believe in clear, open communication throughout the entire process. This starts with a thorough explanation of the problem, the proposed solution, the cost breakdown, and the timeline. I listen carefully to their concerns, answer their questions patiently, and provide regular updates on the progress of the project. I take pride in my responsiveness and ensure I am available to address their questions and concerns promptly.

I always treat clients’ homes with respect, keeping the work area clean and tidy. I also obtain their approval before commencing any significant work. My goal is not just to repair or replace a roof; it’s to build trust and provide a positive experience for my clients. Several of my clients have become repeat customers, which is a testament to the quality of my work and the strength of our relationship.

Q 13. How do you manage a team or crew on a roofing project?

Managing a roofing crew effectively involves clear communication, proper delegation, and maintaining a safe work environment. Before starting a project, I hold a pre-job meeting to review the plans, safety procedures, and individual responsibilities. I delegate tasks based on team members’ skills and experience, ensuring each person understands their role and responsibilities.

On-site, I maintain constant communication, addressing any questions or concerns promptly. I ensure that everyone follows safety protocols, using appropriate safety equipment and adhering to industry best practices. Regular check-ins help to ensure that the project stays on track and that any potential problems are identified and addressed immediately. A well-managed team translates to efficient work, high-quality results, and a safe work environment for everyone involved.

Q 14. What is your experience with roof inspections and reporting?

I have extensive experience conducting thorough roof inspections and preparing comprehensive reports. My inspections go beyond a simple visual check; they involve using specialized tools like moisture meters, thermal cameras, and drones to detect hidden issues. I assess the condition of all components, including shingles, underlayment, flashing, vents, gutters, and the structural elements of the roof. My reports are detailed and include high-quality photographs, diagrams, and a clear summary of findings, including any necessary repairs or recommendations.

These reports provide clients with a comprehensive understanding of their roof’s condition and are critical for insurance claims or when planning future maintenance or repairs. The reports follow a standardized format that includes details about the inspection date, the address, the condition of each component, any identified issues, and the recommended course of action. The goal is to provide clients with the information they need to make informed decisions about their roof’s maintenance and repair.

Q 15. How do you handle complaints or issues from clients?

Handling client complaints is crucial for maintaining a positive reputation. My approach is always to listen empathetically, understand their concerns fully, and then collaboratively find a solution. I start by acknowledging their frustration and assuring them that their issue is important to me. Then, I carefully examine the situation, often returning to the site to assess the work firsthand. Depending on the nature of the complaint, this might involve reviewing photos, invoices, or even consulting with the crew involved in the original project. Once I fully understand the issue, I present options for resolution, whether it’s a repair, a partial refund, or a replacement of materials. Transparency and open communication are key throughout the process. For instance, one client complained about some minor shingle damage after a particularly windy storm. After inspecting the roof, I explained that while some minor wear was expected given the weather, the damage exceeded what was considered normal wear and tear. We agreed on a solution where we replaced the affected shingles at no additional cost to the client, ensuring they felt heard and valued.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with different types of roof structures (e.g., gable, hip, flat).

My experience encompasses a wide range of roof structures. I’ve worked extensively with gable roofs, characterized by their triangular ends and simple design; hip roofs, with sloping sides meeting at a central ridge; and flat roofs, which require specialized attention to waterproofing and drainage. Understanding the specific characteristics of each type is essential for proper repair and maintenance. For example, gable roofs are generally easier to access and inspect, while hip roofs present challenges due to their complex angles. Flat roofs often require more meticulous attention to detail concerning proper drainage to prevent water pooling and subsequent damage. My expertise includes identifying potential vulnerabilities in each type, such as weak points in the structural framing or areas prone to leakage, ensuring I can effectively address any issues.

Q 17. How do you determine the cause of roof damage after a storm?

Determining the cause of storm damage requires a systematic approach. I begin with a thorough visual inspection of the entire roof, looking for signs of impact damage, such as missing shingles, punctures, or displaced flashing. I then check for areas of water penetration, such as leaks in the ceiling or interior walls, which can help pinpoint the origin of the damage. I consider the type and intensity of the storm, focusing on factors like wind speed, hail size, and rainfall. For instance, high winds might cause shingle blow-off, while hail could cause dents and cracks. Finally, I document my findings with photos and a detailed report. A recent case involved a client whose roof was damaged during a severe hailstorm. My inspection revealed significant hail damage to the shingles, leading to numerous cracks and some missing pieces. The report highlighted these findings and provided a detailed cost estimate for repair, ensuring the client received a clear understanding of the extent of the damage and the necessary repairs.

Q 18. What is your understanding of different types of roofing warranties?

Roofing warranties vary significantly, ranging from manufacturer warranties covering materials to workmanship warranties provided by contractors. Manufacturer warranties typically cover defects in materials for a specified period, often 20-30 years for asphalt shingles. These warranties generally cover defects in materials, not damage caused by weather or improper installation. Workmanship warranties, on the other hand, are provided by roofing contractors and typically cover defects in installation for a shorter period, ranging from 1 to 10 years. It is important to understand the terms and conditions of each warranty, including any exclusions or limitations. For example, some warranties might exclude damage from extreme weather events or improper maintenance. Reading and understanding the fine print of a warranty ensures that clients know exactly what is and is not covered, preventing any misunderstandings or disputes down the line.

Q 19. Describe your experience working with subcontractors or suppliers.

I have a strong network of reliable subcontractors and suppliers. Building and maintaining these relationships is crucial for efficient and quality work. I carefully select subcontractors based on their experience, reputation, and licensing. We have a well-established system for communication and coordination, ensuring projects proceed smoothly. This includes regular updates and open channels for addressing any concerns. With suppliers, I prioritize established businesses that provide high-quality materials at competitive prices. This guarantees project success and helps meet client expectations. For instance, I often collaborate with a trusted supplier for specialized roofing materials, ensuring prompt delivery and quality control. This reliable partnership reduces potential delays and allows for consistent high-quality work.

Q 20. How do you ensure the quality of your workmanship?

Quality workmanship is paramount. I use a multi-faceted approach to ensure high standards. This begins with meticulous planning and preparation, including careful measurements and material selection. Throughout the project, I adhere strictly to building codes and industry best practices. Regular quality checks are performed during each stage of the process, ensuring proper installation and addressing any issues immediately. My team receives ongoing training on the latest techniques and safety standards. We maintain a clean and organized worksite, minimizing the risk of damage and ensuring efficiency. Furthermore, I conduct a thorough final inspection before project completion, ensuring all aspects meet or exceed expectations. Client satisfaction is always my highest priority.

Q 21. Describe your experience with using different types of sealant or waterproof materials.

My experience with sealants and waterproof materials is extensive. I’m proficient in using various types, including asphalt-based sealants, silicone caulk, polyurethane foam, and liquid rubber coatings. Each material has its strengths and weaknesses and is chosen based on the specific application and environmental conditions. For instance, silicone caulk is excellent for sealing small gaps and cracks, while liquid rubber is ideal for creating a seamless waterproof membrane on flat roofs. Understanding the properties of each material, such as its adhesion, flexibility, and durability, is critical for selecting the appropriate product and ensuring a long-lasting repair. Proper application techniques are also crucial. In one project, we used a high-performance polyurethane foam to seal gaps around flashing and chimneys, ensuring a durable and weatherproof seal that prevented water penetration.

Q 22. Explain your knowledge of proper disposal and handling of roofing materials.

Proper disposal and handling of roofing materials is crucial for environmental protection and worker safety. It involves understanding local regulations and employing best practices throughout the project lifecycle, from initial material selection to final waste removal.

- Material Selection: Opting for recycled or sustainably sourced materials minimizes environmental impact. For example, choosing recycled asphalt shingles reduces landfill waste.

- On-Site Handling: Careful handling prevents damage and waste. This includes using proper lifting techniques, protecting materials from weather damage, and minimizing spills or breakage. We utilize designated storage areas to keep materials organized and prevent accidents.

- Waste Separation: Different roofing materials require different disposal methods. We carefully separate shingles, underlayment, flashing, and other debris. This allows for proper recycling or disposal according to local regulations.

- Disposal & Recycling: We work with licensed waste haulers who specialize in construction debris. Many materials, like asphalt shingles, can be recycled into new products. Proper documentation of disposal is maintained to ensure compliance.

- Hazardous Materials: Special care is taken with hazardous materials like asbestos or lead-based paint. These require specialized handling, removal, and disposal by certified professionals, ensuring compliance with all relevant environmental and safety regulations. We never attempt to handle hazardous materials ourselves without appropriate certification and permits.

Q 23. How do you handle difficult weather conditions during roofing work?

Working in challenging weather is a common aspect of roofing. Safety is paramount. We employ a multifaceted approach to ensure both project completion and worker safety.

- Weather Monitoring: We constantly monitor weather forecasts. Work is postponed if conditions become unsafe, such as during thunderstorms, high winds, or extreme temperatures. Safety is always prioritized over schedule.

- Appropriate Equipment: We use weather-resistant equipment and materials. This includes tarps for material protection, specialized fasteners for windy conditions, and appropriate safety gear for all team members.

- Safety Procedures: Strict safety protocols are in place, emphasizing fall protection, proper use of tools, and clear communication between crew members. We have detailed emergency procedures in case of unexpected weather events.

- Adaptive Techniques: The roofing process may need to be modified to accommodate the weather. For example, we may adjust the pace of work during intense heat or reduce crew size in high winds.

- Project Planning: Weather is a key consideration during project planning. We strive to schedule work during favorable conditions to minimize delays and ensure optimal working conditions.

Q 24. What is your experience with roof maintenance schedules and preventative measures?

Roof maintenance is crucial for extending roof lifespan and preventing costly repairs. A proactive approach, including regular inspections and preventative measures, is key.

- Regular Inspections: I recommend annual inspections, or more frequently depending on the roof type and local climate. Inspections identify potential problems early, such as loose shingles, damaged flashing, or signs of leaks.

- Preventative Measures: These include cleaning gutters and downspouts to prevent water damage, removing debris from the roof surface, and sealing cracks or gaps. Regular moss and algae removal is essential for certain climates.

- Schedule Customization: Maintenance schedules should be tailored to the specific roof type, climate, and building usage. For example, a flat roof in a high-rainfall area may require more frequent inspections than a steep-pitched roof in an arid climate.

- Documentation: Maintaining detailed records of inspections and maintenance performed provides a history of the roof’s condition and assists in future planning and warranty claims.

- Client Education: Educating clients about preventative maintenance is a significant part of my role. I explain the importance of regular checks and empower them to address minor issues before they become major problems.

Q 25. Describe your experience using project management software for roofing projects.

I have extensive experience using project management software, specifically CoConstruct and Buildertrend. These platforms streamline various aspects of roofing projects, improving efficiency and communication.

- Scheduling & Resource Management: These tools allow for efficient scheduling of crews, materials, and equipment. This minimizes delays and optimizes labor allocation.

- Communication & Collaboration: They facilitate clear communication between clients, subcontractors, and the roofing crew, ensuring everyone is informed of project progress and any changes.

- Cost Tracking & Budgeting: Software offers robust tools for tracking expenses, managing budgets, and generating accurate reports for clients. This promotes financial transparency and control.

- Document Management: Digital storage of project documents, contracts, permits, and photos simplifies record-keeping and retrieval.

- Progress Reporting: Automated progress reports keep clients informed and facilitate smooth project completion.

For example, using Buildertrend, I can easily create and share customized schedules with clients, upload photos of completed work, and instantly respond to any queries. This level of transparency builds trust and improves client satisfaction.

Q 26. Explain your understanding of OSHA regulations related to roofing safety.

OSHA regulations are critical for ensuring workplace safety in the roofing industry. I have a thorough understanding of these regulations and implement them rigorously in all my projects.

- Fall Protection: This is the most critical aspect, requiring the use of guardrails, safety nets, or personal fall arrest systems (PFAS) depending on the job specifics and roof type. Regular inspections of fall protection equipment are mandatory.

- Scaffolding & Ladders: Proper erection, use, and maintenance of scaffolding and ladders are essential. Training and adherence to safety guidelines are crucial to prevent falls and injuries.

- Personal Protective Equipment (PPE): Appropriate PPE, including hard hats, safety glasses, gloves, and high-visibility clothing, is mandatory for all workers. Regular inspections and replacement of worn or damaged equipment are vital.

- Hazard Communication: Clear communication of potential hazards, including fall risks, electrical hazards, and material handling risks, is crucial. This includes proper labeling of materials and providing safety training to all personnel.

- Emergency Procedures: Having a well-defined plan for handling emergencies, such as falls or injuries, is essential. This includes immediate first aid, contacting emergency services, and ensuring compliance with reporting requirements.

Regular safety meetings and ongoing training are critical to ensure all team members are aware of and comply with OSHA regulations. We maintain thorough documentation of our safety practices and training records.

Q 27. How do you communicate technical information to clients who may not have roofing expertise?

Communicating technical information to non-experts requires clear, concise language and visual aids. I avoid jargon and use relatable analogies to explain complex concepts.

- Plain Language: I use simple, everyday terms instead of technical terms. If technical terms are necessary, I define them clearly.

- Visual Aids: Diagrams, photos, and videos are invaluable tools for illustrating roofing issues and proposed solutions. A picture is truly worth a thousand words.

- Step-by-Step Explanations: Breaking down complex processes into smaller, easily understandable steps makes information more accessible.

- Real-World Examples: Relating technical information to familiar concepts or experiences makes it more relatable and memorable. For example, I might compare a roof’s flashing to a raincoat protecting the house from rain.

- Active Listening & Feedback: I encourage questions and actively listen to client concerns, ensuring they understand the information and feel comfortable making decisions.

For instance, when explaining the need for roof replacement, I might show before-and-after photos of similar projects, highlighting the improved appearance and functionality. This visual representation strengthens my explanation and builds trust.

Q 28. What are your salary expectations for this roofing position?

My salary expectations are commensurate with my experience and skills in the roofing industry. Considering my extensive experience in project management, OSHA compliance, and client communication, my salary range is between $80,000 and $100,000 per year. This is a competitive range based on my research of similar roles in the area and my demonstrated expertise. However, I’m open to discussing a specific compensation package that reflects the value I bring to the company and aligns with your budget and the specifics of the position.

Key Topics to Learn for Roofing Repair and Maintenance Interview

- Roofing Materials: Understanding the properties, lifespan, and applications of various roofing materials (e.g., asphalt shingles, tile, metal, etc.). This includes knowing their strengths and weaknesses and appropriate maintenance practices.

- Roof Inspections and Diagnostics: Mastering techniques for thorough roof inspections, identifying common damage types (e.g., leaks, missing shingles, structural issues), and accurately diagnosing the root causes of problems. Practical application involves using appropriate tools and documenting findings effectively.

- Repair Techniques: Gaining practical knowledge of repairing common roofing issues, including shingle replacement, flashing repair, gutter cleaning and repair, and basic structural repairs. This includes understanding safe work practices and proper material selection.

- Preventive Maintenance: Learning the importance of routine maintenance, including cleaning gutters, inspecting flashing, and addressing minor repairs promptly to prevent major damage and extend roof lifespan. Practical application involves creating and following preventative maintenance schedules.

- Safety Procedures: Demonstrating a strong understanding of safety protocols related to working at heights, using appropriate safety equipment (harnesses, ladders, etc.), and adhering to OSHA regulations. This includes awareness of weather-related risks and how to mitigate them.

- Estimating and Budgeting: Developing skills in accurately estimating material costs, labor hours, and providing competitive quotes for repair and maintenance projects. This includes understanding profit margins and creating professional proposals.

- Customer Communication: Effectively communicating technical information to clients in a clear and concise manner, building rapport, and addressing concerns professionally.

- Troubleshooting and Problem-Solving: Demonstrating the ability to diagnose complex roofing problems, develop effective solutions, and adapt to unexpected challenges on the job site.

Next Steps

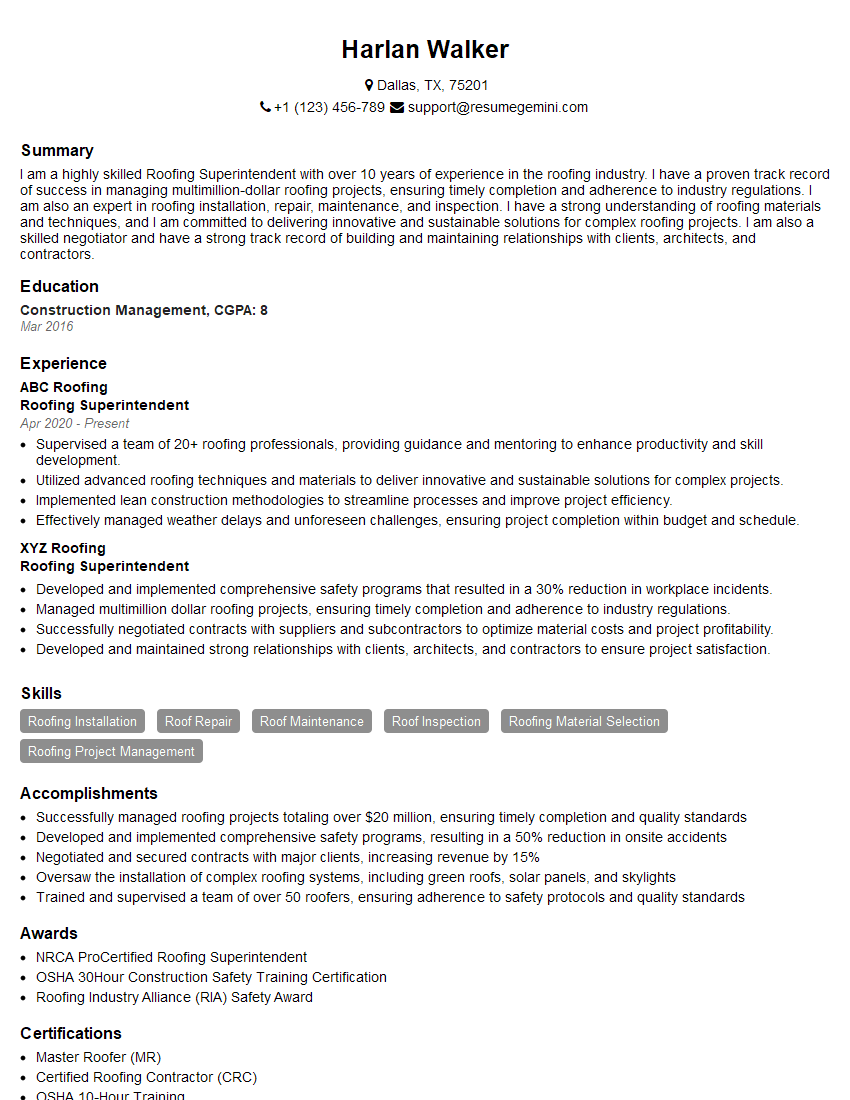

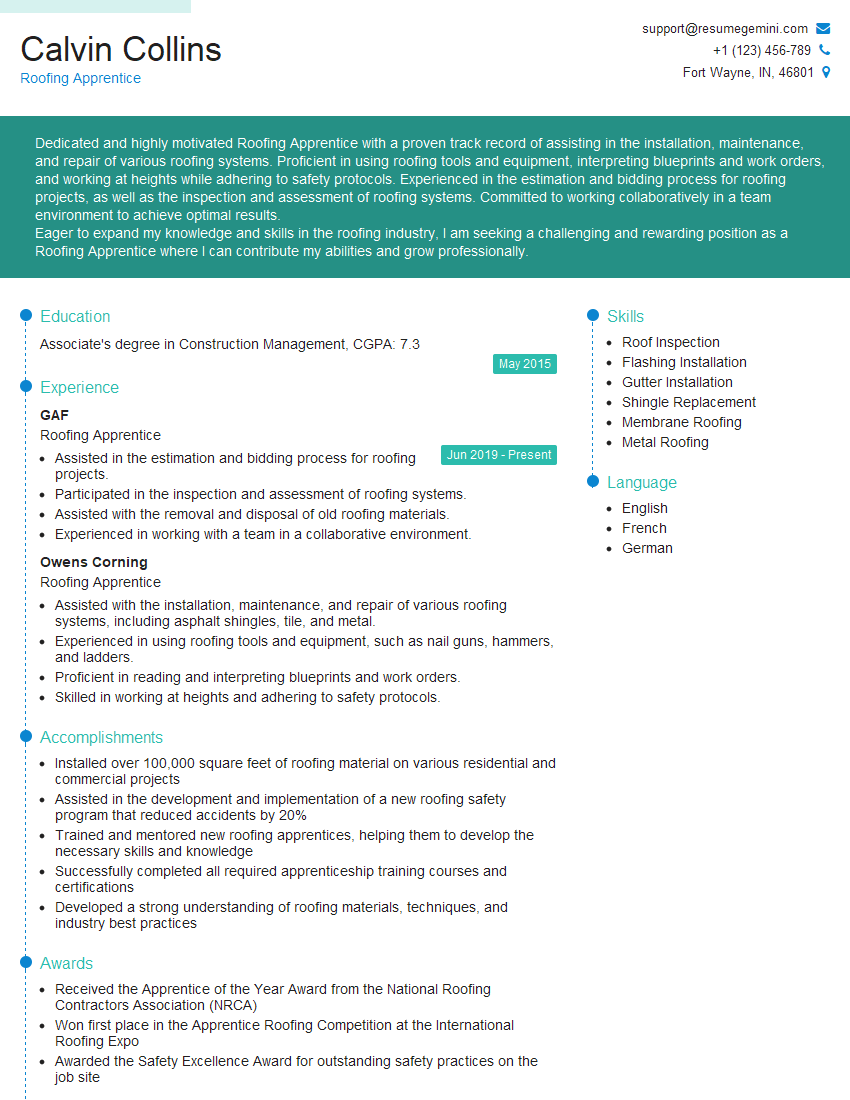

Mastering Roofing Repair and Maintenance opens doors to a rewarding career with excellent growth potential, offering opportunities for specialization, increased responsibility, and higher earning potential. To maximize your job prospects, crafting an ATS-friendly resume is crucial. This ensures your qualifications are effectively communicated to hiring managers and Applicant Tracking Systems. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience in the best possible light. ResumeGemini provides examples of resumes tailored to Roofing Repair and Maintenance to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.