Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Firestop Penetration Sealing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Firestop Penetration Sealing Interview

Q 1. What are the common types of firestop penetrations?

Common firestop penetrations involve openings in fire-rated assemblies, allowing the passage of services like pipes, cables, conduits, and HVAC ducts. Think of them as controlled pathways through a fire-resistant wall or floor.

- Pipes and Ducts: Penetrations for plumbing, sprinkler systems, and HVAC ventilation.

- Electrical Conduits and Cables: Passages for power, communication, and data cables.

- Mechanical Penetrations: Openings for things like sleeves for future installations or equipment mounting.

- HVAC Systems: Large openings accommodating ductwork and associated components.

The type of penetration dictates the firestop system required to maintain the assembly’s fire rating.

Q 2. Explain the difference between through-penetration and boundary firestopping.

The key difference lies in their location and purpose within a fire-rated assembly.

Through-Penetration Firestopping seals openings that completely pass through a fire-rated barrier (e.g., a pipe going from one side of a wall to the other). It aims to prevent the passage of flames, smoke, and hot gases through the penetration.

Boundary Firestopping, on the other hand, addresses situations where a fire-rated assembly is interrupted or meets another assembly at a joint or boundary. It’s about sealing gaps and preventing fire spread along these edges or interfaces. Imagine the gap between two fire-rated walls – boundary firestopping ensures this gap remains fire-resistant.

Think of it this way: through-penetration is like patching a hole in a wall, while boundary firestopping is like sealing the seams between different wall sections.

Q 3. Describe the different firestop materials and their applications.

Many materials are used in firestopping, each chosen based on the penetration type, fire rating requirements, and environmental conditions.

- Intumescent Materials: These expand dramatically when exposed to heat, filling the gaps and creating an insulating barrier. They are versatile and suitable for many penetration types.

- Mineral Wool: A fibrous material providing excellent thermal and acoustic insulation and fire resistance. Often used in combination with other materials.

- Epoxy and Putty-Based Systems: These offer high-strength seals for various penetration sizes and configurations. They’re often chosen for their ability to conform to irregular shapes.

- Silicone-Based Sealants: These are used for smaller gaps and less demanding applications, particularly in areas with movement or vibration.

- Firestop Collars and Gaskets: Pre-fabricated systems designed for specific penetration types and sizes, offering a quick and straightforward installation for simple applications.

Material selection is crucial, as using the wrong material can lead to significant fire safety risks.

Q 4. What are the key considerations when selecting a firestop system?

Choosing the right firestop system requires careful consideration of several factors:

- Required Fire Rating: The system must meet or exceed the fire resistance rating of the penetrated assembly. This is determined by building codes and fire safety regulations.

- Penetration Type and Size: The system should be compatible with the size, shape, and number of penetrations.

- Material Compatibility: Ensure the firestop material is compatible with the materials of the penetrated assembly and the penetrants (pipes, cables, etc.). Some materials can react negatively with others, compromising the effectiveness of the firestop.

- Environmental Conditions: Consider temperature variations, humidity, and potential exposure to chemicals or other environmental factors.

- Installation Method: The system’s installation should be straightforward and achievable with the available tools and expertise. Complicated systems can increase the risk of errors.

- Accessibility and Maintainability: Future access for inspection, repair, or replacement of the penetrants should be considered.

A poorly selected system can lead to catastrophic failures in a fire event.

Q 5. How do you determine the required fire rating for a specific penetration?

The required fire rating for a specific penetration is dictated primarily by building codes and fire safety regulations. These codes vary depending on geographical location and the specific type of building. The building’s occupancy classification also impacts the fire rating requirements. For example, a hospital will have stricter fire safety requirements than an office building.

Often, the required fire rating will be specified in the building plans or fire safety documentation. If not explicitly stated, consultation with local fire authorities or a qualified fire protection engineer is essential to determine the appropriate fire rating.

The fire rating isn’t just a number; it represents the time (in hours) a firestop system can effectively resist the passage of fire and smoke under specific testing conditions.

Q 6. Explain the importance of firestop inspection and testing.

Regular inspection and testing of firestops are vital for maintaining fire safety. Think of it as regular car maintenance—preventative care is far better than emergency repair during a fire.

Inspection involves visual checks for damage, deterioration, or any signs of displacement of the firestop materials. This should be performed regularly, potentially annually, or after any construction activity near the firestop.

Testing is more rigorous and might involve destructive or non-destructive methods to verify the integrity and fire resistance of the firestop system. This is often required at intervals specified by the building codes or after significant events.

Proper documentation of both inspections and tests is critical for maintaining compliance and ensuring liability.

Q 7. What are the common causes of firestop failures?

Firestop failures can stem from various factors, some preventable, others less so.

- Improper Installation: This is the most common cause. Inadequate training, incorrect application of the firestop material, or gaps in the sealant can compromise the system’s effectiveness.

- Material Degradation: Exposure to moisture, chemicals, or UV radiation can degrade firestop materials over time, reducing their fire resistance.

- Mechanical Damage: Physical impacts, accidental cuts, or vibrations can damage the firestop system.

- Incorrect Material Selection: Choosing inappropriate firestop materials for the penetration type, assembly, or environmental conditions can lead to failure.

- Movement and Vibration: Movement of the penetrating services can cause gaps or cracks in the firestop, compromising its integrity.

- Poor Design: Inadequate design of the penetration, such as insufficient space for the firestop material, can contribute to failures.

Addressing these potential failure points through proper design, installation, and regular maintenance is key to ensuring the effectiveness of the firestop system.

Q 8. How do you address firestop deficiencies?

Addressing firestop deficiencies involves a systematic approach that begins with thorough inspection and identification of the problem. This includes identifying the type of penetration (pipes, conduits, cables, etc.), the location, and the severity of the deficiency. Then, we determine the cause of the deficiency; was it improper installation, material degradation, or design oversight? Once the cause is understood, remediation steps can be taken. This might involve:

- Repairing existing firestopping: This could involve cleaning and repairing damaged firestop materials, adding additional sealant, or replacing the entire firestop system if necessary. For instance, if a cable penetration’s firestop sealant has cracked, it requires careful removal of the compromised material, cleaning of the area, and application of a compatible, fresh sealant.

- Installing missing firestopping: Many deficiencies stem from penetrations that weren’t firestopped at all. This necessitates a careful installation of an appropriate firestop system, considering the penetration’s size, material, and fire rating requirements. We carefully follow manufacturer’s instructions and relevant building codes.

- Replacing outdated or unsuitable materials: Building materials and firestop technologies evolve. If the existing firestop is outdated and no longer meets current code requirements, it must be replaced with a compliant system.

- Updating firestop drawings and documentation: Accurate documentation is crucial. Any changes made during remediation are meticulously recorded and updated in the project’s firestop drawings and as-built documentation.

Finally, post-remediation inspection and testing, if required, validate the effectiveness of the repairs. A well-documented process ensures that the building’s fire safety integrity is restored and maintained.

Q 9. What are the relevant fire codes and standards for firestopping?

Firestopping is governed by a variety of codes and standards that vary by location. However, some key international and US-based standards commonly referenced include:

- International Fire Codes (IFC): These provide the model code for fire safety, which many jurisdictions adopt. The IFC specifies requirements for firestopping materials, installation, and testing.

- National Fire Protection Association (NFPA) standards: NFPA 13 (Standard for the Installation of Sprinkler Systems), NFPA 70 (National Electrical Code), and NFPA 252 (Standard Methods of Fire Tests of Building Construction and Materials) directly or indirectly influence firestopping practices. NFPA 13, for example, addresses firestopping around sprinkler systems.

- Local building codes: Individual jurisdictions often have their own building codes that incorporate or modify elements of the IFC and NFPA standards. These codes often specify the required fire resistance ratings for specific building types and occupancy classifications.

- Manufacturer’s specifications: Firestop manufacturers provide detailed installation instructions for their products. These instructions must be followed meticulously to ensure the effectiveness of the firestopping system. This is crucial because it’s often the manufacturer’s data that provides the fire rating details and installation specifications that support compliance with relevant codes.

It’s critical to be aware of and comply with all applicable codes and standards for each project. A comprehensive understanding of these regulations is essential to ensure effective and compliant firestopping installations.

Q 10. Describe your experience with different firestop installation methods.

My experience encompasses a wide range of firestop installation methods, tailored to different penetration types and building materials. This includes:

- Intumescent materials: These expand upon exposure to heat, sealing gaps and preventing fire spread. I have experience installing intumescent foams, mastics, and wraps, carefully following manufacturer guidelines on application thickness and curing time. For example, installing intumescent wraps around pipes requires ensuring complete coverage and proper overlap.

- Firestop sealant: This method involves filling gaps and voids with specialized fire-resistant sealants. Careful attention is paid to achieving a complete and uniform seal, avoiding voids or gaps. Selecting the right sealant type is vital based on the penetration and surrounding materials.

- Firestop putty: Putty is used for smaller gaps and penetrations, offering ease of use and excellent flexibility. Precise application is key to preventing gaps and ensuring a solid seal.

- Mechanical firestops: These are pre-engineered systems, like fire collars or sleeves, offering a straightforward and often faster installation process. The specific installation method will depend on the manufacturer’s specifications. For example, pipe penetration fire collars are carefully secured to maintain the integrity of the seal.

- Combination methods: Often, a combination of methods is necessary to achieve the desired fire rating. For example, a combination of sealant and intumescent materials might be used for larger penetrations.

I always prioritize accurate material selection, ensuring compatibility with the penetration and surrounding materials, and adhering strictly to manufacturer’s instructions for each installation method. Experience helps me anticipate potential challenges and select the most efficient and effective approach for each project.

Q 11. How do you ensure the compatibility of firestop materials with other building materials?

Ensuring compatibility between firestop materials and other building materials is paramount for effective fire protection. Compatibility issues can result in reduced fire resistance or even material failure. I approach this in several ways:

- Material compatibility charts: Most reputable firestop manufacturers provide detailed compatibility charts that specify which firestop materials are compatible with various building materials such as concrete, drywall, steel, and different types of piping. I meticulously consult these charts to select the appropriate firestop materials.

- Testing and certification: Firestop systems undergo rigorous testing to confirm their compatibility and fire resistance ratings. I always select materials with appropriate third-party certifications and test reports, ensuring they meet the project’s requirements and building codes.

- On-site assessment: Before selecting materials, I conduct a thorough on-site assessment to identify all materials involved in the penetration and its surroundings. This includes verifying material types and identifying any potential incompatibility issues.

- Manufacturer consultation: If any uncertainty exists regarding compatibility, I directly consult with the firestop manufacturer for technical advice. They offer expert knowledge and can confirm suitability for specific applications.

By following these steps, I ensure that the chosen firestop system performs optimally and maintains its fire-resistant properties, integrating seamlessly with the surrounding building materials.

Q 12. What safety precautions do you take during firestop installation?

Safety is always my top priority during firestop installations. My safety precautions include:

- Personal Protective Equipment (PPE): This is essential and includes safety glasses, gloves, respirators (depending on the materials used), and appropriate clothing to protect against potential hazards. For instance, working with some sealants necessitates the use of respirators to prevent inhalation of harmful fumes.

- Fall protection: If working at heights, appropriate fall protection measures such as harnesses and safety lines are strictly enforced.

- Confined space entry procedures: If working in confined spaces, such as within walls or ceilings, I follow strict confined space entry procedures, including ventilation, monitoring atmospheric conditions, and using appropriate safety equipment. This ensures that oxygen levels are sufficient and that hazardous gases are not present.

- Tool safety: Proper use and maintenance of tools are paramount to prevent injuries. Damaged or malfunctioning tools are immediately taken out of service.

- Communication and coordination: Clear communication with other tradespeople on the site ensures a safe working environment and avoids potential conflicts. This reduces risks of accidental damage to firestop installations or other building components during work processes.

By implementing a comprehensive safety program, I ensure a safe working environment, minimize risks, and prevent accidents during firestop installations.

Q 13. How do you manage firestop projects within budget and schedule?

Managing firestop projects within budget and schedule requires meticulous planning and execution. My approach involves:

- Detailed project scoping: A thorough assessment of the project’s scope, including the number of penetrations, types of penetrations, and required fire ratings, allows for accurate material estimation and labor costing.

- Realistic scheduling: Developing a realistic project schedule that accounts for material procurement, installation time, and potential delays, is crucial for on-time completion.

- Efficient material procurement: Ordering materials in a timely manner and negotiating favorable pricing from suppliers are essential to control costs. This also minimizes potential delays due to material shortages.

- Effective labor management: Utilizing a skilled and efficient team, properly trained in firestop installation methods, minimizes installation time and improves productivity. It also assists in minimizing potential rework.

- Regular progress monitoring: Regularly monitoring progress against the schedule and budget allows for early detection and resolution of any potential problems. This proactive approach minimizes cost overruns and schedule delays.

- Change management: A well-defined change management process ensures that any changes to the project scope are carefully evaluated, documented, and appropriately reflected in the budget and schedule.

By combining meticulous planning with proactive problem-solving, I consistently deliver firestop projects on time and within budget, while upholding the highest safety and quality standards.

Q 14. Describe your experience with documenting firestop installations.

Accurate documentation is crucial for demonstrating compliance with fire codes and ensuring the long-term integrity of firestop systems. My documentation practices include:

- Detailed firestop drawings: These drawings illustrate the locations of all firestop installations, the types of materials used, and the fire ratings achieved. They serve as essential references throughout the project and beyond.

- Installation records: Detailed records of each firestop installation, including dates, materials used, installers, and any deviations from the original plans, are meticulously maintained. These records often include photographs.

- Test reports (if applicable): If testing is required to verify the fire resistance of the firestop system, I ensure that all test reports are properly documented and filed. This provides irrefutable evidence of compliance.

- As-built drawings: As-built drawings reflect the final installed firestop system, incorporating any changes made during construction. These are particularly important for future maintenance and repairs.

- Material certification: Copies of the material certifications confirming that the firestop materials used meet the required standards are kept on file.

Comprehensive documentation not only ensures compliance but also provides valuable information for future inspections, maintenance, and potential renovations. A complete and accurate documentation package supports the ongoing safety and integrity of the building’s fire protection.

Q 15. What is your experience with different types of fire rated walls and floors?

My experience encompasses a wide range of fire-rated walls and floors, including those constructed from various materials such as concrete, gypsum board, and masonry. I’m proficient in identifying the specific fire-resistance ratings (often denoted as F-ratings, e.g., F-60 for 60 minutes of fire resistance) for each construction type. This is crucial because the selection of appropriate firestop systems is directly dependent on the wall or floor’s rating. For example, a through-penetration in an F-90 rated wall demands a firestop system with a minimum 90-minute rating. I’ve worked extensively with both framed and non-framed constructions, understanding the unique challenges each presents to maintaining fire integrity.

I have hands-on experience with various wall assemblies, including those incorporating fire-resistant insulation and those with complex designs incorporating multiple layers and materials. I understand the importance of considering the entire assembly when selecting and installing firestopping, not just the individual penetrations.

- Concrete Walls: Often require specialized firestop systems designed to adhere to the robust surface and potentially accommodate larger penetrations.

- Gypsum Board Walls: These require careful consideration of fastener types and the potential for damage during installation of the firestop system.

- Masonry Walls: These walls present challenges regarding penetration sealing due to the irregular surface and the need for materials compatible with mortar and brick.

Career Expert Tips:

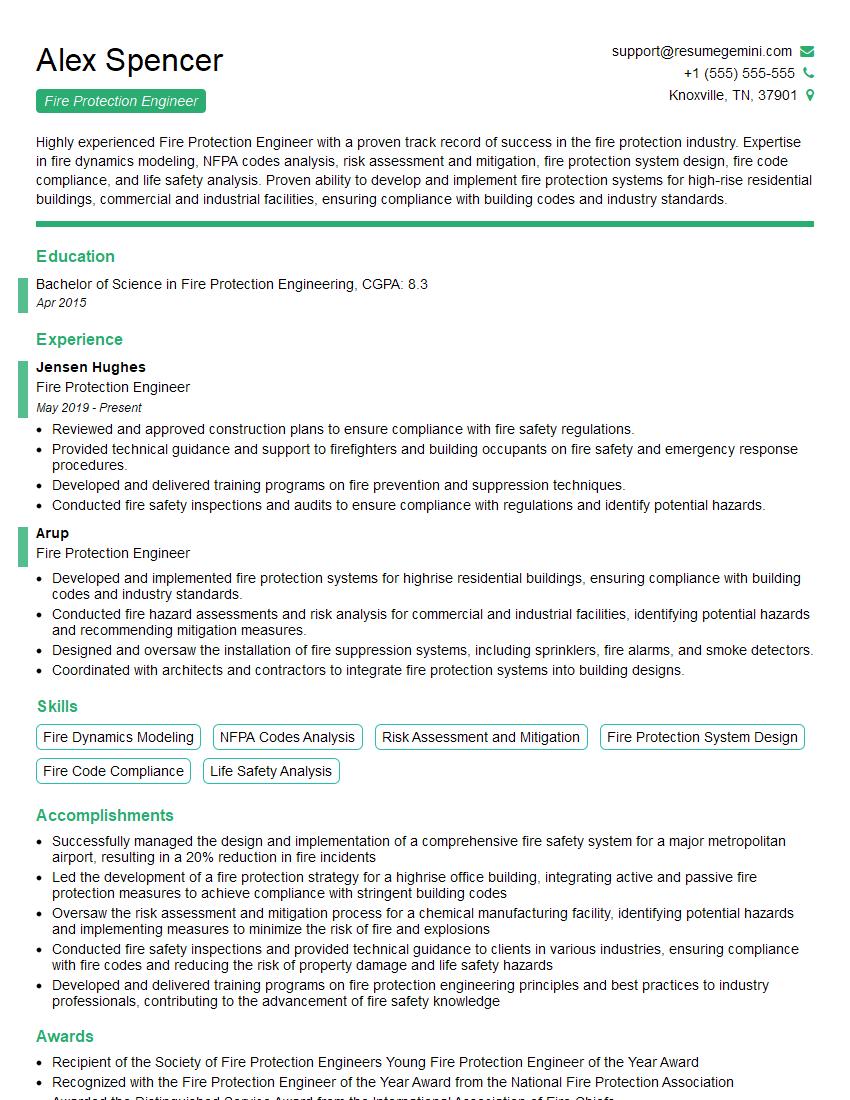

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the significance of maintaining accurate firestop records.

Maintaining accurate firestop records is paramount for several crucial reasons. First, it ensures compliance with building codes and insurance regulations. These records act as irrefutable proof that the fire protection systems are in place and installed according to specifications. Secondly, precise records are essential for effective maintenance and future inspections. Without detailed documentation, pinpointing locations and identifying the specific firestop materials used becomes an extremely time-consuming and potentially hazardous task.

These records should include information such as the date of installation, the specific type and manufacturer of the firestop system used, the location of each penetration, and any relevant drawings or specifications. They also serve as a valuable reference point for future construction or renovation work. In the event of a fire, these records can be invaluable in assisting investigators with determining the efficacy of fire protection measures. Imagine a situation where a fire occurs; having detailed records will drastically reduce the time taken to ascertain whether firestopping measures were properly in place, significantly aiding the investigation.

Q 17. How do you handle changes or revisions during a firestop project?

Handling changes or revisions during a firestop project requires a methodical approach. First, any change request should be formally documented and reviewed with all relevant stakeholders, including the architect, fire engineer, and contractor. I would ensure that the modifications are compliant with all applicable codes and regulations. Secondly, I will assess the implications of the changes, determine if any additional materials or labor are required, and update the project schedule accordingly. This often involves revisiting the original firestop design and potentially performing calculations to ensure the amended design meets the required fire rating.

A common example would be a change in the location of a pipe penetration. This requires careful re-evaluation, ensuring the integrity of the existing firestop is maintained while safely incorporating the modification. Effective communication is key. I always use detailed drawings and photos to clearly document the ‘as-built’ conditions, reflecting any revisions made. This meticulous approach avoids costly mistakes and ensures the long-term fire safety of the building.

Q 18. What is your familiarity with different firestop manufacturers’ products?

I possess extensive familiarity with various firestop manufacturers’ products, including Hilti, 3M, and Roxul. My knowledge extends to understanding the specific applications, limitations, and performance characteristics of their different firestop systems, such as intumescent materials, fire-resistant caulk, and firestop collars. I understand the importance of selecting appropriate systems based on factors like penetration size, material type, and the fire rating required.

For instance, I know that Hilti offers a wide range of solutions for various penetrations, including those for cable trays and pipes. 3M’s intumescent sealants are well-regarded for their effectiveness in creating fire-resistant seals around penetrations, while Roxul’s mineral wool products provide effective fire protection within wall and floor assemblies. My experience extends beyond product knowledge; I can effectively compare and contrast different manufacturers’ offerings to select the most suitable option for each specific project.

Q 19. Describe your problem-solving skills related to firestop challenges.

My problem-solving approach to firestop challenges involves a systematic process: Firstly, I carefully assess the situation, identifying the nature of the problem and its potential impact on fire safety. Then, I gather all relevant information, such as drawings, specifications, and existing firestop materials. This comprehensive understanding forms the basis for developing solutions.

For instance, I’ve encountered situations where a penetration was improperly sealed, leaving gaps that compromised the fire rating. In such cases, I would carefully remove the existing firestop material, thoroughly clean the area, and then reinstall the system per manufacturer specifications. When facing unforeseen challenges, I utilize my network of industry contacts and consult relevant literature to find appropriate solutions. I meticulously document each step of the problem-solving process, ensuring a clear record of the challenge, solution, and any lessons learned. This detailed documentation proves invaluable for improving future procedures and avoiding repetitive errors.

Q 20. How do you ensure the long-term effectiveness of installed firestops?

Ensuring the long-term effectiveness of installed firestops is crucial. This involves several key strategies. First and foremost is proper installation, adhering strictly to the manufacturer’s instructions and relevant codes. Regular inspections are vital, allowing for early detection of any signs of damage or deterioration. I recommend a scheduled inspection program, the frequency of which is determined by factors such as the environmental conditions and the type of penetration. These inspections often involve visual checks, but may also include more invasive methods depending on the specific firestop material.

Also crucial is ongoing maintenance. This might involve repairing minor damage or replacing deteriorated sections of the firestop system. Environmental factors, such as excessive moisture or vibration, can compromise the integrity of firestops, necessitating proactive maintenance measures. Finally, accurate record-keeping helps track inspections and maintenance, providing a comprehensive history of the fire protection system.

Q 21. What are your strategies for communicating firestop installation details to others?

Clear and effective communication of firestop installation details is critical. I employ various strategies, including detailed drawings, photographs, and written reports, to convey information accurately. I prioritize using clear and concise language, avoiding technical jargon unless absolutely necessary. When communicating with non-technical personnel, I use analogies and visual aids to ensure understanding. For instance, I might explain the function of a firestop system as a ‘seal’ that prevents the spread of fire and smoke through penetrations.

I conduct regular meetings with relevant stakeholders to discuss the firestop installation process and any potential issues. I always maintain open communication channels to facilitate timely problem resolution. This collaborative approach ensures everyone is informed and on the same page, contributing to a successful project and maintaining fire safety throughout the building’s lifespan.

Q 22. How do you address conflicting requirements for firestop installation?

Conflicting requirements in firestop installation are common, often arising from architectural design, MEP (Mechanical, Electrical, and Plumbing) systems, and fire safety codes. Addressing these conflicts requires a systematic approach. First, I meticulously review all relevant documents, including architectural drawings, specifications, and fire codes. This allows me to identify discrepancies early on. Next, I prioritize the requirements based on their criticality to life safety. For example, a conflict between a desired aesthetic and a critical fire rating would prioritize the fire rating. I then engage in collaborative discussions with the architects, engineers, and contractors to find solutions that meet all essential requirements while minimizing compromises. This often involves exploring alternative firestop systems, adjusting penetrations, or proposing design modifications that accommodate all needs. A successful outcome relies on effective communication and a willingness to find mutually agreeable solutions. For instance, I once encountered a situation where a large pipe penetration clashed with an aesthetic wall design. By suggesting a slightly relocated pipe and a cleverly concealed firestop system, we achieved both fire safety and the intended architectural look.

Q 23. What is your understanding of the different firestop testing methods?

Firestop testing methods are crucial for verifying the effectiveness of firestop systems. The most common methods include:

- ASTM E814: This standard evaluates the fire resistance of wall assemblies and floor assemblies containing penetrations. It measures the time it takes for flames, hot gases, and smoke to penetrate through the firestop.

- UL 1479: This standard focuses on testing firestop systems for specific applications, such as those used around pipes, conduits, cables, or other penetrations. The test evaluates the system’s ability to prevent fire spread under different fire conditions.

- Third-Party Testing: Independent testing laboratories like UL and Intertek conduct rigorous testing to certify the performance of firestop systems. This certification is critical for ensuring compliance with building codes and insurance requirements.

Understanding the different standards and test procedures allows for selecting the appropriate firestop system for a given application and ensuring the system’s efficacy in real-world fire scenarios. For example, when working on a high-rise building, I would prioritize firestop systems with UL 1479 certification that meet the specific requirements of the building’s fire safety plan.

Q 24. Explain your experience with firestop design and specification review.

My experience in firestop design and specification review involves a thorough understanding of fire codes, building plans, and the various types of firestop systems available. I start by reviewing the architectural and engineering drawings to identify all penetrations requiring firestopping. Then, I cross-reference this information with the project specifications to ensure that the selected firestop systems meet the required fire ratings and performance criteria. This process often involves identifying potential conflicts and recommending appropriate modifications to the design or specifications to ensure compliance. I utilize my knowledge of different material properties and system limitations to select the optimal firestop solution for each penetration. I also ensure the specifications clearly outline installation procedures, inspection requirements, and necessary certifications. I’ve often found that proactive review at the design stage saves considerable time and cost during the construction phase. A recent project involved detecting a potential conflict between the chosen firestop and the building’s insulation type. By identifying and addressing this early on, we prevented significant delays and cost overruns.

Q 25. How do you manage different subcontractors involved in firestop work?

Managing multiple subcontractors during firestop work requires careful coordination and communication. I begin by establishing clear lines of responsibility and communication protocols. This often involves regular meetings and site visits to ensure everyone is aware of the project schedule and their respective roles. To avoid conflicts, I create detailed work packages for each subcontractor, outlining specific tasks, materials, and installation procedures. Regular inspections are conducted to monitor progress and adherence to specifications. Open communication channels are crucial to address any concerns or challenges promptly. Detailed documentation, including photographs and inspection reports, is maintained throughout the process to facilitate efficient conflict resolution and accountability. In one instance, a conflict arose between the drywall installer and the firestop contractor regarding the sequence of their work. Through careful planning and communication, I was able to create a phased approach that minimized delays and ensured proper installation of both the drywall and firestop systems.

Q 26. How do you stay updated with the latest advancements in firestop technology?

Staying updated on firestop technology is crucial for providing the best possible solutions. I achieve this through several avenues:

- Professional Organizations: Active membership in organizations like the Society of Fire Protection Engineers (SFPE) provides access to technical publications, conferences, and networking opportunities.

- Industry Publications and Websites: I regularly read industry publications and visit websites of major firestop manufacturers to learn about new products and technologies.

- Training Courses and Workshops: I actively participate in training courses and workshops offered by firestop manufacturers and industry experts.

- Networking: Networking with other professionals in the field allows me to exchange knowledge and learn about best practices.

- Manufacturer Representatives: Maintaining contact with manufacturer representatives keeps me updated on product advancements and technological innovations.

Continuous learning is key to remaining competent in this rapidly evolving field. For example, recent advancements in intumescent materials have broadened the options for firestop solutions. This knowledge enables me to offer more efficient and cost-effective solutions to clients.

Q 27. Describe your experience with firestop systems in various building types.

My experience spans various building types, including high-rise buildings, hospitals, data centers, and industrial facilities. Each building type presents unique challenges and requires specialized firestop solutions. In high-rise buildings, the focus is on maintaining structural integrity and providing a pathway for safe evacuation. Hospitals require stringent fire safety measures to protect patients and medical equipment. Data centers need firestop systems that protect sensitive electronic equipment and ensure business continuity. Industrial facilities often involve larger penetrations and potentially hazardous materials, requiring robust and reliable firestop solutions. My experience in these diverse settings has allowed me to adapt my approach and select the most suitable firestop systems for each specific application. For example, I’ve used specialized firestop systems in hospitals to protect critical medical gas lines, and I’ve utilized high-performance firestop systems in data centers to maintain the integrity of network infrastructure.

Q 28. What are some common mistakes to avoid when installing firestops?

Several common mistakes can compromise the effectiveness of firestop systems. Some critical errors to avoid include:

- Improper Material Selection: Choosing the wrong firestop system for the given application can lead to inadequate fire protection.

- Incorrect Installation: Failure to follow the manufacturer’s instructions carefully can render the firestop ineffective.

- Insufficient Material: Using too little firestop material can leave gaps, compromising fire resistance.

- Damage During Construction: Accidental damage to the firestop system during construction must be carefully repaired to maintain its integrity.

- Lack of Proper Inspection: Neglecting thorough inspection can leave critical deficiencies undetected.

Avoiding these mistakes involves meticulous planning, proper training for installers, and rigorous quality control. A simple oversight can have serious consequences, emphasizing the importance of attention to detail and adherence to best practices. I’ve witnessed projects where improper installation led to costly rework and potential safety hazards. Thorough training, meticulous documentation, and proactive inspection procedures minimize these risks.

Key Topics to Learn for Firestop Penetration Sealing Interview

- Firestop System Selection: Understanding the various firestop systems available (intumescent, cementitious, etc.) and their appropriate applications based on penetration type, fire rating, and building codes.

- Penetration Types & Classifications: Identifying and classifying different types of building penetrations (pipes, conduits, cables, ducts) and their impact on fire safety. Knowing relevant industry standards and classifications.

- Installation Techniques & Best Practices: Mastering proper installation methods for different firestop systems, ensuring compliance with manufacturer’s instructions and relevant codes. This includes understanding surface preparation, sealant application, and inspection procedures.

- Code Compliance & Regulatory Requirements: Familiarity with building codes (e.g., IBC, NFPA) and relevant firestop standards. Understanding the importance of documentation and record-keeping for compliance.

- Firestop Inspection & Testing: Knowledge of inspection and testing procedures to ensure the integrity and effectiveness of firestop systems. This includes understanding common inspection methods and potential failure points.

- Troubleshooting & Problem Solving: Ability to identify and resolve common firestop installation issues and challenges. Understanding the causes of firestop failures and implementing corrective actions.

- Material Properties & Limitations: Understanding the physical and chemical properties of different firestop materials and their limitations in various applications. Knowing how environmental factors can affect firestop performance.

- Health & Safety: Awareness of relevant health and safety regulations and practices associated with firestop installation, including handling of potentially hazardous materials.

Next Steps

Mastering firestop penetration sealing is crucial for a successful and rewarding career in construction and fire protection. A strong understanding of these principles will significantly enhance your job prospects and allow you to contribute effectively to building safety. To increase your chances of landing your dream role, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to the specific requirements of the firestop industry. Examples of resumes tailored to Firestop Penetration Sealing are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.