Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential New and Retrofit Construction interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in New and Retrofit Construction Interview

Q 1. Explain the difference between new construction and retrofit construction.

New construction and retrofit construction are fundamentally different approaches to building projects. New construction involves building a structure from the ground up, starting with site preparation and ending with final finishes. It offers the advantage of complete control over design and materials, resulting in a building tailored precisely to specifications. Retrofit construction, on the other hand, focuses on modifying or improving an existing structure. This could range from minor upgrades like replacing windows to major renovations that significantly alter the building’s functionality and appearance. Think of building a house from scratch versus renovating an older home.

Key Differences Summarized:

- New Construction: Starts from scratch, complete design control, predictable timeline (generally), fewer unforeseen issues (ideally).

- Retrofit Construction: Modifies an existing structure, design constraints imposed by existing building, unpredictable timeline due to hidden issues, potential for unforeseen complexities and costs.

Q 2. Describe your experience managing budgets on construction projects.

Budget management is critical in both new and retrofit construction. My experience spans over 15 years, involving projects ranging from small-scale residential renovations to large-scale commercial retrofits. I employ a multi-stage approach. First, I develop a detailed, comprehensive budget, breaking down costs into categories like labor, materials, permits, and contingency. This often involves using specialized software for cost estimation and tracking. Second, I establish regular budget reviews, typically weekly or bi-weekly, comparing actual spending against the projected budget. Third, I implement proactive measures to identify and mitigate potential cost overruns. This includes value engineering – finding cost-effective alternatives without sacrificing quality – and close collaboration with subcontractors to ensure competitive pricing. Finally, I maintain meticulous financial records, ensuring transparency and accountability.

For example, on a recent retrofit project, we discovered significant asbestos during demolition. By quickly adapting the budget and collaborating with specialized abatement contractors, we managed to minimize the project delay and stay within the revised budget.

Q 3. How do you handle unexpected changes or challenges during a project?

Unexpected challenges are inevitable in construction. My approach emphasizes proactive risk management and a flexible, adaptable strategy. When faced with unforeseen changes, my first step is a thorough assessment. This involves identifying the scope of the problem, determining its impact on the project schedule and budget, and exploring potential solutions. I then convene a meeting with the project team—including architects, engineers, subcontractors, and the client—to discuss options. Transparent communication is crucial here. We evaluate each solution’s feasibility, cost implications, and potential impact on the project timeline. Once a solution is agreed upon, we document the change order, update the project schedule and budget accordingly, and communicate these changes to all stakeholders. The key is to act swiftly, decisively, and transparently to minimize disruption and maintain project momentum.

For instance, on a new construction site, we encountered unexpected soil conditions requiring deeper foundation work. By immediately engaging a geotechnical engineer, adjusting the design, and securing additional funding, we were able to avoid significant delays and maintain a positive relationship with the client.

Q 4. What are the key considerations for scheduling a retrofit project?

Scheduling a retrofit project requires careful consideration of several factors, often more so than new construction. First, a thorough assessment of the existing structure is essential to identify potential challenges. This often includes inspections to detect structural weaknesses, hidden utilities, or hazardous materials like asbestos or lead paint. Second, the scheduling needs to account for the sequential nature of tasks. Demolition, for example, can’t start before inspections are complete. Third, the schedule should incorporate sufficient buffer time to account for unforeseen delays caused by discovering hidden problems or material delivery delays. Fourth, coordinating work with existing building occupants and their needs (if any) is paramount. Fifth, the schedule should be broken down into manageable phases, with clear milestones and deadlines for each phase. Finally, regular progress monitoring and communication with stakeholders are essential to track performance and identify potential issues early on.

For example, in a school retrofit, we carefully scheduled work around school hours to minimize disruption to students and teachers.

Q 5. What are some common risks associated with retrofitting existing structures?

Retrofitting carries unique risks. Structural issues are a major concern – hidden damage or deterioration might not be apparent until demolition or renovation begins. Unexpected utilities, like old plumbing or electrical wiring, can be costly and time-consuming to address. Hazardous materials, including asbestos, lead paint, or mold, pose significant safety and environmental risks and require specialized handling. Permitting and regulatory compliance can be challenging, given the complexities of modifying existing structures. Cost overruns are more frequent in retrofits due to the inherent uncertainties associated with the condition of the existing building. Finally, compatibility issues can arise when integrating new systems or materials with older ones.

Q 6. How do you ensure safety on a construction site during a retrofit project?

Safety is paramount. My approach to safety on retrofit projects involves a multi-layered strategy. First, a thorough site safety plan is developed before work commences, addressing specific hazards associated with the project. This plan includes detailed safety procedures, emergency response protocols, and personal protective equipment (PPE) requirements. Second, regular safety inspections are conducted to identify and rectify potential hazards. Third, all workers receive comprehensive safety training before starting work, covering topics such as fall protection, hazardous material handling, and emergency procedures. Fourth, clear communication channels are maintained to report incidents and near misses promptly. Fifth, regular toolbox talks are conducted to reinforce safety awareness. Finally, I maintain close collaboration with regulatory bodies to ensure compliance with all applicable safety regulations. Proper scaffolding, fall protection, and confined space entry procedures are crucial aspects of our safety plan.

Q 7. What experience do you have with building codes and regulations?

I have extensive experience navigating building codes and regulations, both nationally and locally. My knowledge encompasses the International Building Code (IBC), ADA compliance, fire safety codes, and energy efficiency standards. I ensure all projects comply with relevant regulations by proactively consulting code books, engaging qualified inspectors, and working closely with architects and engineers to incorporate code requirements into the design and construction process. Staying current on code changes is critical. I regularly attend industry seminars and training sessions to update my knowledge base. My experience includes obtaining permits, working with inspectors throughout the construction process, and addressing any code-related issues that may arise during construction.

Q 8. Explain your experience with different types of construction materials.

My experience encompasses a wide range of construction materials, from traditional to cutting-edge. I’m proficient in selecting and specifying materials based on project requirements, budget constraints, and sustainability goals. This includes:

- Structural Materials: Steel, reinforced concrete, timber (including engineered wood products like glulam and LVL), and masonry (brick, block, stone).

- Exterior Cladding: Brick veneer, stucco, fiber cement siding, metal panels, and various types of roofing materials (asphalt shingles, tile, metal).

- Interior Finishes: Gypsum board (drywall), various flooring types (carpet, hardwood, tile, vinyl), paint, and cabinetry materials.

- Insulation and Waterproofing: Different types of insulation (fiberglass, spray foam, rigid foam), and waterproofing membranes for foundations and roofs.

- Sustainable Materials: I have experience with incorporating sustainable and recycled materials, such as reclaimed wood, recycled metal, and low-VOC paints, to minimize the environmental impact of construction projects.

For example, on a recent high-rise project, we utilized high-strength concrete and a lightweight steel frame to maximize efficiency and minimize the building’s environmental footprint. On a residential renovation, I specified reclaimed wood flooring to add character and meet the client’s sustainability goals.

Q 9. Describe your experience with various construction methods and techniques.

My expertise spans various construction methods and techniques, including:

- Traditional Construction: This encompasses stick-built framing, concrete formwork, and masonry construction, relying heavily on skilled labor.

- Prefabrication and Modular Construction: I’ve worked with prefabricated components, such as wall panels and roof trusses, to accelerate construction schedules and improve quality control. Modular construction, where entire building sections are assembled off-site, is another area of my experience.

- Tilt-Up Construction: This method involves casting concrete walls on-site and then tilting them into place, which is highly efficient for certain building types.

- Design-Build: I’ve been involved in design-build projects where the same team is responsible for both the design and construction, enabling greater collaboration and cost efficiency.

- Lean Construction Principles: I actively implement lean construction principles to eliminate waste, optimize workflows, and improve project delivery.

For instance, on a recent school renovation project, we employed prefabricated modular classrooms to minimize disruption to students and teaching schedules. On a commercial project, the tilt-up construction method significantly shortened the construction timeline.

Q 10. How do you manage subcontractors on a construction project?

Managing subcontractors requires clear communication, strong organizational skills, and proactive problem-solving. My approach includes:

- Thorough Pre-qualification: I carefully vet subcontractors based on their experience, reputation, insurance coverage, and safety record.

- Detailed Contracts: Contracts clearly outline scope of work, payment schedules, timelines, and responsibilities, preventing disputes.

- Regular Communication: I maintain open communication with subcontractors through regular meetings, email updates, and on-site visits.

- Performance Monitoring: I track subcontractor progress, quality of work, and adherence to safety regulations.

- Prompt Payment: I ensure timely payment to subcontractors to maintain positive working relationships.

If a subcontractor experiences delays or quality issues, I address them promptly and collaboratively, working with them to find solutions rather than simply issuing penalties. Building strong relationships with subcontractors is key to successful project outcomes.

Q 11. Describe your experience with conflict resolution on a construction site.

Conflict resolution on a construction site is crucial for maintaining productivity and project success. My strategy is built on proactive communication and collaboration:

- Early Identification: I encourage open communication and actively monitor for potential conflicts, addressing them before they escalate.

- Mediation: I act as a mediator, facilitating discussions between conflicting parties to reach mutually acceptable solutions.

- Documentation: Thorough documentation of all communication, agreements, and changes is essential for resolving disputes fairly and efficiently.

- Escalation Protocol: If mediation fails, I have a clear escalation protocol for resolving conflicts, involving project management, legal counsel, or even arbitration as needed.

- Focus on Solutions: My focus is always on finding solutions that are mutually beneficial and that preserve positive working relationships.

For example, on a recent project, a disagreement arose between the framing and electrical subcontractors. By facilitating a joint meeting and clarifying responsibilities in the contract, we resolved the conflict amicably and avoided significant delays.

Q 12. What software and tools do you use to manage construction projects?

I utilize a range of software and tools to manage construction projects efficiently. These include:

- Project Management Software: Such as Procore, Autodesk BIM 360, or Microsoft Project, for scheduling, cost control, document management, and communication.

- Building Information Modeling (BIM) Software: Autodesk Revit or ArchiCAD, for 3D modeling, clash detection, and coordination among different disciplines.

- Estimating Software: For accurate cost estimating and budget tracking.

- Scheduling Software: For creating and managing project schedules, identifying critical paths, and tracking progress.

- Field Management Apps: For daily reporting, communication, and issue tracking on the construction site.

Example of a simple schedule entry in MS Project: Task Name: Foundation; Duration: 10 days; Start Date: 2024-03-01

Combining these tools enables efficient project management, ensuring accurate budgeting and timely completion.

Q 13. How do you develop and maintain relationships with clients?

Developing and maintaining strong client relationships is paramount. My approach focuses on:

- Clear Communication: Regular updates, transparent communication about project progress and potential challenges.

- Active Listening: Understanding client needs, expectations, and concerns.

- Responsiveness: Promptly addressing client inquiries and resolving any issues that may arise.

- Collaboration: Involving clients in decision-making processes wherever appropriate.

- Professionalism: Maintaining a high level of professionalism and integrity throughout the project.

I often hold regular meetings with clients, providing them with visual progress reports and addressing any questions or concerns. This proactive communication helps build trust and ensures the project aligns with their vision.

Q 14. How do you ensure the quality of work on your projects?

Ensuring quality is a continuous process, starting with the initial design phase and continuing through construction and completion. My methods include:

- Quality Control Plans: Developing detailed quality control plans that outline procedures and standards for each phase of construction.

- Regular Inspections: Conducting regular inspections to monitor work quality and adherence to plans and specifications.

- Subcontractor Oversight: Closely monitoring the work of subcontractors to ensure they meet quality standards.

- Material Testing: Using material testing to verify that materials meet specifications and are properly installed.

- Quality Assurance: Implementing a robust quality assurance program to prevent defects and ensure consistent quality.

For example, regular inspections during framing ensure proper alignment and structural integrity. Similarly, testing concrete strength before pouring ensures structural safety. A proactive approach to quality control minimizes rework and ensures a high-quality final product.

Q 15. How do you handle changes in project scope during construction?

Managing scope changes in construction is crucial for project success. It requires a proactive approach, clear communication, and a well-defined change management process. Ignoring scope creep can lead to cost overruns, schedule delays, and strained client relationships.

My approach involves:

- Formal Change Request Process: All scope changes, no matter how small, must be submitted formally. This includes a detailed description of the change, its impact on the schedule and budget, and supporting documentation.

- Impact Assessment: Before approving any change, a thorough assessment is performed to determine its implications on the project’s timeline, budget, and resources. This often involves collaboration with the project team, subcontractors, and the client.

- Cost and Schedule Updates: A revised budget and schedule are generated to reflect the approved changes. This transparency ensures all stakeholders are informed of any financial or timeline adjustments.

- Contractual Considerations: All changes are documented and agreed upon in writing, amending the original contract as necessary. This protects all parties involved.

- Regular Monitoring: Post-change implementation, close monitoring is essential to ensure the change is executed correctly and its impact is aligned with the updated plan.

For example, on a recent retrofit project, the client requested an upgrade to the HVAC system after the initial design phase. We followed the formal change request process, assessed the impact (additional cost and a minor schedule delay), and presented the client with options. They selected the preferred upgrade, which was then incorporated into the project with revised contracts and schedules.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with project closeout procedures.

Project closeout is a critical stage often overlooked, yet it’s essential for finalizing project documentation, ensuring payment, and resolving any outstanding issues. A thorough closeout process protects both the contractor and the client.

My experience includes:

- Final Inspections: Conducting thorough inspections to verify that the project meets all specifications and is free from defects.

- Documentation Completion: Gathering and organizing all project documents, including contracts, drawings, specifications, change orders, and as-built drawings. This ensures a complete record for future reference.

- Warranty Information: Compiling and distributing all relevant warranty information to the client.

- Financial Closure: Ensuring all invoices are paid, and all financial records are reconciled. This involves final payments, lien releases, and closure of accounts.

- Client Handover: Formally handing over the completed project to the client, providing necessary instructions and support.

- Post-Project Review: Conducting a post-project review to identify lessons learned and areas for improvement in future projects.

In one project, meticulous documentation during closeout prevented a potential dispute regarding a specific aspect of the completed work. Having comprehensive records allowed for a swift and amicable resolution.

Q 17. What is your experience with value engineering in construction projects?

Value engineering is a systematic process of analyzing project design and construction methods to identify opportunities for cost reduction without sacrificing quality or functionality. It’s about finding creative solutions that deliver the same or better results at a lower cost.

My experience demonstrates proficiency in:

- Identifying Cost-Saving Opportunities: Analyzing design drawings, specifications, and construction methods to identify areas where costs can be reduced without compromising performance or aesthetics.

- Developing Alternative Solutions: Proposing cost-effective alternatives that maintain or improve the project’s overall value.

- Collaboration and Communication: Working closely with architects, engineers, and clients to explore various options and reach mutually beneficial decisions.

- Life-Cycle Cost Analysis: Considering the long-term costs of various solutions, including maintenance, repairs, and energy consumption, to make informed decisions.

On a recent new construction project, we successfully implemented value engineering by substituting a less expensive material with comparable performance characteristics, resulting in substantial cost savings without impacting the project’s quality or intended outcomes.

Q 18. How do you assess and mitigate risks related to material costs and availability?

Material cost and availability risks are significant challenges in construction. Effective risk mitigation requires proactive planning and constant monitoring.

My approach:

- Market Research: Regularly monitoring market trends and price fluctuations for key materials. This allows us to anticipate potential price increases and adjust the budget accordingly.

- Early Procurement: Procuring materials early to secure favorable pricing and avoid potential shortages. This requires careful planning and accurate forecasting.

- Alternative Sourcing: Identifying multiple suppliers for critical materials to mitigate the risk of supply disruptions.

- Material Substitution: Having readily available alternative materials with comparable performance characteristics to ensure project continuity in case of shortages.

- Contractual Protection: Incorporating clauses in contracts that protect the project from unforeseen price increases or supply chain disruptions.

For instance, during a period of lumber price volatility, we secured a significant portion of our lumber needs early, locking in a competitive price and avoiding the substantial increases experienced later in the project.

Q 19. Explain your experience with sustainable building practices.

Sustainable building practices are increasingly critical. My experience encompasses various aspects of green construction, focusing on environmentally friendly materials, energy efficiency, and waste reduction.

Specific examples of my experience:

- Material Selection: Prioritizing the use of recycled and locally sourced materials to reduce the environmental impact of transportation and manufacturing.

- Energy Efficiency: Incorporating energy-efficient designs and technologies, such as high-performance windows, insulation, and HVAC systems, to minimize energy consumption.

- Water Conservation: Implementing water-saving fixtures and strategies to reduce water usage.

- Waste Management: Developing comprehensive waste management plans to minimize construction waste and maximize recycling and reuse.

- Indoor Environmental Quality: Selecting low-VOC (volatile organic compound) materials to improve indoor air quality.

In a recent project, we successfully integrated several sustainable features, resulting in LEED certification and significant reductions in the building’s carbon footprint.

Q 20. How do you ensure compliance with environmental regulations on construction sites?

Compliance with environmental regulations is paramount in construction. Ignoring these regulations can lead to significant fines and legal repercussions.

My approach involves:

- Thorough Site Assessment: Conducting a thorough environmental site assessment to identify any potential environmental concerns before commencing work.

- Permitting and Approvals: Obtaining all necessary permits and approvals from relevant environmental agencies.

- Erosion and Sediment Control: Implementing effective erosion and sediment control measures to prevent soil erosion and water pollution.

- Hazardous Waste Management: Developing a plan for the proper handling, storage, and disposal of hazardous materials.

- Air Quality Control: Utilizing dust suppression techniques and other measures to maintain acceptable air quality levels.

- Stormwater Management: Managing stormwater runoff to prevent pollution of local waterways.

- Regular Monitoring and Reporting: Regularly monitoring environmental conditions on the site and reporting to the relevant authorities.

A critical incident on a past project highlighted the importance of meticulous adherence to stormwater management regulations. Our proactive approach prevented a potential violation and ensured project compliance.

Q 21. Describe your experience with LEED certification or similar green building standards.

I have extensive experience with LEED certification and other green building standards. LEED (Leadership in Energy and Environmental Design) is a widely recognized green building rating system that provides a framework for sustainable design and construction.

My experience includes:

- LEED Project Management: Leading and coordinating LEED certification efforts for multiple projects.

- Documentation and Reporting: Preparing and submitting all required documentation to the LEED certification body.

- Sustainable Design Strategies: Integrating sustainable design strategies into the design and construction process to achieve LEED points.

- Material Selection and Procurement: Selecting materials that meet LEED requirements and contribute to the project’s sustainability goals.

- Commissioning and Verification: Ensuring proper commissioning and verification to confirm the building’s performance and meet LEED requirements.

For example, on a recent project we achieved LEED Gold certification by implementing several strategies, including using recycled materials, optimizing energy efficiency, and reducing water consumption. This involved meticulous tracking of all relevant metrics and adherence to the LEED rating system’s criteria.

Q 22. What is your experience with pre-construction planning and estimating?

Pre-construction planning and estimating is the critical foundation of any successful construction project. It involves meticulously analyzing project plans, specifications, and site conditions to develop a comprehensive budget and schedule. My experience spans over 15 years, encompassing both new construction and retrofit projects of varying scales and complexities. I’ve worked on everything from small-scale residential renovations to large-scale commercial developments.

My process typically involves a detailed quantity takeoff, where I carefully measure and quantify all materials and labor needed. This information is then used to develop a detailed cost estimate, factoring in material costs, labor rates, equipment rentals, permits, and contingency for unforeseen issues. For instance, on a recent retrofit project of a historic building, I had to account for unexpected asbestos abatement, which I successfully integrated into the budget without exceeding the client’s allocated funds by carefully re-evaluating the scope of work for less critical areas.

I utilize sophisticated estimating software like ProEst and also excel spreadsheets to manage data, ensuring accuracy and transparency throughout the process. Beyond cost estimation, I also participate in value engineering, identifying ways to optimize designs and materials to reduce costs without compromising quality or functionality.

Q 23. Explain your process for creating a detailed construction schedule.

Creating a detailed construction schedule is an iterative process that requires close collaboration with the entire project team, from architects and engineers to subcontractors. I begin by breaking down the project into smaller, manageable tasks, defining their dependencies and durations. This usually involves using a Work Breakdown Structure (WBS) to organize tasks logically.

Then, I leverage scheduling software like Microsoft Project or Primavera P6 to create a critical path method (CPM) schedule. This visually represents the sequence of tasks, identifying the critical path – the sequence of tasks that determine the shortest possible project duration. Any delays on the critical path directly impact the overall project completion date. I meticulously input task durations, resource allocation, and dependencies into the software to generate a realistic schedule. This includes considering potential weather delays, material delivery timelines, and availability of skilled labor.

For example, on a recent new construction project of a multi-family dwelling, I carefully scheduled foundation work to precede framing, ensuring a smooth and efficient workflow. Regularly reviewing and updating the schedule based on actual progress is crucial, allowing for proactive adjustments to mitigate potential issues.

Q 24. How do you manage and track project progress against the schedule?

Project progress tracking is vital for ensuring timely completion and preventing cost overruns. My approach involves a multi-pronged strategy incorporating both regular on-site inspections and sophisticated tracking tools.

I conduct weekly site visits to observe progress, identify any potential roadblocks, and confirm the accuracy of reported progress. I also use project management software to track task completion, resource allocation, and budget expenditures. This software allows me to generate progress reports, compare planned vs. actual progress, and highlight any deviations from the schedule. Daily progress reports from subcontractors are a crucial component of this process. We often use collaborative platforms to share documents and updates, enhancing communication and transparency.

For example, if a subcontractor falls behind schedule, we use the project management software to analyze the impact on the critical path and discuss mitigation strategies. This proactive approach allows us to prevent minor delays from escalating into significant problems.

Q 25. What is your experience with different types of contracts (e.g., lump sum, cost-plus)?

I have extensive experience working with various contract types, including lump sum, cost-plus, and unit price contracts. Understanding the nuances of each contract type is essential for managing risk and ensuring a successful project.

- Lump Sum Contracts: These offer a fixed price for the entire project scope. This is advantageous for clients as it provides budget certainty but requires precise planning and accurate estimating from the contractor’s side.

- Cost-Plus Contracts: These reimburse the contractor for actual costs incurred, plus a pre-agreed markup or fee. This offers flexibility for projects with evolving scopes, but it requires rigorous cost tracking and transparency.

- Unit Price Contracts: These specify a price per unit of work, allowing for flexibility in quantities. This is ideal for projects with variable quantities of work.

My experience enables me to navigate the complexities of each contract type, ensuring compliance and protecting the interests of both the client and the contractor. I carefully review and negotiate contract terms to identify and mitigate potential risks, ensuring a mutually beneficial agreement.

Q 26. How do you handle disputes with clients or subcontractors?

Disputes are an unfortunate reality in construction. My approach emphasizes proactive communication and conflict resolution. I always strive to build strong relationships with clients and subcontractors based on trust and transparency.

When disagreements arise, I address them promptly and professionally, using a collaborative approach. This often involves facilitated discussions where all parties are encouraged to express their perspectives and explore mutually agreeable solutions. I maintain detailed documentation throughout the process, including meeting minutes, emails, and change orders. If a resolution can’t be reached through amicable means, I’m prepared to leverage alternative dispute resolution mechanisms such as mediation or arbitration, to avoid costly and time-consuming litigation.

For instance, on a recent project, a dispute arose regarding a change order. By involving all stakeholders in a collaborative discussion, we were able to reach an agreement that satisfied everyone involved. This prevented any unnecessary delays or legal battles.

Q 27. Describe your experience with project documentation and reporting.

Meticulous project documentation and reporting are essential for project success and compliance. My approach involves maintaining a comprehensive digital archive of all project-related documents.

This includes contracts, drawings, specifications, RFIs, change orders, meeting minutes, inspection reports, and payment applications. I utilize a cloud-based document management system to ensure easy access and version control. I also generate regular progress reports, both internally and for clients, highlighting key milestones, budget expenditures, and any potential issues. These reports include visual aids such as charts and graphs to enhance understanding and facilitate informed decision-making.

Furthermore, I ensure all documentation adheres to industry best practices and legal requirements. This attention to detail protects the interests of all parties involved and minimizes the risk of disputes.

Q 28. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and qualifications in the construction industry. Considering my fifteen years of experience, expertise in both new construction and retrofits, and proven track record of successful project delivery, I am seeking a salary range of $150,000 to $180,000 annually. However, I’m open to discussing this further based on the specific details of the role and the overall compensation package.

Key Topics to Learn for New and Retrofit Construction Interview

- Project Planning & Management: Understanding the unique challenges and processes involved in both new construction and retrofit projects. This includes scheduling, budgeting, and risk management specific to each type of project.

- Building Codes & Regulations: Familiarity with relevant building codes, safety regulations, and permitting processes for both new and existing structures. Knowing how these differ and how to navigate the complexities of compliance is crucial.

- Material Selection & Sustainability: Understanding the selection criteria for materials in new construction versus retrofitting, considering factors like cost, durability, sustainability, and environmental impact. Knowing sustainable practices is a major plus.

- Structural Analysis & Design: Understanding basic structural principles and how they apply to both new and existing structures. For retrofits, this includes assessing the existing structure’s integrity and designing appropriate reinforcements.

- Construction Methods & Techniques: Familiarity with various construction methods and techniques relevant to each project type. This includes understanding the differences in approaches and challenges presented by working with existing infrastructure.

- Cost Estimation & Control: Developing accurate cost estimates and managing project budgets effectively, considering potential unforeseen challenges specific to retrofit projects (e.g., hidden damage).

- Health & Safety Regulations: Thorough understanding and implementation of all relevant health and safety regulations on both new and retrofit construction sites.

- Problem-Solving & Decision-Making: Demonstrating the ability to analyze problems, develop solutions, and make informed decisions under pressure, especially in the context of unexpected issues that arise during retrofit projects.

Next Steps

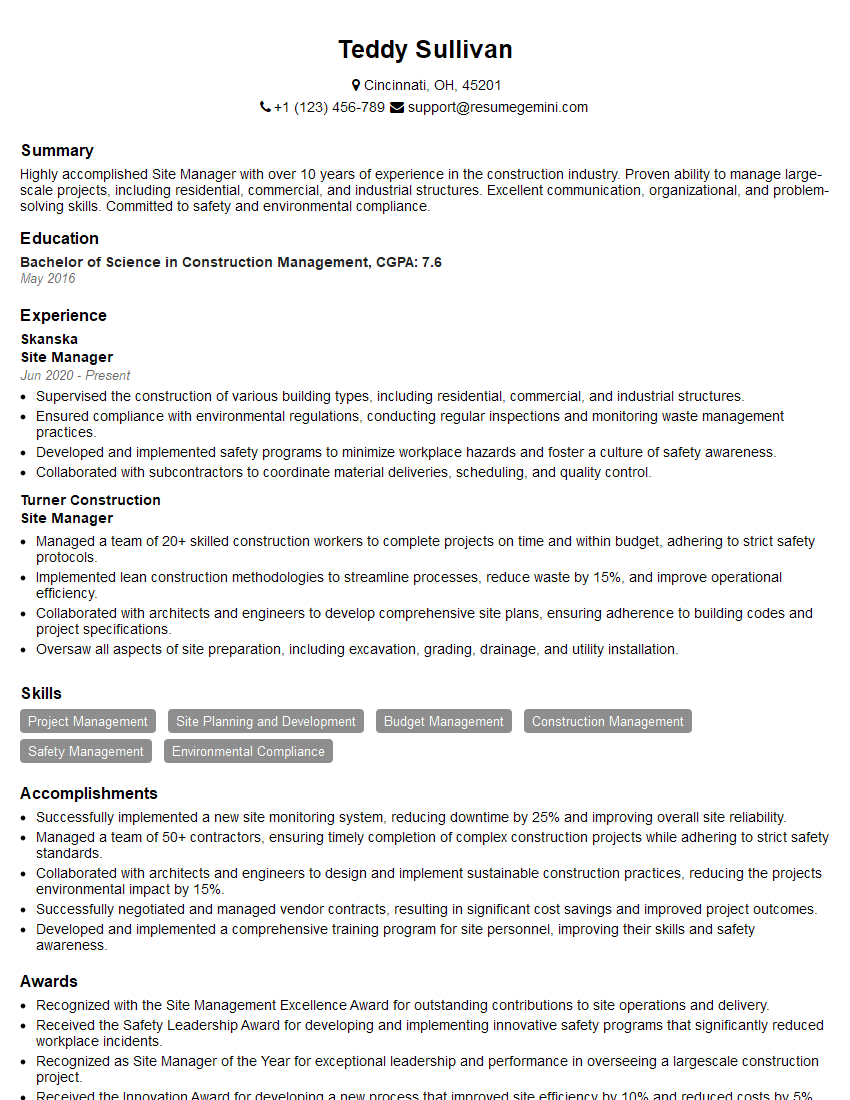

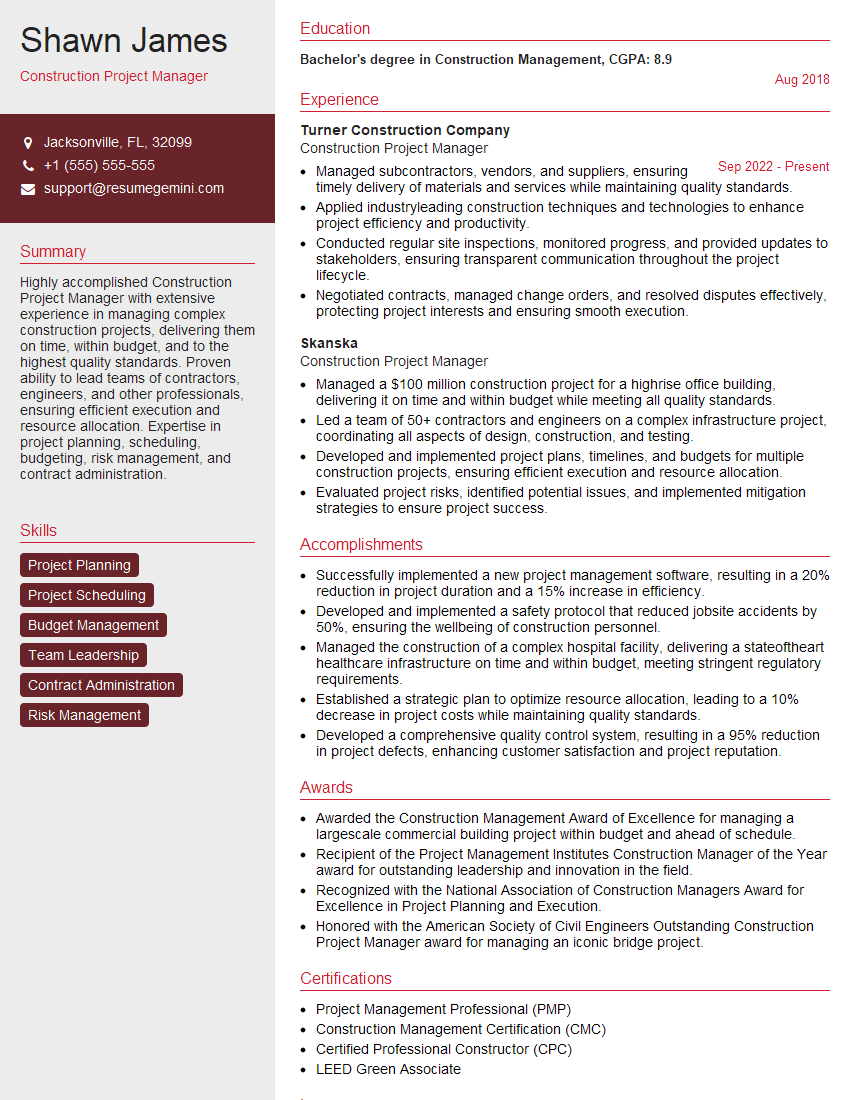

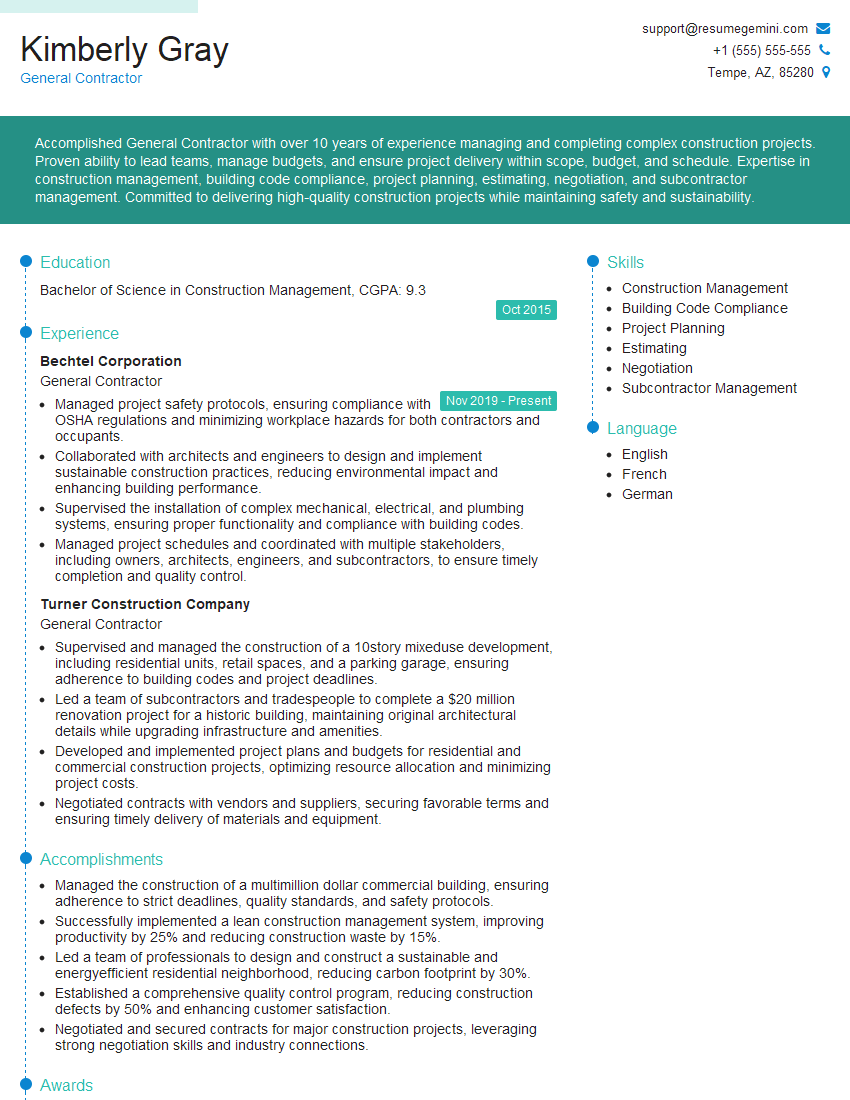

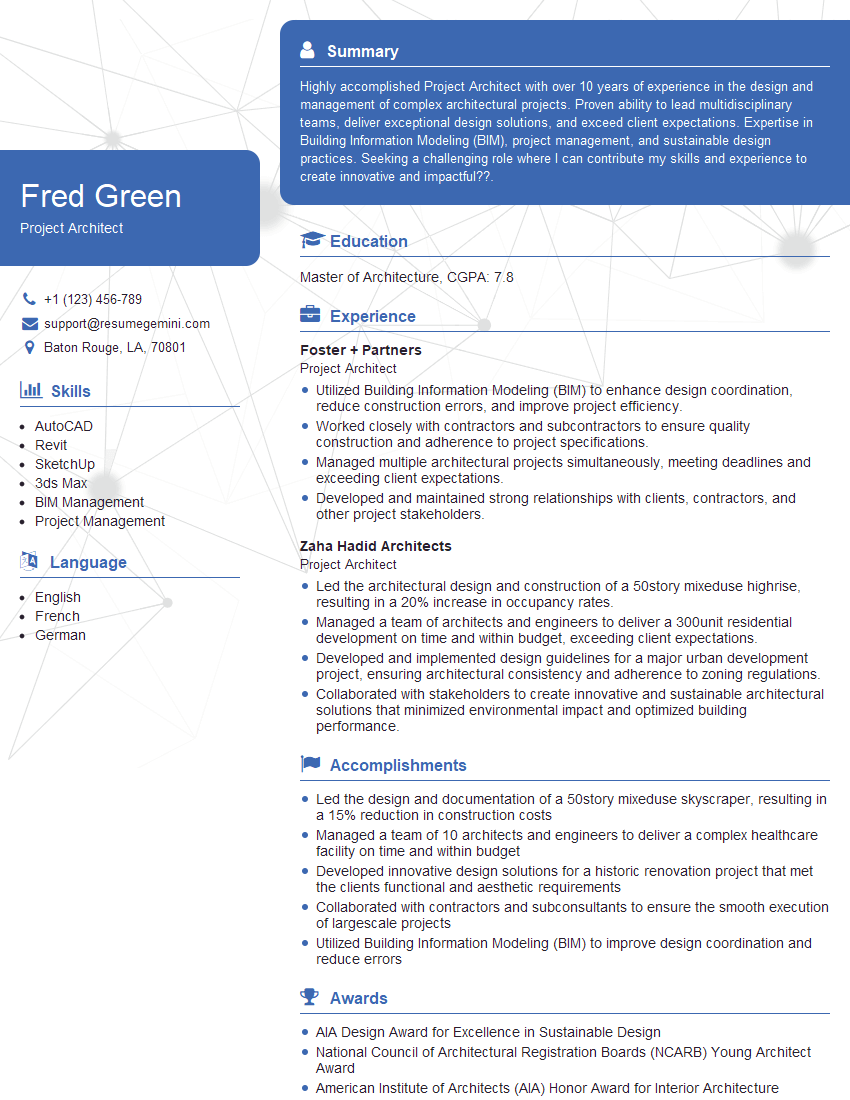

Mastering both new and retrofit construction methodologies significantly enhances your career prospects, opening doors to diverse and challenging roles within the construction industry. To maximize your job search success, it’s vital to create an ATS-friendly resume that highlights your skills and experience effectively. We strongly encourage you to leverage ResumeGemini, a trusted resource for building professional and impactful resumes. ResumeGemini provides examples of resumes tailored specifically to the New and Retrofit Construction sector to help you craft a compelling application that stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.