Unlock your full potential by mastering the most common Fire Retardant Application interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Fire Retardant Application Interview

Q 1. What are the different types of fire retardant materials?

Fire retardant materials come in various forms, each designed to inhibit or delay the spread of fire. They can be broadly classified into several categories:

- Intumescent Coatings: These expand significantly when exposed to heat, creating a thick insulating char layer that protects the underlying substrate. Think of it like a protective shield that swells up to block the fire’s path. They are commonly used on steel structures.

- Reactive Coatings: These coatings release fire-suppressing chemicals when exposed to heat. These chemicals interrupt the combustion process, hindering the fire’s ability to spread. They often contain compounds like ammonium phosphates.

- Mastics and Sealants: These are pastes or gels applied to fill gaps and cracks, preventing fire spread through these openings. They’re particularly useful in firestopping applications.

- Fire-Resistant Fabrics and Treatments: These materials are treated with chemicals to enhance their fire resistance. This is commonly seen in upholstery, curtains, and protective clothing.

- Additive Fire Retardants: These are incorporated directly into the manufacturing process of materials like plastics or wood. The retardant becomes part of the material’s structure.

The choice of fire retardant depends heavily on the substrate material, the level of fire protection required, and the specific application environment.

Q 2. Explain the process of applying intumescent coatings.

Applying intumescent coatings is a multi-step process that demands precision and attention to detail. Here’s a breakdown:

- Surface Preparation: The substrate must be clean, dry, and free from any contaminants that could hinder adhesion. This often involves cleaning, sanding, and possibly priming.

- Mixing: Intumescent coatings are typically supplied as multiple components that need to be thoroughly mixed according to the manufacturer’s instructions. Improper mixing can significantly affect the coating’s performance.

- Application: The coating is usually applied using specialized spray equipment, brushes, or rollers, depending on the viscosity and the nature of the substrate. Multiple coats might be necessary to achieve the desired thickness.

- Curing: After application, the coating needs sufficient time to cure fully. This allows the chemical reactions within the coating to complete and the film to develop its full fire-retardant properties. The curing time varies depending on the specific product and environmental conditions.

- Inspection: Once cured, a thorough inspection should be carried out to ensure the coating is uniformly applied, free from defects, and meets the specified thickness requirements.

Imagine painting a wall; intumescent coating application shares similarities, but with a much stronger focus on achieving consistent thickness and adhering strictly to the manufacturer’s guidelines.

Q 3. Describe the safety precautions necessary when applying fire retardants.

Safety is paramount when working with fire retardants. The specific precautions depend on the type of retardant, but general safety measures include:

- Respiratory Protection: Many fire retardants contain chemicals that can irritate the lungs or be toxic. Always use appropriate respirators with the correct filters.

- Eye Protection: Safety glasses or goggles are crucial to protect eyes from splashes or dust.

- Skin Protection: Wear gloves, long sleeves, and protective clothing to prevent skin contact with the fire retardant.

- Ventilation: Adequate ventilation is essential to prevent buildup of harmful fumes or dust. In confined spaces, consider using respirators and mechanical ventilation.

- Fire Safety Precautions: Be mindful of any fire hazards present during application. Keep fire extinguishers readily available.

- Following SDS (Safety Data Sheets): Always consult the Safety Data Sheet (SDS) for the specific fire retardant being used for detailed safety information and handling instructions.

Remember, safety is not optional. It’s crucial to prioritize your well-being and follow all safety protocols rigorously.

Q 4. How do you determine the appropriate fire retardant for a specific substrate?

Selecting the right fire retardant involves considering several factors:

- Substrate Type: Different substrates (wood, steel, concrete, fabric) require different types of fire retardants. A coating suitable for steel might not be appropriate for wood.

- Fire Rating Requirements: Building codes and regulations dictate the required fire resistance rating for specific applications. The chosen retardant must meet or exceed these requirements.

- Environmental Conditions: The expected environmental conditions (temperature, humidity, exposure to UV light) can affect the performance and durability of the fire retardant.

- Aesthetic Considerations: The final appearance of the treated substrate might be important in some applications. The choice of fire retardant can affect the color, texture, and gloss of the surface.

- Cost and Application Method: The cost of the fire retardant and the ease of application are also practical considerations.

Often, a consultation with a fire protection engineer is valuable in determining the best solution. For example, a high-rise building would have different needs than a small wooden structure.

Q 5. What are the common challenges encountered during fire retardant application?

Applying fire retardants can present various challenges:

- Poor Adhesion: Inadequate surface preparation can lead to poor adhesion, resulting in the coating peeling or flaking off.

- Inconsistent Coating Thickness: Uneven application can compromise fire protection, leaving areas vulnerable to fire spread.

- Environmental Conditions: Extreme temperatures, humidity, or rain can interfere with the application process and affect the curing of the coating.

- Difficult-to-Reach Areas: Applying fire retardants to complex shapes or hard-to-reach areas might require specialized equipment or techniques.

- Compatibility Issues: Using incompatible fire retardants or mixing them improperly can lead to reduced effectiveness or unexpected chemical reactions.

Overcoming these challenges requires careful planning, proper training, and attention to detail during every stage of the application process.

Q 6. How do you ensure proper adhesion of fire retardant materials?

Ensuring proper adhesion of fire retardant materials is crucial for their effectiveness. This begins with meticulous surface preparation and continues through the application process. Here’s how:

- Thorough Cleaning: Remove all dust, dirt, grease, oil, loose paint, and other contaminants from the substrate. This might involve cleaning with solvents, pressure washing, or abrasive blasting.

- Surface Profiling: For certain substrates, creating a textured surface can improve adhesion. This can be achieved through abrasive blasting or mechanical methods.

- Priming: Applying a suitable primer helps to improve adhesion between the substrate and the fire retardant. The primer acts as a bonding agent.

- Proper Application Techniques: Following the manufacturer’s instructions for application is essential. The correct application method, coat thickness, and drying time will all influence adhesion.

- Environmental Control: Controlling temperature and humidity during the application and curing process helps to ensure optimal adhesion.

Think of it like gluing two pieces of wood together – a clean, prepared surface with the right adhesive is key to a strong, lasting bond.

Q 7. Explain the importance of surface preparation before applying fire retardants.

Surface preparation is the cornerstone of successful fire retardant application. A poorly prepared surface will compromise adhesion, leading to premature failure of the fire retardant coating and reduced fire protection. The consequences of inadequate surface prep can range from costly repairs to compromised structural integrity. Here’s why it’s so important:

- Improved Adhesion: A clean surface provides a better bond for the fire retardant, ensuring it stays in place during a fire.

- Enhanced Performance: Proper surface preparation ensures the fire retardant can perform its intended function effectively.

- Increased Durability: A well-prepared surface leads to a more durable coating that is resistant to weathering and degradation.

- Prevention of Coating Failures: Proper preparation prevents issues like peeling, blistering, and flaking.

Neglecting this critical step is like building a house on a weak foundation. The entire system becomes vulnerable and might not withstand the intended stress, in this case, the heat of a fire.

Q 8. What are the different methods for applying fire retardant materials?

Applying fire retardants involves various methods, each suited to different materials and applications. The choice depends on factors like the substrate’s type, porosity, and desired fire resistance rating. Common methods include:

- Spray Application: This is widely used for large surfaces, offering even coverage. Think of painting a wall, but with a fire retardant instead of paint. Different spray techniques exist, from airless sprayers for thicker coatings to air-assisted sprayers for finer control. The pressure and nozzle size are critical for achieving the right film thickness.

- Brush and Roller Application: Suitable for smaller areas or intricate details, this method is similar to applying paint. It requires more labor but offers good control, particularly on textured surfaces. For example, applying fire retardant to wooden beams might be best done with a brush.

- Dip Coating: This involves immersing the material completely in the fire retardant solution. It’s efficient for smaller items and ensures thorough penetration, often used for fabrics or wood components before assembly.

- Vacuum Pressure Impregnation: For deeper penetration into porous materials like wood, this method forces the fire retardant into the wood under vacuum. This process is often used for large timber structures to achieve superior fire protection.

- High-Pressure Injection: A more specialized method that injects fire retardant directly into the material, particularly effective for concrete or masonry where surface treatment is insufficient.

Each method has its pros and cons regarding efficiency, cost, and final finish. The selection process is always tailored to the specific project requirements.

Q 9. How do you ensure compliance with relevant fire codes and standards?

Ensuring compliance with fire codes and standards is paramount in fire retardant application. This involves a multi-step process:

- Identifying Applicable Codes: The first step is to determine the specific codes and standards relevant to the project’s location and the type of construction. These can vary widely depending on the jurisdiction and building type (residential, commercial, industrial). Common standards include NFPA (National Fire Protection Association) and ASTM (American Society for Testing and Materials) standards.

- Specifying the Right Product: Once the codes are identified, I select a fire retardant product that meets or exceeds the required fire resistance ratings. This information is typically found in the product’s data sheet, which needs to be carefully reviewed for compliance and certification.

- Proper Application: The chosen application method must align with the manufacturer’s instructions and the relevant standards. Accurate film thickness, consistent coverage, and proper drying time are crucial factors that must be carefully monitored and documented.

- Testing and Documentation: Post-application testing, such as fire testing or verification by a qualified inspector, might be required to demonstrate compliance. Detailed records including the product used, application method, and testing results must be meticulously maintained for future reference and auditing purposes.

Failure to comply can lead to serious legal repercussions and safety risks. My experience has shown that proactive compliance planning is far more cost-effective than dealing with non-compliance issues later.

Q 10. Describe your experience with different types of fire retardant application equipment.

My experience encompasses a wide range of fire retardant application equipment. I am proficient with:

- Airless Sprayers: These are workhorses for large-scale projects. I’ve used them extensively on structural steel, concrete, and large wooden structures. Their high-pressure capability ensures even coverage, but careful control is essential to avoid overspray and waste.

- Air-Assisted Sprayers: These provide finer control, ideal for detailed work and applications requiring thinner coats. They’re particularly useful when applying fire retardant to delicate materials or in tight spaces.

- Conventional Spray Equipment: This includes lower-pressure diaphragm pumps and various nozzle configurations, suitable for a range of viscosities and application scenarios. I’ve used these on projects where airless systems would be too aggressive.

- Brush and Roller Systems: These are essential for smaller projects or areas inaccessible to spray equipment. Proper brush and roller selection is important for achieving a smooth, even finish.

- Specialized Equipment: My experience includes working with more specialized equipment for vacuum pressure impregnation and high-pressure injection systems for treating larger wood components and masonry structures. These systems require extensive training and expertise to operate correctly.

The choice of equipment depends heavily on the job requirements, the substrate, and the specific fire retardant being used. Proper equipment maintenance and operator training are vital to ensure safe and efficient operation.

Q 11. How do you monitor the curing process of fire retardant materials?

Monitoring the curing process of fire retardant materials is critical for ensuring effectiveness and durability. The methods employed depend on the type of fire retardant and the substrate. Common monitoring techniques include:

- Visual Inspection: Regularly checking for proper film thickness, even coverage, and the absence of defects like runs, sags, or pinholes is essential. This is a fundamental step, and often the most important one.

- Moisture Meter Readings: For water-based fire retardants, measuring the moisture content of the treated substrate helps determine the extent of curing. Over-application or insufficient drying can lead to reduced performance.

- Temperature Monitoring: For some systems, particularly those involving chemical reactions, monitoring temperature changes can indicate the progress of the curing process. This is especially important for high-performance systems.

- Testing: In some cases, laboratory testing might be required to verify that the fire retardant has properly cured and meets the desired specifications. This might involve checking for hardness, adhesion, and other relevant properties.

The curing time can vary greatly depending on environmental factors like temperature and humidity. Thorough documentation of the curing process is crucial for ensuring the longevity and effectiveness of the fire protection system. Failure to allow adequate curing can result in reduced fire resistance and premature material degradation.

Q 12. What are the potential hazards associated with fire retardant application?

Fire retardant application involves several potential hazards:

- Toxicity: Some fire retardants contain chemicals that can be harmful if inhaled or absorbed through the skin. Proper personal protective equipment (PPE), including respirators, gloves, and eye protection, is crucial. Understanding the Safety Data Sheet (SDS) for each product is non-negotiable.

- Flammability: While designed to resist fire, some fire retardants can still be flammable under certain conditions. Proper handling, storage, and application techniques minimize this risk.

- Respiratory Issues: The spray application of fire retardants can generate airborne particles that can irritate the lungs. Adequate ventilation is vital, and respirators are mandatory.

- Skin Irritation: Direct contact with some fire retardants can cause skin irritation or allergic reactions. Protective clothing and prompt skin cleansing are necessary.

- Environmental Concerns: Proper disposal of waste materials is critical to minimize environmental impact. Regulations regarding the disposal of fire retardant waste must be strictly adhered to.

A comprehensive safety plan, including worker training, emergency procedures, and appropriate PPE, is essential to mitigate these hazards. Prioritizing safety is not just a best practice; it is a legal and ethical obligation.

Q 13. How do you handle waste materials generated during fire retardant application?

Waste management is a critical aspect of responsible fire retardant application. My approach involves:

- Minimizing Waste: Careful planning and precise application techniques help reduce waste generation. Accurate material calculations and efficient application methods are key factors.

- Proper Containment: Using appropriate containers and absorbent materials to capture spills and leftover materials prevents contamination.

- Designated Disposal: Waste materials are disposed of according to local and national regulations. This often involves specialized waste haulers equipped to handle hazardous materials.

- Recycling and Reclamation: Whenever feasible, I explore opportunities for recycling or reclaiming usable materials. This approach contributes to sustainable practices.

- Documentation: Detailed records of waste generation, disposal methods, and associated paperwork are maintained to ensure full compliance with environmental regulations.

Improper waste disposal can lead to environmental damage and legal consequences. Following established procedures and collaborating with licensed waste management services is crucial for environmental stewardship.

Q 14. What is your experience with firestop systems?

My experience with firestop systems is extensive, encompassing various types and applications. Firestop systems are critical for preventing the spread of fire and smoke through penetrations in fire-rated walls and floors. This includes:

- Penetration Sealing: I have experience in sealing gaps and openings around pipes, conduits, cables, and other penetrations using a variety of firestop materials such as intumescent foams, firestop putty, and firestop caulk. The selection of the appropriate firestop material is critical to achieving the required fire resistance rating.

- Firestop Systems for Walls and Floors: I am familiar with installing and inspecting firestop systems in various construction types, including concrete, drywall, and masonry. This includes the application of firestop collars, sleeves, and other components.

- Inspection and Testing: I understand the importance of regular inspection and testing to ensure the integrity and effectiveness of firestop systems. This often involves working with qualified testing personnel to verify compliance with relevant codes and standards.

- Understanding Material Compatibility: Selection of firestop materials involves careful consideration of their compatibility with the surrounding construction materials to ensure proper adhesion and effectiveness. I prioritize thorough material compatibility studies before starting any firestop application.

Effective firestop systems are crucial for building safety. My work focuses on ensuring that these systems are correctly installed and regularly maintained to safeguard lives and property.

Q 15. How do you inspect and test the effectiveness of applied fire retardants?

Inspecting and testing the effectiveness of fire retardants involves a multi-faceted approach, combining visual inspections with rigorous laboratory testing. Visual inspection checks for proper coating thickness, evenness of application, and the absence of defects like cracks or peeling. This initial assessment gives a quick overview of the application quality. However, to truly verify effectiveness, we employ standardized testing methods.

Laboratory testing typically involves subjecting treated samples to controlled fire exposure. Common tests include:

- Cone Calorimeter Test: Measures heat release rate, smoke production, and mass loss to quantify the material’s response to fire.

- UL-723 Test (Small-Scale Fire Test): Evaluates the fire resistance of materials used in building construction.

- ASTM E84 (Steiner Tunnel Test): Measures the flame spread and smoke development of interior finishes.

These tests provide quantitative data on the fire retardant’s performance and help determine whether the treatment meets the required fire safety standards for the specific application. For example, in a recent project involving the treatment of wooden beams in a historical building, we used the Steiner Tunnel Test to ensure the flame spread index was below the regulatory limits, protecting the structure’s integrity.

Career Expert Tips:

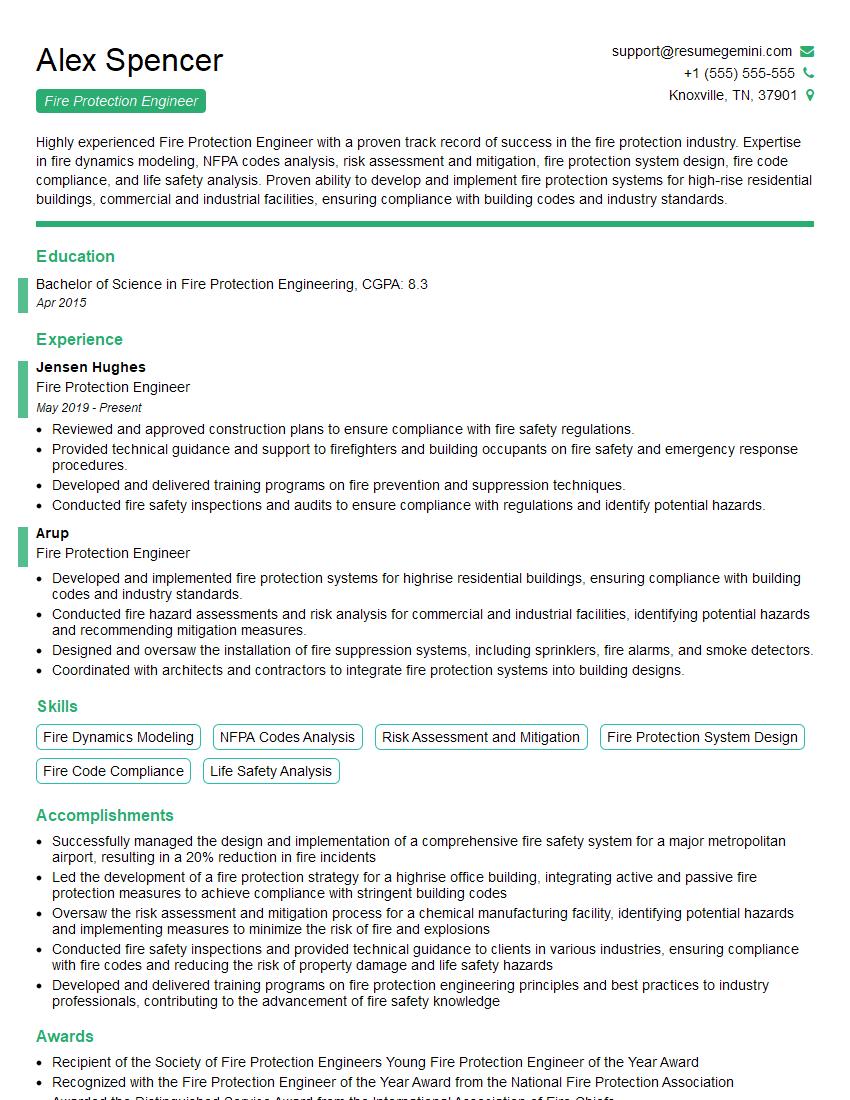

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of fire-resistant coatings?

Fire-resistant coatings come in various forms, each with its own mechanism of action. Here are some key types:

- Intumescent Coatings: These coatings expand significantly when exposed to heat, creating an insulating char layer that protects the underlying substrate. Think of it like a protective shield that grows in response to fire.

- Ablative Coatings: These coatings sacrifice themselves to protect the substrate. They form a charred layer that absorbs heat and slows down the fire’s spread. It’s like a sacrificial layer that burns slowly, allowing the underlying material to remain intact.

- Water-Based Coatings: These are environmentally friendly options that contain fire retardants suspended in water. They are often easier to apply and have lower VOCs (Volatile Organic Compounds).

- Solvent-Based Coatings: These coatings offer excellent durability and penetration but require careful handling due to the volatile organic compounds they contain. They are often chosen for applications needing high-performance and lasting protection.

- Epoxy Coatings: Known for their excellent adhesion and durability, these coatings provide a robust barrier against fire.

The choice of coating depends on factors like the substrate material, the required fire resistance level, environmental concerns, and budget constraints. For instance, intumescents are ideal for steel structures, while ablatives are often preferred for wood.

Q 17. Explain the difference between intumescent and ablative fire retardants.

Intumescent and ablative fire retardants operate on fundamentally different principles. Intumescent coatings expand upon heating, forming a thick, insulating char layer that protects the substrate from the flames. Think of it as a sponge-like reaction that creates a thermal barrier. This char layer slows down heat transfer, preventing the underlying material from reaching its ignition temperature.

In contrast, ablative coatings work by sacrificing themselves to protect the underlying material. Upon exposure to fire, they decompose, creating a protective char layer that absorbs heat and slows the fire’s spread. It’s like a layer that burns slowly, taking the brunt of the fire. This char layer insulates, but also consumes itself during this process, reducing the material overall.

The key difference lies in their mechanism: intumescence involves expansion to create a thermal barrier, while ablation involves sacrificing material to slow the fire’s progress.

Q 18. How do you ensure the quality control of fire retardant application?

Quality control in fire retardant application is crucial for ensuring fire safety and regulatory compliance. Our approach involves several key steps:

- Material Testing: Before application, we rigorously test the fire retardant material to verify it meets the specified standards. This includes checking the chemical composition and performing fire resistance tests on samples.

- Surface Preparation: Proper surface preparation is essential for good adhesion. This involves cleaning, sanding, and priming the substrate to ensure optimal bonding with the fire retardant coating.

- Application Process Control: We follow strict application procedures, including precise measurement of coating thickness, application methods, and drying times. Regular monitoring ensures consistent application quality.

- In-Process Inspection: Visual inspection during the application process checks for defects like uneven coating, pinholes, and missed areas. Any problems are immediately rectified.

- Post-Application Testing: After the application is complete, we conduct further testing to verify the achieved fire resistance level. This includes checking the coating thickness, adhesion, and performing fire tests on treated samples.

- Documentation: Detailed records of all materials used, application procedures, and test results are meticulously maintained for traceability and future reference. This includes compliance with relevant safety standards.

By implementing this rigorous quality control system, we ensure the fire retardant application meets the required standards and provides the expected level of fire protection.

Q 19. Describe your experience with specific fire retardant application techniques.

My experience encompasses a wide range of fire retardant application techniques, tailored to the specific project requirements. I’ve worked extensively with spray application, brush application, and dipping techniques. Spray application, using airless sprayers, is efficient for large-scale projects and provides an even coating. However, it’s crucial to manage overspray and ensure proper ventilation. Brush application is well-suited for smaller areas and intricate details, requiring skilled craftsmanship for consistent coverage. Dipping is most suitable for smaller items which require complete coverage.

In one project, we used a specialized airless spray system for applying intumescent coating to a steel framework of a high-rise building. The project demanded precision and high efficiency to meet the tight deadlines. In another instance, we applied a water-based fire retardant to wooden beams in a historic building using brush application to avoid damage to the delicate structure. The success of these projects underlines the importance of tailoring the application technique to the material and the context.

Q 20. What are the environmental considerations related to fire retardant application?

Environmental considerations are paramount in fire retardant application. Many traditional fire retardants contain hazardous chemicals that can have adverse effects on human health and the environment. Therefore, we prioritize the use of environmentally friendly alternatives wherever possible. This includes using water-based coatings with low or zero VOCs and selecting fire retardants with minimal toxicity and bioaccumulation potential.

Proper disposal of waste materials is another crucial aspect. We adhere to strict waste management procedures, ensuring that waste products are disposed of responsibly in accordance with relevant regulations. We also strive to minimize waste generation through careful planning and precise application techniques. We often collaborate with environmental consultants to ensure compliance with all relevant environmental regulations, and the selection of materials which minimize long-term environmental impact. This includes the evaluation of materials’ life cycle, and appropriate recycling initiatives.

Q 21. How do you manage a fire retardant application project?

Managing a fire retardant application project involves a systematic approach that encompasses several key phases:

- Planning & Design: This includes assessing the project scope, identifying the substrate material and fire safety requirements, selecting appropriate fire retardants, and developing a detailed application plan.

- Preparation: This involves site preparation, surface cleaning and preparation of the substrate, acquisition and testing of materials.

- Application: This phase includes executing the chosen application method, ensuring quality control, and managing on-site personnel and resources.

- Testing & Inspection: This involves conducting regular quality checks during and after application to ensure the fire protection meets the required standards.

- Documentation & Reporting: Maintaining detailed records of all materials used, application procedures, and test results.

- Cleanup & Waste Management: Responsible disposal of materials and ensuring safety compliance.

Effective project management involves strong communication, coordination amongst team members, and adherence to safety protocols throughout the project lifecycle. For instance, in a large-scale project, a detailed schedule is paramount, along with risk assessments and contingency plans to handle unforeseen issues. Proper communication amongst the team, client, and relevant regulatory bodies is crucial for a seamless execution and final approval.

Q 22. Describe a time you had to troubleshoot a problem during fire retardant application.

During a recent project involving the application of intumescent paint to steel beams in a high-rise building, we encountered unexpected high humidity levels in the construction site. This significantly slowed the drying time of the paint, threatening to delay the project and potentially compromise the fire protection efficacy.

To troubleshoot, I first analyzed the weather conditions and the building’s ventilation system. I confirmed the high humidity through readings from multiple hygrometers placed strategically around the work area. We then implemented a three-pronged approach: improving site ventilation with additional dehumidifiers, modifying the paint application schedule to allow for extended drying times, and using infrared thermal cameras to monitor the drying progress of the paint layers. This ensured even drying and avoided issues caused by trapped moisture. The meticulous monitoring and adaptive strategies ensured the successful completion of the project without compromising fire safety standards.

Q 23. What is your experience working with different types of building materials?

My experience spans a wide range of building materials, including steel, wood, concrete, gypsum board, and various fabrics. I’m proficient in applying fire retardants to each, understanding the unique challenges and optimal application methods for every material. For instance, applying fire retardant to wood requires a different approach than applying it to steel. Wood requires penetration, while steel needs surface coating for effective protection. I have extensive hands-on experience with both intumescent coatings for structural steel and water-based fire retardants for wood framing. I also have experience with spray-applied fire-resistive materials (SFRM) for various substrates. This diverse experience allows me to tailor my approach to the specific materials present in any project.

Q 24. How do you communicate effectively with clients and colleagues about fire protection?

Effective communication is crucial in fire protection. I believe in using clear, concise language, avoiding technical jargon unless absolutely necessary, and tailoring my communication style to my audience. With clients, I prioritize explaining the importance of fire safety in straightforward terms, outlining the benefits of various fire-retardant treatments, and addressing their concerns transparently. I present options clearly, detailing the costs and benefits of each. With colleagues, I maintain open and collaborative communication, ensuring everyone understands their roles and responsibilities. I readily share information, actively listen to their insights, and proactively address any potential problems. Regular project meetings, comprehensive reports, and ongoing dialogue are key elements of my approach. For example, if a client is concerned about the aesthetic impact of a fire-retardant treatment, I show them examples of aesthetically pleasing applications and discuss options to minimize visual impact.

Q 25. Explain your understanding of relevant building codes and standards related to fire safety.

My understanding of building codes and standards related to fire safety is comprehensive. I’m familiar with NFPA (National Fire Protection Association) codes, IBC (International Building Code), and local building ordinances. I understand the requirements for fire-resistance ratings, smoke barriers, and the specific fire-retardant treatments needed based on the building’s occupancy classification and construction type. For example, I know the distinctions between Type I, II, III, IV, and V construction and how those impact the necessary fire protection measures. I regularly update my knowledge to stay current with the latest code changes and industry best practices. This ensures that all projects are executed according to the highest safety standards and in compliance with all regulations. This includes understanding the documentation requirements needed to ensure compliance, such as testing reports and certificates of compliance.

Q 26. What are your salary expectations?

My salary expectations are commensurate with my experience and expertise in the field of fire retardant application, considering the industry standards and the responsibilities of this position. I am open to discussing a specific salary range after learning more about the comprehensive compensation package offered.

Q 27. What are your long-term career goals?

My long-term career goals involve becoming a recognized leader in the fire protection industry. I aim to expand my expertise into more specialized areas, such as passive fire protection design, and potentially pursue professional certifications like a Certified Fire Protection Specialist. Ultimately, I aspire to contribute to improving fire safety standards and practices through research, training, and the mentorship of others. I also envision myself heading a team focused on developing innovative and sustainable fire protection solutions.

Q 28. Why are you interested in this position?

I am highly interested in this position because it offers a unique opportunity to apply my extensive knowledge and experience in a challenging and rewarding environment. The company’s reputation for innovation and commitment to safety strongly aligns with my professional values. I am particularly excited about the chance to contribute to significant projects, work collaboratively within a talented team, and leverage my skills to make a tangible impact on fire safety. The opportunity for professional growth within the organization is also a significant motivator.

Key Topics to Learn for Fire Retardant Application Interview

- Types of Fire Retardants: Understanding the chemical properties and applications of various fire retardants (e.g., intumescent coatings, halogenated compounds, inorganic salts).

- Application Methods: Mastering different application techniques including spraying, dipping, brushing, and roller coating, and their suitability for various substrates and fire retardant types.

- Substrate Preparation: Knowing the importance of proper surface cleaning and preparation to ensure optimal adhesion and fire retardant effectiveness.

- Safety Regulations and Compliance: Familiarity with relevant safety standards, regulations (OSHA, etc.), and handling procedures for fire retardant materials.

- Testing and Quality Control: Understanding the methods used to test the effectiveness of fire retardant application and ensuring consistent quality control throughout the process.

- Environmental Impact: Awareness of the environmental considerations associated with different fire retardants and responsible disposal methods.

- Cost-Effectiveness and Material Selection: Analyzing different fire retardant options based on cost, performance, and application requirements.

- Troubleshooting and Problem Solving: Developing the ability to identify and solve common problems encountered during the application process, such as uneven coating or poor adhesion.

- Industry Best Practices: Staying updated on current industry best practices and advancements in fire retardant technology.

Next Steps

Mastering fire retardant application opens doors to exciting career opportunities in construction, manufacturing, and various safety-critical industries. A strong understanding of these techniques is highly valued and demonstrates your commitment to safety and compliance. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. We strongly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to create a compelling document, and examples of resumes tailored to Fire Retardant Application are available to guide you. Take the next step in your career journey today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.