The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Gas Compressor Operations interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Gas Compressor Operations Interview

Q 1. Explain the different types of gas compressors and their applications.

Gas compressors are categorized based on their design and operating principles. The most common types include:

- Centrifugal Compressors: These use rotating impellers to accelerate the gas, increasing its pressure. They are ideal for high-volume, low-pressure applications like natural gas pipelines and petrochemical plants. Think of it like a fan—the impeller pushes the gas outwards, increasing its speed and pressure.

- Reciprocating Compressors: These use pistons moving back and forth within cylinders to compress the gas. They are excellent for high-pressure, low-volume applications, commonly found in refrigeration systems and boosting gas pressure in smaller facilities. Imagine a bicycle pump—the piston compresses air in a contained space.

- Rotary Screw Compressors: These utilize two intermeshing helical screws to compress the gas. They offer a smooth, continuous flow and are widely used in various industries including oil and gas, manufacturing, and power generation. They are a good compromise between the high volume of centrifugal and high pressure of reciprocating compressors.

- Axial Compressors: These compressors use a series of rotating blades on a shaft to progressively increase gas pressure. They are frequently utilized in aircraft engines and large industrial gas turbines due to their high efficiency and capacity. Think of them as a series of fans, each adding a bit of pressure.

The choice of compressor type depends heavily on factors such as required pressure ratio, flow rate, gas properties, and overall cost-effectiveness.

Q 2. Describe the process of gas compression from intake to discharge.

The gas compression process, from intake to discharge, can be explained in these steps:

- Intake: Gas enters the compressor through an intake valve or port. This gas is typically at a lower pressure than the desired discharge pressure.

- Compression: The gas is compressed using the compressor’s mechanism (impellers, pistons, screws, or blades). This compression increases the gas’s pressure and temperature. The specific method varies based on the compressor type.

- Cooling (Optional): In many cases, intercoolers are used between compression stages to cool the gas and improve overall efficiency. This is crucial as compression significantly heats the gas.

- Discharge: Finally, the compressed gas is discharged from the compressor through an outlet valve or port. It exits at the desired higher pressure and elevated temperature.

Imagine a water pump. The intake is where the low-pressure water enters, the pump (compressor) increases the pressure, and the discharge is where the high-pressure water flows out. The same basic principles apply to gas compression.

Q 3. What are the key performance indicators (KPIs) for gas compressors?

Key Performance Indicators (KPIs) for gas compressors are crucial for monitoring their health and efficiency. Some of the most important ones include:

- Discharge Pressure: Measures the final pressure of the compressed gas. Deviations indicate potential problems.

- Flow Rate: Indicates the volume of gas processed per unit time. A decrease may signal issues with the intake or compressor itself.

- Power Consumption: Monitors the energy used by the compressor. High power consumption points to potential inefficiencies or malfunctions.

- Efficiency (Adiabatic Efficiency): Measures the actual work done compared to the ideal work required for compression. This is a crucial indicator of performance.

- Vibration Levels: High levels indicate mechanical issues like imbalance, bearing wear, or misalignment.

- Temperature: High temperatures can indicate overheating, potentially due to leakage, lubrication problems, or insufficient cooling.

- Oil Condition (for lubricated compressors): Regularly checking oil parameters like level, pressure, and contamination is essential to detect lubrication issues early.

Regular monitoring of these KPIs is essential for proactive maintenance and avoiding costly downtime.

Q 4. How do you troubleshoot a compressor experiencing low discharge pressure?

Troubleshooting low discharge pressure in a gas compressor requires a systematic approach. Here’s a step-by-step process:

- Check the Intake Pressure: Ensure sufficient intake pressure is available. Low intake pressure directly impacts discharge pressure.

- Inspect the Suction Filter/Strainer: A clogged filter restricts gas flow, reducing discharge pressure. Clean or replace as needed.

- Verify Valve Operation: Check the intake and discharge valves for proper operation. Leaking or stuck valves can significantly reduce pressure.

- Examine the Compressor’s Internal Components (If Possible): For reciprocating compressors, inspect for piston damage, worn rings, or valve problems. For centrifugal compressors, check the impeller for wear or damage. This often requires specialized knowledge and equipment.

- Assess Lubrication System: Inadequate lubrication can cause friction and reduced efficiency, leading to low discharge pressure. Check oil levels, pressure, and quality.

- Check Intercoolers (If Applicable): Clogged intercoolers restrict gas flow, impacting discharge pressure. Ensure they are clean and functioning properly.

- Review the Drive System: A problem with the motor or driving mechanism (belts, couplings) may reduce the compressor’s speed and consequently the discharge pressure.

Remember safety precautions when working with high-pressure systems. Consult operational manuals and seek professional assistance if needed.

Q 5. Explain the importance of lubrication in gas compressor operation.

Lubrication plays a vital role in gas compressor operation. It serves multiple crucial functions:

- Reduces Friction and Wear: Lubricant minimizes friction between moving parts (bearings, pistons, gears, etc.), reducing wear and tear, extending the lifespan of the compressor, and minimizing maintenance.

- Cooling: Lubricants help dissipate heat generated during the compression process, preventing overheating and component damage.

- Sealing: Lubricant assists in sealing against gas leakage, maintaining pressure and efficiency.

- Corrosion Protection: Lubricants protect internal components from corrosion, especially in environments with corrosive gases.

Proper lubrication is not merely beneficial—it’s essential for reliable and efficient gas compressor operation. Neglecting lubrication can lead to catastrophic failures and expensive repairs.

Q 6. Describe the different types of compressor seals and their functions.

Compressor seals prevent gas leakage and maintain system pressure. Common types include:

- Stuffing Box Seals (Mechanical Seals): These are relatively simple, using packing material compressed around a shaft to prevent leakage. They are often found in older or less demanding applications. Think of it like tightly packing a piston with rings to prevent leakage.

- Mechanical Seals: These utilize precisely engineered faces that rub against each other with a thin film of lubricant. They offer better sealing capabilities and are frequently used in high-pressure applications.

- Magnetic Bearings: These non-contact seals use magnetic fields to support the rotating shaft, eliminating the need for physical contact and achieving nearly zero leakage. They are highly reliable and efficient but are typically more expensive.

- Gas Seals (also known as Labyrinth Seals): These utilize a series of closely spaced chambers to restrict gas flow, creating a barrier against leakage. They are often used in conjunction with other seal types.

The selection of the seal type depends on factors such as the gas being compressed, the pressure and temperature conditions, and the desired level of leakage prevention. Each seal type has its advantages and disadvantages, and choosing the right one is crucial for efficient and safe operation.

Q 7. How do you identify and address compressor vibration issues?

Compressor vibration is a significant concern, indicating potential mechanical problems. Here’s how to address it:

- Identify the Source: Utilize vibration monitoring equipment to pinpoint the source and frequency of the vibration. This could involve measuring vibration at various points on the compressor.

- Analyze the Vibration Data: Frequency analysis helps to diagnose the root cause. Certain frequencies correlate with specific problems (e.g., imbalance, misalignment, bearing wear).

- Check Alignment: Misalignment of the compressor’s shafts can cause excessive vibration. Ensure proper alignment using laser alignment tools.

- Inspect Bearings: Worn or damaged bearings are a common cause of vibration. Inspect them for wear, damage, or contamination.

- Assess Rotor Balance: An unbalanced rotor is a major source of vibration. Dynamic balancing is necessary to correct this.

- Check Foundation: A weak or unstable foundation can amplify vibrations. Ensure the foundation is strong and properly installed.

- Inspect Couplings: Damaged or misaligned couplings can contribute to vibration problems. Inspect for wear and ensure correct alignment.

Addressing vibration issues promptly is critical to prevent catastrophic failure and ensure smooth, efficient operation. Ignoring them can lead to significant damage and potentially dangerous situations.

Q 8. What are the safety procedures for operating and maintaining gas compressors?

Safety is paramount in gas compressor operations. Procedures must be meticulously followed to prevent accidents. This begins with comprehensive training for all personnel, covering lockout/tagout procedures, confined space entry protocols, and emergency response plans. Regular safety inspections are crucial, checking for leaks, worn components, and proper functioning of safety devices like pressure relief valves and fire suppression systems. Personal Protective Equipment (PPE), including safety glasses, hard hats, gloves, and hearing protection, must be worn at all times in designated areas. Furthermore, detailed operating procedures, including pre-start checks and shutdown procedures, must be strictly followed. Regular safety meetings and drills reinforce safe work practices and emergency response capabilities. Think of it like piloting an airplane – a series of checks and balances is necessary before, during, and after operation to ensure safety.

- Lockout/Tagout (LOTO): Before any maintenance or repair, energy sources must be isolated and locked out, preventing accidental start-up.

- Confined Space Entry: Proper permits, atmospheric monitoring, and rescue plans are essential when entering enclosed compressor spaces.

- Regular Inspections: Visual inspections, pressure tests, and vibration analysis are critical for early detection of potential problems.

Q 9. Explain the role of instrumentation and control systems in gas compressor operations.

Instrumentation and control systems are the nervous system of a gas compressor, ensuring safe, efficient, and reliable operation. They monitor key parameters like pressure, temperature, flow rate, vibration, and speed. This data is fed to a control system, often a Programmable Logic Controller (PLC), which automatically adjusts the compressor’s operation to maintain optimal performance and prevent dangerous conditions. For example, if the discharge pressure gets too high, the control system might automatically reduce the speed of the compressor or activate a pressure relief valve. Advanced systems incorporate SCADA (Supervisory Control and Data Acquisition) which allows remote monitoring and control from a central location. This provides real-time visibility into the compressor’s performance and facilitates rapid response to any anomalies. Think of a sophisticated car’s dashboard; it provides vital information for the driver, and a PLC acts similarly, automatically adjusting parameters to maintain smooth functioning and prevent critical situations.

Q 10. How do you perform a compressor performance test?

A compressor performance test is a systematic evaluation of its efficiency and effectiveness. It involves measuring key parameters under various operating conditions, comparing these against the manufacturer’s specifications, and identifying areas for improvement. Typical measurements include inlet and outlet pressures and temperatures, flow rate, power consumption, and suction and discharge gas compositions. These measurements allow for the calculation of important metrics such as adiabatic efficiency, isothermal efficiency, and volumetric efficiency. The test often involves varying the compressor’s operating speed and discharge pressure to obtain a comprehensive picture of its performance across its operational range. For instance, we might compare the actual power consumed against the theoretical power required for a given flow rate to assess the overall efficiency. Any deviations from the expected values point towards potential problems such as fouling, internal leaks, or mechanical issues that necessitate maintenance or repair.

Q 11. Describe the process of starting and shutting down a gas compressor.

Starting and shutting down a gas compressor is a carefully choreographed process to prevent damage to equipment and ensure safety. The start-up sequence typically involves checking all safety systems, verifying proper lubrication, and confirming no obstructions. The compressor is then slowly brought up to speed, while closely monitoring critical parameters such as bearing temperatures and vibration levels. The shutdown process is equally important; it involves gradually reducing the compressor’s speed, ensuring a controlled pressure decrease to avoid surge (discussed later), and properly securing the equipment to prevent accidental start-up. Detailed procedures are established and followed, and checklists are used to ensure each step is completed before proceeding to the next. Failure to adhere to the proper start-up and shut-down procedures can lead to expensive equipment damage and potentially hazardous situations.

Q 12. Explain the concept of surge in gas compressors and how to prevent it.

Surge is a dangerous condition in gas compressors characterized by violent pressure oscillations and flow reversals. It can lead to severe damage to the compressor, piping, and associated equipment. It occurs when the compressor’s operating point falls outside its stable operating region – essentially, when the compressor is trying to push more gas than it can handle. This often happens due to a sudden change in downstream pressure or flow rate. Surge prevention strategies include installing surge protection devices (e.g., anti-surge control systems), implementing proper control strategies, and designing systems with adequate surge capacity. Anti-surge systems often incorporate a bypass valve that diverts gas flow to prevent pressure from building up excessively. These systems constantly monitor the compressor’s operating point and proactively adjust the bypass valve to prevent surge. Thinking of a garden hose, if you suddenly close the end completely, a pressure surge occurs. Similarly, uncontrolled closure or unexpected changes in flow create pressure surges in gas compressors.

Q 13. How do you maintain optimal compressor efficiency?

Maintaining optimal compressor efficiency involves a multi-faceted approach. Regular maintenance is key, including cleaning, inspecting, and repairing or replacing worn components. This includes checking for leaks, ensuring proper lubrication, and cleaning the compressor’s internal surfaces to reduce fouling, which significantly impacts efficiency. Proper valve maintenance is also crucial for efficient operation. Furthermore, optimization of the compressor’s control system can improve efficiency. Regular performance testing and analysis can help identify areas for improvement, and periodic adjustments of the compressor’s operating parameters can be implemented to maximize efficiency based on changing operating conditions. Imagine your car—regular maintenance like oil changes and tire rotations ensures peak performance and fuel efficiency. Gas compressors require similar attention to optimize their performance and minimize energy consumption.

Q 14. What are the common causes of compressor failures?

Compressor failures can stem from a variety of causes. Mechanical failures are common, including bearing wear, rotor blade damage, and seal leaks. These often result from inadequate lubrication, vibration, or excessive loads. Corrosion, particularly in the presence of aggressive gases, can weaken compressor components. Fouling, the buildup of deposits on internal surfaces, restricts flow and reduces efficiency, eventually leading to failure. Control system malfunctions, such as sensor failures or software errors, can result in unsafe operating conditions and compressor damage. In addition, improper operation and inadequate maintenance contribute significantly to compressor failures. Regular inspections, preventative maintenance, and proper operational procedures are essential to extend the life of gas compressors and prevent costly breakdowns. A systematic approach to maintenance and proactive troubleshooting can mitigate these common causes of compressor failure.

Q 15. Describe your experience with different types of compressor control systems (e.g., PLC, DCS).

Throughout my career, I’ve extensively worked with both Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCSs) in managing gas compressor operations. PLCs are typically used for smaller, simpler compressor systems, offering precise control over individual components. Think of a PLC as a dedicated, highly specialized computer brain for a single machine. I’ve used them to manage everything from motor speed to valve actuation on smaller reciprocating compressors. Conversely, DCSs are employed in larger, more complex facilities with multiple compressors and ancillary equipment. A DCS offers a centralized control system with redundancy and advanced features, providing an overview and control of a larger process. For example, I’ve worked with DCS systems in large pipeline compressor stations, where they monitored and controlled multiple centrifugal compressors, optimizing flow and pressure across the entire pipeline network, along with safety systems and alarms.

The difference in implementation is significant. PLCs often require more individual programming for each function, while DCSs use a more structured approach involving configurable software modules. Both systems are equally critical, the choice depending primarily on the scale and complexity of the operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret compressor performance curves?

Compressor performance curves are crucial for understanding a compressor’s efficiency and capacity at various operating points. These curves typically plot pressure ratio against volumetric flow rate at constant speed. Interpreting these curves involves understanding several key aspects: the surge line (the left boundary where compressor flow becomes unstable), the choke line (the right boundary where the compressor is choked), and the best efficiency point (BEP). The BEP represents the operating point with the highest efficiency. The compressor should be operated as close to the BEP as possible for optimal performance and energy efficiency.

For example, if the operating point is far from the BEP, it indicates a potential problem such as fouling or mechanical issues. Analyzing the curve’s characteristics helps identify potential areas for improvement. For instance, a shift in the curve could point towards problems like valve leakage or changes in the gas composition. I regularly use these curves for troubleshooting and identifying opportunities for process optimization, ensuring that the compressor operates within its safe and efficient limits.

Q 17. Explain the significance of API standards in gas compressor operations.

API (American Petroleum Institute) standards are paramount in gas compressor operations, setting benchmarks for safety, design, and operation. These standards help ensure consistency and reliability across the industry. They cover various aspects, from compressor design and installation (like API 617 for centrifugal compressors and API 618 for reciprocating compressors) to testing, maintenance, and safety procedures. Compliance with these standards is not merely a suggestion but a necessity for safe and efficient operation, minimizing risk and ensuring regulatory compliance.

In practice, adherence to API standards is critical in preventing accidents, ensuring equipment longevity, and meeting regulatory requirements. For example, adhering to API 617 for centrifugal compressor design helps prevent shaft failures, and adhering to maintenance standards as outlined in API recommendations extends the life of the equipment and reduces the risk of catastrophic failures. Ignoring these standards can lead to severe consequences, ranging from costly downtime to significant safety hazards.

Q 18. Describe your experience with gas compressor maintenance schedules and preventative maintenance.

My experience with gas compressor maintenance schedules is extensive, encompassing both preventative and predictive maintenance strategies. Preventative maintenance follows a structured plan with regular inspections, lubrication, and component replacements based on manufacturer recommendations and operating hours. This proactive approach helps to prevent failures and extends the life of the equipment. I’ve managed maintenance schedules using Computerized Maintenance Management Systems (CMMS) to track work orders, parts inventory, and maintenance history.

Predictive maintenance uses data analysis such as vibration monitoring and oil analysis to anticipate potential problems before they lead to failures. For example, detecting increased vibration levels in a compressor can signal impending bearing failure, allowing for timely intervention and preventing a more significant breakdown. This approach minimizes unexpected downtime and reduces the overall cost of maintenance. The optimal approach often involves a combination of both preventative and predictive maintenance strategies, customized to the specific compressor type and operating conditions.

Q 19. How do you handle emergency situations involving gas compressor malfunctions?

Handling emergency situations with gas compressor malfunctions requires a calm, systematic approach. My experience involves immediately assessing the situation to determine the nature and severity of the malfunction. This includes reviewing alarm conditions, verifying instrument readings, and quickly identifying the root cause. The safety of personnel and equipment is always the top priority. Following established emergency procedures is crucial.

For example, if a fire occurs, activating the emergency shutdown system (ESD) and contacting emergency services are immediate priorities. Following the specific emergency response procedures for that situation is key. In other cases, such as a surge event, quickly adjusting the compressor’s operating parameters to restore stability may be required. In all situations, careful documentation of the event, including root cause analysis, is crucial for implementing corrective actions and preventing future incidents. Regular emergency drills and training sessions help ensure effective response during crisis situations.

Q 20. Explain the principles of gas dynamics as they relate to compressor operation.

Gas dynamics are fundamental to compressor operation. They govern the flow of gas through the compressor and dictate its performance. Key concepts include compressibility, isentropic processes, and the relationship between pressure, temperature, and volume. Understanding these principles helps to determine the required compressor power, predict pressure and temperature changes, and optimize the compressor’s efficiency.

For example, the compressibility factor (Z) accounts for deviations from ideal gas behavior. This is especially important at high pressures and low temperatures, which are common in natural gas pipeline applications. An accurate understanding of this, as well as isentropic processes and the corresponding calculations, enables proper compressor sizing and performance optimization. Failure to consider these factors can lead to inaccurate predictions, inefficient operation, and potential equipment damage. I’ve leveraged my knowledge of gas dynamics to create accurate compressor performance models and simulations, leading to improved efficiency and reduced operational costs.

Q 21. What are the environmental considerations associated with gas compressor operations?

Environmental considerations are crucial in gas compressor operations. The main concerns revolve around greenhouse gas emissions (like methane leakage), noise pollution, and potential air and water contamination. Reducing emissions involves regular leak detection and repair programs, minimizing venting, and using efficient compressors. Noise reduction can be achieved through acoustic enclosures and optimized equipment design.

For example, implementing a regular leak detection and repair (LDAR) program is vital to minimize methane emissions. Furthermore, choosing environmentally friendly refrigerants in the case of refrigeration compressors, or using energy-efficient motor drives, also plays a significant role in minimizing environmental impact. Regulations and standards like those set by the EPA help define acceptable limits for emissions and noise levels. Meeting these standards is a critical aspect of responsible and sustainable gas compressor operations.

Q 22. How do you ensure compliance with environmental regulations?

Ensuring compliance with environmental regulations in gas compressor operations is paramount. This involves a multi-faceted approach focusing on emissions reduction, waste management, and adherence to specific local and national legislation.

- Emissions Monitoring and Control: We regularly monitor emissions of pollutants like NOx, CO, and VOCs (Volatile Organic Compounds), using continuous emission monitoring systems (CEMS). Data is meticulously logged and reported to regulatory bodies. Exceeding permitted limits triggers immediate investigation and corrective actions, potentially involving process adjustments or equipment upgrades. For instance, implementing selective catalytic reduction (SCR) systems can significantly reduce NOx emissions.

- Leak Detection and Repair (LDAR): Regular leak detection and repair programs are crucial to minimize fugitive emissions of refrigerants (if applicable) and other harmful gases. We utilize advanced leak detection technologies, like infrared cameras and ultrasonic detectors, to promptly identify and repair leaks. This reduces environmental impact and prevents hazardous situations.

- Waste Management: Proper disposal of used oil, filters, and other hazardous waste is mandatory. We strictly adhere to guidelines set by relevant agencies, ensuring responsible handling and disposal through licensed contractors. Detailed records are maintained for traceability and audit purposes.

- Permitting and Reporting: Maintaining up-to-date permits and submitting accurate environmental reports is non-negotiable. This includes air quality permits, waste disposal permits, and compliance reports detailing operational performance and emissions data. Proactive communication with regulatory agencies is crucial to anticipate and address potential compliance issues.

Ultimately, environmental compliance is not just about meeting legal requirements; it’s about responsible stewardship of the environment. We view it as an integral part of our operational excellence, and our commitment goes beyond simply complying—we actively seek opportunities to improve our environmental performance.

Q 23. Describe your experience with gas compressor capacity calculations and optimization.

Gas compressor capacity calculations and optimization are critical for efficient and profitable operations. My experience involves utilizing various methods, including thermodynamic calculations and performance curves, to determine the optimal compressor capacity for a given application.

For instance, I’ve worked on projects where we needed to increase the throughput of a natural gas pipeline. This involved a detailed assessment of the existing compressor station, including the performance characteristics of each compressor unit. Using specialized software and considering factors like pipeline pressure, gas properties (temperature, density, composition), and elevation changes, I performed simulations to determine the optimal compressor configuration. This might involve adding new compressors, upgrading existing ones, or optimizing the operating parameters of the existing fleet.

Optimization goes beyond just calculating capacity; it involves continuous monitoring of compressor performance and adjusting operational parameters—like speed, suction pressure, and discharge pressure—to maximize efficiency while staying within safety limits. This often involves implementing control strategies to dynamically adjust the compressor performance based on real-time operating conditions and demand fluctuations. I’ve personally implemented advanced control strategies that have led to significant improvements in energy efficiency and reduced operational costs in several projects.

Q 24. Explain your understanding of different types of compressor drivers (e.g., electric motor, gas turbine).

Gas compressors can be driven by various types of prime movers, each with its strengths and weaknesses.

- Electric Motors: These offer precise speed control, high efficiency at optimal loads, and relatively low maintenance. However, they might be less suitable for remote locations lacking reliable power grids. Additionally, the initial capital cost can be significant.

- Gas Turbines: These are highly reliable and suitable for remote locations as they use the same gas being compressed as fuel. They offer high power output and fast response times but typically exhibit lower efficiency at partial loads and higher emissions than electric motors. They also tend to have higher maintenance costs.

- Diesel Engines: A robust and reliable choice, particularly in locations with limited access to electricity or pipeline gas. They provide high torque at low speeds but are generally less fuel-efficient than gas turbines and can be noisy and produce significant emissions.

- Steam Turbines: Often used where steam is readily available as a byproduct of other processes. They are efficient but require a reliable steam source.

The choice of driver depends on factors like the application’s specific requirements (power output, efficiency, environmental impact), location (accessibility to power grids and fuel), and economic considerations (capital and operational costs).

Q 25. How do you troubleshoot issues related to compressor intercoolers and aftercoolers?

Troubleshooting compressor intercoolers and aftercoolers involves a systematic approach to identify and resolve performance issues. Intercoolers cool the gas between compressor stages, while aftercoolers cool the compressed gas at the discharge. Common problems include:

- Reduced Cooling Capacity: This can be caused by fouling (accumulation of dirt, oil, or other contaminants) on the heat exchanger surfaces, leaks in the cooling system, or insufficient cooling water/air flow. We address this by cleaning or replacing the heat exchanger, checking for leaks and repairing them, and ensuring adequate coolant flow. I’ve encountered instances where we had to optimize the cooling system design to improve efficiency.

- High Pressure Drop: Excessive pressure drop across the intercooler or aftercooler indicates a blockage or restriction in the flow path. This might be due to fouling, damaged fins, or improper piping design. We would inspect the unit, clean or replace components as needed, and ensure proper piping configuration.

- Temperature Excursions: Inconsistent temperatures upstream and downstream of the coolers might point to problems with the cooling system or the cooler itself. This requires a detailed investigation to determine the root cause, which might involve reviewing sensor calibration, examining the cooling water/air flow, and checking for leaks.

My approach involves thorough inspections, reviewing operational data (temperatures, pressures, flow rates), and performing performance tests to pinpoint the root cause. I also rely heavily on preventive maintenance practices, including regular cleaning and inspection of these critical components, to prevent major issues and extend their lifespan.

Q 26. Describe your experience with compressor anti-surge systems.

Anti-surge systems are critical safety features preventing compressor surge, a potentially damaging phenomenon that can occur when the compressor operates outside its stable operating range. My experience encompasses several types of anti-surge systems:

- Recirculation Systems: These systems divert a portion of the compressed gas back to the compressor suction, preventing surge by maintaining a minimum flow rate. The level of recirculation is controlled dynamically by a surge control valve that opens or closes based on operating conditions. This is a common and effective method that I’ve used extensively.

- Inlet Guide Vane Control: This approach uses adjustable inlet guide vanes to adjust the compressor’s flow capacity, preventing surge by regulating the amount of gas entering the compressor. I’ve worked with systems that use advanced control algorithms to precisely manage inlet guide vane positions for optimal surge protection.

- Variable Speed Drives (VSDs): VSDs provide precise control over the compressor’s speed, enabling smooth transitions and preventing surge. They are particularly beneficial in applications with varying flow demands. My expertise includes selecting, configuring, and maintaining these systems.

Understanding the limitations and capabilities of the anti-surge system and its interaction with other process parameters is vital. Regular testing and maintenance are essential to ensure its reliability, and effective training is crucial for personnel who operate and maintain these systems. I’ve overseen numerous projects where rigorous testing and operator training have prevented costly surge events and ensured safe operations.

Q 27. Explain your understanding of gas compressor suction and discharge piping systems.

Suction and discharge piping systems are critical for the efficient and safe operation of gas compressors. The suction piping system transports gas from the source to the compressor inlet, while the discharge piping system conveys the compressed gas to its destination.

Proper design considerations include:

- Pressure Drop: Minimizing pressure drop in both the suction and discharge piping systems is crucial to maximize compressor efficiency and avoid excessive energy consumption. This requires careful selection of pipe diameter, material, and fittings. I’ve utilized computational fluid dynamics (CFD) modeling to optimize piping layouts and minimize pressure losses in several projects.

- Pipe Sizing and Material Selection: The pipe diameter must be adequate to handle the required gas flow rate without excessive pressure drop. Material selection depends on the gas properties (temperature, pressure, corrosiveness), operating conditions, and regulatory requirements. I’ve worked with a variety of piping materials, including carbon steel, stainless steel, and specialized alloys.

- Flow Control and Instrumentation: Valves, flow meters, and pressure gauges are essential components of the piping system, allowing for precise control of gas flow and monitoring of system performance. Proper sizing and selection of these instruments are crucial for efficient operation and safety. I have overseen the design and implementation of several complex piping systems, ensuring proper integration of instrumentation and control devices.

- Stress Analysis and Support Structures: Proper structural support is vital, especially in high-pressure systems, to prevent pipe failure. I have experience utilizing engineering analysis techniques, including finite element analysis (FEA), to ensure structural integrity of the piping system.

In summary, designing and maintaining robust and efficient suction and discharge piping systems is critical for the safe and reliable operation of a gas compressor installation.

Q 28. How do you ensure the safe handling of refrigerants used in gas compressor systems (if applicable)?

Safe handling of refrigerants in gas compressor systems (if applicable) requires strict adherence to established safety protocols and regulatory requirements. This is crucial to prevent environmental damage and health risks.

- Proper Training and Certification: Personnel involved in handling refrigerants must undergo thorough training on safe handling procedures, leak detection, and emergency response. Certifications like EPA Section 608 are essential to demonstrate competency. I’ve always prioritized comprehensive training and ensured that all team members are adequately certified.

- Leak Detection and Repair: Regular leak detection and prompt repair are crucial to minimize refrigerant emissions. We utilize sophisticated leak detection technologies, such as electronic leak detectors and infrared cameras, to rapidly identify and address any leaks.

- Refrigerant Recovery and Recycling: When servicing or decommissioning equipment, it’s essential to recover the refrigerant in a responsible manner. We utilize specialized equipment to recover and recycle refrigerants, minimizing environmental impact and maximizing cost efficiency. This is in line with industry best practices and regulatory requirements.

- Emergency Preparedness: Having a well-defined emergency response plan is crucial to deal with potential refrigerant releases. This includes procedures for evacuation, containment, and cleanup, as well as procedures for alerting emergency services. Regular drills and training are essential to ensure preparedness for various scenarios.

- Storage and Handling: Refrigerants must be stored and handled according to manufacturer’s instructions and regulatory guidelines. This involves proper labeling, storage in designated areas, and the use of appropriate personal protective equipment (PPE).

Safe refrigerant handling isn’t just a matter of compliance; it’s a core value in our operations. It protects the environment, our personnel, and the reputation of our organization. My commitment to safety is unwavering.

Key Topics to Learn for Gas Compressor Operations Interview

- Compressor Types and Applications: Understanding centrifugal, reciprocating, and rotary compressors; their suitability for different gas compositions and pressures; and real-world applications in oil and gas, petrochemical, and industrial settings.

- Thermodynamics and Gas Laws: Applying principles of thermodynamics, including ideal gas law and compressibility factors, to analyze compressor performance, efficiency, and energy consumption. Practical application involves calculating compressor power requirements and optimizing operating parameters.

- Compressor Controls and Instrumentation: Familiarization with various control systems (e.g., PLC, DCS) used in compressor stations; understanding pressure, temperature, flow, and speed sensors; troubleshooting common instrumentation issues and their impact on compressor operation.

- Safety Procedures and Regulations: Deep understanding of safety protocols, emergency shutdown procedures, and relevant industry regulations (e.g., API, OSHA) for safe and efficient compressor operation. Practical application involves risk assessment and mitigation strategies.

- Compressor Maintenance and Troubleshooting: Knowledge of routine maintenance tasks, preventative maintenance schedules, and troubleshooting common compressor malfunctions (e.g., bearing failures, valve issues, seal leaks). Practical application involves diagnosing problems using diagnostic tools and implementing effective repair strategies.

- Compressor Performance Analysis and Optimization: Analyzing compressor performance data to identify inefficiencies and areas for improvement. Implementing strategies to optimize compressor operation, enhance efficiency, and reduce energy consumption. This includes understanding performance curves and using data analysis techniques.

- Gas Compression Systems: Understanding the entire system including suction scrubbers, intercoolers, aftercoolers, and discharge piping. This includes knowledge of pressure drops and their impact on overall system efficiency.

Next Steps

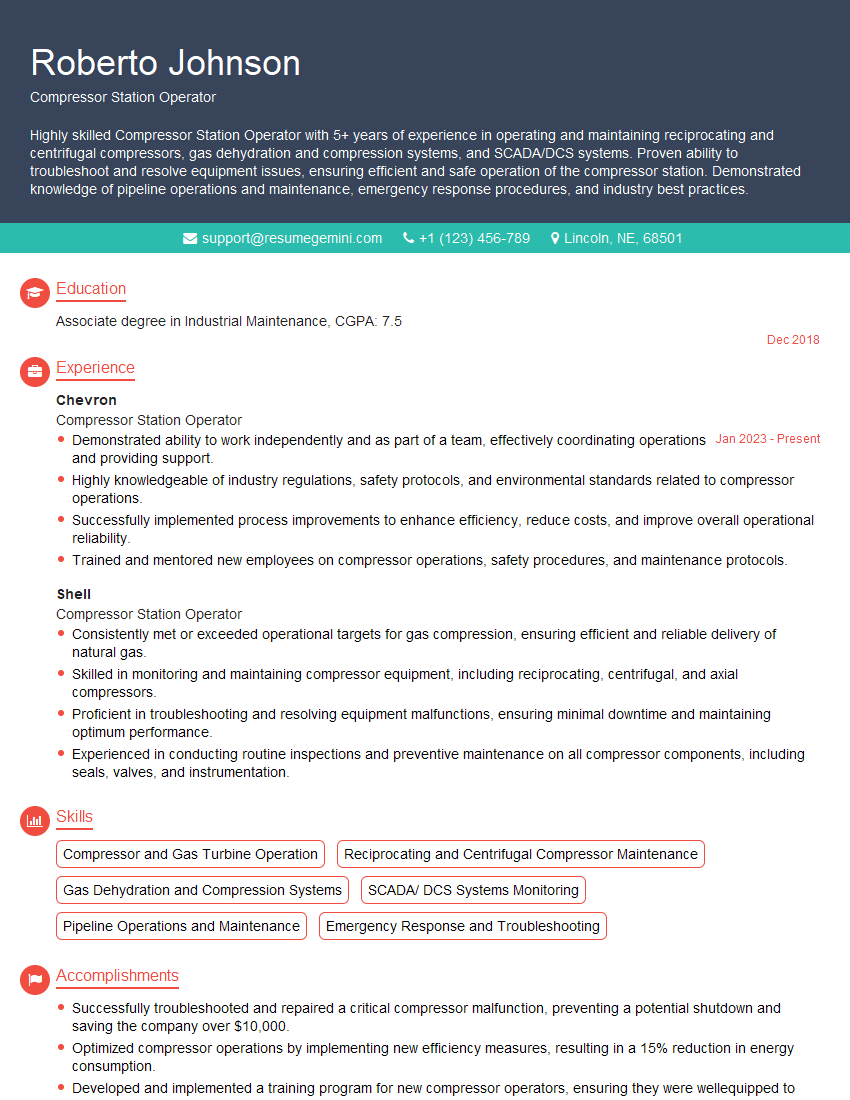

Mastering Gas Compressor Operations is crucial for a successful and rewarding career in the energy sector, opening doors to diverse roles with increasing responsibility and compensation. A well-crafted resume is your first step toward showcasing your skills and experience to potential employers. Creating an ATS-friendly resume is essential for maximizing your chances of getting noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out from the competition. We offer examples of resumes specifically tailored to Gas Compressor Operations to guide you in crafting your own compelling application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.