Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Airtightness and Envelope Tightness Testing interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Airtightness and Envelope Tightness Testing Interview

Q 1. Explain the difference between air leakage and air infiltration.

While often used interchangeably, air leakage and air infiltration have subtle differences. Air leakage refers to the unintended movement of air through any opening in the building envelope, regardless of whether it’s driven by pressure differences. This includes gaps around windows, penetrations for pipes, or even porous building materials. Air infiltration, on the other hand, is a more specific type of air leakage – it’s the movement of air into or out of a building driven primarily by pressure differences between the inside and outside.

Think of it like this: a hole in your window (leakage) will always let air pass, but only when the wind pushes harder on one side than the other, is it considered infiltration. Infiltration is a subset of leakage.

Q 2. Describe the various methods used for airtightness testing.

Several methods exist for airtightness testing, each with its strengths and weaknesses. The most common is the blower door test. This involves sealing all openings except the blower door itself, a large fan that’s installed in an exterior door. The fan either pressurizes or depressurizes the building, creating a pressure difference between the inside and outside. Leakage is then measured using specialized equipment that records the airflow rate at a specific pressure difference.

Other methods include:

- Tracer gas techniques: These involve introducing a non-toxic tracer gas into the building and measuring its concentration over time. This method is less common but useful for pinpointing specific leak locations.

- Smoke testing: A more qualitative method; smoke is introduced to visually identify air leakage paths. Useful for finding smaller leaks not easily detected by a blower door.

- Pressure decay testing: This involves pressurizing or depressurizing the building and then monitoring the rate at which the pressure changes. It helps assess general airtightness but doesn’t provide detailed leakage information.

The choice of method depends on factors like budget, the level of detail required, and the building’s size and complexity.

Q 3. What are the common pressure differentials used in airtightness testing?

The pressure differential used in airtightness testing varies depending on the standard being followed and the building type. Common pressure differentials range from 50 Pascals (Pa) to 75 Pa. Sometimes, tests are also conducted at lower pressures, such as 25 Pa or 4 Pa, to better assess the performance under typical conditions. Higher pressure differences can reveal more leaks but might not be representative of real-world conditions, while lower pressure differences might miss smaller leaks.

For example, in some regions, a 50 Pa test is used for initial assessments, with a 75 Pa test following if issues are found. It’s important to choose the appropriate pressure differential based on local regulations and the test’s objectives.

Q 4. How do you interpret the results of an airtightness test?

Airtightness test results are usually reported as a leakage rate, often expressed in cubic meters per hour per square meter at 50 Pa pressure difference (m³/h·m²@50Pa) or a similar metric at a different pressure. This number represents the volume of air leaking through the building envelope per unit area at the specified pressure difference. Lower numbers indicate better airtightness.

Along with the leakage rate, the test report should also include details on the test procedure, the pressure difference used, temperature, and humidity. Additionally, a blower door test often includes a visual inspection to locate major air leakage paths, and this information should be noted in the report.

Interpreting the results requires an understanding of acceptable leakage rates for different building types (discussed in the next question) and identifying areas that need improvement to meet the desired levels.

Q 5. What are the acceptable airtightness levels for different building types?

Acceptable airtightness levels vary considerably depending on the building type, climate, and local building codes. There isn’t a single universal standard. However, general guidelines exist. Passive houses, for instance, often aim for leakage rates well below 0.6 m³/h·m²@50Pa. More conventional buildings might have target values ranging from 1.0 to 3.0 m³/h·m²@50Pa or higher. Building codes frequently set minimum requirements, and often these requirements are more stringent in colder climates where reducing heat loss is critical.

It is crucial to consult local building codes and standards for the specific region to determine the appropriate level. Higher standards may be necessary for energy-efficient designs or when achieving certain levels of comfort and indoor air quality.

Q 6. Explain the importance of airtightness in energy efficiency.

Airtightness plays a crucial role in energy efficiency. A leaky building envelope is like a sieve, constantly allowing conditioned air (heated or cooled) to escape. This leads to significant energy loss and increased heating and cooling costs. Reducing air leakage through proper sealing and construction techniques minimizes heat transfer, improving thermal performance and lowering energy consumption. Think of it like plugging up holes in a water bottle to keep the water from escaping.

Besides energy savings, good airtightness also contributes to better indoor air quality by reducing the infiltration of pollutants from outside and improving the effectiveness of ventilation systems. Well-sealed buildings are more comfortable because they have less drafts and more consistent temperatures.

Q 7. What are some common causes of air leakage in buildings?

Many factors contribute to air leakage in buildings. Common causes include:

- Poorly sealed windows and doors: Gaps around frames, worn seals, and poorly fitted components.

- Penetrations for pipes and electrical wiring: These openings often lack sufficient sealing.

- Openings around chimneys and other fixtures: Inadequate sealing of these elements can lead to significant air leakage.

- Cracks and gaps in walls, floors, and ceilings: These can arise from settling or poor construction techniques.

- Porous building materials: Some materials themselves can allow air to pass through, unless adequately sealed or applied.

- Insufficient sealing of joints: Joints between different building materials need proper sealing with appropriate sealants.

Identifying and addressing these leakage paths during construction or through retrofits is essential to achieve a properly airtight building envelope.

Q 8. How does airtightness testing relate to building codes and standards?

Airtightness testing is increasingly mandated by building codes and standards worldwide to ensure energy efficiency and indoor environmental quality. Codes often specify minimum acceptable airtightness levels, usually expressed as air changes per hour at 50 Pascals (ACH50). For example, Passive House standards demand exceptionally low ACH50 values, typically below 0.6. Meeting these standards requires careful design, construction, and testing. Failure to meet the required airtightness levels can result in project delays, additional costs to rectify issues, and potential penalties. The specific requirements vary by region and jurisdiction, so consulting the local building code is crucial.

Think of it like this: a leaky house is like a leaky bucket – you’re constantly trying to fill it, wasting energy and resources. Airtightness testing helps ensure your ‘bucket’ is sealed, minimizing energy waste and maximizing comfort.

Q 9. Describe the role of air barriers in achieving airtightness.

Air barriers are the primary defense against air leakage in a building envelope. They’re continuous layers of material designed to resist the passage of air, preventing uncontrolled airflow between the interior and exterior. An effective air barrier minimizes drafts, reduces energy loss, and prevents moisture intrusion, which can lead to mold and structural damage. It’s vital to understand that an air barrier is not necessarily a vapor barrier; they serve different, though often overlapping, functions. The air barrier’s primary role is to stop air movement, while a vapor barrier controls moisture movement.

Imagine your house’s walls as a sponge. Without a proper air barrier, air flows freely through the porous materials, causing drafts and energy loss. An air barrier creates a sealed shell, preventing this uncontrolled airflow.

Q 10. What are the different types of air barriers and their applications?

Several types of air barriers exist, each with its own strengths and weaknesses:

- Polymeric Films: These are thin, flexible sheets of polyethylene or other polymers. They’re relatively inexpensive and easy to install but can be vulnerable to tears and punctures.

- Spray-Applied Air Barriers: These are liquid-applied coatings that create a continuous, seamless layer. They’re excellent for complex shapes and difficult-to-reach areas but require specialized equipment and skilled applicators.

- Rigid Insulation Boards: Certain types of rigid insulation, like closed-cell spray foam or high-density fiberglass, can also function as effective air barriers. They offer both insulation and air barrier properties in a single layer.

- Sheet Materials: Products like gypsum board or OSB can be part of an air barrier system, but require careful sealing of joints and penetrations for effectiveness.

The choice of air barrier depends on factors such as the building’s design, budget, and climate. For example, spray-applied foam is ideal for complex geometries, while polyethylene film might be suitable for simpler constructions.

Q 11. How do you identify and address air leakage pathways during construction?

Identifying air leakage pathways requires a systematic approach. This often starts with a pre-construction meeting to review the design and construction plans, identifying potential weak points such as penetrations for pipes, electrical wiring, and windows. During construction, regular inspections are crucial. We utilize infrared cameras to detect thermal anomalies, indicating air movement. Air leakage can also be detected through pressure testing or smoke testing.

Addressing leakage involves sealing gaps and cracks with appropriate sealants, tapes, and caulk. Particular attention must be paid to seams, joints, and penetrations. Any gaps, however small, should be sealed effectively. For larger penetrations, specialized sealing techniques and materials might be necessary. Documentation of all repairs is crucial for quality control.

Imagine a detective investigating a crime scene. We meticulously inspect every possible entry point, using various tools to identify and seal the gaps.

Q 12. Explain the use of blower door testing and its limitations.

A blower door test is the most common method for measuring building airtightness. It involves installing a calibrated fan in an exterior door, pressurizing the building, and measuring the airflow rate required to maintain the pressure difference. The result is expressed as ACH50 (Air Changes per Hour at 50 Pascals). Lower ACH50 values indicate better airtightness.

While highly effective, blower door tests have limitations. They primarily measure air leakage in the building envelope, not the individual components. It may miss hidden leaks and requires specific testing conditions and skilled operators. It doesn’t test for the effectiveness of individual air barrier components, but rather the entire building envelope. The test also does not show the location or the quality of individual air leaks.

Q 13. Describe the process of preparing a building for airtightness testing.

Preparing a building for airtightness testing is a critical step that directly affects the accuracy of the results. All doors and windows must be closed and sealed securely. Any openings (other than the blower door itself) – such as fireplaces or exhaust vents – must be sealed temporarily. The building’s HVAC system must be turned off. Finally, the inside of the building needs to be at roughly the same pressure as the outside before the test begins. This ensures the test accurately reflects the building’s inherent airtightness and is not influenced by fluctuating internal air pressures. This includes turning off any exhaust fans and ensuring that there are no leaks in the building’s plumbing system that can cause air pressure to fluctuate.

Imagine getting ready for a medical check-up – thorough preparation is vital for an accurate assessment.

Q 14. What are the safety precautions involved in airtightness testing?

Safety is paramount during airtightness testing. The blower door creates a pressure difference that can be hazardous if not managed correctly. Never operate a blower door alone. Always ensure adequate ventilation to prevent oxygen depletion and maintain a safe environment. If the building is significantly under or over-pressurized during the test, this can create a risk of structural damage. Therefore, experienced personnel and accurate equipment calibration are needed. Regular inspections of the equipment before and during the test are imperative for preventing any safety-related incidents.

Working with depressurization or pressurization can feel counterintuitive. Following established safety protocols is crucial for protecting the building and the technicians conducting the test.

Q 15. How do you calculate the airtightness performance of a building?

Airtightness performance is calculated by measuring the rate at which air leaks into or out of a building. This is typically done using a blower door test. The blower door creates a pressure difference between the inside and outside of the building, and the resulting airflow is measured. This airflow is then used to calculate various metrics, most commonly the ACH50 value (explained further in a later question). The calculation involves using the volume of the building, the pressure difference created by the blower door, and the measured airflow rate. Specific formulas vary depending on the standards and software used, but the fundamental principle remains the same: quantifying the air leakage.

Imagine a balloon. A perfectly airtight balloon wouldn’t lose any air. A building is similar; the less air it loses, the tighter it is. We use precise tools to measure this air loss and quantify it into a standardized value.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key performance indicators (KPIs) in airtightness testing?

Key Performance Indicators (KPIs) in airtightness testing focus on quantifying air leakage and identifying areas needing improvement. The most crucial KPI is the ACH50 (Air Changes per Hour at 50 Pascals), which represents the number of times the building’s air volume is exchanged per hour at a 50 Pascal pressure difference. Other important KPIs include:

- Air Leakage Area (ALA): The total area of the air leaks expressed in square meters. This gives a sense of the magnitude of the leakage.

- Leakage Distribution: Identifying specific locations (e.g., windows, doors, penetrations) of major air leaks through visual inspection or using advanced tools such as thermographic cameras or infrared cameras. This is crucial for targeted remediation.

- Pressure Difference vs. Airflow Curve: This curve illustrates the relationship between the pressure difference and the airflow rate. It helps determine the overall airtightness performance and can identify non-linear leak behaviors.

These KPIs provide a comprehensive picture of the building’s airtightness, allowing for targeted improvements and verification of remedial works. For example, a high ACH50 value suggests significant air leakage, demanding detailed investigation and remediation.

Q 17. What is the significance of the ACH50 value?

The ACH50 value (Air Changes per Hour at 50 Pascals) is a crucial indicator of a building’s airtightness. It represents the rate at which the air inside a building is completely replaced with outside air per hour when a 50 Pascal pressure difference is applied using a blower door. A lower ACH50 value indicates better airtightness. For example, an ACH50 of 1 means that the entire volume of air within the building is replaced once per hour at a pressure difference of 50 Pascals. An ACH50 of 5 means the air is replaced five times per hour.

This value is standardized and allows for comparison between different buildings and building types. Building codes often set target ACH50 values to ensure energy efficiency and indoor air quality. Lower ACH50 values typically translate into lower energy consumption for heating and cooling, improved indoor comfort, and reduced drafts.

Q 18. Explain the concept of air permeability.

Air permeability describes the ease with which air can pass through a material or building assembly. It is a measure of how porous or leaky a building envelope is. High air permeability indicates significant air leakage, leading to energy loss, discomfort, and potential moisture problems. Low air permeability, conversely, indicates a tighter building envelope, improving energy efficiency and indoor comfort.

Think of a sieve: a fine-mesh sieve has low permeability (less water passes through), while a coarse sieve has high permeability (more water passes through). Similarly, a building with many gaps and cracks will have high air permeability, while a well-sealed building will have low air permeability.

Air permeability is often expressed as a flow rate (e.g., cubic meters per hour per square meter at a specific pressure difference), depending on the test method used.

Q 19. How does climate affect airtightness testing and results?

Climate significantly impacts airtightness testing and results. Temperature and wind speed particularly influence the measurements. Higher wind speeds increase the pressure difference across the building envelope, leading to artificially higher air leakage readings. Temperature differences between inside and outside also influence infiltration and exfiltration rates.

For accurate results, testing should be conducted under relatively calm wind conditions. Ideally, testing should be performed on a day with minimal wind and relatively stable temperature. Additionally, corrections can be applied to the results to account for these climatic factors. Software used in airtightness testing often accounts for these considerations using established meteorological data.

For instance, testing during a storm would produce unreliable results, as the wind would significantly influence air leakage measurements. Likewise, significant temperature fluctuations during testing can skew the results.

Q 20. How do you troubleshoot issues encountered during airtightness testing?

Troubleshooting during airtightness testing involves systematic investigation to pinpoint and address air leakage issues. This often starts with a thorough visual inspection, using tools such as a thermal camera to identify cold spots indicating air leakage.

Step-by-step troubleshooting approach:

- Review the test data: Analyze the ACH50 value, leakage distribution, and pressure-flow curve to identify areas of concern.

- Visual Inspection: Examine areas with high leakage identified by the blower door test. Look for gaps around windows, doors, penetrations, and building junctions.

- Instrumentation: Utilize smoke pencils or smoke guns to visualize air movement and pinpoint leakage paths. A thermal camera can also help identify cold spots indicating air leakage.

- Targeted Sealing: Seal identified leaks using appropriate materials (e.g., sealant, weather stripping, caulk). Re-test after sealing to verify effectiveness.

- Documentation: Keep detailed records of the testing process, identified leaks, sealing methods, and retest results.

For example, if a high ACH50 is primarily attributed to a particular window, the focus will be on sealing around that window. Repeated testing and sealing will refine the results until the desired airtightness is achieved.

Q 21. What software or tools do you use for airtightness testing and data analysis?

Various software and tools are used in airtightness testing and data analysis. These include dedicated blower door software packages that control the blower door, collect data, and perform the necessary calculations to determine the ACH50 value and other KPIs. These packages also frequently include functionalities for data visualization and report generation.

Examples include:

- Data acquisition systems: These systems record the pressure difference, airflow rate, and other relevant parameters during testing.

- Blower door control software: This software controls the blower door and ensures that the pressure difference is maintained at the desired level during the testing process.

- Data analysis software: This software processes the collected data, calculates the ACH50 value, air leakage area, and other KPIs. They also generate comprehensive reports.

- Thermal imaging cameras: These cameras identify areas of significant heat loss which often coincide with air leakage.

These tools, in combination with other visual inspection instruments, allow for an accurate and comprehensive analysis of building airtightness, ultimately enhancing the efficiency and reliability of the process.

Q 22. Describe your experience with different types of airtightness testing equipment.

My experience encompasses a wide range of airtightness testing equipment, from the commonly used blower door systems to more specialized tools. Blower door systems are the cornerstone of airtightness testing, measuring the air leakage rate of a building by pressurizing or depressurizing the structure and measuring the airflow needed to maintain that pressure difference. I’ve worked extensively with different blower door models, varying in size and capacity to accommodate buildings of diverse sizes and types. This includes both portable and larger, more powerful units suitable for larger commercial projects.

Beyond blower doors, I’m proficient in using various ancillary tools. This includes pressure gauges for verifying pressure differentials across specific building components, smoke pencils to visualize air leakage pathways, thermal cameras to identify areas of heat loss (which often correlate with air leakage), and data acquisition systems to record and analyze the large volumes of data generated during a test.

For instance, on a recent renovation project of a historic building, we used a smaller, more maneuverable blower door to avoid damaging the delicate interior. For a large, newly constructed office complex, a larger blower door, coupled with a sophisticated data acquisition system, enabled precise mapping of air leakage paths to pinpoint and rectify deficiencies quickly.

Q 23. How do you communicate airtightness test results to clients or stakeholders?

Communicating airtightness test results effectively is crucial for project success. I tailor my communication to the audience. For clients, I emphasize the results’ implications for energy efficiency, comfort, and long-term cost savings. I use clear, concise language, avoiding jargon, and always provide a summary report with key findings.

This report typically includes a clear statement of the building’s airtightness performance (e.g., achieving a target air changes per hour at 50 Pascals), a graphic representation (such as a pressure-flow curve), and photos highlighting areas of significant air leakage. I then explain the data’s meaning in practical terms – for example, how improved airtightness will reduce heating bills by a specific percentage.

For stakeholders like architects or contractors, I provide more detailed reports containing technical specifications, data logs, and analysis. I’m prepared to discuss the testing methodology, identify potential areas for improvement, and recommend specific corrective actions. Clear visual aids, like thermal images showing air leaks, are particularly helpful.

In all communications, I maintain transparency and address any concerns or questions promptly. The goal is not just to present data, but to foster collaboration and ensure that everyone understands the steps required for successful project completion.

Q 24. What are some best practices for achieving and maintaining airtightness in buildings?

Achieving and maintaining airtightness requires a holistic approach, starting with meticulous planning and extending throughout the construction process. Key best practices include:

- Comprehensive design: Incorporating airtightness details into the building design from the outset is crucial. This involves specifying airtight construction techniques, selecting appropriate materials, and coordinating the work of various trades.

- Continuous insulation: Using continuous insulation systems minimizes thermal bridging and air leakage paths. This significantly contributes to better energy efficiency and airtightness.

- Proper sealing: All penetrations (e.g., pipes, wires, windows) must be carefully sealed using appropriate airtight sealing materials. This includes using high-performance tapes, sealants, and gaskets.

- Quality control: Regular on-site quality control checks are vital to ensure that airtightness measures are followed throughout construction. This might involve visual inspections and the use of smoke pencils to identify and seal gaps.

- Airtightness testing: Conducting airtightness testing during and after construction is essential to verify performance and identify any areas requiring further attention.

- Training and education: Training construction crews on proper airtightness techniques ensures consistent application and minimizes errors.

For example, neglecting to seal around window frames during construction can lead to significant air leakage, undermining the overall airtightness of the building. Regular quality control and training can prevent such issues.

Q 25. Discuss the relationship between airtightness and moisture control in buildings.

Airtightness and moisture control are intrinsically linked. A well-sealed building envelope prevents uncontrolled air movement, minimizing the risk of moisture ingress and condensation. Stagnant, humid air trapped within a leaky building can lead to mold growth and other problems. Airtightness helps to maintain a stable indoor climate, reducing the risk of condensation.

However, airtightness alone is not enough. Effective moisture control requires a balanced approach that includes adequate ventilation. A perfectly airtight building with no ventilation can still suffer from moisture problems. Therefore, achieving a balance between airtightness and controlled ventilation is key. This usually involves utilizing a mechanical ventilation system with heat recovery (MVHR) to supply fresh air while minimizing energy loss.

Imagine a house with a leaky envelope – wind can drive moisture into the walls, leading to rot and mold. An airtight house with proper ventilation, on the other hand, allows for controlled air exchange, preventing moisture buildup while maintaining thermal comfort.

Q 26. Explain the impact of airtightness on indoor air quality.

Airtightness significantly impacts indoor air quality (IAQ). A well-sealed building envelope prevents the infiltration of outdoor pollutants, such as pollen, dust, and automotive emissions. This is crucial for individuals with allergies or respiratory sensitivities. By reducing air leakage, you reduce the amount of outdoor contaminants entering the space.

However, as previously mentioned, airtightness alone is insufficient for good IAQ. It needs to be coupled with sufficient ventilation to prevent the buildup of indoor pollutants generated by occupants and building materials (VOCs from furniture and finishes, for example). Controlled ventilation, through systems like MVHR, ensures a continuous supply of fresh air while removing stale, polluted air. This strategy creates a healthy indoor environment while maintaining energy efficiency.

In essence, airtightness acts as a shield, reducing infiltration of external pollutants, while controlled ventilation ensures the removal of internally generated pollutants, creating a healthier indoor environment for building occupants.

Q 27. Describe your experience with airtightness testing in different building materials and constructions.

My experience encompasses airtightness testing in a variety of building materials and constructions. I’ve worked on projects involving timber-framed structures, masonry buildings, concrete structures, and steel-framed buildings. Each building type presents unique challenges regarding airtightness.

Timber-framed buildings often require meticulous attention to detail in sealing joints and penetrations. Masonry buildings can present challenges due to the porous nature of the materials. In concrete structures, sealing joints and penetrations is crucial, and care must be taken to ensure proper curing to avoid cracking. Steel-framed buildings frequently require attention to the sealing of the connections and cladding.

For instance, when testing a timber-framed house, the focus is on ensuring that the connections between the timber framing members and the airtight membrane are properly sealed. In a masonry building, careful inspection of mortar joints and the interfaces between different materials is crucial. The testing methodologies are adapted to each material’s characteristics to yield reliable and meaningful results.

Q 28. How do you stay updated on the latest advancements in airtightness testing and building science?

Staying updated in this rapidly evolving field is crucial. I achieve this through a multifaceted approach.

- Professional organizations: I actively participate in professional organizations like ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) and the Building Performance Association, attending conferences and webinars, and engaging with industry leaders.

- Publications and journals: I regularly read peer-reviewed journals and industry publications focused on building science and airtightness, staying informed on new research and best practices.

- Continuing education: I dedicate time to ongoing professional development courses and training programs, focusing on advancements in testing technologies and construction techniques.

- Networking: I maintain a strong network of colleagues and industry experts, exchanging knowledge and insights through discussions and collaborations on projects.

For example, attending the recent ASHRAE conference allowed me to learn about the latest advancements in blower door technology and data analysis techniques. This knowledge is immediately applicable to my work and helps to ensure that I am using the most efficient and reliable methods.

Key Topics to Learn for Airtightness and Envelope Tightness Testing Interview

- Airtightness Testing Methods: Understanding different testing methods like fan pressurization, blower door testing, and tracer gas techniques, including their respective applications and limitations.

- Data Interpretation and Analysis: Mastering the interpretation of test results, including airflow rates, leakage areas, and pressure differences. Develop skills in identifying potential issues and areas for improvement based on data analysis.

- Building Envelope Components: Thorough knowledge of building materials and their impact on airtightness, including windows, doors, walls, roofs, and penetrations. Understand how construction details affect performance.

- Standards and Regulations: Familiarity with relevant building codes, standards (e.g., ASHRAE, Passivhaus), and best practices related to airtightness and envelope tightness.

- Practical Application in Construction: Understanding the role of airtightness testing throughout the construction process, from initial design to final inspection. Be prepared to discuss quality control measures and troubleshooting techniques.

- Troubleshooting and Problem Solving: Developing the ability to diagnose and address airtightness issues, including identifying and resolving air leaks. Understanding the impact of different repair methods on building performance.

- Energy Efficiency and Sustainability: Connecting airtightness testing to energy efficiency and the reduction of carbon footprint. Be able to articulate the environmental benefits of achieving high levels of building airtightness.

- Reporting and Documentation: Proficiency in preparing clear and concise reports detailing test procedures, results, and recommendations. Understanding the importance of accurate and complete documentation.

Next Steps

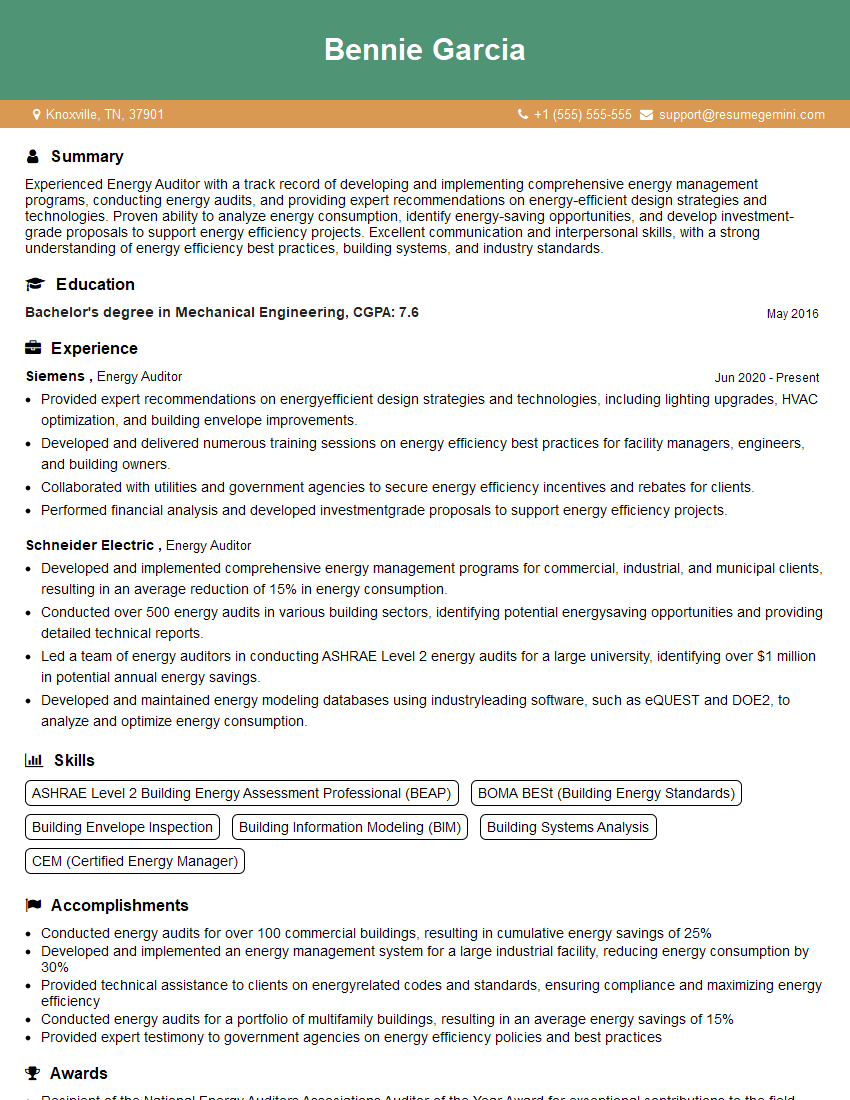

Mastering Airtightness and Envelope Tightness Testing is crucial for advancing your career in the building science and construction industries. Employers highly value professionals with expertise in ensuring energy-efficient and durable buildings. To maximize your job prospects, crafting a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume tailored to showcase your skills and experience. We provide examples of resumes specifically designed for professionals in Airtightness and Envelope Tightness Testing to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.