Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Insulation Value and R-Value Assessment interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Insulation Value and R-Value Assessment Interview

Q 1. Define R-value and explain its significance in building construction.

R-value, or thermal resistance, is a measure of a material’s ability to resist the flow of heat. Think of it like this: a higher R-value means the material is a better insulator, slowing down heat transfer. In building construction, R-value is crucial because it directly impacts energy efficiency. A building with properly insulated walls, roofs, and floors (high R-values) will require less energy to heat in winter and cool in summer, resulting in lower energy bills and a smaller carbon footprint.

For example, a wall with an R-value of 15 will resist heat flow much better than a wall with an R-value of 5, meaning the higher R-value wall will stay warmer in winter and cooler in summer with less energy needed from your HVAC system.

Q 2. What factors influence the R-value of insulation materials?

Several factors influence the R-value of insulation materials:

- Material Type: Different materials have inherently different insulating properties. Fiberglass, cellulose, and foam insulation all have distinct R-values per inch of thickness.

- Thickness: The thicker the insulation, the higher the R-value. This is because there’s more material to resist heat flow. Doubling the thickness generally, but not always, approximately doubles the R-value.

- Density: For some materials, higher density means better insulation, leading to a higher R-value. However, this isn’t universally true; the relationship between density and R-value is material-specific.

- Air Gaps and Moisture: Air gaps within insulation can significantly reduce its effectiveness, lowering the R-value. Similarly, moisture absorption can drastically reduce the insulating capacity of some materials.

- Temperature: While less significant than the other factors, the operating temperature of the insulation can slightly affect its R-value.

Q 3. How does the R-value of insulation affect energy consumption?

The R-value of insulation directly affects energy consumption in buildings. Higher R-values mean less heat transfer through building components (walls, roof, floors). This reduces the load on heating and cooling systems. For instance, a home with inadequate insulation (low R-values) will require your furnace and air conditioner to work harder to maintain a comfortable temperature, leading to increased energy use and higher utility bills. Conversely, a well-insulated home with high R-values will experience less temperature fluctuation, resulting in lower energy consumption and cost savings.

Consider this: A home in a cold climate with poorly insulated walls might require twice the energy for heating compared to a similar home with properly insulated walls. This translates into significant savings over the lifespan of the building.

Q 4. Explain the difference between R-value and U-value.

R-value and U-value are both measures of thermal performance, but they represent different aspects. R-value, as discussed, represents thermal resistance – the material’s resistance to heat flow. U-value, on the other hand, is the thermal transmittance, representing the rate of heat flow through a building component (like a wall or window). It’s the inverse of the R-value: U-value = 1/R-value. A lower U-value indicates better insulation, just as a higher R-value does.

Think of it this way: R-value tells you how well a material resists heat flow, while U-value tells you how much heat actually flows through it. A high R-value means a low U-value, and vice-versa.

Q 5. How do you calculate the total R-value of a wall assembly?

Calculating the total R-value of a wall assembly is straightforward: you simply add the R-values of each component in the assembly. This includes the insulation, sheathing, siding, drywall, and any other layers.

Example: A wall assembly consists of:

- 1/2 inch drywall (R-0.45)

- 3.5 inches of fiberglass insulation (R-13)

- 1/2 inch sheathing (R-0.8)

The total R-value would be 0.45 + 13 + 0.8 = R-14.25

Important Note: This is a simplified calculation. In reality, factors like thermal bridging (heat transfer through solid components like studs) can reduce the effective R-value of the assembly. More sophisticated calculations are often needed for accurate assessments, especially in complex assemblies.

Q 6. Describe different types of insulation materials and their respective R-values.

Several types of insulation materials are commonly used, each with its own R-value per inch:

- Fiberglass Batt and Roll: Widely used, relatively inexpensive, with R-values ranging from R-3 to R-15 per inch, depending on density.

- Cellulose: Made from recycled paper, often blown into wall cavities, offers good R-value (R-3.7 per inch), and good sound absorption properties.

- Spray Foam: Offers high R-value (R-6 to R-7 per inch for closed-cell, R-3.6 to R-4 per inch for open-cell), excellent air sealing capabilities, but is more expensive.

- Mineral Wool (Rock Wool and Glass Wool): Good thermal performance (R-values comparable to fiberglass), moisture resistant, and good fire resistance.

- Polyisocyanurate (Polyiso): High R-value per inch (R-5 to R-8), often used in roofing applications.

Note: The specific R-value of a given insulation material can vary based on manufacturer and thickness, so always refer to the manufacturer’s data sheet for precise values.

Q 7. What are the common installation errors that reduce the effectiveness of insulation?

Several common installation errors can significantly reduce the effectiveness of insulation, leading to lower R-values and reduced energy efficiency:

- Insufficient Insulation Thickness: Not using enough insulation to meet the recommended R-value for the climate zone.

- Air Gaps and Gaps around penetrations: Air gaps within the insulation layer or around pipes, wires, and other penetrations create pathways for heat transfer, dramatically decreasing the overall R-value.

- Compression of Insulation: Compressing insulation materials reduces their thickness and thus their R-value. This is particularly crucial for batt and roll insulation.

- Moisture Intrusion: Moisture significantly reduces the insulating properties of many materials. Proper vapor barriers and moisture-resistant insulation are essential.

- Uneven Installation: Uneven distribution of insulation leaves some areas under-insulated and prone to heat loss or gain.

Careful attention to detail during installation is vital to maximize the effectiveness of insulation and achieve the desired R-value.

Q 8. How does moisture affect the R-value of insulation?

Moisture significantly degrades the R-value of insulation. Think of it like this: insulation works by trapping air pockets, which are excellent insulators. When moisture enters the insulation, it displaces the air, reducing the number of air pockets and thus decreasing the insulation’s ability to resist heat flow. Water itself is a much better conductor of heat than air.

Different insulation materials react differently to moisture. Fiberglass, for instance, can absorb some moisture without catastrophic R-value loss, but prolonged exposure can lead to significant degradation. Cellulose insulation, while often more environmentally friendly, is especially vulnerable to moisture damage and can lose its insulating properties considerably if wet.

Preventing moisture intrusion is crucial for maintaining the R-value of insulation. This involves proper vapor barriers, adequate ventilation, and careful installation techniques to avoid water leaks or condensation.

Q 9. Explain the concept of thermal bridging and its impact on R-value.

Thermal bridging occurs when heat flows easily through materials with high thermal conductivity, bypassing the insulation. Imagine a cold winter day – heat is escaping from your house through the walls. If there’s a continuous piece of metal studding running through the wall, that metal acts as a thermal bridge; heat will travel rapidly through the metal, negating the insulating effect of the materials around it.

Thermal bridging significantly reduces the effective R-value of a building assembly. The overall R-value is lowered because heat transfer is increased along these paths. For example, if you have a wall with a high R-value insulation but metal studs running through, the heat will bypass the insulation via the studs, resulting in a lower overall energy efficiency.

Minimizing thermal bridging involves using materials with low thermal conductivity, such as wood instead of metal studs, adding thermal breaks in metal framing, and properly insulating around these thermal bridges. Continuous insulation on the exterior of the building can also greatly reduce this effect.

Q 10. How do you assess the existing insulation in a building?

Assessing existing insulation requires a multi-faceted approach. It’s rarely a simple visual inspection. First, a thorough visual inspection of accessible areas is necessary; this checks for visible gaps, damaged insulation, or signs of moisture.

Next, I’d use thermal imaging. This non-destructive method uses infrared cameras to detect temperature variations on the surface of the walls, ceiling, or floors. Colder areas indicate heat loss, pinpointing areas with insufficient or compromised insulation. This helps identify areas needing additional insulation or repair.

In some cases, invasive methods might be necessary. This involves accessing the insulation through small openings to take samples for material identification and moisture content testing. This approach is used when thermal imaging is inconclusive or when more detailed information is needed. Finally, reviewing building plans can help determine the originally installed insulation type and thickness.

Q 11. What are the methods used to measure R-value in the field?

Field measurement of R-value is challenging and not as precise as laboratory testing. The most common method involves using a thermal imaging camera combined with a heat flux meter. The heat flux meter measures the rate of heat flow through a section of the wall, while the thermal camera identifies temperature differences. Together, these devices allow for an estimation of the effective R-value.

Another less precise approach uses a thermal resistance meter. This device involves placing probes on either side of the insulation to measure temperature differences and heat flow. This method is only suitable for direct measurement of an insulation material sample and provides a less accurate estimation of R-value in situ because it doesn’t account for the numerous factors impacting the building’s thermal performance.

It is important to note that in-situ measurements will only provide an estimate of the effective R-value. The accuracy depends heavily on environmental conditions, the accuracy of the equipment and the expertise of the technician using it.

Q 12. Describe the role of air sealing in improving overall building insulation.

Air sealing is crucial for maximizing the effectiveness of insulation. Think of your house like a thermos: insulation is the insulation in the thermos, but if there are large gaps in the lid, heat will still escape. Air sealing focuses on eliminating air leaks that allow heat to escape in winter and enter in summer.

Air sealing reduces air infiltration, preventing convective heat transfer – which is a much more significant heat loss mechanism than conduction, which the insulation addresses. By reducing air leaks, air sealing works synergistically with insulation to significantly improve a building’s overall thermal performance. The better the air seal, the more effective the insulation becomes.

Air sealing involves sealing cracks and gaps around windows, doors, pipes, and other penetrations in the building envelope. Common materials used include caulking, weatherstripping, and spray foam.

Q 13. How does climate affect the choice of insulation material and R-value requirements?

Climate significantly impacts insulation material selection and R-value requirements. In colder climates, higher R-values are essential to reduce heating loads and minimize energy consumption. Materials with higher thermal resistance, such as spray foam or dense-packed cellulose, might be preferred.

Conversely, in warmer climates, the focus shifts to reducing cooling loads. While insulation is still vital to reduce heat gain, the required R-value may be lower, and materials with good thermal mass or reflective properties may be beneficial. Proper ventilation also plays a more significant role.

Furthermore, moisture management becomes critical. Humid climates may require vapor barriers or breathable insulation to prevent moisture accumulation and subsequent R-value degradation. Dry climates might focus on preventing excessive moisture loss.

Q 14. What are the building codes and standards related to insulation requirements in your region?

Building codes and standards related to insulation requirements vary significantly by region and jurisdiction. It’s crucial to consult local and regional building codes, as well as any relevant energy codes. These codes often specify minimum R-values for walls, roofs, floors, and attics, considering climate zones and building types. For example, the International Energy Conservation Code (IECC) provides guidelines frequently adopted and adapted by many jurisdictions, though specific requirements and interpretations vary by location.

In many areas, stricter energy efficiency standards are being implemented to promote sustainability and reduce greenhouse gas emissions, often leading to higher minimum insulation requirements. Local building departments are the best resource for specific, up-to-date information. Failure to comply with these standards can lead to penalties and building permit delays.

Q 15. How do you determine the appropriate R-value for a given building and climate zone?

Determining the appropriate R-value for a building involves considering several crucial factors, primarily climate zone and building type. The climate zone dictates the heating and cooling loads a building will experience. Colder climates necessitate higher R-values to minimize heat loss during winter, while hotter climates require sufficient insulation to reduce heat gain in summer. Building codes often specify minimum R-values for different building components (walls, roofs, floors) based on the climate zone. The International Energy Conservation Code (IECC) provides a framework for this, and specific regional codes may offer even more tailored requirements.

For example, a building in a cold northern climate might require an R-value of R-20 or higher for walls, whereas a building in a mild southern climate might suffice with R-13. Other factors, like the building’s orientation (sun exposure), window placement, and the presence of other energy-efficient features, can also influence the optimal R-value. Consult a building energy modeling software or a qualified energy consultant to accurately calculate R-value requirements for specific projects.

A home energy audit is another effective tool for determining your specific R-value needs. This audit assesses your current insulation levels and identifies areas for improvement to maximize energy efficiency.

Career Expert Tips:

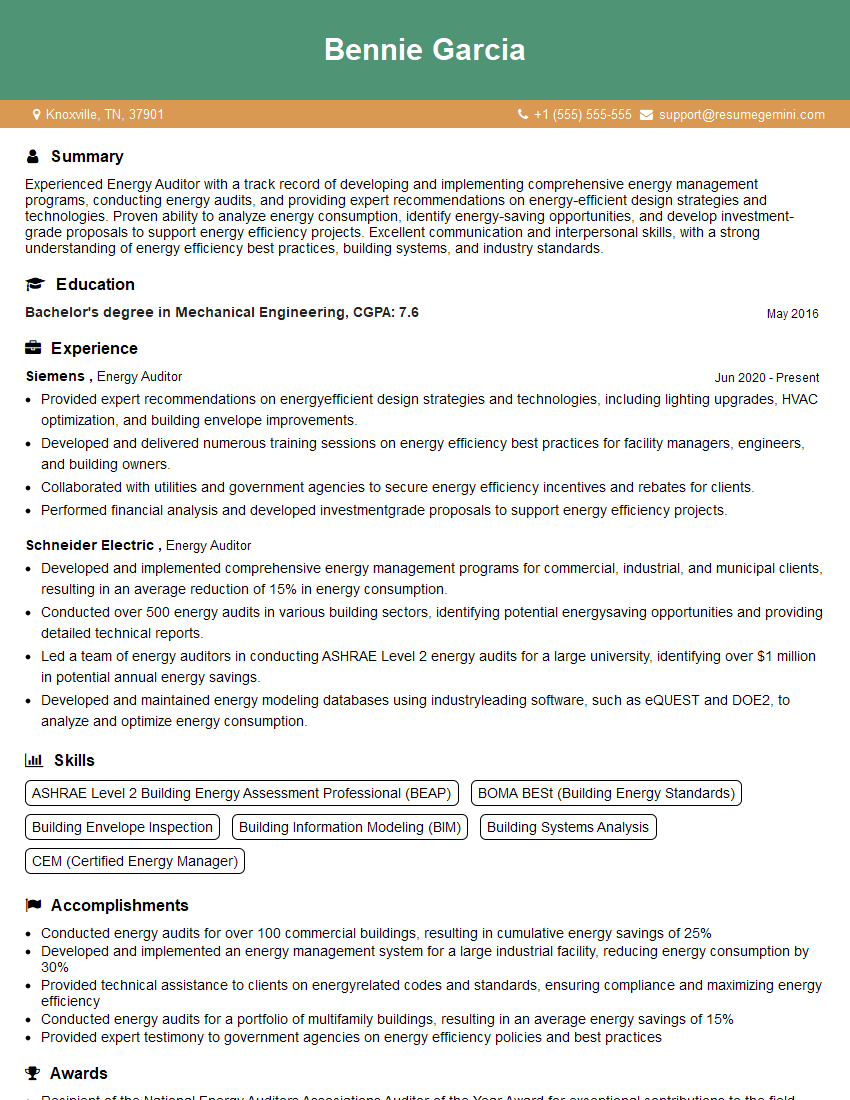

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of considering thermal comfort when designing insulation systems.

Thermal comfort is paramount in building design, directly impacting occupant well-being and productivity. Inadequate insulation can lead to significant temperature fluctuations within the building, causing discomfort in both hot and cold weather. In winter, insufficient insulation results in cold drafts and uneven temperatures, making spaces feel chilly and potentially unhealthy. In summer, poor insulation can trap heat, causing overheating and discomfort. A properly designed insulation system will create a consistent indoor temperature, regardless of exterior conditions, thus optimizing thermal comfort.

Consider a scenario where a room has insufficient insulation on the north-facing wall. This wall will likely remain significantly cooler than the rest of the room, causing drafts and a feeling of persistent chilliness for occupants near that wall. Conversely, inadequate roof insulation can cause rooms to overheat during summer months, necessitating higher energy consumption for air conditioning and compromising occupant comfort.

Designing for thermal comfort begins with a thorough understanding of the building’s climate and occupants’ preferences. Employing appropriate insulation levels and strategies, such as using thermal mass materials or incorporating radiant heating/cooling systems, ensures optimum thermal comfort within the building envelope.

Q 17. What are the environmental impacts of different insulation materials?

Different insulation materials have varying environmental impacts, spanning their manufacturing process, lifespan, and end-of-life management. Fiberglass insulation, while widely used, often relies on energy-intensive manufacturing processes and contains recycled glass content which, although beneficial, still involves a carbon footprint. The embodied energy and manufacturing emissions of these products should be factored into their assessment. Cellulose insulation, made from recycled paper, offers a more sustainable alternative with lower embodied energy, though its transportation distance and potential for pest infestation require consideration.

Spray foam insulation presents a more complex picture. While offering excellent R-value, some types contain blowing agents with high global warming potential (GWP). However, newer formulations use blowing agents with significantly lower GWPs. Similarly, mineral wool insulation, such as rock wool and slag wool, has its own life-cycle implications. The extraction of raw materials and manufacturing processes contribute to its overall environmental footprint. A life-cycle assessment (LCA) should be performed to understand a product’s total environmental impact for a comprehensive understanding.

Choosing sustainable insulation materials requires careful evaluation of their entire lifecycle, comparing not only their R-value but also their embodied carbon, energy consumption during manufacturing, and recyclability or end-of-life disposal options.

Q 18. How do you address concerns about VOC emissions from insulation materials?

Addressing VOC (Volatile Organic Compound) emissions from insulation materials is crucial for indoor air quality. Many insulation materials can release VOCs, potentially causing health problems like respiratory irritation, headaches, and allergic reactions. The best way to mitigate this is to select low-VOC or zero-VOC insulation products. Manufacturers often provide VOC emission data sheets outlining the levels of VOCs released by their products. Selecting products with certifications like GreenGuard Gold assures low VOC emissions.

Beyond product selection, proper installation practices minimize VOC emissions. Ensuring adequate ventilation during and after installation helps disperse any released VOCs. Using appropriate personal protective equipment (PPE) during installation protects installers from potential exposure. Proper sealing of insulation also helps reduce potential emissions and the subsequent release into the occupied space.

Post-installation, monitoring indoor air quality is recommended. If excessive VOC levels are detected, additional ventilation strategies or air purification systems can be employed to mitigate their impact on the indoor environment.

Q 19. What are some common challenges encountered during insulation installation?

Insulation installation presents various challenges depending on the building type, existing structure, and chosen insulation material. One common challenge is accessing hard-to-reach areas, such as attics with low clearance or crawl spaces with limited entry points. This necessitates specialized equipment and experienced installers. Another common problem is ensuring proper air sealing before installing insulation. Gaps and cracks allow air infiltration, reducing insulation effectiveness and increasing energy waste. Poor air sealing negates the benefits of high R-value insulation. Air sealing is often the most critical aspect of the process, and often receives the least attention.

Existing structural conditions can also create hurdles. Uneven surfaces, existing obstructions, or inconsistent framing can make installation difficult and compromise the insulation’s effectiveness. Dealing with existing moisture or pest infestations can require pre-treatment before insulation is installed to avoid creating a breeding ground or worsening moisture damage. Finally, improper installation techniques, such as insufficient compression of batt insulation or uneven distribution of loose-fill insulation, can significantly decrease performance.

Q 20. How do you ensure quality control during insulation installation and assessment?

Quality control during insulation installation and assessment is vital for ensuring optimal performance and energy efficiency. Pre-installation checks involve verifying the chosen insulation’s R-value, confirming its suitability for the application, and inspecting the building structure for any issues affecting installation. During installation, regular inspections ensure proper techniques are used. This includes verifying proper air sealing, checking for consistent insulation thickness and density, and ensuring proper installation in hard-to-reach areas.

Post-installation assessments involve visual inspections to check for any gaps or irregularities and, if needed, thermal imaging to detect areas with insufficient insulation or air leakage. A blower door test can quantify air leakage throughout the building envelope. This comprehensive approach identifies areas for improvement and ensures the insulation system meets the desired performance standards. Documentation of the entire process—from material selection to installation and inspection—is vital for maintaining records and ensuring accountability.

Q 21. Explain the difference between batt, loose-fill, and spray foam insulation.

Batt, loose-fill, and spray foam insulation represent distinct approaches to improving a building’s thermal performance. Batt insulation comes in pre-cut sections (commonly fiberglass or mineral wool) and is easily installed between wall studs or joists. It’s relatively inexpensive and simple to install for DIYers but can leave gaps if not installed carefully.

Loose-fill insulation, such as cellulose or mineral wool, is blown into wall cavities or attics, conforming to irregular surfaces and filling gaps effectively. This method is suitable for retrofitting existing structures but requires specialized equipment for installation. Spray foam insulation is applied as a liquid and expands to fill cavities completely, creating an air- and moisture-tight seal. It offers superior R-values but is more expensive and requires professional installation.

The choice among these methods depends on various factors including budget, the structure’s accessibility, and desired thermal performance. Batt insulation is suitable for straightforward projects with easy access to cavities, while loose-fill and spray foam are better suited for more complex situations, such as uneven spaces or retrofit applications.

Q 22. How do you calculate the cost-effectiveness of different insulation options?

Calculating the cost-effectiveness of insulation involves comparing the upfront cost of installation with the long-term savings on energy bills. It’s not just about the initial price tag; we need to consider the insulation’s R-value (a measure of thermal resistance), the projected energy savings, and the lifespan of the material.

Here’s a step-by-step approach:

- Determine Energy Costs: Calculate your current annual heating and cooling expenses. This provides a baseline.

- Estimate Energy Savings: Use energy modeling software (like those mentioned in question 4) or online calculators to estimate the reduction in energy consumption with different insulation options. Input factors like R-value, climate zone, and building characteristics.

- Calculate the Simple Payback Period: Divide the total cost of the insulation by the annual energy savings. This gives you the number of years it will take for the insulation to ‘pay for itself’.

- Consider the Lifespan: Insulation materials have different lifespans. Divide the total cost by the lifespan to determine an annualized cost. Compare this to the annual energy savings.

- Factor in other costs: Installation costs, potential removal of existing insulation, and any rebates or tax credits should also be included in the calculation.

Example: Let’s say Insulation A costs $2000 and saves $300 annually, while Insulation B costs $3000 and saves $450 annually. Insulation A has a payback period of 6.67 years (2000/300), while B has a payback period of 6.67 years (3000/450). While the payback periods are the same, a deeper dive into lifespan and annualized cost may reveal one is more cost effective in the long run.

Q 23. Describe your experience with different insulation installation techniques.

My experience spans various insulation installation techniques for different applications. I’ve worked with:

- Batt Insulation: This is common in walls and attics. Proper installation involves ensuring consistent thickness and minimizing gaps. I’ve handled both fiberglass and mineral wool batts, understanding their different properties and application techniques.

- Loose-fill Insulation: This involves blowing cellulose, fiberglass, or mineral wool into wall cavities or attics. Precise application is crucial to avoid settling and ensure uniform coverage. I’m proficient in using the necessary equipment and techniques to achieve optimal density.

- Spray Foam Insulation: This offers excellent air sealing and thermal performance. I have experience with both open-cell and closed-cell spray foam, understanding their varying properties and applications for different climates and building types. Proper safety precautions and equipment handling are paramount.

- Rigid Foam Board Insulation: Often used on exterior walls or roofs, this requires precision cutting and secure fastening to achieve a continuous air barrier. I’m familiar with different board thicknesses and R-values and have hands-on experience ensuring proper installation.

In each case, I prioritize proper preparation, careful measurement, and meticulous installation to ensure the insulation performs to its specifications and meets building codes.

Q 24. How do you identify and troubleshoot problems related to inadequate insulation?

Identifying inadequate insulation involves a multi-pronged approach combining visual inspection, thermal imaging, and energy auditing.

- Visual Inspection: I look for signs like drafts, visible gaps in insulation, or areas where insulation is compressed or missing. I also check for air leaks around windows, doors, and other penetrations.

- Thermal Imaging: Infrared cameras reveal temperature variations on surfaces, highlighting areas with heat loss or gain. This provides a clear picture of where insulation is lacking or ineffective. Cold spots indicate heat loss.

- Energy Audits: A comprehensive energy audit uses blower door tests to identify air leaks and assess the building’s overall energy performance. This helps quantify the impact of inadequate insulation and guide remediation efforts.

Troubleshooting: Once the problem areas are identified, the solution involves addressing the root cause. This might include adding more insulation, sealing air leaks with caulk or weatherstripping, or even replacing damaged insulation. The appropriate solution depends on the specific problem and the type of building construction.

For example, if thermal imaging reveals cold spots around windows, replacing outdated windows with high-efficiency ones might be more effective than just adding more insulation to that area.

Q 25. What software or tools do you use for R-value calculations and thermal modeling?

For R-value calculations and thermal modeling, I utilize several software tools depending on the complexity of the project. These include:

- EnergyPlus: A whole-building energy simulation program that allows detailed modeling of building energy performance. This software provides precise R-value calculations, taking into account various building materials and construction techniques.

- COMSOL Multiphysics: A powerful finite element analysis (FEA) software for detailed thermal analysis. It’s particularly useful for complex geometries and materials where more precise modeling is needed.

- REScheck: A software tool specifically for compliance with energy codes. It facilitates verifying that the building’s insulation levels meet the required standards.

- Various Online Calculators: For simpler calculations, I often use reputable online R-value calculators, verifying the accuracy and source.

These tools help me accurately predict the thermal performance of different insulation solutions and optimize designs for energy efficiency.

Q 26. Describe a situation where you had to solve a problem related to poor insulation performance.

I once worked on a renovation project where the homeowner complained of consistently high energy bills despite recent upgrades. A thorough inspection revealed that while new insulation had been installed in the attic, the installers had failed to properly seal gaps around recessed lighting fixtures and plumbing penetrations. This resulted in significant air leakage and negated a considerable portion of the insulation’s effectiveness.

Solution: I used spray foam sealant to fill the gaps around these penetrations, effectively creating a continuous air barrier. We also added additional insulation around the affected areas. Following these improvements, the homeowner reported a significant decrease in energy consumption, validating the importance of detail-oriented installation.

Q 27. How do you stay up-to-date with the latest advancements in insulation technology?

Staying current in the dynamic field of insulation technology requires a multi-faceted approach:

- Professional Organizations: Active membership in organizations like ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) provides access to the latest research, publications, and industry best practices.

- Industry Publications and Journals: I regularly read industry-specific magazines and journals to stay informed about new materials, techniques, and regulatory changes.

- Conferences and Workshops: Attending industry conferences and workshops allows for networking and learning about new technologies from leading experts.

- Manufacturer Resources: Direct engagement with insulation manufacturers provides access to technical data, installation guides, and updates on their product lines.

- Online Resources and Continuing Education: Utilizing online resources, webinars, and continuing education courses ensures that my knowledge base remains current and comprehensive.

This continuous learning ensures I can offer the most effective and up-to-date insulation solutions to my clients.

Q 28. How would you explain the concept of R-value to a homeowner?

Imagine your house as a thermos. The R-value of your insulation is like the insulation of that thermos – the higher the R-value, the better it prevents heat from escaping in the winter and entering in the summer.

R-value is a measure of thermal resistance. It tells you how well a material resists the flow of heat. A higher R-value means better insulation and lower energy bills. For example, an R-13 wall insulation is better than an R-7 insulation. Think of it as a measure of how effective the material is at keeping your house comfortable all year round, without having to use your heating and cooling systems as much.

Key Topics to Learn for Insulation Value and R-Value Assessment Interview

- Understanding R-Value: Defining R-value, its significance in heat transfer, and factors influencing its calculation. Learn how to interpret R-value data for various insulation materials.

- Insulation Materials: Become familiar with the properties and applications of different insulation materials (fiberglass, cellulose, foam board, etc.). Understand their respective R-values and limitations.

- Calculating R-Value in Assemblies: Master the techniques for calculating the total R-value of building assemblies, considering factors like air gaps and thermal bridging.

- Practical Application: Prepare examples demonstrating your ability to assess insulation needs for different building types and climates. Be ready to discuss energy efficiency calculations and cost-benefit analyses.

- Moisture and Insulation: Discuss the impact of moisture on insulation performance and how to mitigate issues like condensation and water damage. This includes understanding vapor barriers and their importance.

- Building Codes and Standards: Familiarize yourself with relevant building codes and standards related to insulation requirements and energy efficiency.

- Problem-Solving Scenarios: Practice diagnosing insulation-related problems in buildings, such as heat loss or excessive energy consumption, and propose effective solutions.

- Energy Modeling Software: If applicable to your experience, showcase your proficiency with energy modeling software used to analyze insulation performance in building designs.

Next Steps

Mastering Insulation Value and R-Value Assessment is crucial for career advancement in the construction, energy efficiency, and building science fields. A strong understanding of these concepts will significantly enhance your job prospects and allow you to contribute effectively to projects focused on sustainable and energy-efficient buildings. To increase your chances of landing your dream role, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Insulation Value and R-Value Assessment are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.