The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Upstream oil and gas knowledge interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Upstream oil and gas knowledge Interview

Q 1. Explain the difference between conventional and unconventional reservoirs.

The primary difference between conventional and unconventional reservoirs lies in how easily the hydrocarbons (oil and gas) can be extracted. Conventional reservoirs are characterized by high porosity and permeability, meaning the rock has many interconnected pores allowing fluids to flow relatively freely. Think of it like a sponge – easily squeezed to release its water. These reservoirs often require less advanced recovery techniques and are typically found in easily accessible locations. Examples include sandstone and carbonate reservoirs.

Unconventional reservoirs, on the other hand, have low permeability, trapping hydrocarbons within tight rock formations. Imagine a tightly packed sponge that resists releasing its contents. Extracting hydrocarbons from these reservoirs requires advanced techniques such as hydraulic fracturing (fracking) or horizontal drilling. Examples include shale gas, tight gas sands, and heavy oil reservoirs found in tar sands. The challenge lies in overcoming the rock’s resistance to fluid flow.

Q 2. Describe the process of hydraulic fracturing.

Hydraulic fracturing, or fracking, is a technique used to enhance the permeability of unconventional reservoirs. It involves injecting a high-pressure mixture of water, sand, and chemicals into a wellbore to create fractures in the surrounding rock formation. The sand acts as a proppant, keeping the fractures open after the pressure is released, creating pathways for hydrocarbons to flow to the wellbore. Think of it as creating artificial pathways in that tightly packed sponge mentioned before.

The process typically begins with drilling a horizontal well into the target formation. Once the well is in place, multiple stages of fracturing are performed along the length of the wellbore. Each stage involves perforating the well casing to allow the fracturing fluid to enter the formation. After the fracturing fluid is injected, the pressure is carefully monitored to ensure the fractures propagate effectively. Finally, the well is put into production, allowing the hydrocarbons to flow to the surface.

Environmental concerns related to fracking include potential water contamination and induced seismicity, highlighting the need for careful planning, regulatory oversight, and the development of more environmentally friendly fracturing fluids.

Q 3. What are the key factors affecting reservoir pressure?

Reservoir pressure is the pressure exerted by the fluids (oil, gas, and water) within a reservoir. Several key factors influence this pressure:

- Hydrostatic Pressure: The pressure exerted by the weight of the overlying fluids and rock column. This is the primary component of reservoir pressure in most cases. A deeper reservoir will naturally have higher hydrostatic pressure.

- Hydrocarbon Expansion: As hydrocarbons are produced, the remaining fluids expand to occupy the freed space, reducing reservoir pressure. This effect is particularly significant for gas reservoirs.

- Water Influx: Water entering the reservoir from surrounding aquifers can help maintain or increase reservoir pressure. The rate and magnitude of water influx depend on aquifer properties and reservoir characteristics.

- Rock Compaction: As reservoir fluids are produced, the rock matrix may compact, further reducing reservoir pressure.

- Temperature: Temperature affects fluid density and viscosity, indirectly influencing reservoir pressure.

Understanding these factors is critical for accurate reservoir management and production forecasting. For example, if water influx is high, it could potentially offset pressure declines caused by hydrocarbon production, extending the productive life of the reservoir. Conversely, rapid pressure decline due to hydrocarbon expansion requires strategies like artificial lift to maintain production rates.

Q 4. Explain the concept of well logging and its applications.

Well logging is the process of making measurements in a borehole to gather information about the subsurface formations. Various tools are lowered into the wellbore to record data, providing insights into rock properties, fluid saturation, and other reservoir characteristics. Think of it as a detailed medical scan of the reservoir.

Applications of well logging are diverse and crucial in reservoir management:

- Formation Evaluation: Determining the porosity, permeability, and fluid content of the reservoir rocks. This information helps estimate the amount of hydrocarbons in place.

- Reservoir Characterization: Mapping the reservoir’s geometry, identifying fluid contacts (oil-water, gas-oil), and understanding reservoir heterogeneity (variations in rock properties).

- Well Completion Design: Optimizing well completion strategies (e.g., perforating, fracturing) based on the well log data. This ensures efficient hydrocarbon production.

- Monitoring Production Performance: Tracking changes in reservoir pressure, fluid saturation, and other parameters over time to assess the effectiveness of production operations.

Different types of logs provide specific information, such as gamma ray logs (measuring radioactivity), resistivity logs (measuring the electrical conductivity of formations), and sonic logs (measuring sound wave travel times). The combined interpretation of these logs provides a comprehensive understanding of the subsurface formation.

Q 5. Describe different types of drilling fluids and their functions.

Drilling fluids, also known as muds, are crucial in drilling operations. They serve multiple functions:

- Removing cuttings: Lifting rock cuttings from the wellbore to the surface.

- Controlling wellbore pressure: Preventing formation fluids from entering the wellbore (kicks) and controlling pressure within the well.

- Lubricating the drill bit: Reducing friction and wear on the drill bit.

- Cooling and lubricating the drill string: Preventing overheating and wear of the drill string.

- Supporting wellbore walls: Preventing wellbore collapse.

Different types of drilling fluids are used depending on the geological conditions and drilling requirements:

- Water-based muds: The most common type, consisting of water, clay, and various additives.

- Oil-based muds: Used in challenging conditions where water-based muds might not be effective, for instance, in very reactive shale formations. They offer better lubricity and shale inhibition.

- Synthetic-based muds: Environmentally friendly alternatives to oil-based muds, offering many of the same benefits.

Selecting the appropriate drilling fluid is critical for safe and efficient drilling operations. The wrong choice can lead to problems such as wellbore instability, stuck pipe, and environmental damage.

Q 6. What are the challenges of drilling in deepwater environments?

Deepwater drilling presents unique and significant challenges compared to land or shallow-water operations:

- Extreme water depths: The immense pressure and harsh environmental conditions at great depths pose significant technical challenges in drilling and well control.

- Harsh environmental conditions: Hurricanes, storms, and currents can disrupt operations and pose safety risks.

- Remote locations: Deepwater wells are often located far from shore, requiring specialized vessels and support infrastructure.

- Complex well designs: Deepwater wells often require complex well designs (e.g., long horizontal sections, multiple laterals) to access and produce hydrocarbons efficiently.

- High costs: The specialized equipment, infrastructure, and expertise required for deepwater drilling make it a very costly endeavor.

- Well control challenges: Managing pressure and preventing blowouts in deepwater wells is significantly more difficult due to the high pressures and the remoteness of the location. Advanced blowout preventers (BOPs) and well control procedures are crucial for safety.

These challenges necessitate meticulous planning, robust safety protocols, and advanced technology. The cost of failure in deepwater is exceptionally high, both in terms of financial losses and environmental impact.

Q 7. Explain the concept of reservoir simulation.

Reservoir simulation is a powerful tool used to predict and manage the performance of oil and gas reservoirs. It involves using mathematical models and computer software to simulate the complex physical processes occurring within the reservoir, such as fluid flow, pressure changes, and hydrocarbon production. Think of it as a virtual laboratory for testing different production strategies.

Reservoir simulation models use detailed information about the reservoir’s geometry, rock properties, fluid properties, and production history. The model is then used to predict future reservoir behavior under different scenarios. This allows engineers to optimize production strategies, plan drilling programs, and evaluate the economic viability of development projects. For example, reservoir simulations can help determine the optimal number and location of wells, the appropriate injection rates for waterflooding or gas injection projects, and the impact of various production strategies on ultimate hydrocarbon recovery.

The output of a reservoir simulation can include predictions of pressure profiles, production rates, cumulative production, and ultimate recovery. This information is essential for informed decision-making in reservoir management and helps maximize the economic recovery of hydrocarbons.

Q 8. How do you determine the optimal well spacing in a reservoir?

Determining optimal well spacing is crucial for maximizing reservoir production and minimizing operational costs. It’s a complex interplay of geological factors, reservoir characteristics, and economic considerations. The goal is to drain the reservoir efficiently without excessive well interference or uneconomic well density.

Several factors influence well spacing:

- Reservoir heterogeneity: A highly heterogeneous reservoir (with varying permeability and porosity) may require closer spacing to capture production from all zones effectively. Think of it like watering a garden with uneven soil; you might need more sprinklers in drier areas.

- Reservoir pressure: High initial reservoir pressure allows for wider spacing, as the pressure naturally drives the hydrocarbons towards the wells. Conversely, lower pressure might necessitate closer wells to maintain production.

- Well drainage radius: This refers to the area around a well from which hydrocarbons are drawn. It depends on reservoir permeability and well characteristics. Accurate modelling helps predict this radius.

- Economic factors: Drilling and completing wells are expensive. The optimal spacing balances the increased production from closer wells against the cost of drilling more wells.

Methods for determining optimal well spacing involve:

- Reservoir simulation: Sophisticated software models the reservoir’s behavior under different well spacing scenarios, allowing for optimization.

- Analytical methods: Simpler, faster calculations based on reservoir properties to provide initial estimates.

- Field experience and historical data: Understanding previous drilling results in similar reservoirs guides decision-making.

For example, in a tight gas reservoir with low permeability, closer well spacing might be necessary compared to a conventional reservoir with high permeability. The ultimate decision often involves a balance between maximizing recovery and minimizing expenses.

Q 9. Describe different types of well completion techniques.

Well completion refers to the processes carried out after drilling a well to prepare it for production. Different techniques are employed depending on the reservoir type and production goals. Some common types include:

- Openhole completion: The simplest method, where the wellbore is left open to the reservoir, allowing hydrocarbons to flow freely. Suitable for formations with high permeability and minimal risk of sand production. Think of it like leaving a water pipe open to let water flow.

- Cased and perforated completion: A steel casing is cemented into the wellbore to provide support and prevent wellbore collapse. Perforations (small holes) are then created in the casing to allow hydrocarbons to enter the wellbore. This is very common and allows for better control over the well.

- Gravel pack completion: A layer of gravel is placed around the wellbore in the perforations to prevent sand from entering the wellbore and damaging equipment. Essential for reservoirs prone to sand production.

- Fracturing completion: This technique involves creating fractures in the reservoir rock to increase permeability and improve hydrocarbon flow. High-pressure fluids are pumped into the wellbore to create these fractures, often in conjunction with proppants (small particles like sand) to keep the fractures open. It’s like creating cracks in a rock to make it more porous and allow water to flow through it easier.

- Horizontal well completion: Drilling a horizontal section at the end of a vertical well significantly increases the contact area with the reservoir, enhancing production, especially in unconventional resources like shale gas.

The choice of completion technique depends on factors like reservoir pressure, formation strength, permeability, and the presence of sand. Each method has its advantages and disadvantages, and the most suitable method is selected after careful analysis of reservoir properties and well characteristics.

Q 10. What are the key parameters used to evaluate reservoir performance?

Evaluating reservoir performance involves analyzing various parameters to assess its production potential and efficiency. Key parameters include:

- Reservoir pressure: A decline in reservoir pressure indicates depletion and impacts production rate. Monitoring pressure helps optimize production strategies.

- Production rate: The volume of hydrocarbons produced over time indicates the reservoir’s productivity.

- Water cut: The proportion of water in the produced fluids. An increasing water cut signals water breakthrough and signifies reservoir depletion.

- Gas-oil ratio (GOR): The volume of gas produced per volume of oil. Changes in GOR reflect reservoir pressure changes and can indicate changes in production.

- Oil and Gas Composition: Analyzing the composition of produced hydrocarbons provides insights into reservoir properties and potential for further recovery.

- Permeability and Porosity: These rock properties directly affect fluid flow and storage capacity within the reservoir. Data acquired during formation evaluation (discussed later) is crucial here.

- Fluid saturation: The amount of oil, gas, and water present in the reservoir’s pore spaces. This aids in understanding reservoir composition and recovery potential.

These parameters are typically monitored over time to understand how the reservoir responds to different production strategies. A comprehensive analysis of these parameters is vital for decision-making related to reservoir management, including well placement, production optimization, and enhanced oil recovery.

Q 11. Explain the concept of artificial lift techniques.

Artificial lift techniques are employed when the natural reservoir pressure is insufficient to bring hydrocarbons to the surface at an economically viable rate. These techniques supplement the natural energy to enhance production.

Common artificial lift methods include:

- Rod pumps: A subsurface pump driven by a surface motor using a series of rods. It’s a very reliable and widely used method.

- Electric submersible pumps (ESPs): Submersible pumps powered by electricity, often used in high-volume, high-pressure wells. They’re very efficient but can be expensive to install and maintain.

- Gas lift: Injecting gas into the wellbore to reduce the fluid density and help it flow to the surface. This is simpler and less capital-intensive than other methods but may not be suitable for all reservoirs.

- Hydraulic pumps: Surface-driven pumps that utilize high-pressure fluids to lift the produced hydrocarbons. Often used for high-viscosity fluids.

Selecting the appropriate artificial lift technique depends on factors such as well depth, fluid properties, production rate, and economic considerations. Choosing the most efficient and cost-effective method is crucial for maximizing profitability.

Q 12. Describe different methods for enhanced oil recovery (EOR).

Enhanced oil recovery (EOR) techniques are employed to increase the amount of oil recovered from a reservoir beyond what is achievable with primary and secondary recovery methods. These techniques aim to improve the flow of oil to the wellbore. Common EOR methods include:

- Waterflooding: Injecting water into the reservoir to displace oil towards production wells. This is the most common EOR method.

- Gas injection: Injecting gas (e.g., natural gas or CO2) to maintain reservoir pressure and improve oil mobility.

- Chemical flooding: Injecting chemicals (e.g., polymers, surfactants) to alter the oil-water interfacial tension, reducing oil viscosity, and improving oil mobility. These are more sophisticated but can significantly enhance recovery.

- Thermal recovery: Heating the reservoir to reduce oil viscosity and improve flow. Methods include steam injection and in-situ combustion.

The selection of the most suitable EOR technique depends on reservoir characteristics, oil properties, and economic feasibility. EOR projects require careful planning and execution, often involving complex simulations and modeling.

Q 13. What are the key environmental concerns associated with upstream oil and gas operations?

Upstream oil and gas operations present several significant environmental concerns:

- Greenhouse gas emissions: The extraction, processing, and transportation of oil and gas release greenhouse gases (GHGs) like methane and carbon dioxide, contributing to climate change.

- Air pollution: Fugitive emissions from wells, processing facilities, and transportation can release pollutants like volatile organic compounds (VOCs) and particulate matter, impacting air quality.

- Water pollution: Spills, leaks, and produced water disposal can contaminate surface and groundwater sources with oil, chemicals, and heavy metals.

- Habitat destruction: Exploration and production activities can lead to habitat loss and fragmentation, affecting wildlife populations.

- Seismic activity: Hydraulic fracturing (fracking), a common stimulation technique for unconventional reservoirs, has been linked to induced seismicity in some regions.

- Waste management: The industry generates substantial waste, including drilling muds, produced water, and solid waste, requiring proper management and disposal to minimize environmental impact.

Mitigating these concerns involves employing environmentally responsible practices, such as reducing methane emissions, improving waste management, minimizing water usage, and conducting thorough environmental impact assessments. The industry is under increasing pressure to reduce its environmental footprint and adopt more sustainable practices.

Q 14. Explain the concept of formation evaluation.

Formation evaluation is the process of determining the physical and chemical properties of subsurface formations penetrated by a wellbore. This critical process helps assess the reservoir’s hydrocarbon potential, productivity, and suitability for development.

Common formation evaluation techniques include:

- Wireline logging: Various tools are lowered into the wellbore to measure different properties, including porosity, permeability, fluid saturation, and lithology (rock type). Common logs include gamma ray, resistivity, neutron porosity, and density logs.

- Mud logging: Monitoring the drilling mud for indications of hydrocarbons and other reservoir properties during the drilling process.

- Core analysis: Retrieving samples of the reservoir rock (cores) to perform detailed laboratory analyses to determine petrophysical properties like porosity, permeability, and fluid saturations.

- Fluid sampling: Collecting samples of the reservoir fluids (oil, gas, water) to determine their composition and properties.

The data gathered from these techniques are integrated to create a comprehensive picture of the reservoir, enabling accurate reservoir modeling, well planning, and production optimization. For instance, resistivity logs help determine the presence of hydrocarbons, while porosity logs reveal the storage capacity of the reservoir. This integrated data significantly enhances the success rate of well development.

Q 15. How do you interpret seismic data to identify potential hydrocarbon reservoirs?

Seismic data interpretation for hydrocarbon reservoir identification involves analyzing subsurface reflections of sound waves to identify geological structures and properties indicative of potential oil and gas accumulations. Think of it like a sophisticated echolocation system for the Earth. We’re looking for specific patterns and anomalies that suggest the presence of porous and permeable rock formations (reservoirs) trapped beneath impermeable layers (cap rocks).

Amplitude analysis: Strong reflections can indicate the presence of gas, which has a higher acoustic impedance than water or rock. We look for amplitude anomalies – unusually strong or weak reflections – that might highlight reservoir boundaries.

Velocity analysis: Changes in seismic wave velocity can suggest variations in rock properties. High-velocity zones could indicate the presence of denser rocks or hydrocarbons.

Structural interpretation: Seismic data allows us to map geological structures like faults, folds, and domes. These structures can trap hydrocarbons, forming potential reservoirs. For example, a dome structure, where rock layers bend upwards, can act as a natural trap.

Stratigraphic interpretation: Analyzing subtle changes in seismic reflections helps to identify sedimentary layers and their characteristics. We look for patterns that suggest reservoir layering and thickness, which are crucial for reservoir evaluation.

Ultimately, seismic interpretation is an iterative process involving advanced software, geological understanding, and experience. We combine the seismic data with well log data and other geological information to build a comprehensive subsurface model and identify promising drilling locations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the process of well testing.

Well testing is a crucial process to determine the reservoir’s properties and the well’s productivity. It involves temporarily producing a well under controlled conditions, measuring the pressure and flow rate, and analyzing the data to assess the reservoir’s potential.

Purpose: To determine reservoir pressure, permeability (how easily fluids flow through the rock), and fluid properties (oil, gas, or water).

Procedure: A well is opened and production is initiated, while monitoring pressure and flow rate. Various test types exist, including pressure buildup tests (well shut-in to measure pressure recovery) and drawdown tests (measuring pressure decline during production). Data are then plotted and analyzed using specialized software.

Interpretation: Pressure transient analysis, explained in more detail in the next question, helps determine reservoir characteristics from the data collected during these tests.

Example: Imagine a water well; when you first start pumping, the water flow rate is high, but it gradually decreases as the reservoir pressure reduces. A pressure buildup test afterward would measure how quickly the pressure recovers after the pumping stops, revealing information on the well’s productivity and the size of the reservoir.

Q 17. What are the key factors affecting production rates?

Production rates in oil and gas wells are governed by several interconnected factors. It’s like trying to drain a water tank – the rate depends on the size of the tank, the size of the drain, and the pressure inside the tank.

Reservoir properties: Reservoir pressure, permeability, porosity (amount of space available to store fluids), and fluid viscosity (thickness of the oil or gas) are all paramount.

Wellbore conditions: The diameter of the wellbore, the presence of any restrictions (e.g., scaling, sand production), and the completion design (how the well is equipped to produce) directly influence production.

Artificial lift methods: If natural reservoir pressure isn’t sufficient, artificial lift techniques (such as pumps or gas lift) are employed, directly affecting production.

Production facilities: The capacity and efficiency of processing facilities (separators, pipelines, etc.) ultimately limit the amount of fluid that can be extracted from the well.

For example, a well with high reservoir pressure and permeability will naturally produce at a higher rate than a well with low pressure and low permeability, all other factors being equal. Managing and optimizing these factors is key to maximizing production over the life of a well.

Q 18. Explain the concept of pressure transient analysis.

Pressure transient analysis (PTA) is a powerful technique used to interpret well test data and determine reservoir properties. It’s like a medical examination for the reservoir, allowing us to understand its health and productivity. We analyze the pressure changes within the reservoir as a function of time during well testing.

The analysis involves using mathematical models (like the diffusivity equation) to simulate pressure behavior. By matching the observed pressure changes to the models, we can estimate key reservoir parameters such as:

Permeability: The ability of the rock to transmit fluids.

Porosity: The amount of pore space in the reservoir rock.

Reservoir pressure: The pressure within the reservoir.

Wellbore storage: The capacity of the wellbore to store fluids.

Reservoir boundaries: The extent of the reservoir.

Software tools and specialized expertise are needed for accurate PTA interpretation. This information is crucial for reservoir management, production forecasting, and optimizing field development plans.

Q 19. How do you manage risks associated with drilling operations?

Managing risks in drilling operations is paramount for safety, environmental protection, and cost efficiency. A proactive, multi-layered approach is essential.

Pre-drill risk assessment: Thorough geological and geophysical studies, including seismic surveys and well log analysis, are conducted to assess potential hazards like high-pressure zones, unstable formations, and presence of H2S (hydrogen sulfide).

Well planning and design: The well plan incorporates risk mitigation measures based on the assessment. This includes selecting appropriate drilling fluids, casing design, and drilling procedures.

Real-time monitoring and control: Sensors and sophisticated monitoring systems are used during drilling to detect potential issues early, allowing immediate corrective actions. Parameters like mud pressure, rate of penetration, and wellbore stability are constantly tracked.

Emergency response planning: Detailed emergency procedures and contingency plans are developed and regularly practiced to handle potential incidents like well control issues, blowouts, or environmental spills.

Safety training and procedures: Strict safety protocols and comprehensive training programs for drilling crews are critical to minimize human error, a significant risk factor.

For instance, if a high-pressure zone is identified, specialized equipment and procedures will be employed to prevent a blowout. Effective risk management is a continuous process involving regular audits, improvement strategies, and communication among all stakeholders.

Q 20. Describe different types of production facilities.

Production facilities encompass a range of equipment and infrastructure used to process and transport hydrocarbons from the wellhead to the market.

Wellhead facilities: This is the initial point of production, encompassing the christmas tree (valves and controls for flow regulation), flowlines, and potentially early separation (removing gas or water from oil).

Processing facilities: These include separators (to separate oil, gas, and water), dehydration units (to remove water from gas or oil), and treating equipment (to remove impurities).

Storage facilities: Tanks and other storage vessels are necessary for temporary storage of produced fluids before transportation.

Export facilities: These include pipelines, loading terminals, and other infrastructure for transporting produced fluids to refineries or other destinations.

The complexity and scale of production facilities vary widely depending on the size and characteristics of the field. A small onshore field might have relatively simple facilities, while a large offshore field will often involve extensive and sophisticated platforms, pipelines, and processing equipment.

Q 21. What are the key factors affecting pipeline design and operation?

Pipeline design and operation are governed by numerous factors, ensuring safe and efficient transportation of hydrocarbons.

Fluid properties: The type of fluid (oil, gas, or water), pressure, temperature, and viscosity influence pipeline diameter, material selection, and operating pressures.

Terrain and environmental conditions: Pipeline routes are carefully selected to minimize environmental impact and consider factors like topography, soil conditions, seismic activity, and potential crossing of waterways.

Safety and regulations: Stringent safety standards and regulatory compliance are critical, encompassing material specifications, leak detection systems, and emergency shutdown procedures.

Capacity and flow rate: Pipeline design must meet required throughput capacity while maintaining acceptable flow velocity and pressure drops.

Corrosion and erosion: Pipeline materials must resist corrosion and erosion caused by the transported fluids and environmental factors. Protective coatings and cathodic protection are often implemented.

For example, pipelines transporting high-pressure gas require thicker walls and higher-grade steel compared to those carrying low-pressure liquids. Proper pipeline design and operation are essential to prevent leaks, spills, and other hazards, protecting both the environment and human safety.

Q 22. Explain the concept of reservoir management.

Reservoir management is the systematic process of optimizing hydrocarbon production from a reservoir throughout its entire lifecycle. It’s essentially about maximizing the economic recovery of oil and gas while minimizing environmental impact and ensuring operational safety. Think of it like managing a complex, underground farm, where you need to understand the soil (reservoir rock), the crops (hydrocarbons), and the best harvesting techniques (production methods) to get the maximum yield.

This involves a multidisciplinary approach, integrating geology, geophysics, reservoir engineering, petroleum engineering, and production operations. Key aspects include:

- Reservoir characterization: Understanding the reservoir’s properties like porosity, permeability, fluid saturation, and geometry.

- Reservoir simulation: Building computer models to predict reservoir behavior under different production scenarios.

- Production optimization: Implementing strategies to maximize hydrocarbon recovery, such as waterflooding, gas injection, or improved oil recovery (IOR) techniques.

- Monitoring and control: Continuously monitoring reservoir performance through data acquisition and analysis, adjusting production strategies as needed.

- Economic evaluation: Assessing the profitability of different production strategies and making informed decisions based on economic forecasts.

Effective reservoir management ultimately leads to increased profitability, reduced environmental impact, and enhanced operational efficiency.

Q 23. How do you evaluate the economic viability of an upstream oil and gas project?

Evaluating the economic viability of an upstream oil and gas project is a crucial step, requiring a thorough analysis of various factors. It’s not just about looking at the potential profits; we need to weigh them against the risks and costs involved. A common approach involves Discounted Cash Flow (DCF) analysis.

Key elements considered in the evaluation:

- Reserves estimation: Accurately estimating the amount of hydrocarbons in place and the amount that can be economically recovered (proven, probable, and possible reserves).

- Capital expenditure (CAPEX): Estimating costs associated with exploration, appraisal, development, and production infrastructure (e.g., drilling wells, pipelines, processing facilities).

- Operating expenditure (OPEX): Estimating ongoing operational costs (e.g., labor, chemicals, maintenance).

- Revenue projections: Forecasting future oil and gas prices, production rates, and sales volumes.

- Discount rate: Reflecting the risk associated with the project; a higher discount rate implies higher risk.

- Taxes and royalties: Accounting for government levies.

- Sensitivity analysis: Assessing how changes in key parameters (e.g., oil price, production rate) impact the project’s profitability.

By analyzing these factors and utilizing DCF analysis, a project’s Net Present Value (NPV) and Internal Rate of Return (IRR) can be determined. A positive NPV and an IRR exceeding the hurdle rate (minimum acceptable return) generally indicates economic viability.

Q 24. Describe the different stages of an upstream oil and gas project lifecycle.

The upstream oil and gas project lifecycle can be divided into several key stages:

- Exploration: This involves identifying potential hydrocarbon reserves through geological surveys, seismic studies, and exploratory drilling. The goal is to assess the presence and size of potential reservoirs.

- Appraisal: Once a discovery is made, appraisal drilling and further studies are undertaken to accurately define the reservoir’s characteristics, size, and production potential. This stage provides data for reservoir modeling and production planning.

- Development: This stage focuses on designing and implementing the infrastructure necessary for hydrocarbon production. This includes drilling production wells, constructing pipelines, and building processing facilities. This requires significant investment.

- Production: Hydrocarbons are extracted, processed, and transported to market. This phase is usually the longest, and effective reservoir management is critical for maximizing recovery and profitability.

- Decommissioning: Once the reservoir is depleted, the facilities are safely dismantled and the site is restored to its pre-development condition. Environmental regulations strictly govern this phase.

Each stage has its own specific challenges and requires different expertise and resources. A well-planned project will carefully manage the transition between each stage to ensure optimal efficiency and cost-effectiveness.

Q 25. What is your experience with different types of reservoir characterization techniques?

My experience encompasses a wide range of reservoir characterization techniques, both conventional and advanced. I’ve worked extensively with:

- Seismic data interpretation: Analyzing seismic surveys to image subsurface structures and identify potential hydrocarbon traps.

- Well log analysis: Interpreting data from various well logging tools (e.g., gamma ray, resistivity, porosity logs) to characterize the reservoir properties along the wellbore.

- Core analysis: Analyzing physical rock samples (cores) to determine porosity, permeability, fluid saturation, and other key reservoir parameters.

- Petrophysical modeling: Integrating data from different sources to create a comprehensive 3D model of the reservoir, predicting its behavior under various production scenarios.

- Reservoir simulation: Using numerical models to simulate reservoir performance and optimize production strategies. I have experience with various simulators such as Eclipse and CMG.

- Production logging: Analyzing data acquired from production logs to assess well performance and identify production issues.

I’m proficient in using industry-standard software and have experience in applying advanced techniques like machine learning for improved reservoir characterization and prediction. For example, I recently utilized machine learning algorithms to improve the prediction of permeability in a low-permeability sandstone reservoir, leading to a significant improvement in reservoir simulation accuracy.

Q 26. How do you ensure compliance with safety and environmental regulations?

Ensuring compliance with safety and environmental regulations is paramount in the upstream oil and gas industry. It’s not just a matter of legal compliance; it’s a crucial aspect of responsible operation that protects both the environment and personnel. Our approach involves a multi-layered strategy:

- Rigorous risk assessment: Identifying potential hazards associated with each operation and implementing mitigation measures. This includes regular safety audits and training programs.

- Strict adherence to regulatory standards: We meticulously follow all applicable local, national, and international regulations related to safety, environmental protection, and waste management. This includes complying with permits and reporting requirements.

- Emergency response planning: Developing and regularly practicing emergency response plans to deal with potential incidents such as spills, fires, or equipment failures. This includes regular drills and training.

- Environmental monitoring: Continuously monitoring environmental parameters (e.g., water quality, air emissions) to ensure that our operations do not exceed permitted levels. We also conduct environmental impact assessments before undertaking new projects.

- Waste management: Implementing effective waste management systems, including recycling, reuse, and disposal of waste materials in accordance with environmental regulations.

- Stakeholder engagement: Communicating regularly with local communities and other stakeholders to address their concerns and ensure transparency in our operations.

Compliance is not merely a checklist; it’s a continuous process of improvement, adaptation, and commitment to responsible operations. We believe that safety and environmental protection are integral to our business success.

Q 27. Describe a situation where you had to solve a complex technical problem in an upstream oil and gas setting.

In a previous role, we faced a significant challenge with unexpected water breakthrough in a producing well. The water influx was rapidly reducing oil production and threatening the economic viability of the field. Initial analysis suggested a potential problem with the well’s completion design, but further investigation was needed.

We implemented a multi-pronged approach:

- Detailed data analysis: We meticulously analyzed production data, pressure measurements, and well logs to understand the nature and extent of the water influx.

- Reservoir simulation: We updated our reservoir simulation model to incorporate the new data and simulate different scenarios to determine the likely source and pathways of the water.

- Advanced well logging: We conducted advanced logging operations to obtain a more detailed understanding of the wellbore and reservoir conditions around the affected well.

- Engineering solution: Based on the data analysis and simulations, we designed and implemented a remedial solution involving selective plugging of the water-producing zones using specialized techniques.

This integrated approach allowed us to successfully mitigate the water influx, restore oil production, and prevent further economic losses. The successful resolution demonstrated the importance of collaboration, meticulous data analysis, and creative problem-solving in tackling complex technical challenges in the upstream oil and gas industry.

Q 28. Explain your understanding of the current trends and challenges facing the upstream oil and gas industry.

The upstream oil and gas industry is currently undergoing a period of significant transformation, driven by several key trends and challenges:

- Declining conventional reserves: The discovery of new conventional oil and gas reserves is slowing down, necessitating exploration in more challenging and remote locations.

- Increased focus on unconventional resources: The industry is increasingly focused on developing unconventional resources such as shale oil and gas, which require specialized technologies and techniques.

- Energy transition: Growing global concerns about climate change are driving a shift towards renewable energy sources, creating pressure on the oil and gas industry to reduce its carbon footprint.

- Technological advancements: The industry is witnessing rapid advancements in technologies such as digitalization, automation, and artificial intelligence, which are enhancing efficiency and improving decision-making.

- Geopolitical instability: Political and economic uncertainties in different parts of the world can significantly impact the oil and gas market and project economics.

- Cost pressures: Operating costs, including labor and materials, are continually increasing, making efficient operations even more crucial.

- ESG (Environmental, Social, and Governance) factors: Investors and stakeholders are increasingly demanding greater transparency and accountability concerning environmental and social responsibility.

Successfully navigating these challenges requires a multi-faceted approach, involving innovation, collaboration, and a strong commitment to sustainability. Companies that embrace technological advancements, prioritize efficient operations, and actively manage their environmental and social impact are best positioned for success in the long term.

Key Topics to Learn for Upstream Oil and Gas Knowledge Interviews

- Exploration & Appraisal: Understanding geological surveys, seismic interpretation, reservoir characterization, and drilling strategies. Practical application: Analyzing geological data to assess the viability of a potential oil or gas field.

- Drilling & Well Completion: Familiarize yourself with drilling techniques, wellbore stability, completion methods, and production optimization. Practical application: Troubleshooting issues related to drilling efficiency and well performance.

- Reservoir Engineering: Master concepts like reservoir simulation, fluid flow, and production forecasting. Practical application: Developing reservoir management plans to maximize hydrocarbon recovery.

- Production Operations: Understand facility operations, process engineering, and production optimization strategies. Practical application: Analyzing production data to identify bottlenecks and improve efficiency.

- Health, Safety, and Environment (HSE): Demonstrate knowledge of HSE regulations and best practices within the Upstream sector. Practical application: Identifying and mitigating potential risks in drilling and production operations.

- Project Management & Economics: Understand project lifecycle management, cost estimation, and economic evaluation of Upstream projects. Practical application: Evaluating the profitability of different development scenarios.

- Data Analysis & Interpretation: Develop skills in interpreting technical data from various sources, using software for analysis and visualization. Practical application: Identifying trends and patterns in production data to make informed decisions.

Next Steps

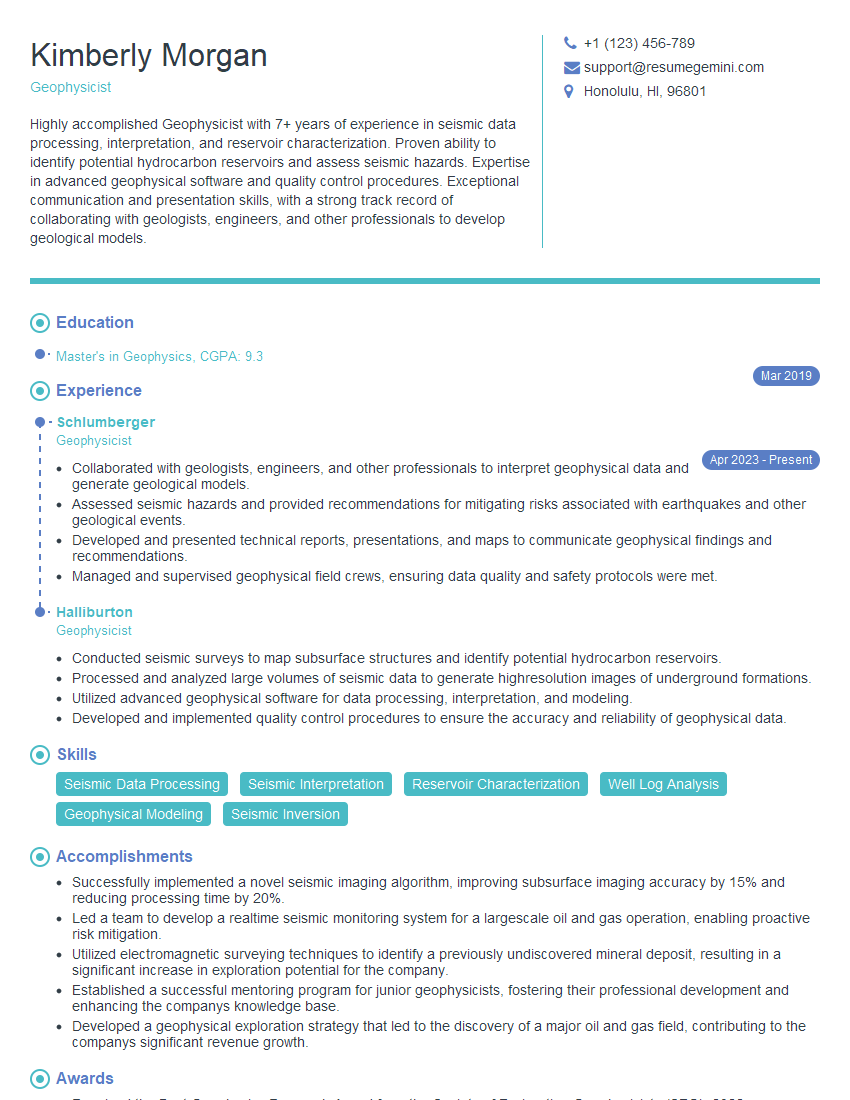

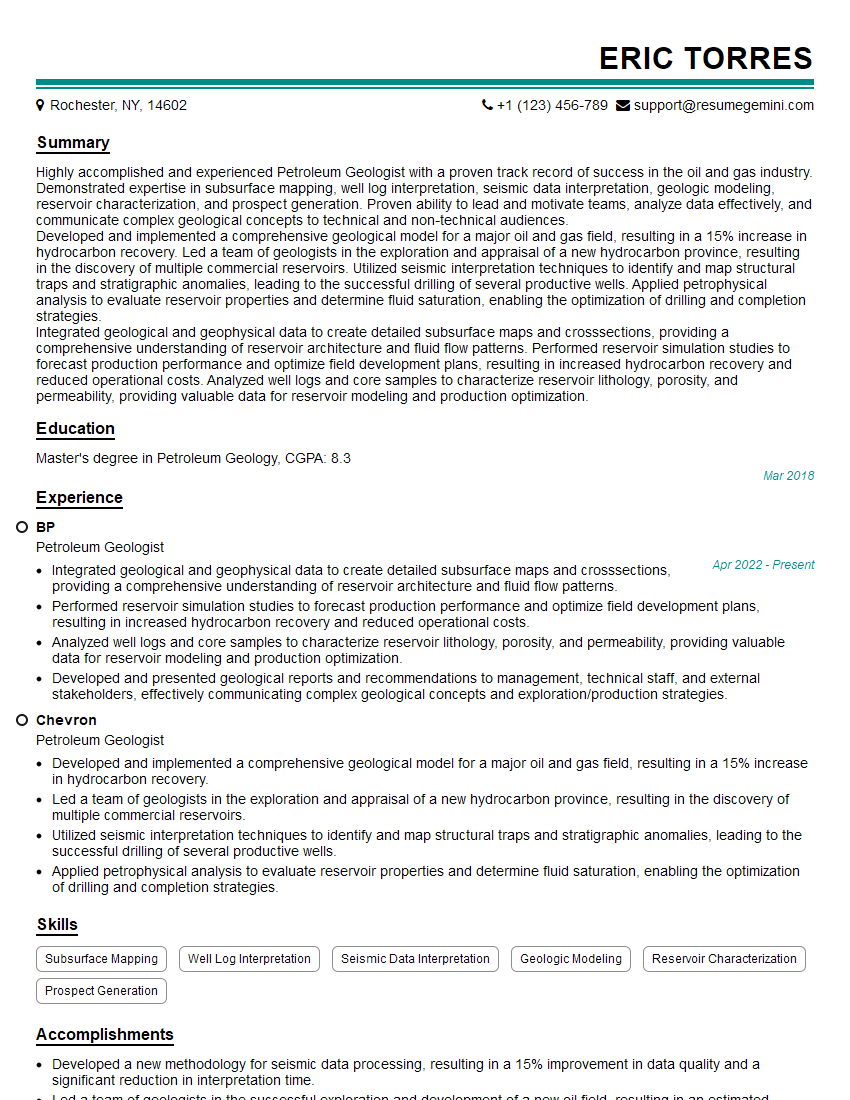

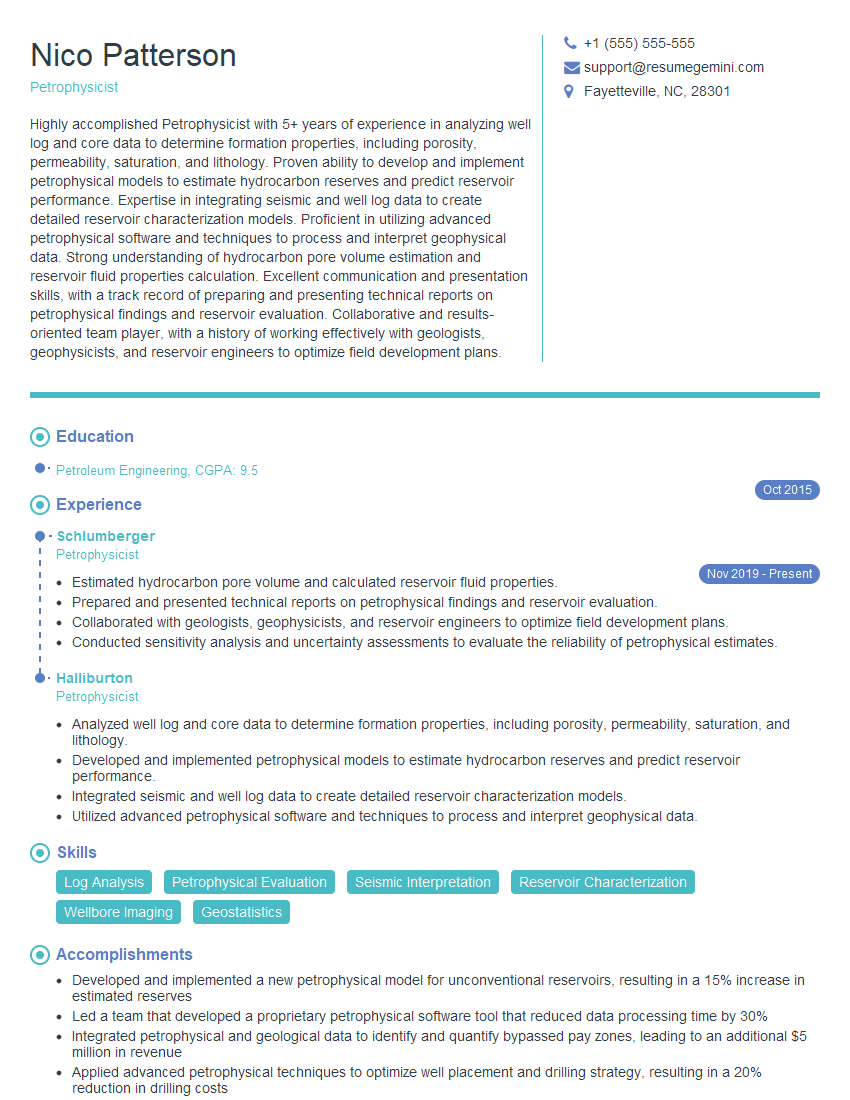

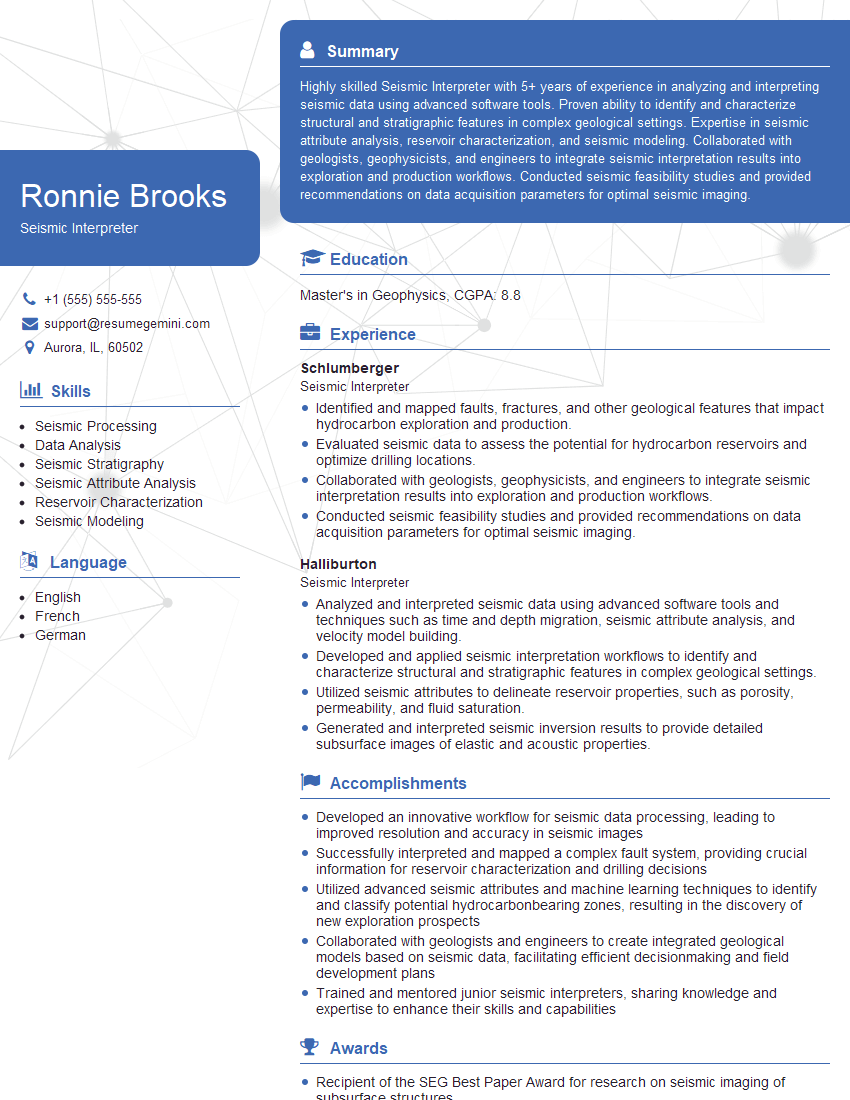

Mastering Upstream oil and gas knowledge is crucial for career advancement in this dynamic industry. A strong understanding of these technical areas opens doors to exciting opportunities and higher-level roles. To maximize your job prospects, create a compelling and ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini can be a trusted partner in this process, helping you craft a professional resume that stands out. We provide examples of resumes tailored to Upstream oil and gas knowledge to guide you – use them as inspiration to build your own impactful document.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.