The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Linoleum and vinyl flooring interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Linoleum and vinyl flooring Interview

Q 1. Explain the differences between sheet vinyl and vinyl tile.

Sheet vinyl and vinyl tile are both popular flooring choices, but they differ significantly in their installation and appearance. Sheet vinyl comes in large, continuous rolls, much like a giant carpet, offering a seamless look across large areas. Think of it as a ‘one-piece’ solution for a room. This minimizes seams and creates a cleaner aesthetic. Vinyl tile, on the other hand, consists of individual squares or planks, offering flexibility in design and pattern choices. Imagine creating a mosaic or patterned floor using smaller components. This allows for easier replacement of damaged tiles, but requires more precise installation to ensure evenness and straight lines.

The choice between them often depends on the size of the area, the desired aesthetic, and the budget. Sheet vinyl is typically easier and faster to install for large, uninterrupted spaces, while vinyl tile provides more design versatility and allows for easier repairs.

Q 2. Describe the proper subfloor preparation for linoleum installation.

Proper subfloor preparation is crucial for a successful linoleum or vinyl installation. A poorly prepared subfloor can lead to unevenness, buckling, and premature failure of the flooring. The process begins with a thorough cleaning to remove any dirt, debris, or old adhesive residue. The surface must then be level; any significant imperfections (more than 1/4 inch variation over 10 feet) need to be addressed by using self-leveling compound. This is like creating a perfectly flat canvas for your flooring. This ensures a smooth surface that will prevent issues like bubbling or uneven wear over time. After the leveling compound dries completely, the subfloor should be primed with a suitable primer recommended by the flooring manufacturer. Priming helps create better adhesion between the subfloor and the adhesive, improving the lifespan of your floor. Finally, before adhesive is applied, ensure the subfloor is completely dry to avoid moisture problems.

Q 3. What are the common types of adhesives used for linoleum and vinyl?

The type of adhesive used for linoleum and vinyl depends largely on the subfloor material and the specific flooring product. Common types include pressure-sensitive adhesives (PSA), which are easy to use and often come pre-applied to the backing of certain vinyl products. Think of them as a sticky note, already ready to adhere. Then there are water-based adhesives, which are known for their low odor and are typically used for sheet vinyl installations and are considered environmentally friendly. Solvent-based adhesives provide strong adhesion but require careful handling due to their strong fumes and potential flammability; these are generally reserved for professional installers. Always refer to the manufacturer’s instructions for both the flooring and the adhesive to ensure compatibility and proper application. Choosing the wrong adhesive can severely compromise the longevity and integrity of your flooring installation.

Q 4. How do you measure for linoleum and vinyl flooring?

Accurate measurement is key to avoiding costly mistakes and material waste when installing linoleum or vinyl. Begin by measuring the length and width of each area you intend to cover. It’s best to measure multiple times to ensure accuracy. For irregular spaces, divide the area into smaller, more manageable shapes. Add extra to account for waste and ensure you have enough material to cover the area fully. Always factor in the allowance for pattern matching, especially important for sheet vinyl and some vinyl tiles. Remember, it’s better to have slightly more than you need to avoid running short. Don’t forget to consider transitions between rooms and allowances for doorways and thresholds. Making a detailed sketch of the space with measurements marked will help to visualize the process and avoid errors.

Q 5. What tools and equipment are essential for installing linoleum and vinyl?

Installing linoleum and vinyl requires specific tools and equipment for a professional finish. These include a measuring tape, a utility knife with sharp blades for cutting, a straight edge (like a long metal ruler) for making straight cuts, a seam roller to ensure proper adhesion and to flatten seams, a knee kicker (helpful for larger sheet vinyl installations), and a trowel to spread adhesive evenly. For vinyl tile installations, you may also need a tapping block to seat tiles properly. Safety equipment, such as gloves and eye protection, is essential throughout the entire process. A quality floor scraper can be helpful for removing old adhesive residue if you’re working over existing flooring. Finally, a wet/dry vacuum is invaluable for keeping the workspace clean and free of debris during and after installation.

Q 6. Explain the process of seam welding vinyl flooring.

Seam welding is a crucial step in installing sheet vinyl to create a watertight and durable seal between seams. It’s especially important in areas prone to moisture, like kitchens and bathrooms. First, ensure the seams are perfectly aligned and the vinyl is firmly adhered to the subfloor. Then, a special seam welding rod, heated with a welding iron, is used to melt the vinyl along the seam, creating a strong bond. The process requires a steady hand and precise technique. The melted vinyl is smoothed immediately with a seam roller to ensure a clean, flat surface and a watertight seal. Improper seam welding can lead to water damage and compromise the integrity of the flooring. Practice on scraps of vinyl before attempting it on the actual installation. Proper seam welding is a hallmark of professional vinyl flooring installation.

Q 7. How do you handle transitions between different flooring materials?

Transitions between different flooring materials require careful planning and execution to ensure a smooth, aesthetically pleasing, and functional change. Common transitions include changes from vinyl to tile or wood. Various transition strips are available for this purpose, designed to bridge the gap and create a visually appealing finish. These strips can be metal, wood, or plastic and come in a variety of styles to match your flooring and aesthetic preferences. The appropriate transition strip will need to be carefully measured and cut to fit precisely, and should be installed securely using appropriate adhesive. Ensure that the transition is flush with the surrounding flooring to prevent tripping hazards. Properly installed transitions enhance the overall look and quality of the flooring job, providing a professional finish that seamlessly blends different flooring materials.

Q 8. Describe the proper methods for cutting linoleum and vinyl.

Cutting linoleum and vinyl requires precision and the right tools to avoid damage. For straight cuts, a sharp utility knife with a fresh blade is essential. Score the material deeply several times along the cutting line before pushing the blade all the way through. For curved cuts, a jigsaw with a fine-tooth blade is ideal. Always use a metal straightedge or a cutting guide for straight cuts to ensure accuracy. For intricate cuts, you might consider using a rotary cutter with a sharp blade and a cutting mat to prevent damage to your work surface. Remember to always wear safety glasses to protect your eyes from flying debris.

Think of it like cutting a thick piece of paper; you wouldn’t try to slice through it in one go. Multiple passes with a sharp blade are key to a clean, straight cut. After cutting, use sandpaper or a sanding block to smooth any rough edges to prevent tripping hazards.

Q 9. What are the common problems encountered during linoleum and vinyl installation?

Common problems during linoleum and vinyl installation often stem from poor preparation or improper techniques. Uneven subfloors are a major culprit, leading to ripples and bumps. Insufficient acclimation of the flooring material before installation can result in shrinkage, gaps, and buckling after installation. Improper adhesive application, such as using the wrong type or applying it unevenly, also creates problems. Additionally, moisture issues beneath the flooring can cause bubbling or delamination. Failing to properly seam the flooring can lead to unsightly gaps and potential water damage.

In one project, I encountered a severely uneven concrete subfloor. We had to spend extra time leveling it using a self-leveling compound before we could even begin installing the flooring, saving the client from future issues.

Q 10. How do you troubleshoot issues like bubbling or wrinkling in vinyl flooring?

Bubbling and wrinkling in vinyl flooring usually indicate problems with the adhesive or subfloor preparation. Bubbling often suggests inadequate adhesive coverage or air trapped beneath the flooring. Wrinkling might point to an uneven subfloor or the flooring not being properly stretched during installation. Troubleshooting involves identifying the root cause.

- For small bubbles: Carefully pierce the bubble with a pin, then gently press the air out from underneath, smoothing the vinyl back down. A heat gun can be used to soften the vinyl, allowing for better adhesion (be cautious not to overheat).

- For larger bubbles or wrinkles: It’s usually necessary to lift a section of the flooring, reapply adhesive, and then carefully reposition it. In extreme cases, the flooring might need to be completely removed and reinstalled. If wrinkling is present near the edges, there might be too much or too little expansion space. It might be necessary to trim and re-install.

Remember, always diagnose the problem before starting any repair. A quick fix might make the problem worse if the underlying cause isn’t addressed.

Q 11. What are the safety precautions you take during linoleum and vinyl installation?

Safety is paramount during linoleum and vinyl installation. Always wear appropriate safety gear, including safety glasses to protect your eyes from flying debris and sharp objects, work gloves to prevent cuts and blisters, and a dust mask to avoid inhaling particles from cutting or sanding. Use caution when working with knives and other sharp tools. Proper ventilation is crucial when using adhesives or sealants, as some contain volatile organic compounds (VOCs). Ensure the work area is well-lit and free of tripping hazards. Always follow the manufacturer’s instructions for handling and applying adhesives and other materials.

I once had a near miss when a piece of vinyl slipped from my hand while using a utility knife. Fortunately, my safety glasses prevented injury. That reinforced the importance of constant vigilance and attention to detail.

Q 12. Describe your experience with different types of linoleum and vinyl.

My experience encompasses a wide range of linoleum and vinyl types. I’ve worked with various thicknesses and patterns, including sheet vinyl, vinyl tiles, and both inlaid and printed linoleum. Sheet vinyl offers seamless coverage, ideal for larger spaces, whereas tiles provide flexibility in design and are easier to replace if damaged. Inlaid linoleum, with its multiple layers, is known for its durability and rich colors, making it ideal for high-traffic areas. Printed linoleum offers a vast array of designs at a more affordable price point. The choice of material depends largely on the project’s requirements, budget, and aesthetic preferences.

Recently, I worked on a project that used a luxurious inlaid linoleum in a kitchen. The client loved the durability and unique look it provided, and it really enhanced the space. It’s rewarding to see how the right flooring choice can completely transform a room.

Q 13. How do you ensure proper acclimation of flooring materials before installation?

Proper acclimation is crucial to prevent issues such as shrinkage, expansion, and buckling after installation. Before installation, the flooring materials should be allowed to acclimate to the ambient temperature and humidity of the room for at least 48 hours, and often longer depending on the material and climate. This allows the material to adjust to the environment and prevents it from reacting to temperature and humidity fluctuations post-installation.

The flooring should be stored in the room where it will be installed, ideally in its original packaging. This allows for a gradual acclimation process. Failing to properly acclimate can lead to significant problems down the line, potentially voiding warranties.

Q 14. What is the proper method for cleaning and maintaining linoleum and vinyl?

Cleaning and maintaining linoleum and vinyl is straightforward, but consistent care is key to preserving their appearance and extending their lifespan. Regular sweeping or vacuuming removes loose dirt and debris. For mopping, use a damp (not wet) mop and a pH-neutral cleaner designed specifically for vinyl or linoleum floors. Avoid harsh chemicals, abrasive cleaners, and excessive water, as these can damage the finish. Always test any cleaning solution in an inconspicuous area first. After cleaning, ensure the floor dries completely to prevent moisture buildup. Regularly inspect for scratches or damage and repair as needed to avoid further issues.

Think of it like caring for your skin; harsh chemicals or overly aggressive cleaning will cause damage, whereas gentle care ensures longevity and a healthy appearance.

Q 15. Explain the importance of using appropriate safety gear.

Safety is paramount in flooring installation. Appropriate safety gear protects you from potential hazards like cuts, slips, and chemical exposure. This includes sturdy work boots with slip-resistant soles to prevent falls on wet or uneven surfaces. Safety glasses protect your eyes from flying debris during cutting or handling sharp tools. A dust mask is crucial, particularly when working with adhesives, to prevent inhalation of harmful fumes. Gloves protect your hands from cuts, abrasions, and chemical irritants found in adhesives and cleaning solutions. Ignoring these precautions can lead to serious injury, so it’s non-negotiable for me.

For example, I once witnessed a colleague cut his hand badly while using a utility knife without gloves. This resulted in a trip to the emergency room and a week off work. This underscores the critical importance of wearing appropriate protective gear at all times.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of underlayment used for linoleum and vinyl?

Underlayment plays a crucial role in achieving a smooth, even surface and improving the longevity of your linoleum or vinyl flooring. The choice of underlayment depends on factors like the subfloor condition, the type of flooring, and the desired level of comfort and sound insulation. Common types include:

- Foam underlayment: Offers excellent cushioning and sound insulation. Different thicknesses and densities are available, offering varying levels of comfort and support. Thicker foam is ideal for older homes with less-than-perfect subfloors.

- Fiberboard underlayment: Provides a stable base and helps to level minor imperfections. It’s a more rigid option compared to foam.

- Cork underlayment: Offers excellent sound insulation and cushioning, creating a warmer and more comfortable feel underfoot. It’s also naturally moisture-resistant.

- Combination underlayments: Combine different materials, such as foam and a moisture barrier, to offer superior performance in terms of cushioning, insulation, and moisture protection.

For instance, in a project involving an older home with some subfloor irregularities, I opted for a thicker foam underlayment to compensate for the imperfections and provide added comfort. In a commercial setting with a concrete subfloor, a thin fiberboard underlayment might be sufficient for leveling and stability.

Q 17. How do you calculate the amount of flooring material needed for a job?

Accurately calculating flooring material is essential to avoid waste and ensure you have enough for the job. First, you need to measure the length and width of each room accurately. For rectangular rooms, simply multiply length x width to get the square footage. For irregularly shaped rooms, divide them into smaller, more manageable shapes (rectangles, triangles) and calculate the area of each, then sum the totals.

Always add extra material to account for waste due to cuts, patterns, and potential mistakes (typically 5-10%, depending on complexity). For example, a room measuring 12ft x 15ft is 180 square feet. Adding 10% for waste means you need approximately 198 square feet of flooring. Remember to account for any door or window openings; deduct these from the total area. If you’re working with patterned tiles, consider the pattern repeat; you may need even more extra material.

Total Area = (Length x Width) + Waste Percentage

Q 18. Describe your experience with using heat welding equipment.

Heat welding is a crucial technique for creating strong, seamless joints in vinyl flooring, especially in large commercial projects. My experience includes using various types of heat welding equipment, from portable welders to larger, more powerful machines. It involves using a hot-air welder to melt the edges of the vinyl sheets and fuse them together. It requires precision and skill to ensure a clean, invisible seam, and I’m proficient in various welding techniques for different types of vinyl.

A successful heat weld needs the right temperature, consistent pressure, and a steady hand to prevent burning or creating an uneven weld. Mastering heat welding eliminates visible seams and improves the overall aesthetic and durability of the installation. I regularly maintain and clean my welding equipment to maintain optimal performance. Proper safety precautions, like eye protection and adequate ventilation, are also followed strictly during heat welding operations.

Q 19. How do you handle uneven subfloors during installation?

Uneven subfloors are a common challenge in flooring installations, impacting the final look and longevity of the floor. Addressing this requires a systematic approach. Minor imperfections can often be addressed with self-leveling compound, applied according to the manufacturer’s instructions. This creates a smooth, even surface for the flooring. For more significant unevenness, the subfloor might need repair or leveling using plywood or other appropriate materials. The objective is to create a perfectly flat and stable base for your flooring installation.

For example, I once encountered a subfloor with significant dips and humps. After assessing the situation, I used self-leveling compound in areas with minor imperfections and strategically placed plywood patches in areas with greater variations, ensuring a solid and level base for the vinyl flooring. Then, the flooring installation resulted in a perfectly smooth and beautiful final product.

Q 20. What are the different types of seams used in vinyl flooring installation?

The type of seam used depends on the type of vinyl flooring and the desired aesthetic. Common seam types include:

- Heat-welded seams: These are virtually invisible and create the strongest, most durable bond, especially suitable for commercial or high-traffic areas. They are typically used with homogeneous vinyl.

- Cold-welded seams: Use a special adhesive to bond the edges of the vinyl sheets together. This is a faster method than heat welding but might not be as durable.

- Overlap seams: This method involves overlapping the edges of the vinyl sheets and sealing them with adhesive. It’s generally less desirable, as the seam is more visible and less durable, making it unsuitable for high-traffic areas.

The choice of seam type significantly affects the longevity and aesthetic appeal of the vinyl flooring. For instance, in a busy kitchen, a heat-welded seam is the preferred option for its strength and water resistance, whereas in a less trafficked room, cold welding may be sufficient.

Q 21. Explain your experience working with different patterns and designs in vinyl flooring.

I have extensive experience working with a wide range of vinyl flooring patterns and designs, from classic wood and stone imitations to abstract and contemporary styles. Understanding the pattern repeat and matching the design precisely is crucial for a professional finish. This involves careful planning, accurate measuring, and precise cutting. Working with large-scale patterns requires extra attention to ensure a smooth transition between sheets, avoiding any misalignment.

One memorable project involved installing a complex geometric pattern in a high-end residential setting. The pattern required careful planning to manage the pattern repeats. This project demonstrated that accurate planning and attention to detail are critical in achieving an excellent result. Careful consideration of the lighting in the room also influences the perception of the patterns and is important in advising clients on pattern choices.

Q 22. How do you handle customer complaints or concerns?

Handling customer complaints starts with active listening and empathy. I always aim to understand their concerns fully before offering solutions. I believe in transparent communication; I explain the situation clearly, outlining potential causes and solutions. For instance, if a customer is unhappy with the color match, I’ll explain the inherent variations in natural materials like linoleum or the potential for slight discrepancies between samples and the installed flooring. I then work collaboratively to find a resolution, whether it’s a replacement, repair, or adjustment in pricing. If the issue is a result of a mistake on my part, I take full responsibility and rectify it promptly. Documentation is key; I maintain detailed records of the complaint, the proposed solution, and the final outcome to ensure accountability and prevent future issues.

For example, on a recent project, a customer complained about some minor bubbling in their newly installed vinyl flooring. After investigating, I discovered a moisture issue beneath the subfloor, which was not detected during the initial assessment. I explained the situation, outlined the steps needed for remediation (including addressing the moisture problem), and worked with them to create a revised timeline. Open communication and a commitment to finding a fair solution resulted in a positive outcome, despite the initial setback.

Q 23. Describe your experience working on large-scale flooring projects.

I have extensive experience in large-scale flooring projects, ranging from commercial office spaces to entire apartment complexes. My expertise spans project management, including coordinating with multiple subcontractors (e.g., electricians for underfloor heating, plumbers for moisture mitigation), managing material procurement and logistics, and ensuring projects are completed on time and within budget. I’m adept at reading and interpreting blueprints, scheduling the work efficiently, and overseeing the installation process to ensure quality control. For instance, on a recent project renovating a large office building, I managed a team of five installers, overseeing the seamless installation of over 5,000 square feet of commercial-grade vinyl flooring across various rooms and hallways. This involved meticulous planning to minimize disruption during office hours, coordinating deliveries, and managing the disposal of waste materials responsibly.

My experience extends to managing the complexities involved in large projects, such as ensuring proper acclimation of materials to prevent expansion or contraction issues, coordinating with building management for access and permits, and addressing unexpected site conditions. For instance, discovering a hidden plumbing leak during demolition required immediate action, careful coordination with plumbers, and a revised project timeline – demonstrating my ability to handle unforeseen circumstances effectively.

Q 24. How do you manage your time effectively on a flooring installation project?

Effective time management on flooring projects involves meticulous planning and execution. My approach begins with a detailed project timeline, breaking down the work into manageable tasks with assigned deadlines. This timeline considers factors such as material delivery, subfloor preparation, installation, and cleanup. I use project management software to track progress, manage resources, and identify potential delays. I prioritize tasks based on their dependencies and critical path, ensuring that essential steps are completed on time to avoid bottlenecks. Regular communication with the client and subcontractors keeps everyone informed and aligned. Daily updates allow for quick problem-solving and prevent small issues from escalating. For example, I allocate specific time slots for material cutting and installation, ensuring sufficient time for each phase without rushing. This approach maintains high-quality work while adhering to the schedule.

Furthermore, contingency plans for unforeseen delays (e.g., material shortages, equipment malfunctions) are crucial. Having backup plans helps maintain the project schedule and minimizes disruptions. This proactive approach ensures that projects are completed efficiently and on time, even in the face of unexpected challenges.

Q 25. Explain your process for ensuring a clean and organized worksite.

Maintaining a clean and organized worksite is not only crucial for safety but also demonstrates professionalism and respect for the client’s property. My process starts with thorough preparation. Before starting any work, I cover furniture and other items that may be affected. A designated area is set aside for waste materials, ensuring proper disposal methods. Throughout the installation, I regularly clean up debris and excess materials, ensuring the work area remains organized. Proper tool storage and management further enhance workplace safety and efficiency. For instance, I use designated bins for different types of waste (e.g., cardboard, plastic, hazardous materials) adhering to local recycling regulations.

Protective measures are implemented to minimize damage to existing surfaces and features. This includes using floor protectors, masking tape, and drop cloths where needed. At the end of each workday, the site is left clean and orderly, minimizing disruption to the client. Following such meticulous procedures reduces the chance of accidents, maintains a professional image, and leaves a positive impression on the client.

Q 26. How do you stay up-to-date with the latest trends and technologies in flooring?

Staying current in the flooring industry is paramount. I achieve this through a multi-pronged approach. I regularly attend industry trade shows and conferences, such as Surfaces and The International Surface Event, to learn about new products, installation techniques, and design trends. I subscribe to industry publications and online resources, staying informed about the latest technological advancements in flooring materials and installation equipment. Networking with other professionals, including installers, manufacturers, and designers, provides invaluable insights and perspectives. I’m also an active member of professional organizations like the Floor Covering Installation Contractors Association (FCICA), which provides access to training and industry best practices.

Specifically, I’m always exploring new materials, such as sustainable and eco-friendly options in linoleum and vinyl, or innovative click-lock installation systems which improve efficiency and reduce installation time. Continuous learning allows me to offer clients the best and most current options available.

Q 27. What is your experience with estimating flooring installation costs?

Accurate cost estimation is vital for project success. My approach involves a thorough site survey to accurately assess the area to be covered, identify any existing conditions that could impact the installation (e.g., subfloor unevenness, moisture issues), and account for material waste. I use specialized software to create detailed estimates, considering factors such as material costs, labor costs, permits, and disposal fees. I obtain multiple quotes for materials to ensure competitive pricing. The estimate clearly outlines all costs and payment schedules, providing transparency and preventing misunderstandings.

For instance, I factor in the square footage, type of flooring (linoleum vs. vinyl, luxury vinyl plank etc.), the complexity of the installation (e.g., intricate patterns, transitions between different flooring types), and the labor hours required. I provide clients with a detailed breakdown of these costs allowing them to make informed decisions. Accurate estimating protects both the client and myself, avoiding costly surprises down the line.

Q 28. How do you deal with unexpected challenges or problems during a job?

Unexpected challenges are inevitable in any flooring project. My approach involves proactive problem-solving and careful planning. When unforeseen problems arise, my first step is to assess the situation thoroughly. This includes identifying the cause of the problem, assessing the impact on the project timeline and budget, and exploring all possible solutions. I always communicate transparently with the client, explaining the issue and the proposed solutions. Collaboration is key – working with the client, subcontractors, or suppliers to find the best solution while minimizing disruption is essential. Documenting the problem, solutions, and any additional costs involved maintains accountability and protects both parties involved.

For example, if I discover unexpected damage to the subfloor during demolition, I’ll immediately inform the client, document the damage, and explore solutions such as subfloor repair or replacement, adjusting the timeline and budget accordingly. My experience helps me anticipate and mitigate potential problems, but when unforeseen circumstances arise, my focus remains on transparent communication, collaborative problem-solving, and ensuring the project’s successful completion.

Key Topics to Learn for Linoleum and Vinyl Flooring Interviews

- Material Properties: Understanding the composition, durability, and maintenance requirements of both linoleum and vinyl flooring. This includes knowing the differences between various types (e.g., sheet vinyl, luxury vinyl plank, inlaid linoleum).

- Installation Techniques: Familiarize yourself with proper subfloor preparation, adhesive selection, and installation methods for both materials. Consider the nuances of working with different flooring patterns and transitions.

- Maintenance and Repair: Learn common issues like seams separation, scratches, and water damage. Understand how to perform basic repairs and recommend preventative maintenance strategies to clients.

- Safety Procedures: Understand and adhere to workplace safety regulations, including the proper handling of tools and materials, and the use of personal protective equipment (PPE).

- Estimating and Budgeting: Practice calculating material needs, labor costs, and providing accurate estimates to clients. Understanding profit margins and potential cost overruns is crucial.

- Customer Service and Communication: Develop strong communication skills to effectively interact with clients, address concerns, and manage expectations. This includes explaining technical aspects in a clear and concise manner.

- Industry Trends and New Technologies: Stay updated on the latest advancements in flooring materials, installation techniques, and sustainable practices. This demonstrates initiative and a commitment to professional development.

Next Steps

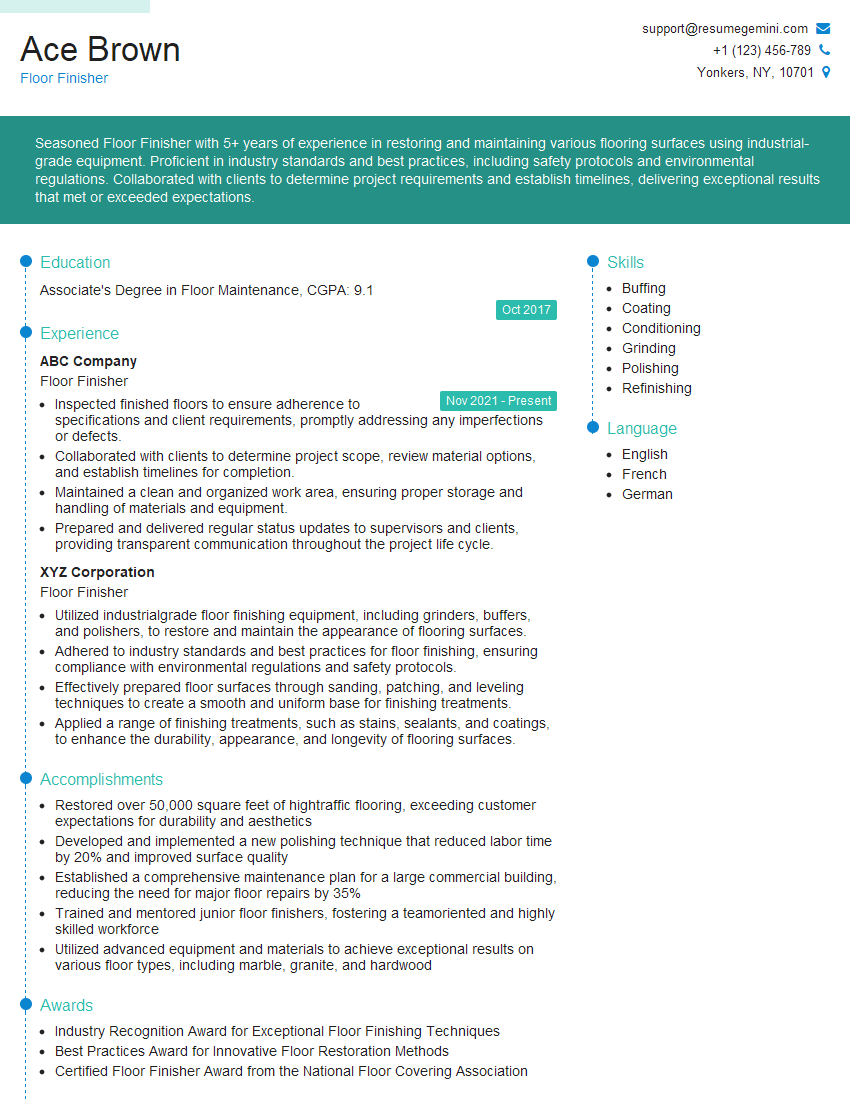

Mastering the intricacies of linoleum and vinyl flooring opens doors to a rewarding career with excellent growth potential. The ability to install, maintain, and troubleshoot these materials is highly valued in the construction and renovation industries. To maximize your job prospects, create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume designed to get noticed. We provide examples of resumes tailored specifically to the Linoleum and vinyl flooring industry to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.