Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Use of Power and Hand Tools for Wallcovering Installation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Use of Power and Hand Tools for Wallcovering Installation Interview

Q 1. What types of power tools are commonly used in wallcovering installation?

While many wallcovering installations rely heavily on hand tools, certain power tools significantly improve efficiency and precision. The most common are:

- Seam Roller: A powered roller ensures consistent pressure along seams, preventing air bubbles and creating a smoother finish. Think of it like a really efficient clothes iron for wallpaper. I’ve found that the consistent pressure prevents those annoying little bumps that can spoil an otherwise perfect job.

- Scoring Tool (optional, but helpful): Some installers use a powered scoring tool to lightly score the back of heavy wallpaper, helping it conform to uneven walls. This prevents tearing and assists with difficult patterns.

- Utility Knife (with safety precautions): While not strictly a power tool, a sharp utility knife with a retractable blade greatly aids in trimming excess wallpaper precisely, particularly around outlets and difficult corners. Using a power-assisted knife in this context can be dangerous and often results in mistakes, a sharp manual knife, on the other hand, allows for control and accuracy.

It’s crucial to remember that safety always comes first when using any power tool. Always follow manufacturer’s instructions and wear appropriate safety gear.

Q 2. Describe your experience with different types of wallpaper paste and their application.

My experience encompasses a wide range of wallpaper pastes, each suited to different wallpaper types and project demands. Choosing the correct paste is crucial for achieving a professional finish.

- Pre-mixed Pastes: These are convenient for smaller jobs and less experienced installers. They require minimal preparation and reduce the risk of incorrect mixing ratios. However, they tend to have a shorter working time, so you must work quickly.

- Powdered Pastes: These offer better adhesion, longer working time, and better value for larger projects. Mixing the paste precisely is essential; I always follow the manufacturer’s instructions carefully to avoid issues. A slightly incorrect mix can lead to a sticky mess or inadequate adhesion.

- Specialty Pastes: Specific pastes are designed for particular wallpaper types – like heavy vinyl, fabric, or grasscloth – each requiring a specific adhesive for best results. For example, a heavy-duty paste is essential for grasscloth, while a clear paste is sometimes needed to avoid discoloration of lighter-colored wallpapers.

Application is generally the same – applying the paste evenly to either the back of the wallpaper or to the wall, depending on the manufacturer’s instructions. Always use a paste brush or roller to achieve even coverage. The right tools combined with the right knowledge makes all the difference.

Q 3. How do you prepare a wall surface for wallpaper installation?

Proper wall preparation is the foundation of a successful wallpaper installation. Neglecting this step often leads to problems down the line. My process involves these key steps:

- Clean the surface: Thoroughly clean the walls to remove dust, dirt, grease, and any loose paint or plaster. A sugar soap solution is often excellent for this, followed by a clean rinse. You don’t want anything interfering with the adhesive.

- Repair imperfections: Fill any holes or cracks using spackle or drywall compound, sanding smooth once dry. This ensures a smooth, even surface for the wallpaper to adhere to.

- Prime the walls (if necessary): If the wall is painted with a glossy finish, a primer is necessary to create a surface for the wallpaper to stick to properly. This increases the durability and longevity of the job.

- Check for moisture: It’s crucial to check for any signs of dampness or moisture. Installing wallpaper on a damp wall could cause peeling or mildew.

I always allow sufficient drying time between each step, ensuring that the surface is completely dry before moving to the next.

Q 4. Explain the process of measuring and cutting wallpaper accurately.

Accurate measuring and cutting are critical for a professional-looking finish. I always follow these steps:

- Measure the wall height and width: I always measure multiple times to ensure accuracy. Walls are seldom perfectly straight, so I measure in several places to account for irregularities.

- Calculate the number of strips needed: Consider pattern repeats and waste. It’s always better to have a little extra, it’s very difficult to seamlessly match patterns if you are short.

- Add seam allowance: Add extra length to each strip to allow for matching patterns and trimming, usually around 2-4 inches. This creates room for pattern matching and trimming.

- Cut the wallpaper: Using a sharp utility knife and a metal straightedge, cut each strip precisely to the calculated length. I always double-check my measurements before cutting.

- Match the pattern (if applicable): For patterned wallpapers, carefully match the pattern across each strip before hanging, overlapping strips for pattern alignment. This step takes patience and accuracy.

Precise measuring and cutting avoids wasted materials and ensures the job looks flawless.

Q 5. What safety precautions do you take when using power tools for wallcovering?

Safety is paramount when using power tools. My safety precautions include:

- Eye protection: I always wear safety glasses or goggles to protect my eyes from flying debris.

- Hearing protection: When using power tools, I wear earplugs or earmuffs to protect my hearing.

- Proper ventilation: Ensure adequate ventilation when working with adhesives to avoid inhaling fumes.

- Sharp blades: A dull blade is more dangerous than a sharp one – always use a sharp blade, ensuring it is properly secured in the tool.

- Proper tool maintenance: Regular maintenance ensures that tools function correctly, reducing the risk of accidents. I always check for any damage before use.

- Appropriate clothing: Wear close-fitting clothing to avoid snagging on tools or equipment.

I always follow the manufacturer’s safety instructions carefully and ensure I have a clear and safe workspace.

Q 6. How do you handle challenging wall surfaces, such as textured walls or corners?

Challenging wall surfaces require extra care and attention to detail. My approach to textured walls and corners involves:

- Textured Walls: For textured walls, I may need to use a powered seam roller to ensure proper adhesion and avoid air bubbles in the wallpaper. Sometimes, a paste designed for textured surfaces is necessary. The key is to work slowly and carefully, ensuring the wallpaper conforms to all the textures. Think of it like sculpting – you need to carefully work the wallpaper to fit the surface.

- Corners: Corners require precision. I carefully measure and cut the wallpaper, making small cuts around light switches and outlets. I always overlap the wallpaper slightly, creating a clean, sharp finish. If wallpaper is not carefully scored and trimmed in corners, the paper will bubble and crease.

Patience and attention to detail are crucial when working with challenging surfaces, and a little pre-planning goes a long way.

Q 7. Describe your experience with different types of wallpaper materials (e.g., vinyl, fabric, grasscloth).

My experience includes working with various wallpaper materials, each presenting unique challenges and advantages:

- Vinyl: Vinyl is durable, easy to clean, and relatively inexpensive. It’s a popular choice for high-traffic areas. However, it can be more challenging to work with if not prepared correctly.

- Fabric: Fabric wallpapers add a touch of elegance and texture. They are more delicate than vinyl and require extra care during installation. A specialty paste is normally needed and you often need to ensure the fabric is correctly aligned prior to applying the paste to avoid unsightly creasing.

- Grasscloth: Grasscloth wallpapers are made from natural fibers and offer a unique, organic look. They are very durable but can be expensive and difficult to install due to their texture and weight. A heavy-duty paste is a must and you often need to employ careful scoring to ensure the paper conforms to the wall without tearing. Sometimes, a textured wall is less troublesome than a perfectly smooth one, given the weight and composition.

Understanding the properties of each material and choosing the appropriate paste and installation techniques are crucial for a successful outcome. I always thoroughly research the material before starting the job to minimise waste and guarantee a professional result.

Q 8. How do you match patterns when installing wallpaper?

Matching wallpaper patterns is crucial for a professional finish. It involves carefully aligning the repeating design elements on adjacent strips. This process depends heavily on the type of pattern.

- Straight Match: The easiest type, where the pattern repeats directly from one strip to the next. Simply align the edges.

- Drop Match: The pattern aligns vertically but requires a slight offset from one strip to the next. Measuring the drop repeat, often indicated on the wallpaper roll label, is critical. For example, a ‘6-inch drop match’ means the pattern aligns 6 inches down on the next strip.

- Random Match: These patterns don’t have a defined repeat, making installation much simpler. No precise alignment is needed.

Practical Tip: Always unroll several strips before starting, laying them out on a flat surface to visually check the pattern alignment and make any necessary adjustments. This prevents frustrating mismatches mid-installation.

Q 9. What are some common problems encountered during wallcovering installation and how do you solve them?

Wallcovering installation presents various challenges. Some common problems include:

- Uneven Walls: Imperfect walls can lead to bubbling or wrinkling. Preparation is key. Use joint compound to smooth out major imperfections and prime the walls for better adhesion.

- Incorrect Paste Application: Too much or too little paste can lead to slippage or weak bonds. Always follow the manufacturer’s instructions on paste type and application technique.

- Air Bubbles: These often result from inadequate smoothing or trapped air during installation. Use a smoothing tool and a seam roller to carefully eliminate air pockets.

- Seams Not Aligning: Precise measuring and careful pattern matching are essential to avoid misaligned seams.

- Wallpaper Stretching: Improper handling or not allowing the wallpaper to relax after pasting can cause stretching and unevenness.

Solution Strategy: Always thoroughly prepare the wall surface, use the correct adhesive, pay meticulous attention to pattern matching, and carefully smooth out any air bubbles or wrinkles during installation. Pre-measuring and planning are vital to avoid most of these problems.

Q 10. What is your experience with different types of seam rollers and their use?

Seam rollers are essential tools for creating smooth, invisible seams. Different types are available, each with its own purpose:

- Standard Seam Rollers: These are typically made of hard plastic or rubber and are used to press the edges of adjacent strips together, expelling any air and ensuring a tight bond. I generally start with a standard roller to remove most air bubbles, working from the center outward.

- Soft Seam Rollers: These have a softer material, often felt or fabric covered, ideal for delicate wallpapers or textured surfaces to avoid damage. I use these after the initial smoothing with a standard roller, especially on delicate materials.

- Specialty Seam Rollers: Some rollers have specialized features, like serrated edges, designed to help work out wrinkles or textured patterns more effectively. These are best suited for specific wallpaper types and are less common in everyday use.

Example: When installing vinyl wallpaper, I’ll initially use a standard seam roller and then carefully follow up with a soft roller to ensure a perfectly smooth and even seam without damaging the material.

Q 11. Explain the process of removing old wallpaper.

Removing old wallpaper can be laborious, depending on the type and the condition of the wallpaper. The steps are as follows:

- Score the Wallpaper: Use a scoring tool to make small slits in the wallpaper’s surface. This helps the removal solution penetrate.

- Apply a Removal Solution: Use a wallpaper removal solution or a solution of hot water and fabric softener. Allow ample time for the solution to soak into the wallpaper.

- Scrape the Wallpaper: Use a scraper, plastic putty knife, or a wallpaper steamer (for stubborn cases) to carefully peel away the loosened wallpaper. Work in small sections to avoid tearing.

- Clean the Wall: Once the wallpaper is removed, thoroughly clean the wall to remove any remaining adhesive residue. This is crucial for a proper bond for new wallpaper. You may need a cleaning solution specifically designed for this purpose.

Important Note: Always wear appropriate safety gear, including gloves and eye protection, when removing wallpaper.

Q 12. How do you clean up after a wallcovering installation job?

Cleaning up after a wallcovering job is critical for both safety and professional presentation. Here’s my process:

- Dispose of Waste Properly: Gather all scraps of wallpaper and packaging material, ensuring responsible disposal according to local regulations.

- Clean Up Spills and Excess Adhesive: Use damp cloths to wipe up any excess adhesive or paste that may have spilled onto the floor or other surfaces.

- Vacuum Thoroughly: Vacuum the area to remove any lingering dust, debris, or loose pieces of wallpaper.

- Inspect and Re-Clean: Inspect the work area for any remaining messes, and repeat the cleaning process as needed to ensure a spotless finish.

Professional Tip: Using drop cloths protects the floor and simplifies cleanup.

Q 13. Describe your experience with using a seam sealant or sizing.

Seam sealants and sizing play crucial roles in achieving professional results.

- Seam Sealant: This product is applied to the seams after installing the wallpaper, creating a water-resistant barrier and enhancing the durability of the installation. It’s particularly important with vinyl wallpapers. This helps prevent water damage and ensures seams stay strong over time.

- Sizing: Sizing is a preparatory treatment applied to the wall before hanging wallpaper. It acts as an adhesive primer, improving the wallpaper’s adhesion and helping it to sit more smoothly on the wall. It also helps create a uniform surface and prevents the absorption of paste by the wall, resulting in a better finished product.

Example: I regularly use seam sealant on all vinyl wallpaper installations, particularly in bathrooms and kitchens. For porous or absorbent walls, I will always pre-size the walls.

Q 14. What is your preferred method for cutting wallpaper around outlets and switches?

My preferred method for cutting wallpaper around outlets and switches involves precision and careful measurement. I usually:

- Score and Cut: I use a utility knife with a sharp blade to carefully score the wallpaper directly over the edge of the outlet or switch plate. I then carefully cut through the wallpaper along this scored line.

- Remove Excess Wallpaper: After scoring, I carefully peel away the excess wallpaper, leaving a clean edge around the plate.

- Tuck the Wallpaper Edges: The remaining edges of the wallpaper are neatly tucked beneath the edge of the outlet cover plate. This hides the cuts and gives a clean, professional look. If the cut is imperfect, it is hidden.

- Use a Utility Knife: A sharp utility knife is critical to achieve a neat cut.

Important: Always ensure the power is switched off before working near electrical outlets or switches.

Q 15. How do you ensure proper ventilation when using adhesive?

Proper ventilation is crucial when working with wallpaper adhesive, as many adhesives release volatile organic compounds (VOCs) that can be harmful if inhaled in poorly ventilated areas. These VOCs can cause headaches, dizziness, and respiratory irritation. To ensure proper ventilation, I always start by opening windows and doors to create a cross-breeze. If this isn’t enough, I’ll use fans to circulate the air and actively draw out fumes. For larger jobs or those in spaces with limited natural ventilation, I would use industrial-grade air purifiers equipped with HEPA filters to remove the VOCs. In some extreme cases, depending on the adhesive type, I even consider using respirators with appropriate cartridges for added protection. Think of it like painting a room; you wouldn’t dream of doing it in a sealed environment. The same logic applies to wallpaper installation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of hand tools used for wallcovering installation?

A variety of hand tools are essential for precise and efficient wallpaper installation. These include:

- Measuring Tape and Pencil: For accurate measurements and marking.

- Utility Knife/Razor Blade: For trimming excess wallpaper precisely and cleanly, crucial for sharp corners and intricate designs.

- Seam Roller: This tool ensures proper adhesion at the seams, eliminating air bubbles and ensuring a smooth, professional finish. I always use a seam roller with a soft, durable rubber to avoid damaging the wallpaper surface.

- Smoothing Brush or Plastic Smoothing Tool: These help to smooth out the wallpaper and remove any air pockets or wrinkles during application. A soft brush is better for delicate papers to prevent tearing.

- Putty Knife or Scraping Tool: Used for removing old wallpaper, loose paint or imperfections from the wall surface before installing new wallpaper.

- Scissors: For cutting smaller pieces of wallpaper or trimming around outlets and switches.

- Level: Ensuring the wallpaper is perfectly aligned is critical for a professional look; a level helps achieve this.

- Sponges/Damp cloths: To wipe off excess adhesive or clean up spills.

These tools, combined with proper techniques, ensure a high-quality installation.

Q 17. How do you maintain your power and hand tools?

Maintaining my power and hand tools is paramount for both safety and longevity. For power tools like a wallpaper steamer (if used), I meticulously follow the manufacturer’s instructions for cleaning and storage. This typically involves emptying the water tank, cleaning the exterior, and storing it in a dry location. For hand tools, regular cleaning and sharpening are key. I wipe down blades and rollers after each use to remove adhesive residue. Utility knives get their blades replaced as needed to maintain sharpness and prevent accidents. Seam rollers should be inspected for wear and tear. I keep all my tools organized and stored in a dedicated toolbox, protecting them from damage and ensuring quick access.

Q 18. What is your experience working from ladders or scaffolding?

I have extensive experience working from ladders and scaffolding, always prioritizing safety. Before commencing any work at height, I meticulously inspect the equipment. This includes checking the stability of the ladder, ensuring proper placement, and verifying that the scaffolding is securely assembled and level. I always use the appropriate safety equipment – a harness, for example, when working at significant heights above ground – and always have a spotter if possible. I understand the limitations of the equipment and my own physical capabilities, and I always adhere to all safety regulations and industry best practices. Working from heights requires meticulous attention to detail and a commitment to safety; a fall can have devastating consequences.

Q 19. How do you determine the amount of wallpaper needed for a job?

Accurately determining the amount of wallpaper needed is crucial to avoid costly overruns or material shortages. I begin by carefully measuring the height and width of each wall, subtracting areas like doors and windows. I then calculate the total square footage. It’s crucial to account for pattern matching, especially with complex designs where significant waste can occur. I always add at least 10% extra to account for waste, miscuts and matching patterns. For complex designs, I may even add 20% to be on the safe side. I also factor in the width of the rolls to determine the number of strips needed to minimize waste from pattern matching. I double check my calculations to avoid mistakes and confirm the required number of rolls with the client before ordering.

Q 20. Explain the importance of proper surface preparation in wallcovering installation.

Proper surface preparation is the cornerstone of any successful wallcovering installation. A poorly prepared surface will lead to a sub-standard finish, wallpaper peeling, and ultimately, client dissatisfaction. My preparation process involves several key steps: first, I thoroughly clean the walls to remove dirt, dust, and loose paint. Any imperfections, cracks, or holes are filled and sanded smooth. Old wallpaper must be completely removed. Finally, I prime the walls to ensure a consistent surface for adhesion, especially important with textured walls. This meticulous approach ensures that the wallpaper adheres properly and creates a flawless, long-lasting installation. Think of it like preparing a canvas before painting; a smooth, clean surface guarantees a masterpiece.

Q 21. Describe a time you had to troubleshoot a problem during a wallcovering installation.

During a recent installation of a textured wallpaper, I encountered a problem with consistent adhesion in one area of the wall. Despite careful preparation and application, the wallpaper kept lifting in a specific section. Initially, I suspected a problem with the adhesive, but after closer inspection, I discovered that a previous layer of paint wasn’t properly bonded to the wall, creating a slightly uneven surface. My troubleshooting strategy involved carefully removing the affected section of wallpaper. I then applied a bonding agent to the poorly adhered area of the wall to improve its surface quality and create a secure base for the wallpaper. After allowing the bonding agent to dry, I reapplied the wallpaper and the problem was resolved, resulting in a perfect finish. This experience reinforced the importance of thorough surface preparation and adaptable problem-solving skills in wallcovering installations.

Q 22. How do you handle difficult clients or unexpected challenges?

Handling difficult clients requires patience, clear communication, and a problem-solving approach. I start by actively listening to their concerns, validating their feelings, and then focusing on finding solutions. For instance, if a client is unhappy with the color, I’ll explain the selection process, review the samples together, and explore options like adding accent walls or suggesting complementary trims. Unexpected challenges, such as discovering damaged walls during prep work, require immediate adaptation. I would assess the damage, inform the client transparently, propose solutions (like wall repair before installation), and adjust the timeline accordingly to ensure the project remains on track. My proactive communication and commitment to finding mutually agreeable solutions helps de-escalate tensions and maintains a positive working relationship.

Q 23. What is your understanding of industry best practices for wallcovering installation?

Industry best practices in wallcovering installation emphasize precision, quality, and durability. This begins with proper surface preparation – ensuring the walls are clean, smooth, and free of imperfections. Accurate measurements are crucial to minimize waste and ensure a seamless installation. Using the correct adhesive for the specific wallpaper type is paramount; using the wrong adhesive can lead to peeling, bubbling, or other defects. Proper seam matching and careful pattern alignment are essential for a professional finish. Finally, adhering to manufacturer’s recommendations for the wallpaper and adhesive is key, as well as using appropriate tools and techniques, such as proper cutting and trimming. This meticulous approach guarantees a long-lasting, aesthetically pleasing result.

Q 24. What are the different types of wallpaper seams and how are they created?

There are several types of wallpaper seams, each created with a different technique. A butt seam is the most straightforward, where the edges of adjacent strips are simply butted together. This requires precise cutting and matching. A straight match involves aligning the pattern directly, while a drop match requires a vertical offset between adjacent strips to align the pattern. A half-drop match involves offsetting the pattern by half the repeat length. The creation process involves precisely cutting the wallpaper strips to length, applying adhesive according to the manufacturer’s instructions, carefully aligning the edges, and pressing firmly to ensure proper adhesion and prevent gaps. The type of seam used depends on the wallpaper pattern and the desired visual effect.

Q 25. Describe your experience with various wallcovering installation techniques.

My experience encompasses various techniques, from traditional paste-the-paper methods to more modern paste-the-wall techniques. I am proficient in installing various types of wallpaper, including vinyl, fabric-backed vinyl, grasscloth, and textured wallpapers. I’ve worked with different patterns and materials, ranging from simple solids to complex, intricate designs, requiring precise pattern matching and meticulous seam alignment. I’m comfortable working with both large and small spaces, as well as tackling challenging areas like corners, windows, and doors. I regularly employ techniques for handling curves and unusual shapes to ensure a seamless, professional finish, always paying close attention to detail to ensure a high-quality installation.

Q 26. How do you ensure the longevity and durability of a wallcovering installation?

Ensuring the longevity and durability of a wallcovering installation begins with thorough surface preparation. Properly cleaning and repairing wall imperfections prevents future issues. Using the correct adhesive and following the manufacturer’s instructions are crucial. Proper seam alignment and pressure during installation prevents peeling and bubbling. Finally, avoiding excessive moisture and heat can help maintain its structural integrity. I always advise clients on appropriate cleaning methods and avoid abrasive cleaners to prevent damage. In my experience, careful attention to these details translates to a long-lasting, visually appealing installation that stands the test of time.

Q 27. What types of adhesives are suitable for different types of wallpaper?

The choice of adhesive depends heavily on the type of wallpaper. Heavier wallpapers, such as grasscloth or textured vinyl, require stronger, more powerful adhesives. Lighter wallpapers, like vinyl or non-woven, can often use a lighter-duty adhesive. Pre-pasted wallpapers already have adhesive applied; only requiring activation with water. It’s essential to read the manufacturer’s recommendations for both the wallpaper and the adhesive to ensure compatibility and optimal performance. Using the wrong adhesive can lead to poor adhesion, peeling, bubbling, or even damage to the wallpaper itself. I always check the manufacturer’s specifications before starting any project.

Q 28. Are you familiar with different types of wallpaper borders and their installation?

Yes, I am familiar with various wallpaper borders and their installation. Borders come in numerous materials, patterns, and widths. Installation involves measuring and cutting the border to the correct length, applying adhesive to the back (depending on the type), and carefully placing it along the designated area. Precise alignment and smooth application are crucial to avoid gaps or wrinkles. Similar to wallpaper installation, proper surface preparation is essential for a clean and secure bond. I frequently incorporate borders into projects to enhance the overall aesthetic appeal, adding a decorative element that complements the main wallpaper.

Key Topics to Learn for Use of Power and Hand Tools for Wallcovering Installation Interview

- Tool Selection and Maintenance: Understanding the appropriate tools for different wallcovering materials (e.g., vinyl, fabric, wallpaper paste) and their proper maintenance for optimal performance and safety. This includes knowing when to replace worn parts or blades.

- Measuring and Cutting Techniques: Mastering precise measuring and cutting techniques to minimize waste and ensure clean, professional seams. This includes understanding pattern matching and adjusting for wall irregularities.

- Paste Application Methods: Proficiency in various paste application techniques, including the use of pasting tables, brushes, rollers, and spray systems for different wallpaper types. Understanding the importance of even paste distribution for proper adhesion.

- Hanging Techniques: Understanding and demonstrating proficiency in various hanging techniques to ensure proper alignment, avoid bubbling, and achieve a smooth, professional finish. This includes working with different types of seams and edges.

- Seam Finishing and Trimming: Knowing how to expertly finish seams and trim excess material precisely and cleanly, creating a seamless and polished final product. Understanding the use of specialized tools for trimming and cleaning up excess adhesive.

- Safety Procedures and Precautions: Demonstrating a thorough understanding of safety procedures related to power tool operation, including proper handling, maintenance, and the use of personal protective equipment (PPE). This includes knowledge of emergency procedures in case of accidents.

- Troubleshooting Common Issues: Ability to identify and resolve common problems encountered during wallcovering installation, such as bubbling, peeling, and uneven seams. This includes understanding the causes of these issues and applying appropriate solutions.

- Understanding Different Wallcovering Materials: Knowledge of various wallcovering materials and their properties, including their suitability for different environments and applications. Understanding how to handle delicate materials and those requiring specialized techniques.

Next Steps

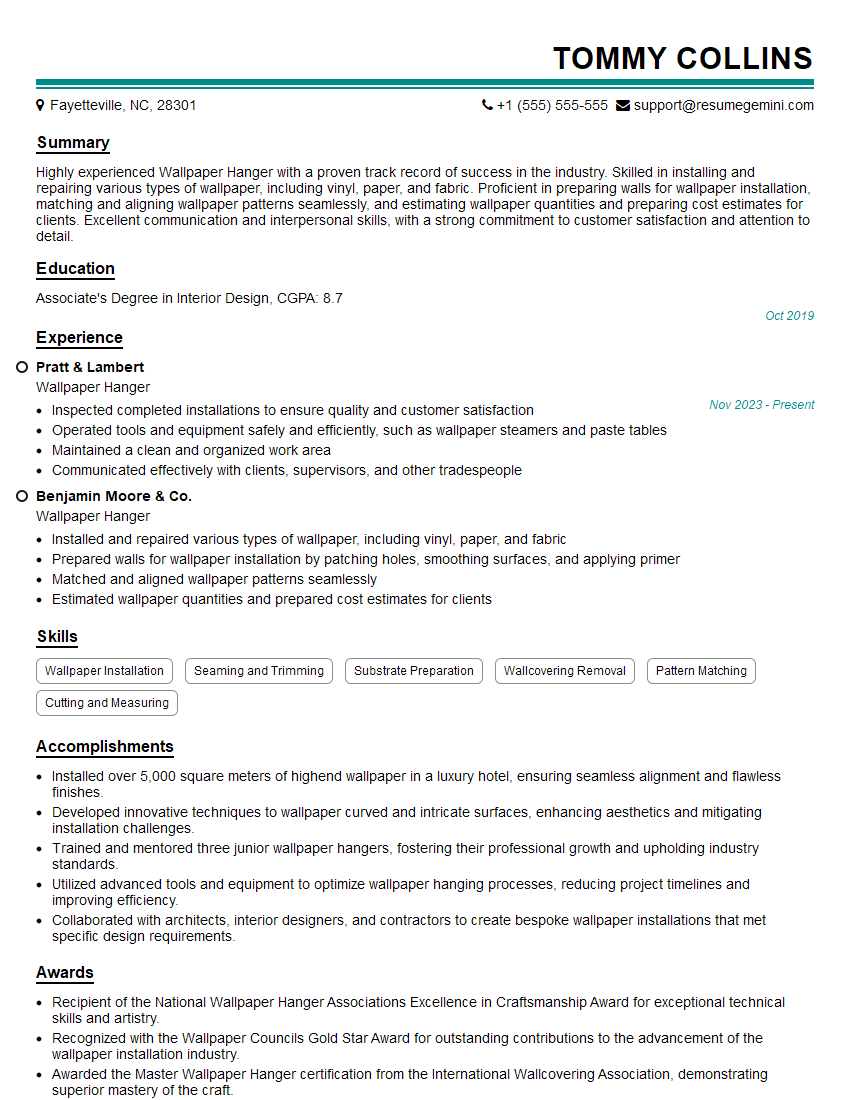

Mastering the use of power and hand tools for wallcovering installation is crucial for career advancement in the construction and interior design fields. It showcases your technical skills, attention to detail, and commitment to quality workmanship. To significantly boost your job prospects, focus on building a strong, ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume. They offer examples of resumes tailored to showcase expertise in Use of Power and Hand Tools for Wallcovering Installation, giving you a head start in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.