Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Biodiesel Process Control interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Biodiesel Process Control Interview

Q 1. Explain the transesterification process in biodiesel production.

Transesterification is the core chemical reaction in biodiesel production. It’s a process where triglycerides (the main component of vegetable oils and animal fats) react with an alcohol (typically methanol or ethanol) in the presence of a catalyst to produce fatty acid methyl esters (FAME) – which is biodiesel – and glycerol, a byproduct.

Imagine it like this: Triglycerides are like three-story buildings, each floor (fatty acid) connected to a central core (glycerol). The alcohol acts like a demolition crew, breaking down the connections between the fatty acid floors and the glycerol core. Each floor (fatty acid) then attaches to a smaller unit (methanol or ethanol) to form the new FAME building (biodiesel).

The reaction can be represented simply as:

Triglyceride + 3 Alcohol → 3 Fatty Acid Alkyl Esters + GlycerolThe efficiency of this reaction depends heavily on factors such as temperature, alcohol-to-oil ratio, catalyst type and concentration, and reaction time. Proper control of these parameters is crucial for high biodiesel yield and quality.

Q 2. Describe the role of catalysts in biodiesel synthesis.

Catalysts significantly accelerate the transesterification reaction without being consumed themselves. They lower the activation energy needed for the reaction to proceed, making it faster and more efficient at lower temperatures. Common catalysts include homogeneous catalysts (like sodium hydroxide or potassium hydroxide) and heterogeneous catalysts (like solid acid or base catalysts).

Homogeneous catalysts dissolve in the reaction mixture, offering high reactivity but making separation and purification more challenging. Heterogeneous catalysts, on the other hand, remain in a separate phase, simplifying the separation process. However, they often exhibit lower activity than homogeneous catalysts.

The choice of catalyst depends on several factors including the quality of the feedstock (especially FFA content), desired reaction conditions, and downstream processing considerations. For example, a feedstock with high FFA content might require a different catalyst than one with low FFA.

Q 3. What are the key parameters monitored in a biodiesel reactor?

Monitoring key parameters in a biodiesel reactor is critical for optimizing the process and ensuring product quality. These parameters include:

- Temperature: Maintaining the optimal temperature range is crucial for reaction kinetics and preventing side reactions. Too low, and the reaction will be slow; too high, and degradation or soap formation can occur.

- Pressure: While transesterification is usually carried out at atmospheric pressure, monitoring pressure can help detect leaks or equipment malfunction.

- Mixing Speed/Agitation: Effective mixing ensures proper contact between reactants and catalyst, promoting uniform reaction and preventing phase separation.

- Alcohol-to-Oil Ratio (Molar Ratio): This ratio directly affects the conversion efficiency. A stoichiometric ratio (typically 6:1) is usually targeted, but it can be adjusted based on the feedstock characteristics and desired product quality.

- Catalyst Concentration: The amount of catalyst used influences reaction rate and biodiesel quality. Too little catalyst results in slow reaction; too much can lead to soap formation or difficulties in separation.

- Methanol/Ethanol Content: Monitoring the alcohol concentration helps track reaction progress and adjust feed rates as needed.

- Glycerol Concentration: Tracking the formation of glycerol, a byproduct, indicates reaction progress and can be used to predict conversion.

Online sensors and automated control systems are often employed to monitor these parameters continuously and maintain them within the optimal ranges.

Q 4. How do you ensure the quality of raw materials used in biodiesel production?

Ensuring raw material quality is paramount in biodiesel production as it directly impacts the final product quality and yield. This involves several steps:

- Source Selection: Choosing reliable suppliers who provide consistent quality feedstock (vegetable oils, animal fats) is essential. The feedstock’s characteristics – like acidity, moisture content, and free fatty acid content – are crucial and should be specified in the purchase agreement.

- Pre-treatment: Raw materials may require pre-treatment steps like filtration, degumming, and neutralization to remove impurities like gums, phospholipids, and free fatty acids that can hinder the transesterification process or affect biodiesel quality.

- Quality Testing: Regular analysis of raw materials using standard methods (such as acid value determination, moisture content measurement, and free fatty acid analysis) helps ensure that the material meets the required specifications before entering the production process. Any deviation triggers remedial measures.

For example, high free fatty acid content necessitates pre-esterification or using a different catalyst, while high moisture content can lead to soap formation, reducing biodiesel yield and quality. Thorough testing and analysis prevent such problems.

Q 5. What are the common impurities found in biodiesel and how are they removed?

Common impurities in biodiesel include:

- Soap: Formed by reaction of free fatty acids with the catalyst, this impurity can cause problems with storage stability and engine performance.

- Glycerol: A natural byproduct of transesterification, excess glycerol needs to be removed to meet quality standards.

- Unreacted Triglycerides: Incomplete conversion of triglycerides to FAME leads to the presence of unreacted triglycerides.

- Catalyst Residues: Leftover catalyst can affect the quality and stability of the biodiesel.

- Water: Water can cause degradation and emulsion formation in biodiesel.

These impurities are typically removed through various methods like:

- Washing: Washing with water helps remove soap, glycerol, and catalyst residues.

- Centrifugation: This separates the biodiesel from the glycerol and other heavy phases.

- Filtration: Used to remove solid particles and remaining catalyst.

- Drying: This removes water from the biodiesel.

The specific purification method depends on the type and level of impurities present. For instance, biodiesel produced using a heterogeneous catalyst often requires less extensive purification compared to that produced using a homogeneous catalyst.

Q 6. Explain the significance of free fatty acid (FFA) content in biodiesel.

Free Fatty Acid (FFA) content is a critical parameter influencing biodiesel quality and the production process. High FFA content in the feedstock can cause several problems:

- Soap Formation: FFAs react with the base catalyst, forming soap, which reduces biodiesel yield and requires extensive purification.

- Reduced Transesterification Efficiency: High FFA content hinders the transesterification reaction, lowering the conversion rate.

- Poor Biodiesel Quality: High FFA levels in the final biodiesel product can lead to poor fuel properties, such as corrosion of engine parts and increased emissions.

Therefore, it is crucial to monitor and control the FFA content of both the raw materials and the final biodiesel. Feedstock with high FFA content may require pre-treatment steps, such as acidification or pre-esterification, before transesterification. The acceptable FFA level varies based on biodiesel standards (e.g., ASTM D6751).

Q 7. Describe different methods for biodiesel water removal.

Water removal from biodiesel is crucial for preventing degradation, oxidation, and microbial growth. Common methods include:

- Vacuum Drying: Reducing pressure lowers the boiling point of water, allowing its removal at lower temperatures, minimizing the risk of biodiesel degradation.

- Centrifugation: This separates water from biodiesel based on density differences. This method is effective if the water is present as a separate phase.

- Adsorption: Using desiccants (like molecular sieves or activated alumina) to absorb water molecules from the biodiesel is an efficient method.

- Distillation: While less commonly used for water removal due to the potential for biodiesel degradation, distillation can be effective for removing trace amounts of water.

The choice of method often depends on the amount of water present, the scale of the operation, and the overall cost-effectiveness. For example, vacuum drying is often preferred in larger-scale operations for its efficiency, while adsorption may be suitable for smaller-scale applications.

Q 8. Discuss the importance of process control in maintaining biodiesel quality.

Process control is paramount in biodiesel production because it directly impacts the final product’s quality, meeting stringent specifications for applications like fuel.

Think of it like baking a cake – precise control of ingredients and temperature ensures a perfect outcome. Similarly, in biodiesel production, factors like reaction temperature, mixing intensity, and reactant ratios must be precisely managed. Deviation from optimal conditions can lead to low yields, poor fuel properties (like high viscosity or free glycerin content), or even the formation of undesirable byproducts.

For example, maintaining the correct methanol-to-oil ratio is crucial. Too little methanol results in incomplete transesterification, leaving excess triglycerides and reducing yield. Too much methanol increases costs and creates waste disposal issues. Sophisticated control systems continuously monitor these parameters, adjusting inputs to maintain the ideal process conditions throughout the reaction and purification stages, resulting in high-quality, consistent biodiesel.

Q 9. How do you troubleshoot common problems encountered in biodiesel production?

Troubleshooting in biodiesel production often involves systematically investigating potential issues across different stages. A systematic approach is key. We’ll often start by reviewing the process parameters logged by the control system.

- Low Yield: This could stem from inadequate mixing, insufficient reaction time, low methanol-to-oil ratio, or catalyst deactivation. We would check the reactor’s impeller speed, reaction temperature profile, and catalyst activity.

- High Free Glycerin: This points to incomplete transesterification. We would analyze the reaction conditions (temperature, time, methanol-to-oil ratio) and potentially the catalyst quality. We might also examine the washing steps in the purification process to ensure efficient glycerin removal.

- High Viscosity: This could be due to incomplete removal of monoglycerides or diglycerides during purification. We’d carefully evaluate the washing and separation stages. Alternatively, improper handling of feedstock (oil quality) can lead to higher viscosity as well.

- Off-Spec Fuel Properties: If the biodiesel doesn’t meet industry standards (e.g., ASTM), we’d conduct detailed analysis of the final product, tracing back the deviation to specific processing steps.

In each case, detailed record-keeping, regular equipment maintenance, and comprehensive product analysis are crucial for accurate diagnosis and effective troubleshooting. We rely heavily on data logging and process analytical technology (PAT) to rapidly identify and address the root causes of these production problems.

Q 10. Explain the role of automation in modern biodiesel plants.

Automation plays a transformative role in modern biodiesel plants, enhancing efficiency, safety, and product consistency.

Automated systems manage critical parameters such as temperature, pressure, flow rates, and reactant ratios with precision far beyond manual control. This translates to higher yields, reduced waste, and improved product quality. Imagine the complexity of manually controlling a multi-stage process involving several reactors, pumps, and purification units – it’s simply not feasible on a large scale.

Specifically, automation includes:

- Supervisory Control and Data Acquisition (SCADA) systems: These provide a centralized platform for monitoring and controlling the entire process, displaying real-time data and alerting operators to deviations from setpoints.

- Programmable Logic Controllers (PLCs): These automate individual process steps, such as valve actuation, pump control, and temperature regulation.

- Advanced Process Control (APC) algorithms: These optimize process variables to maximize yield, minimize energy consumption, and maintain consistent product quality.

Beyond these, automated sampling systems and online analyzers provide real-time feedback, further optimizing the process and ensuring compliance with quality standards.

Q 11. Describe different types of biodiesel reactors and their applications.

Biodiesel reactors vary in design based on the specific process and production scale. The choice of reactor significantly impacts efficiency and product quality.

- Batch Reactors: These are relatively simple, suitable for smaller-scale production. They are easy to operate but less efficient for large volumes. The process is completed in a single batch before being transferred and cleaned.

- Continuous Stirred Tank Reactors (CSTRs): These provide continuous operation, ideal for large-scale production. They offer superior mixing and temperature control but require more complex control systems.

- Plug Flow Reactors (PFRs): These are used for specific processes where controlled residence time is important. They are less common in biodiesel production compared to batch or CSTRs. The reactants flow through a tube or pipe and are progressively converted.

The selection depends on factors like production capacity, desired throughput, capital investment, and the specific transesterification method employed.

Q 12. What are the safety protocols you follow in a biodiesel plant?

Safety in a biodiesel plant is paramount, given the flammability of the reactants and potential for hazardous byproducts.

Our safety protocols encompass several layers:

- Personal Protective Equipment (PPE): Mandatory use of safety glasses, gloves, lab coats, and respirators in all areas of the plant.

- Emergency Response Plan: Detailed procedures for handling spills, fires, and other emergencies, including regular drills and training for all personnel.

- Process Safety Management (PSM): Implementing engineering controls like explosion-proof equipment, emergency shut-off systems, and ventilation systems to minimize risks.

- Lockout/Tagout procedures: Strict protocols for isolating and de-energizing equipment during maintenance or repairs.

- Hazardous Waste Management: Proper handling, storage, and disposal of waste glycerin and other byproducts in compliance with environmental regulations.

Regular safety inspections and training are integral to maintaining a safe working environment. We follow all relevant OSHA regulations and often exceed them.

Q 13. How do you ensure environmental compliance in biodiesel production?

Environmental compliance is a critical aspect of biodiesel production. We actively minimize our environmental footprint throughout the entire process.

Our strategies include:

- Wastewater Treatment: Implementing advanced wastewater treatment systems to remove pollutants before discharge, adhering to all local and national effluent standards. We may use techniques like biological treatment and chemical oxidation.

- Air Emissions Control: Utilizing appropriate air pollution control devices to minimize emissions of volatile organic compounds (VOCs) and other pollutants. This might involve scrubbers or thermal oxidizers.

- Sustainable Feedstock Sourcing: Prioritizing the use of sustainable feedstocks, such as waste cooking oil or non-food crops, to reduce reliance on edible oils and minimize deforestation.

- Energy Efficiency: Optimizing energy consumption through process improvements and the use of energy-efficient equipment, reducing our carbon footprint.

- Glycerin Recovery and Utilization: Recovering and utilizing glycerin, a byproduct of biodiesel production, in other applications to reduce waste and generate additional revenue streams.

We regularly monitor our emissions and waste streams, ensuring our operations remain compliant with all relevant environmental regulations and our own sustainability goals.

Q 14. Explain the concept of biodiesel yield and how to optimize it.

Biodiesel yield refers to the amount of biodiesel produced per unit of feedstock (oil). Maximizing yield is crucial for economic viability.

Several factors influence yield, including:

- Feedstock Quality: High-quality feedstock with minimal impurities results in higher yields.

- Reaction Conditions: Optimizing temperature, reaction time, methanol-to-oil ratio, and catalyst concentration significantly affects the yield. For example, insufficient reaction time leads to lower yields.

- Catalyst Type and Concentration: The choice of catalyst and its concentration play a crucial role in the transesterification efficiency.

- Purification Process: Efficient separation and purification techniques maximize the recovery of biodiesel.

Yield optimization involves careful control of these factors, often employing statistical methods like Design of Experiments (DOE) to systematically investigate the impact of process variables. Continuous monitoring and data analysis are also crucial for identifying areas for improvement and achieving the maximum possible yield for a given feedstock.

Q 15. What are the different methods for analyzing biodiesel quality?

Biodiesel quality analysis is crucial for ensuring the fuel meets specifications and performs reliably. Several methods are employed, categorized broadly into physical and chemical analyses.

- Physical Properties: These include tests like viscosity (measured using a viscometer), density (using a hydrometer or pycnometer), cloud point (temperature at which waxes start to crystallize), and pour point (lowest temperature at which the biodiesel still flows). These parameters significantly impact fuel handling and engine performance.

- Chemical Properties: This is where we delve into the chemical composition. Acid value (amount of free fatty acids), which indicates the extent of esterification, is a key parameter, measured via titration. Water content, determined by Karl Fischer titration, affects stability and engine corrosion. The presence of glycerol, a byproduct of transesterification, is also analyzed. Finally, a critical test is the Fatty Acid Methyl Ester (FAME) profile, often determined using gas chromatography, which identifies the types and quantities of fatty acid methyl esters present. This reveals the feedstock source and potential impacts on fuel properties.

For instance, a high acid value suggests incomplete transesterification, requiring process adjustments. A high water content would indicate a need for improved drying processes, while an unusual FAME profile might signify contamination or unexpected feedstock composition.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with process control instrumentation in biodiesel production.

My experience encompasses a wide range of process control instrumentation in biodiesel production, from basic level measurement to advanced analytical techniques. I’ve worked extensively with:

- Level sensors: Ultrasonic, radar, and hydrostatic level sensors are crucial for monitoring raw material tanks, reaction vessels, and product storage. Precise level control prevents overflows and ensures optimal reaction conditions.

- Flow meters: Coriolis, turbine, and magnetic flow meters accurately measure the flow rates of feedstocks (oil, methanol, catalyst), allowing precise control over stoichiometry and reaction kinetics. Precise control is essential to optimize yield and reduce waste.

- Temperature sensors: Thermocouples and RTDs are vital for monitoring reaction temperature, crucial for efficient transesterification. Precise temperature control ensures optimal reaction kinetics and product quality.

- Pressure sensors: These are used to monitor the pressure within the reaction vessels and downstream processes, ensuring safe operation and efficient product transfer. High pressure can cause safety issues, whereas too low pressure can impact downstream processes.

- Analytical instrumentation: I’ve used online analyzers for parameters such as acid value, water content, and density, providing real-time feedback for process optimization and ensuring product quality consistently.

In one project, we improved the efficiency of a biodiesel plant by 15% by integrating real-time feedback from online acid value analyzers, allowing immediate adjustments to the process parameters.

Q 17. How do you interpret process data to identify areas for improvement?

Interpreting process data requires a systematic approach. I typically begin by visualizing the data using statistical process control (SPC) charts, identifying trends, and looking for deviations from the expected values.

For example, a sudden increase in acid value might indicate a problem with the feedstock quality or incomplete reaction. A decrease in yield could point to problems with reagent ratios, reaction temperature, or catalyst activity. An increase in water content could indicate a leak in the system or inefficient drying.

I then delve into the raw data, correlating different parameters to pinpoint the root cause. For instance, if an increase in acid value coincides with a drop in methanol flow rate, it suggests a problem with methanol metering.

Root cause analysis tools like Fishbone diagrams (Ishikawa diagrams) help to identify potential contributing factors, aiding in systematic troubleshooting and implementing corrective actions.

After identifying the problem area, I propose and implement changes, meticulously tracking the impact of these adjustments through continued monitoring and data analysis.

Q 18. Explain your experience with SCADA systems in a biodiesel plant.

My experience with SCADA (Supervisory Control and Data Acquisition) systems in biodiesel plants is extensive. I’ve worked with various SCADA platforms, overseeing their implementation, configuration, and maintenance.

SCADA systems provide a centralized platform for monitoring and controlling all aspects of the biodiesel production process. This includes visualizing process parameters (temperature, pressure, flow, levels), managing alarms, and generating reports.

In one project, we migrated from an outdated SCADA system to a more modern platform, improving data visualization, enhancing alarm management, and integrating advanced process control algorithms. This resulted in improved process efficiency and reduced downtime. A well-configured SCADA system is essential for operational efficiency and safety. It facilitates better decision-making, improved maintenance scheduling and quicker response to process upsets.

Q 19. Describe your experience with PLC programming in a biodiesel process environment.

My PLC programming experience in biodiesel process environments focuses primarily on implementing control logic for automating various unit operations. I’m proficient in several PLC programming languages, including ladder logic and structured text.

I’ve developed programs for controlling pumps, valves, and other actuators based on sensor readings and setpoints. For instance, a program I developed controls the flow rates of oil and methanol based on real-time measurements from flow meters, ensuring precise stoichiometric control during the transesterification reaction.

//Example Ladder Logic snippet (Illustrative): //Input: High Temperature (bool) //Output: Coolant Pump (bool) //IF High Temperature THEN Coolant Pump ELSE Coolant Pump OFF

My experience also includes integrating PLCs with SCADA systems, allowing remote monitoring and control of the process.

Q 20. How do you maintain and troubleshoot process control equipment?

Maintaining and troubleshooting process control equipment requires a proactive and systematic approach. This involves regular preventative maintenance, including sensor calibration, cleaning, and inspection of equipment, such as pumps, valves, and actuators.

When troubleshooting, I employ a structured approach, starting with a thorough review of the alarm logs and process data. This helps to identify patterns or anomalies indicative of the issue. I use diagnostic tools provided by the equipment manufacturers and check wiring diagrams to systematically check for faults.

For example, if a flow meter malfunctions, I would first check the power supply, then the sensor itself, followed by the signal wiring and finally, the PLC program that utilizes the meter readings. Loop testing – isolating sections to check each element in a control loop – is also essential. I also maintain detailed records of all maintenance activities and repairs, crucial for predictive maintenance planning.

Q 21. What is your experience with process optimization techniques in biodiesel production?

My experience with process optimization techniques in biodiesel production centers around improving efficiency, yield, and product quality. I’ve employed several techniques, including:

- Statistical Process Control (SPC): Using control charts to monitor process variables and identify areas for improvement. This helps in detecting subtle variations or shifts in process parameters that might otherwise be missed.

- Advanced Process Control (APC): Implementing model predictive control (MPC) algorithms to optimize process parameters in real-time, achieving optimal setpoints and reducing variability. MPC considers the process dynamics and future impacts of changes, thus fine-tuning performance.

- Design of Experiments (DOE): Conducting experiments to systematically identify the effect of different process parameters on biodiesel yield and quality. This helps in determining optimal operating conditions.

- Data analytics and Machine learning: Leveraging data analysis techniques to identify trends, patterns and relationships within the extensive dataset generated by modern plants. Employing machine learning can reveal unseen patterns and even predict potential future problems.

For example, using DOE, we were able to optimize the methanol-to-oil ratio, improving yield by 5% while maintaining product quality. Integrating MPC significantly reduced the variability in the final product’s acid value.

Q 22. How do you handle unexpected process deviations or emergencies?

Handling unexpected deviations in a biodiesel process requires a calm, systematic approach. My first step is always to ensure the safety of personnel and equipment. This often involves immediately shutting down non-essential parts of the process or activating emergency shutdown systems if necessary.

Next, I thoroughly investigate the root cause of the deviation. This might involve reviewing process parameters logged by the SCADA system (Supervisory Control and Data Acquisition), checking sensor readings for anomalies, and visually inspecting equipment for malfunctions. For example, a sudden drop in transesterification reaction temperature could point to a malfunctioning heating system or a problem with feedstock preheating. I’d use historical data and process knowledge to identify potential causes.

Once the root cause is identified, I implement corrective actions. This could be anything from replacing a faulty sensor, adjusting process parameters, or performing a thorough cleaning of a clogged filter. I then carefully monitor the process to ensure stability and document all actions taken. Finally, a post-incident review would be conducted to identify areas for improvement in our operational procedures and preventative maintenance strategies.

Q 23. Describe your understanding of process safety management (PSM) in biodiesel plants.

Process Safety Management (PSM) in a biodiesel plant is paramount. It’s a structured approach to preventing accidents and minimizing their impact. A robust PSM program involves several key elements:

- Hazard Identification and Risk Assessment: This involves identifying potential hazards associated with each stage of the biodiesel production process, from feedstock handling to product storage. We use HAZOP (Hazard and Operability) studies and other risk assessment techniques to quantify and prioritize the risks.

- Engineering Controls: Implementing safety systems like emergency shutdown systems, pressure relief valves, and fire suppression systems. These are the first line of defense against accidents.

- Administrative Controls: These include developing standard operating procedures (SOPs), providing thorough training to personnel, and implementing a permit-to-work system for high-risk activities. Regular safety audits and inspections are crucial.

- Emergency Response Planning: Having detailed emergency response plans in place for various scenarios, including fires, spills, and equipment failures. Regular drills ensure personnel are prepared.

- Incident Investigation and Reporting: Thoroughly investigating all incidents, identifying root causes, and implementing corrective actions to prevent recurrence. This involves documenting everything meticulously.

A strong PSM program is a continuous improvement cycle, always striving to reduce risks and improve safety. It’s not just a checklist; it’s a culture of safety ingrained in the entire organization.

Q 24. Explain your experience with different types of biodiesel feedstocks.

I have extensive experience with diverse biodiesel feedstocks, including vegetable oils (soybean, canola, sunflower, palm), animal fats (tallow, grease), and waste cooking oils (WVO). Each feedstock presents unique challenges and opportunities.

Vegetable oils generally offer a relatively consistent feedstock quality, though variations in fatty acid profiles can affect the quality of the final biodiesel. Animal fats often require more pretreatment to remove impurities and reduce free fatty acids (FFAs), which can hinder the transesterification reaction. WVOs are a particularly interesting case: they require rigorous pretreatment to remove contaminants like water, food particles, and potentially harmful chemicals before being used, and often have higher levels of FFAs.

My experience includes optimizing pretreatment processes for each feedstock type, adapting process parameters based on feedstock composition, and troubleshooting issues arising from using different feedstocks. For instance, higher FFA levels in a feedstock might require adjusting the catalyst dosage or using a different catalyst altogether to achieve the desired conversion rate.

Q 25. How do you ensure the consistent quality of biodiesel throughout the production process?

Consistent biodiesel quality is maintained through rigorous process control and quality assurance measures at each stage of production. This begins with careful selection and pretreatment of feedstocks to control impurities.

During transesterification, precise control of temperature, reaction time, and catalyst concentration is critical. Online monitoring of key process parameters such as methanol-oil ratio, free glycerol content, and FFA levels is essential for real-time adjustments. Automated systems coupled with a robust SCADA system, that allows for remote monitoring and control of the process, aids in this process.

Finally, the quality of the final product is verified through extensive laboratory testing, ensuring it meets ASTM (American Society for Testing and Materials) specifications or equivalent standards for biodiesel quality. This includes evaluating parameters like viscosity, cetane number, and acid value. Any deviation from the standards triggers immediate investigation and corrective actions.

Q 26. What is your experience with predictive maintenance in a biodiesel plant?

Predictive maintenance is crucial in a biodiesel plant to minimize downtime and optimize production efficiency. My experience involves implementing and utilizing various predictive maintenance techniques, including:

- Vibration analysis: Monitoring the vibration levels of critical equipment like pumps, motors, and mixers to detect potential bearing failures or imbalances before they lead to catastrophic breakdowns. This is particularly relevant for high-speed centrifugal pumps used in biodiesel processing.

- Infrared thermography: Using thermal imaging cameras to detect overheating in electrical components, bearings, or pipes, indicating potential problems before they escalate.

- Oil analysis: Regularly analyzing lubricating oil samples to detect signs of wear and tear in machinery, such as the presence of metal particles or changes in viscosity.

- Data analytics: Using historical process data and machine learning algorithms to predict potential equipment failures and optimize maintenance schedules. For example, by analyzing the performance of a specific reactor over time, we might predict when a cleaning or replacement of components will be needed.

These techniques help move away from reactive, time-based maintenance toward a proactive strategy, leading to significant cost savings and improved plant reliability.

Q 27. Describe your experience with data logging and analysis in a biodiesel production setting.

Data logging and analysis are integral to effective biodiesel process control. I have extensive experience working with SCADA systems to continuously monitor and record a wide range of process parameters, including temperatures, pressures, flow rates, and compositions. This data is invaluable for process optimization, troubleshooting, and quality control.

The data collected is analyzed using statistical process control (SPC) techniques to identify trends, anomalies, and potential sources of variation. For example, control charts are used to monitor key process variables and detect deviations from set points. Data analysis also helps in optimizing process parameters for improved yields, reduced energy consumption, and enhanced product quality.

Furthermore, I have experience using advanced analytics such as machine learning to build predictive models for process optimization, equipment maintenance, and quality prediction. These models provide valuable insights for proactive decision-making and improved operational efficiency.

Q 28. What are your salary expectations for a Biodiesel Process Control Engineer position?

My salary expectations for a Biodiesel Process Control Engineer position are in the range of $90,000 to $120,000 per year, depending on the specific responsibilities, location, and company benefits package. This expectation is based on my extensive experience, skills, and expertise in biodiesel process control, predictive maintenance, and data analytics. I am confident that my contributions would significantly enhance the efficiency and profitability of your operations.

Key Topics to Learn for Biodiesel Process Control Interview

- Feedstock Handling and Pretreatment: Understanding the impact of various feedstocks (vegetable oils, animal fats) on the process and necessary pretreatment steps like degumming, deacidification, and transesterification.

- Reaction Kinetics and Thermodynamics: Applying knowledge of chemical reaction rates and equilibrium to optimize the transesterification process and predict product yields.

- Reactor Design and Operation: Familiarity with different reactor types (batch, continuous), their advantages and disadvantages, and the control strategies employed for efficient operation and safety.

- Process Monitoring and Instrumentation: Understanding the role of sensors (temperature, pressure, flow, pH) and control systems (PID controllers, SCADA) in maintaining optimal reaction conditions and product quality.

- Product Separation and Purification: Knowledge of techniques like washing, settling, and distillation used to separate glycerol from biodiesel and achieve the desired purity specifications.

- Quality Control and Analysis: Understanding methods for analyzing biodiesel properties (e.g., viscosity, acid number, water content) and ensuring compliance with relevant standards.

- Process Optimization and Troubleshooting: Applying problem-solving skills to diagnose and resolve process deviations, improving efficiency and minimizing downtime.

- Safety and Environmental Considerations: Awareness of safety protocols related to handling chemicals and managing waste streams, as well as environmental regulations concerning biodiesel production.

- Automation and Advanced Process Control: Exploring the application of advanced control strategies (e.g., model predictive control) to enhance process efficiency and consistency.

Next Steps

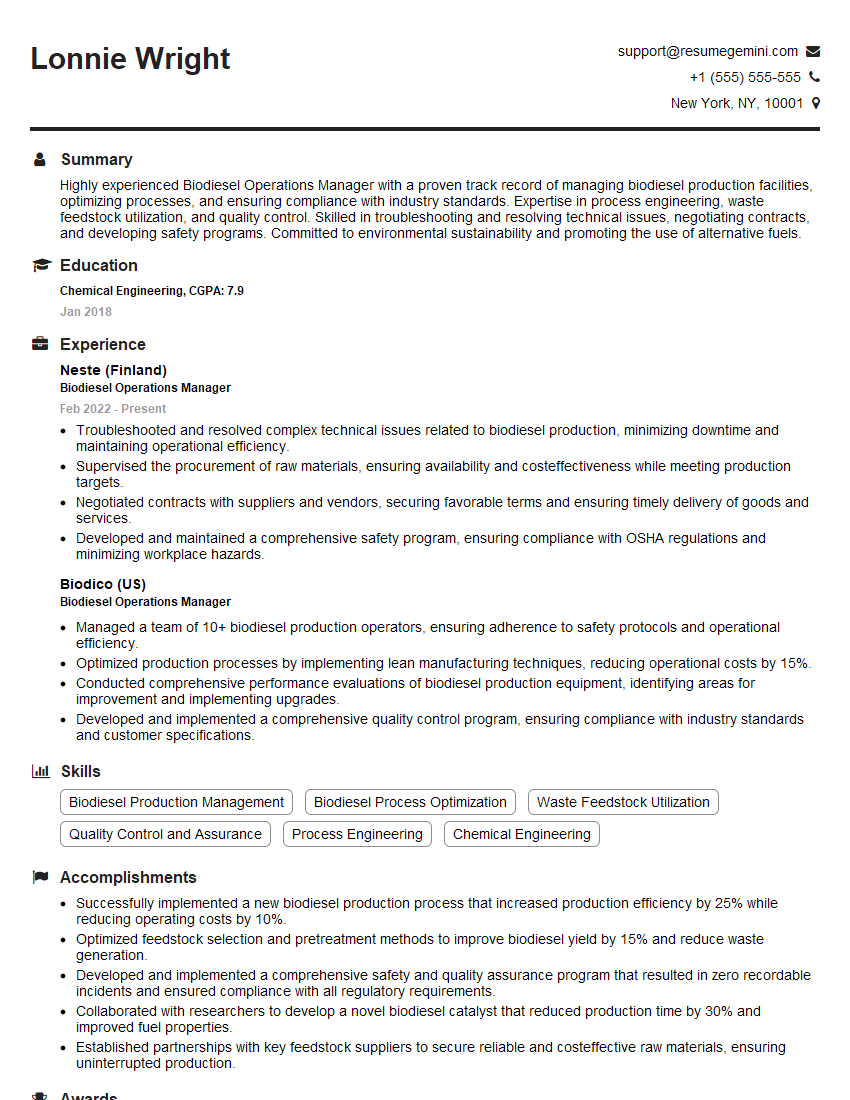

Mastering Biodiesel Process Control opens doors to exciting career opportunities in a growing industry focused on sustainable energy. A strong understanding of these concepts is crucial for showcasing your expertise to potential employers. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. This ensures your application gets noticed by Applicant Tracking Systems used by most companies. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. They offer examples of resumes tailored to the Biodiesel Process Control field, providing you with a valuable head-start in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.