Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Brewing Science interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Brewing Science Interview

Q 1. Explain the process of mashing in beer production.

Mashing is a crucial step in beer production where the crushed malted barley (or other grains) is mixed with hot water to convert the complex starches into simpler fermentable sugars. Think of it as unlocking the sweetness the yeast needs to create alcohol. This process happens in a mash tun, a large vessel that allows for controlled temperature and time.

The process involves several key steps:

- Mash In: The crushed grain is added to the mash tun and mixed with water at a specific temperature (typically 65-70°C for a standard mash). This temperature determines the activity of enzymes, proteins that break down starches.

- Saccharification: This is the main part of the mashing process, where enzymes (amylase, specifically alpha and beta amylase) break down the starches into sugars like maltose and glucose. The temperature is carefully controlled during this phase to optimize enzyme activity and sugar production. A common analogy is think of it as carefully simmering a pot of porridge – the right heat and timing matter to ensure a perfect consistency.

- Mash Out: The temperature is raised to around 78°C to stop enzyme activity and help separate the liquid from the grain. This liquid, called the wort, now contains the fermentable sugars.

- Lautering: The wort is separated from the spent grain (the grain husks that are left behind) via a process called lautering. This usually involves recirculating the wort to ensure clarity and efficient extraction of sugars.

Different mashing techniques exist, like decoction mashing (boiling a portion of the mash to increase enzyme activity), which allow brewers to fine-tune the characteristics of their beer, affecting the body, color, and flavor.

Q 2. Describe the different types of hops and their impact on beer flavor.

Hops are the flowers of the Humulus lupulus plant, added to beer for bittering, aroma, and preservation. Different hop varieties contribute unique flavor profiles. Think of hops as the spices and herbs of the beer world.

Hops are broadly categorized by their alpha acid content (determines bittering potential) and aroma characteristics:

- Bittering Hops: High alpha acid content, contributing to the bitterness of the beer. Examples include Magnum, Hallertau Mittelfrüh.

- Aroma Hops: Lower alpha acid content, added later in the brewing process to impart fruity, floral, citrusy, or spicy aromas. Examples include Cascade, Citra, Mosaic.

- Dual-Purpose Hops: A balance of both bittering and aroma qualities. Examples include East Kent Goldings, Fuggles.

The impact on beer flavor depends heavily on the hop variety, the amount used, and the timing of addition during brewing. Early additions yield more bitterness; later additions contribute more aroma.

Q 3. What are the key factors affecting yeast fermentation?

Yeast fermentation is a complex process significantly influenced by various factors. Think of yeast as tiny living organisms with specific needs to thrive and do their work correctly.

Key factors affecting yeast fermentation include:

- Temperature: Each yeast strain has an optimal temperature range. Too high, and the yeast may die; too low, and fermentation will be slow or incomplete. Temperature also affects the produced esters and other flavor compounds.

- Oxygen: Yeast needs oxygen initially for healthy growth (in the beginning of the fermentation). After the initial stage, oxygen can negatively impact fermentation and flavor.

- pH: The acidity of the wort significantly influences yeast health and fermentation efficiency. An appropriate pH is crucial.

- Nutrient levels: Yeast requires nutrients like nitrogen and vitamins for healthy growth and fermentation. Deficiencies can result in stuck or sluggish fermentations.

- Alcohol tolerance: Different yeast strains have varying alcohol tolerance levels. High alcohol content can inhibit or even kill the yeast.

- Sanitation: Contamination can ruin a batch. Cleanliness throughout the brewing process is essential to prevent unwanted bacteria or wild yeasts from spoiling the beer.

Careful control over these factors is essential to ensure a successful and clean fermentation, producing the desired beer characteristics.

Q 4. How do you ensure consistent beer quality throughout the brewing process?

Consistent beer quality requires meticulous attention to detail throughout the brewing process. Think of it like baking a cake – every step matters for the final product to be right. Consistent procedures, accurate measurements, and rigorous quality control are essential.

Strategies for ensuring consistent quality include:

- Standardized recipes and procedures: Using precise measurements, following documented procedures, and utilizing calibrated equipment are crucial.

- Regular equipment maintenance and calibration: Malfunctioning equipment can significantly impact quality. Preventative maintenance and regular calibration are important.

- Quality control checks at every stage: Sampling and analysis at critical points (e.g., mash, wort, fermentation) helps identify and address issues early on.

- Proper sanitation: Maintaining a clean and sterile environment prevents contamination.

- Consistent raw material quality: Sourcing high-quality ingredients from reliable suppliers and conducting quality checks on these materials is essential.

- Yeast management: Proper yeast handling, propagation, and storage are crucial to ensure consistent fermentation.

- Data logging and analysis: Tracking key parameters (temperature, gravity, pH) allows for trend identification, troubleshooting, and process optimization.

By implementing these measures, brewers can maintain consistent quality and produce beers with predictable characteristics.

Q 5. Explain the role of different types of water in brewing.

Brewing water plays a surprisingly significant role in beer quality. Different water profiles, characterized by their mineral content, contribute to diverse beer characteristics. Think of it like the base of a sauce – it’s often invisible, but drastically impacts the final flavor.

Key mineral components in water affect beer flavor and character:

- Calcium (Ca2+): Important for enzyme activity in mashing and contributes to beer stability.

- Magnesium (Mg2+): Influences yeast health and fermentation.

- Bicarbonates (HCO3–): Act as buffers, influencing mash pH.

- Sulfates (SO42-): Enhance hop bitterness and dryness, often associated with strong beers.

- Chlorides (Cl–): Contribute to malt body and sweetness, a good balance is often preferred.

Different beer styles benefit from different water profiles. For example, pale ales might benefit from higher sulfate levels, while stouts might prefer higher chloride levels. Water adjustment, through techniques like adding salts or using filtration, is often employed to achieve the desired water profile.

Q 6. What are the common causes of beer spoilage and how are they prevented?

Beer spoilage is caused by unwanted microorganisms that can negatively impact the beer’s flavor, aroma, and appearance. Think of it as a unwanted guest crashing the party.

Common causes of beer spoilage and their prevention:

- Infection by bacteria: Bacteria can produce off-flavors (e.g., sourness, lactic acid) and cause spoilage. Prevention: thorough sanitation of equipment and ingredients.

- Wild yeast contamination: Wild yeasts can create off-flavors and cloudiness. Prevention: proper yeast management and sanitation.

- Oxidation: Exposure to oxygen can lead to stale flavors and reduced shelf life. Prevention: minimizing oxygen exposure during brewing and packaging.

- Lightstruck flavor: Exposure to UV light can create skunky flavors. Prevention: using amber or brown bottles, or UV-blocking packaging.

- Infection from other sources: Improper cleaning and sanitization of equipment and fermentation vessels can introduce contaminants. Prevention: strict adherence to sanitation protocols.

Implementing robust sanitation procedures, careful handling of ingredients, and appropriate packaging are essential to prevent beer spoilage.

Q 7. Describe the different types of beer styles and their characteristics.

Beer styles are incredibly diverse, categorized by ingredients, brewing techniques, and resulting characteristics. Think of them as different variations on a culinary theme.

Some examples of beer styles and their characteristics:

- Lagers: Bottom-fermenting beers, generally characterized by clean, crisp flavors. Examples include Pilsners, Märzens, and Bock beers.

- Ales: Top-fermenting beers, offering a wider range of flavors and aromas, often fruitier or more malty than lagers. Examples include IPAs, Stouts, and Porters.

- Wheat Beers (Weizen): Made with a significant portion of wheat malt, these beers often have a cloudy appearance and fruity-spicy notes.

- Stouts: Dark, roasted beers with a variety of flavor profiles, from dry and coffee-like to creamy and chocolatey.

- IPAs (India Pale Ales): Hoppy beers with bitter and aromatic profiles, ranging from pale and fruity to intensely bitter and resinous.

- Sours: Beer styles intentionally soured using bacteria, often showcasing tart or acidic flavors.

The vast world of beer styles offers endless possibilities for brewers and beer enthusiasts alike. Experimentation with ingredients and brewing techniques continues to drive innovation and the creation of new styles.

Q 8. Explain the process of wort boiling and its importance.

Wort boiling is a crucial step in brewing, where the sweet wort (the sugary liquid extracted from malted barley) is vigorously boiled for 60-90 minutes. This seemingly simple process achieves several vital functions:

- Isomerization of alpha acids: Boiling converts the relatively inactive alpha acids from hops into their isomerized forms, which are significantly more effective at contributing bitterness and stability to the finished beer. Think of it like activating a sleeping ingredient.

- Protein coagulation: The heat denatures and precipitates proteins, preventing haze and improving beer clarity. Imagine clearing a cloudy broth by simmering it – the same principle applies here.

- Sterilization: Boiling effectively kills unwanted bacteria and wild yeasts, ensuring a cleaner fermentation and preventing off-flavors. It’s like sterilizing your brewing equipment, but on a larger scale.

- Hop extraction: Beyond bitterness, boiling extracts other desirable hop compounds, contributing aroma, flavor, and aroma stability. Each hop variety offers a unique profile – some are more aromatic, others contribute more bitterness.

- Volatile compound removal: Boiling removes unwanted volatile sulfur compounds (DMS, for example) that can lead to unpleasant flavors. It’s like letting off steam to improve the final product.

The duration and intensity of the boil are carefully controlled to achieve the desired balance of bitterness, aroma, and clarity. Different beer styles require different boiling strategies. For instance, an IPA might have a longer boil to maximize hop bitterness, while a lighter beer might have a shorter boil to retain more delicate hop aromas.

Q 9. How do you measure and control the temperature during fermentation?

Precise temperature control during fermentation is paramount for successful brewing. Yeast, the tiny microorganisms responsible for converting sugars into alcohol and CO2, are sensitive to temperature changes. This control is typically achieved through a combination of methods:

- Temperature-controlled fermenters: These are jacketed vessels with internal coils or external jackets allowing for precise temperature control using glycol-chilled water or other cooling media. This offers the most consistent and accurate control. We often program the desired temperature profile into a computer system.

- Temperature sensors: Accurate sensors (thermocouples, RTDs) constantly monitor the wort temperature inside the fermenter. These sensors are crucial for feedback to the cooling system, providing data that allows us to fine-tune the process.

- Cooling jackets or coils: These transfer heat away from the wort, maintaining the target fermentation temperature. The flow rate of the cooling medium can be adjusted to fine-tune the cooling rate.

- Insulation: Fermenters are often insulated to minimize temperature fluctuations from the ambient environment. Think of it as wrapping your beer in a warm blanket to maintain consistency.

- Temperature monitoring software: Many breweries use software to monitor and log fermentation temperatures. This allows brewers to track fermentation progress and identify any deviations from the desired profile.

Different yeast strains have optimal temperature ranges, impacting the resulting beer’s flavor profile. For example, ale yeasts generally ferment at warmer temperatures (15-24°C), while lager yeasts ferment at cooler temperatures (8-15°C). Deviation from these ranges can lead to off-flavors, stalled fermentation, or even yeast death.

Q 10. What are the different methods of beer filtration and clarification?

Beer filtration and clarification aim to remove yeast, hop particles, and other solids, resulting in a brighter, clearer beer. Several methods exist:

- Plate and frame filter: This uses a series of plates with filter sheets to separate solids from the liquid. It’s effective but can be time-consuming.

- Centrifugation: A high-speed centrifuge separates solids from the beer based on density. It’s faster than plate and frame filtration but requires specialized equipment.

- Membrane filtration: Uses membranes with various pore sizes to remove different sized particles. Microfiltration removes yeast and bacteria, while ultrafiltration removes larger proteins and haze-causing substances.

- Diatomaceous earth (DE) filtration: This uses a filter aid made from fossilized diatoms to trap solids. It’s widely used and relatively cost-effective but involves handling a powdery substance that needs to be disposed of properly.

The choice of filtration method depends on the desired level of clarity, the beer style, and the brewery’s scale and resources. Unfiltered beers, gaining popularity, retain more of the yeast and hop matter, contributing to a fuller body and sometimes a slightly hazy appearance.

Q 11. How do you manage and monitor yeast health in the brewery?

Managing yeast health is crucial for consistent beer quality. We address this through several steps:

- Yeast viability testing: Regularly assessing yeast health through microscopic examination or automated cell counters helps to determine its viability (the percentage of live, healthy yeast cells). A low viability indicates a need for rejuvenation or replacement.

- Yeast propagation (slurrying): Growing a sufficient amount of healthy yeast from a small starter culture in a controlled environment ensures sufficient yeast for fermentation.

- Yeast storage: Proper storage of yeast is crucial for long-term viability. Common methods include cryogenic freezing (-80°C) or cold storage (4°C) on agar slants.

- Yeast harvesting: Carefully harvesting the yeast after fermentation, without excessive stress, is important. This often involves separating the yeast from the beer using centrifugation or settling.

- Yeast washing: Washing the harvested yeast removes spent nutrients and other byproducts from fermentation, improving subsequent generations’ health and performance.

Maintaining a healthy yeast culture minimizes the risk of off-flavors, sluggish fermentation, or stuck fermentations. Using a healthy yeast culture is like choosing fresh ingredients for a delicious meal.

Q 12. Explain the importance of sanitation and hygiene in brewing.

Sanitation and hygiene are paramount in brewing to prevent spoilage microorganisms from competing with yeast or producing off-flavors. It’s like operating a clean surgical room to ensure a perfect product.

- Cleaning-in-place (CIP): Automated systems that clean brewing equipment using hot water, chemicals, and a series of cycles. This is especially effective for large-scale breweries.

- Sanitizing: Using chemical sanitizers (e.g., iodine, peracetic acid) to kill remaining microorganisms after cleaning. This ensures equipment is ready for sterile wort.

- Good Manufacturing Practices (GMP): Following strict protocols to maintain cleanliness throughout the brewery, including personal hygiene, proper equipment handling, and control of the brewing environment.

- Regular inspections: Frequent inspections of equipment and the brewing environment help to identify potential sources of contamination early on.

- Training: Comprehensive training for all brewery staff on sanitation procedures and the importance of maintaining a clean environment.

Contamination can lead to significant losses and spoiled batches. Therefore, consistent sanitation is not just good practice but critical for financial viability and brand reputation.

Q 13. Describe the process of packaging beer (bottles, cans, kegs).

Packaging beer involves transferring the finished beer from the bright tank (the final storage tank) to the chosen packaging format:

- Bottling: The beer is usually filtered and then transferred to bottles, which are then capped and labeled. The bottles may undergo pasteurization to extend their shelf life.

- Canning: Canning lines involve filling the cans with beer, sealing them, and printing labels or directly printing the labels onto the cans. Cans offer excellent protection against light and oxidation.

- Kegging: Kegs are filled with beer under pressure, typically using a system that sanitizes the kegs before filling. This method is popular for draft beer dispensed in pubs and bars.

Each packaging method has its own advantages and disadvantages in terms of cost, shelf life, and impact on the beer’s quality and presentation. For instance, cans prevent light-struck beer, while bottles provide a more traditional aesthetic appeal.

Q 14. What are the common quality control checks performed during brewing?

Quality control checks throughout the brewing process are essential to guarantee consistent product quality and prevent issues.

- Raw material testing: Analyzing the quality of raw materials, such as malted barley and hops, to ensure they meet specifications. This often involves measuring key parameters like moisture content, protein levels, and alpha acid content.

- Wort analysis: Checking the wort’s gravity (a measure of sugar concentration) and pH before fermentation ensures the correct amount of sugars are available for the yeast.

- Fermentation monitoring: Tracking temperature, gravity, and pH during fermentation to ensure that the fermentation progresses as expected. Any deviation could indicate a problem, allowing for timely intervention.

- Finished beer analysis: Testing the final beer for parameters like alcohol content, color, bitterness, and clarity. Sensory evaluations (taste tests) are performed by trained panelists to check for off-flavors or defects.

- Microbial testing: Ensuring that the beer is free from any unwanted microorganisms. This is performed regularly to prevent spoilage organisms from compromising the integrity of the final product.

Thorough quality control ensures that every batch of beer meets the brewery’s standards and delivers a consistently high-quality product to the consumers.

Q 15. Explain the concept of Beer Style Guidelines (BJCP).

The Beer Judge Certification Program (BJCP) Style Guidelines are a comprehensive guide categorizing and describing various beer styles. Think of it as a beer style bible, defining characteristics like color, aroma, flavor, mouthfeel, and overall impression for hundreds of beer types. This standardization allows for consistent judging in competitions and provides brewers with a framework for recipe development and understanding consumer expectations. For example, a ‘Belgian Tripel’ is clearly defined, separating it from an ‘Irish Stout’ through specific parameters for its high carbonation, fruity esters, and spicy phenols. The guidelines help ensure that a ‘Pale Ale’ brewed in California tastes remarkably similar to one brewed in Germany, within the expected range of variation.

The BJCP system uses a hierarchical structure, grouping styles by category (e.g., Ales, Lagers, Wheat Beers) and then further subdividing them into sub-categories and specific styles. Each style description includes detailed sensory characteristics and acceptable ranges, helping brewers and judges alike assess the beer accurately.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different types of brewing equipment and their functions.

Brewing equipment varies widely depending on scale and brewing method. For homebrewing, common equipment includes:

- Mash tun: A vessel where the grains are mixed with hot water to convert starches into sugars. Think of it as a giant teabag for the malt.

- Lauter tun (optional): Separates the sweet wort (liquid) from the spent grain. Many homebrewers use a mash tun that also functions as a lauter tun.

- Kettle: Where the wort is boiled, sterilizing it and concentrating flavors.

- Fermenter: A vessel where yeast converts sugars into alcohol and carbon dioxide. Maintaining temperature control here is vital.

- Bottling bucket: Used for bottling, often with a racking cane for transferring beer without disturbing sediment.

Commercial breweries utilize larger-scale versions of this equipment, often automated and computer-controlled. They might include things like:

- Mash filters: Highly efficient systems for lautering.

- Wort coolers: Rapidly cool the wort to fermentation temperature.

- Large-scale fermenters: Can range from several hundred to thousands of gallons.

- Brite tanks: Used for conditioning the beer before packaging.

The choice of equipment largely dictates the scale, efficiency, and complexity of the brewing process.

Q 17. What is the significance of pH control in brewing?

pH control is crucial in brewing because it directly impacts enzyme activity during mashing and the overall flavor profile of the beer. Enzymes, which break down starches and proteins, have optimal pH ranges. If the pH is too high or too low, enzyme activity is inhibited, resulting in incomplete conversion of starches to fermentable sugars and impacting the beer’s body and mouthfeel. For example, if the pH is too high during mashing, the conversion of starches to sugars will be inefficient, resulting in a thin and less flavorful beer.

Furthermore, pH affects yeast health and fermentation. Yeast thrives within a specific pH range; outside of this range, fermentation can be sluggish or produce off-flavors. Precise pH control throughout the brewing process is essential for producing high-quality beer with consistent characteristics. Brewers monitor and adjust pH using acids (like lactic acid) or bases (like calcium carbonate) to maintain optimal levels.

Q 18. How do you troubleshoot common brewing problems?

Troubleshooting in brewing involves systematic investigation. Here’s a framework:

- Identify the problem: Describe the issue clearly. Is the beer too sour? Is it hazy? Does it have an off-flavor?

- Gather information: Review your brewing log meticulously. When did the problem appear? What steps were taken? What are the sensory characteristics?

- Consider possible causes: Many factors can contribute to brewing problems. Possible causes include:

- Infection: Signs include sourness, off-odors, or haziness.

- Mash issues: Incorrect temperature or pH can lead to incomplete conversion.

- Fermentation problems: High or low temperatures, inappropriate yeast strain, or oxygen exposure can affect fermentation.

- Infection: Signs include sourness, off-odors, or haziness.

- Isolate the variable: Once potential causes are identified, consider them systematically. Compare your current process to successful batches.

- Implement corrective actions: Based on the identified cause, take appropriate steps to rectify the problem. This might involve adjustments to recipes, procedures, or equipment.

- Document findings: Record the problem, its cause, and the solution implemented. This helps avoid future occurrences.

For instance, a hazy beer might be due to protein haze (unclarified proteins), yeast haze (remaining yeast), or bacterial infection. Each requires a different approach for correction.

Q 19. Explain the principles of sensory evaluation in brewing.

Sensory evaluation in brewing involves using our senses – sight, smell, taste, and touch – to assess the quality of beer. It’s a critical step in quality control and improvement. Think of it as a highly trained tasting panel, providing feedback that goes beyond simple ‘good’ or ‘bad’.

Sensory evaluation employs standardized protocols to minimize bias and ensure consistency. This often includes:

- Appearance: Evaluating color, clarity, and head retention.

- Aroma: Identifying various aromatic compounds, such as fruity esters, spicy phenols, or hop aromas.

- Flavor: Assessing the balance, intensity, and complexity of flavors, including malt, hops, and fermentation byproducts.

- Mouthfeel: Determining the body, carbonation, and overall texture.

- Overall impression: A holistic assessment summarizing the beer’s qualities.

Sensory panels ideally consist of trained individuals who can objectively evaluate beer samples. Descriptive analysis methods help clearly communicate sensory attributes, guiding brewers in improving their product. For example, the sensory evaluation might reveal an off-flavor that would be undetectable using solely chemical analysis.

Q 20. What are the different types of malt and their use in brewing?

Malt provides the sugars, color, and flavor components of beer. Several types exist, each with unique properties:

- Pale Malt: Forms the base of most beers, offering a light color and malty sweetness. It’s like the foundation upon which other malts are built.

- Munich Malt: Adds a rich, malty flavor and a subtle reddish hue. It’s often found in amber and darker beers.

- Vienna Malt: Similar to Munich malt but with a lighter color, adding a bready flavor. It’s often used in light lagers and amber ales.

- Crystal Malt (Caramel Malt): Provides color, sweetness, and complexity. The degree of color and flavor varies depending on the roasting level.

- Chocolate Malt: Deeply roasted, imparting a chocolatey flavor and dark color.

- Roasted Barley: Adds color and a roasty character without significant sweetness.

- Black Patent Malt: Very dark malt, creating intensely dark color and a slightly bitter, astringent flavor.

The brewer carefully selects a blend of malts to achieve the desired color, flavor, and body in their beer. For instance, a stout might utilize a combination of pale, chocolate, and roasted barley malts, while a pale ale might primarily consist of pale malt with a small amount of crystal malt for color and complexity.

Q 21. Describe the role of enzymes in the mashing process.

Enzymes are crucial in the mashing process, where they break down complex starches and proteins in the malt into simpler, fermentable sugars and amino acids. This conversion is essential for creating the fermentable wort that yeast uses to produce alcohol. Imagine enzymes as tiny molecular scissors, cutting up large molecules into smaller, usable pieces.

Several key enzymes are involved:

- α-amylase: Breaks down long-chain starches into shorter dextrins, contributing to body.

- β-amylase: Breaks down dextrins into fermentable maltose sugars.

- Proteases: Break down proteins into amino acids, which are essential for yeast nutrition and flavor development.

The temperature during mashing directly influences enzyme activity. Each enzyme has an optimal temperature range. Careful temperature control is essential to ensure efficient starch conversion and proper protein breakdown for a balanced and flavorful beer. Incorrect mash temperatures can result in incomplete conversion (too low temperature) or excessive production of unwanted byproducts (too high temperature).

Q 22. How do you calculate the original gravity (OG) and final gravity (FG) of a beer?

Original Gravity (OG) and Final Gravity (FG) are crucial measurements in brewing, reflecting the sugar concentration before and after fermentation. OG is measured before fermentation begins, indicating the potential alcohol content. FG is measured after fermentation is complete, showing the remaining sugars that weren’t converted to alcohol.

Calculating OG and FG: Both are measured using a hydrometer, which measures the specific gravity (SG) of the wort (unfermented beer) or beer. Specific gravity is the ratio of the density of the liquid to the density of water. A hydrometer reading above 1.000 indicates the presence of dissolved sugars.

OG Calculation: You take a hydrometer reading of your wort *before* pitching yeast. This reading is your OG. For example, an OG of 1.050 means the wort is 5% heavier than water due to dissolved sugars.

FG Calculation: After fermentation is complete, take another hydrometer reading. This is your FG. For example, an FG of 1.010 indicates that a significant portion of the sugars have been fermented. The difference between OG and FG determines the apparent alcohol content.

Example: If your OG is 1.050 and your FG is 1.010, there’s a significant difference, suggesting a higher alcohol content than if the difference were smaller. You would use this data in an alcohol calculation (detailed in question 5).

Q 23. Explain the concept of International Bitterness Units (IBUs).

International Bitterness Units (IBUs) quantify the bitterness of beer, primarily derived from the hops added during the brewing process. Higher IBUs mean a more bitter beer. It’s important to note that IBU is not a perfectly precise measurement, as bitterness perception is complex and influenced by other factors like malt profile and hop variety.

Calculating IBUs: Calculating IBUs is not straightforward and involves several factors: the amount of hops added, the alpha acid content of the hops (a measure of their bitterness potential), the boil time (longer boil times extract more bitterness), and the volume of wort. There are various formulas and online calculators that brewers use, taking these factors into account. These formulas often involve complex calculations based on hop utilization rates.

Example: A pale ale might have IBUs in the range of 20-40, whereas an IPA could range from 40-100 or even higher, reflecting a significantly more bitter taste.

Q 24. What are the different types of brewing vessels and their functions?

Brewing vessels play vital roles in each stage of beer production. The choice of vessel and its material greatly influences the quality and consistency of the final product.

- Mash Tun: Used for mashing, where grains are mixed with hot water to release sugars. Material: Stainless steel is common due to its durability and cleanability.

- Lauter Tun: Used to separate the wort (sugary liquid) from the spent grain. Often combined with a mash tun in modern breweries. Material: Stainless steel.

- Kettle/Brew Kettle: The wort is boiled here, sterilizing it, isomerizing hop acids (for bitterness), and concentrating flavors. Material: Stainless steel.

- Whirlpool Tank: Used to separate hop debris and other solids from the wort after boiling. Improves clarity. Material: Stainless steel.

- Fermenter: The vessel where yeast ferments the sugars in the wort, producing alcohol and carbon dioxide. Material: Stainless steel is common, but other options are used for particular styles. Can be various shapes (cylindrical-conical, etc.).

- Bright Tank: Used for conditioning and clarifying the beer before packaging. Materials: Stainless steel.

Proper vessel selection and maintenance are critical for efficient brewing and consistent quality. Materials such as copper were more common historically, but stainless steel offers better sanitation and longer lifespan in larger operations.

Q 25. Explain the concept of gravity and its significance in brewing.

Gravity, in brewing, refers to the specific gravity (SG) of the wort and beer. It’s a measure of the density of the liquid relative to water. It directly correlates to the amount of dissolved sugars and, consequently, the potential alcohol content of the beer.

Significance: Monitoring gravity throughout the brewing process allows brewers to:

- Assess the efficiency of the mashing process: A high OG indicates efficient sugar extraction from the grains.

- Estimate alcohol content: The difference between OG and FG is crucial in calculating alcohol content (as described in question 5).

- Monitor fermentation progress: Tracking the decrease in gravity during fermentation helps brewers determine when fermentation is complete.

- Ensure consistency: Consistent gravity readings help brewers maintain consistent beer quality.

Think of it like this: Higher gravity means a “heavier” liquid, richer in sugars, leading to a potentially stronger beer. Lower gravity signifies less sugar and a weaker beer.

Q 26. How do you calculate the alcohol content of a beer?

Calculating the alcohol content of beer involves using the OG and FG readings from a hydrometer. Several formulas exist, with the most common being:

Alcohol by Volume (ABV) ≈ (OG - FG) x 131.25

Where OG is the original gravity and FG is the final gravity. This formula provides an approximation, as some factors aren’t perfectly accounted for. More precise methods exist, including using alcohol meters or gas chromatography.

Example: Using the example from question 1, with an OG of 1.050 and an FG of 1.010:

ABV ≈ (1.050 - 1.010) x 131.25 ≈ 5.25%

This means the beer has an approximate alcohol content of 5.25% ABV. Note that this is an approximation. The accuracy varies depending on factors such as yeast strain and fermentation temperature.

Q 27. Describe different methods for measuring and controlling dissolved oxygen in beer.

Dissolved oxygen (DO) in beer is crucial; too much can lead to oxidation, impacting flavor and shelf life, while too little can hinder yeast health during fermentation.

Measurement Methods:

- Dissolved Oxygen Meter: A sensor directly measures the DO level in the beer.

- Chemical Methods: Winkler titration is a classical method, though more time-consuming.

Control Methods:

- Sparging Techniques: During brewing, careful control of sparging (rinsing the grains) minimizes oxygen pickup.

- Blanketing with Inert Gas: Using nitrogen or carbon dioxide blankets the beer surface in the fermenter, preventing oxygen absorption.

- Vacuum Degassing: Removing dissolved oxygen from the beer by creating a vacuum.

- Oxygenation (Controlled): Controlled addition of oxygen before fermentation can be beneficial to promote healthy yeast growth.

Monitoring DO throughout the brewing process, from wort production to packaging, is critical to ensure quality and stability.

Q 28. Explain the challenges and solutions related to maintaining consistent beer quality across large-scale production.

Maintaining consistent beer quality across large-scale production presents numerous challenges, including variations in raw materials, process parameters, and equipment.

Challenges:

- Raw Material Consistency: Variations in malt, hops, and water chemistry can significantly impact beer characteristics.

- Process Control: Maintaining consistent temperature, pressure, and timing across large-scale operations is complex.

- Equipment Maintenance: Ensuring consistent performance of large brewing systems requires meticulous maintenance.

- Human Error: Large-scale processes involve multiple human operators, increasing the potential for error.

Solutions:

- Strict Quality Control (QC): Rigorous testing of raw materials and intermediate products is crucial.

- Automated Systems: Automating process parameters, such as temperature and pressure, improves consistency.

- Statistical Process Control (SPC): Analyzing process data to identify and correct variations.

- Regular Equipment Calibration and Maintenance: Prevents equipment-related inconsistencies.

- Training and Standardization of Procedures: Ensures all operators follow consistent protocols.

- Data Logging and Analysis: Tracking all parameters allows for continuous improvement.

Addressing these challenges through careful planning, rigorous quality control, and automation is vital for the production of consistently high-quality beer at scale.

Key Topics to Learn for Brewing Science Interview

- Malt and Grain Science: Understanding the different types of barley, malting processes, and the impact of grain characteristics on beer flavor and quality. Practical application: Analyzing malt quality and adjusting mashing techniques for optimal yield and flavor.

- Yeast Biology and Fermentation: Knowing various yeast strains, their fermentation characteristics (e.g., attenuation, flocculation), and troubleshooting fermentation issues. Practical application: Managing fermentation temperature and oxygen levels to achieve desired beer styles.

- Hop Chemistry and Utilization: Understanding hop varieties, alpha and beta acids, and their contribution to bitterness, aroma, and flavor. Practical application: Calculating hop additions for target bitterness and aroma profiles.

- Water Chemistry and its Influence on Beer: Understanding water profiles (mineral content), their impact on beer flavor, and techniques for water treatment. Practical application: Adjusting water chemistry to achieve specific beer styles.

- Brewhouse Operations and Process Control: Understanding the brewing process steps (mashing, lautering, boiling, whirlpool), process optimization, and quality control measures. Practical application: Troubleshooting common brewhouse problems and optimizing efficiency.

- Beer Quality and Sensory Evaluation: Understanding beer quality parameters (color, clarity, aroma, flavor, mouthfeel), sensory evaluation techniques, and quality control testing. Practical application: Conducting blind tastings to evaluate beer quality and identify defects.

- Microbiology and Sanitation: Understanding common beer spoilage organisms, sanitation procedures, and hygiene protocols. Practical application: Implementing effective sanitation practices to prevent microbial contamination.

- Beer Styles and Brewing Techniques: A comprehensive understanding of various beer styles and the brewing techniques associated with each. Practical application: Designing recipes and brewing processes for specific beer styles.

Next Steps

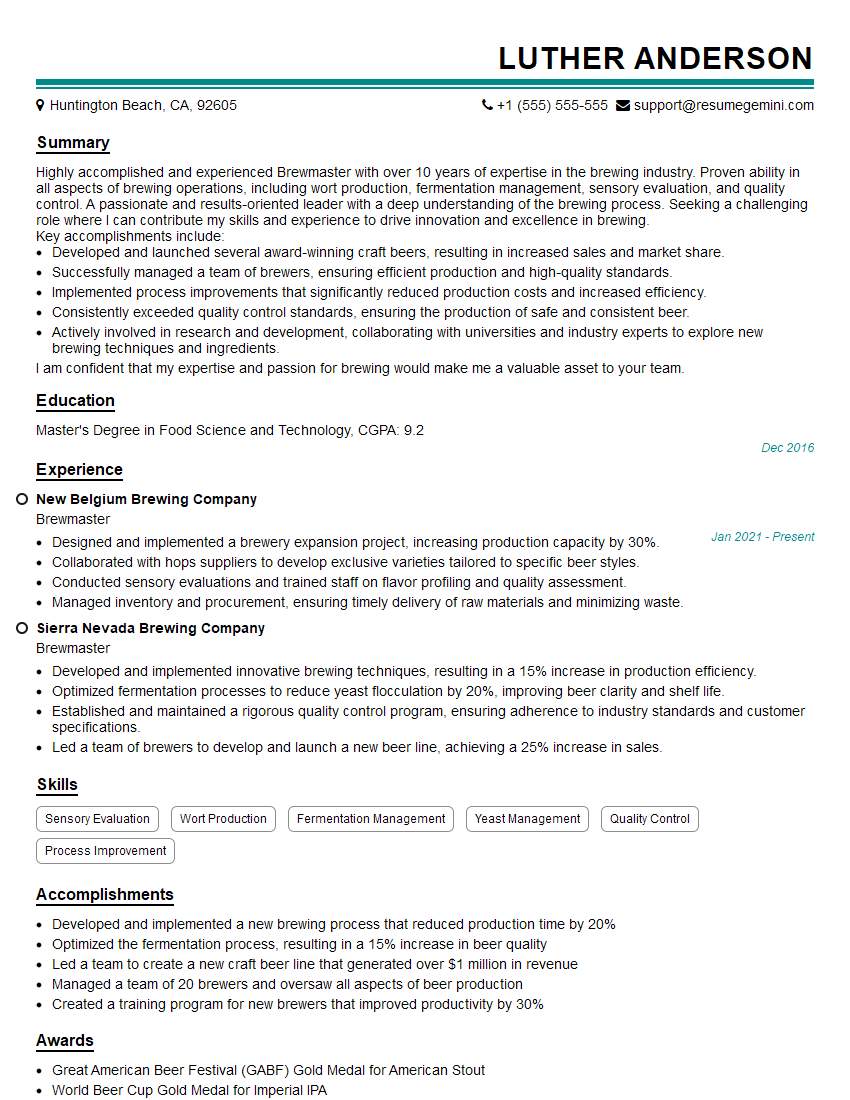

Mastering Brewing Science is crucial for career advancement in the brewing industry, opening doors to diverse roles and increased earning potential. An ATS-friendly resume is essential for getting your application noticed by recruiters. To significantly improve your chances, leverage ResumeGemini to craft a professional and impactful resume that showcases your brewing science expertise. ResumeGemini provides examples of resumes tailored to Brewing Science to help you build a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.