Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Piping Codes and Standards interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Piping Codes and Standards Interview

Q 1. Explain the differences between ASME B31.1, B31.3, and B31.4.

ASME B31 codes are a family of standards covering the design, construction, testing, and operation of piping systems. Each code addresses specific applications, differing primarily in the type of fluids handled and the operating conditions.

- ASME B31.1: This code covers power piping, focusing on high-pressure, high-temperature systems found in power plants, refineries, and similar facilities. Think of the massive steam lines in a power generation plant – those fall under B31.1. It’s rigorous, requiring detailed stress analysis and stringent material requirements.

- ASME B31.3: This code governs process piping, which encompasses a broader range of applications dealing with various fluids, pressures, and temperatures in chemical, petrochemical, and related industries. While still demanding, it offers more flexibility than B31.1, accommodating lower-pressure systems and a wider variety of materials.

- ASME B31.4: This code covers liquid petroleum transportation piping systems. This focuses on pipelines transporting crude oil, refined products, or other liquids across long distances. It emphasizes external factors like soil conditions, corrosion protection, and pipeline integrity management programs crucial for safe long-distance transportation.

In short: B31.1 is for high-pressure power piping, B31.3 for general process piping, and B31.4 for liquid petroleum pipelines. The selection of the appropriate code depends heavily on the specific application and the nature of the fluid being transported.

Q 2. Describe the process of performing a piping stress analysis.

Piping stress analysis is crucial to ensure that a piping system can withstand the loads and stresses it will experience during operation. The process generally involves these steps:

- Define the System: This includes gathering data like pipe specifications (diameter, wall thickness, material), fluid properties (temperature, pressure, density), and operating conditions.

- Develop a Model: A 3D model of the piping system is created using specialized software (e.g., CAESAR II, AutoPIPE). This model accurately represents the piping layout, supports, and equipment connections.

- Apply Loads: Various loads are applied to the model, including:

- Internal Pressure: Pressure of the fluid inside the pipe.

- Weight: The weight of the pipe and fluid.

- Thermal Loads: Expansion and contraction due to temperature changes.

- Wind Loads: Forces caused by wind.

- Seismic Loads: Forces caused by earthquakes (especially important in seismic zones).

- Perform the Analysis: The software calculates stresses, displacements, and support reactions throughout the system based on the applied loads.

- Interpret the Results: The results are analyzed to ensure all stresses are within the allowable limits as defined in the applicable ASME B31 code. This involves checking for stress concentrations, excessive displacements, and adequate support.

- Iterative Design: If stresses exceed allowable limits, the design needs to be modified, such as adding supports, changing pipe size, or using different materials. The analysis process is repeated until a satisfactory design is achieved.

Think of it like building a bridge – we use stress analysis to ensure the bridge can support the weight of traffic and environmental loads without collapsing.

Q 3. What are the common methods used for supporting piping systems?

Piping systems require supports to prevent excessive movement, vibration, and stress. Common methods include:

- Rigid Supports: These restrict movement in all directions, often used for anchoring the system to prevent overall displacement. Think of a large steel bracket rigidly bolted to a building structure.

- Flexible Supports: These allow for some movement to accommodate thermal expansion and contraction. Examples include spring supports and constant support hangers, which absorb movements caused by temperature fluctuations.

- Guides: These restrict movement in one direction, allowing for expansion and contraction in other directions. Imagine a pipe resting on rollers that allow longitudinal movement.

- Anchors: These are similar to rigid supports, firmly securing the pipe at specific points. They are often used in critical locations to prevent overall movement during seismic events.

- Snubbers: These are used to limit or restrain rapid movement, such as seismic movements, thus protecting the pipework and the equipment connected to it.

The selection of support type and location is crucial for effective stress management and ensuring the longevity of the system. Incorrect support placement can lead to excessive stresses and potential failures.

Q 4. How do you determine the appropriate pipe size for a given flow rate and pressure?

Determining the appropriate pipe size involves considering both the flow rate and the pressure drop. There’s no single formula, as it depends on the fluid properties (viscosity, density), the pipe material (roughness), and the required flow velocity.

Engineers typically use tools like:

- Moody Diagram: This chart helps to determine the friction factor based on the Reynolds number (a dimensionless number representing the flow regime) and the pipe’s relative roughness.

- Hazen-Williams Equation: This empirical equation is commonly used for water flow in pipes.

- Darcy-Weisbach Equation: A more fundamental equation, but requires iterative calculations to determine the friction factor.

- Pipe Sizing Software: Specialized software packages simplify this process by providing automated calculations and optimization.

The process generally involves estimating a pipe size, calculating the pressure drop, and iteratively adjusting the size until the desired flow rate and acceptable pressure drop are achieved. Too small a pipe results in high pressure drops and potential pump limitations, while too large a pipe may be unnecessarily expensive and may lead to low flow velocity which encourages corrosion or sedimentation.

Q 5. What are the different types of pipe materials and their applications?

Pipe materials are selected based on factors like the fluid being transported, temperature, pressure, and corrosion resistance. Common materials include:

- Carbon Steel: Widely used for its strength and cost-effectiveness, but susceptible to corrosion, particularly in harsh environments. Suitable for many general-purpose applications where corrosion isn’t a primary concern.

- Stainless Steel: Offers excellent corrosion resistance and high strength, making it suitable for aggressive chemicals or high-temperature applications. More expensive than carbon steel.

- Ductile Iron: A strong and ductile material used where high strength and corrosion resistance are needed, often for water distribution systems and underground piping.

- Copper: Excellent corrosion resistance, making it suitable for potable water applications. Often used in residential plumbing.

- PVC (Polyvinyl Chloride): A plastic material that’s lightweight, corrosion-resistant, and relatively inexpensive. Commonly used for chemical drainage systems and potable water distribution.

- GRP (Glass Reinforced Plastic): Lightweight, strong and corrosion-resistant, often used for chemical processing and wastewater pipelines.

The choice of material involves a trade-off between cost, performance, and the specific demands of the application. For example, a high-pressure steam line in a power plant might require high-temperature, high-pressure resistant stainless steel, while a low-pressure water line might use cost-effective PVC.

Q 6. Explain the concept of pipe flexibility and its importance in piping design.

Pipe flexibility refers to the ability of a piping system to accommodate thermal expansion and contraction, and other movements without causing excessive stress on the pipes, supports, or connected equipment.

Imagine a long pipe heated by a hot fluid running through it. As the temperature increases, the pipe lengthens. If the pipe isn’t designed with sufficient flexibility, this expansion can cause high stresses and even rupture. Flexibility is crucial because:

- Minimizes Stress: By allowing for movement, flexibility reduces stresses within the piping system, extending its lifespan.

- Prevents Failures: Without proper flexibility, thermal expansion can lead to pipe failure, leaks, or damage to connected equipment.

- Improves Reliability: A flexible system is more resilient and less prone to unplanned downtime.

Flexibility is achieved through careful design, appropriate support selection (using expansion joints or flexible supports), and appropriate material selection. It’s a key factor considered during the stress analysis of the piping system to ensure longevity and safety.

Q 7. What are the different types of pipe fittings and their applications?

Pipe fittings are components used to connect pipes, change direction, or modify the flow. Common types include:

- Elbows: Used to change the direction of flow. Various angles are available (e.g., 45-degree, 90-degree).

- Tees: Used to create branches in the piping system, splitting the flow into two directions.

- Reducers: Used to change the diameter of the pipe, typically used to transition between different pipe sizes.

- Flanges: Used to connect sections of pipe, providing a strong and easily detachable joint. Require bolts for connection.

- Unions: Similar to flanges but usually smaller and used for easier disconnection and maintenance.

- Valves: Used to control the flow of fluids, including gate valves, globe valves, ball valves, and check valves.

- Caps: Used to close the ends of pipes.

The selection of the right fitting depends on factors like the pipe material, fluid properties, pressure, temperature, and the specific application requirements. For example, high-pressure systems may require heavier-duty fittings like flanged connections, while lower-pressure systems might use simpler fittings like threaded unions.

Q 8. How do you select appropriate valves for a piping system?

Selecting the right valve for a piping system is crucial for safety, efficiency, and longevity. It’s not a one-size-fits-all process; you need to consider several factors. Think of it like choosing the right tool for a job – a screwdriver won’t work if you need a hammer.

- Fluid characteristics: What’s flowing through the pipe? Is it water, steam, corrosive chemicals, or a slurry? This dictates the valve material and sealing requirements. For example, corrosive chemicals might require a valve made of stainless steel or a special alloy.

- Operating pressure and temperature: The valve must withstand the system’s pressure and temperature without failure. A valve rated for 100 psi won’t suffice in a 500 psi system. Similarly, high temperatures necessitate valves with appropriate thermal properties.

- Flow control requirements: Does the system need on/off control, throttling (precise flow regulation), or quick shut-off? Different valve types excel in different areas. Globe valves, for instance, are great for throttling, while gate valves are better for on/off control.

- Maintenance and accessibility: Consider how easy it will be to maintain and repair the valve. Accessibility is paramount; you don’t want a valve buried deep within a complex system that’s difficult to reach.

- Safety considerations: In hazardous environments, safety is paramount. Consider features like fail-safe mechanisms, fire-safe designs, and emergency shut-off capabilities.

- Cost: Balance cost with performance and longevity. While a cheaper valve might seem appealing, its shorter lifespan and increased maintenance needs could outweigh the initial savings.

Example: In a high-pressure steam system, you’d likely select a high-temperature, high-pressure gate valve for on/off control and a globe valve for throttling, both constructed from materials resistant to steam corrosion.

Q 9. Describe the process of developing a Piping and Instrumentation Diagram (P&ID).

Developing a Piping and Instrumentation Diagram (P&ID) is a systematic process crucial for the design, construction, and operation of any process plant. Think of it as the blueprint for your piping system. It’s a schematic diagram showing the piping, equipment, instrumentation, and control systems.

- Process Definition: This starts with a thorough understanding of the process itself. What are the inputs, outputs, and intermediate steps? What are the desired operating conditions?

- Equipment List: Identify all major equipment involved (reactors, pumps, heat exchangers, etc.) and their specifications.

- Instrumentation: Determine the necessary instrumentation (sensors, transmitters, controllers) for monitoring and controlling the process. This includes specifying locations and types of instruments.

- Piping Layout: Develop a layout showing the piping network connecting the equipment. Consider factors like flow direction, elevation changes, and space constraints. You’ll use standard symbols for valves, pipes, and fittings.

- Instrumentation and Control Logic: Show how the instrumentation and control systems interact to maintain process parameters within acceptable ranges. This might include control loops and alarm systems.

- Review and Revision: The P&ID is reviewed by engineers from various disciplines (process, instrumentation, mechanical) to ensure accuracy, consistency, and completeness. Iterative revisions are common.

- Documentation: The final P&ID is properly documented, including revision history and approval signatures.

Example: A P&ID for a chemical reactor would show the reactor itself, the inlet and outlet pipes, valves controlling flow, temperature sensors, pressure transmitters, and the control system managing the reactor’s temperature and pressure. The P&ID would clearly indicate the connections and interactions between these components.

Q 10. What are the key considerations for designing piping systems for seismic conditions?

Designing piping systems for seismic conditions requires careful consideration of potential earthquake effects. Failure to do so can lead to catastrophic consequences. The goal is to prevent pipe rupture, leaks, and damage to connected equipment.

- Seismic Zone Classification: Determine the seismic zone based on geographical location and associated design ground motion.

- Pipe Material Selection: Use ductile materials with high tensile strength and toughness to withstand seismic forces. This might involve specifying certain grades of steel or other appropriate materials.

- Support System Design: The support system is critical. Supports must be designed to restrain the pipe from excessive movement during an earthquake. This usually involves a combination of rigid and flexible supports. Analysis might involve sophisticated software that considers dynamic loading conditions.

- Pipe Restraints: Proper restraints are essential to prevent pipe whip (sudden, uncontrolled movement). These restraints can be anchored to the building structure to limit pipe displacement.

- Stress Analysis: Perform thorough stress analysis to ensure that the piping system can withstand the seismic loads without exceeding allowable stress limits. This typically involves finite element analysis (FEA).

- Seismic Qualification Testing: For critical systems, seismic qualification testing might be required to demonstrate the system’s ability to withstand simulated earthquake events.

Example: In a high-seismic zone, a chemical plant’s piping system might utilize snubbers (devices that absorb shock) and sway braces to control pipe movement during an earthquake, combined with robust anchoring to the building foundation.

Q 11. Explain the importance of proper pipe insulation and its selection criteria.

Proper pipe insulation is essential for several reasons, including energy efficiency, personnel safety, and process control. Imagine trying to hold a hot pipe without gloves –ouch! Insulation provides a similar protective barrier.

- Energy Conservation: Insulation reduces heat loss (or gain) from pipes, minimizing energy consumption and operating costs. This is especially important for hot and cold water lines, steam pipes, and cryogenic systems.

- Personnel Safety: Insulation protects personnel from burns or frostbite by preventing contact with excessively hot or cold surfaces. This is critical in industrial settings.

- Process Control: For processes sensitive to temperature variations, insulation helps maintain consistent temperatures along the piping system, improving product quality and efficiency.

- Corrosion Prevention: Insulation can protect pipes from corrosion by controlling condensation.

Insulation Selection Criteria:

- Thermal Conductivity: Lower conductivity indicates better insulation. This value is often expressed in units of BTU-in/hr-ft²-°F or W/m·K.

- Temperature Range: The insulation must be suitable for the operating temperature of the pipe.

- Moisture Resistance: Moisture can significantly reduce the insulation’s effectiveness. Choose a moisture-resistant material for outdoor applications or humid environments.

- Durability and Longevity: The insulation should be robust and resistant to damage from mechanical impact, UV exposure, or other environmental factors.

- Environmental Considerations: Choose insulation with minimal environmental impact during manufacturing, installation, and disposal.

Example: For a steam pipe operating at 300°F, calcium silicate insulation with a high temperature rating would be a suitable choice. For chilled water lines, polyurethane foam insulation is often preferred for its superior thermal properties.

Q 12. How do you manage piping system expansion and contraction?

Piping systems expand and contract due to temperature changes. This thermal expansion can cause significant stresses in the piping if not properly managed. Imagine a metal bar heating up – it gets longer; this is the same principle.

- Expansion Loops: These are U-shaped or other shaped bends incorporated into the piping to accommodate expansion and contraction. The loop acts as a flexible element, allowing movement without significant stress on straight pipe sections.

- Expansion Joints: These are specialized components designed to absorb expansion and contraction. They are usually installed at points where expansion loops are impractical or insufficient.

- Pipe Guides and Restraints: These guide the pipe’s movement during thermal expansion, preventing excessive displacement and ensuring proper alignment. Restraints limit movement to prevent excessive loads on other components.

- Stress Analysis: It’s crucial to perform stress analysis to determine the required flexibility of the piping system and to ensure that stresses do not exceed allowable limits.

- Material Selection: The choice of pipe material influences its thermal expansion characteristics. Materials with low coefficients of thermal expansion are preferred to minimize expansion and contraction.

Example: A long, straight steam pipe running across a large plant would likely incorporate multiple expansion loops to absorb temperature-induced expansion and contraction.

Q 13. What are the different types of pipe supports and their applications?

Pipe supports are critical for providing stability, preventing sagging, and managing stresses in a piping system. Choosing the right support depends on factors such as pipe size, material, operating conditions, and environmental considerations.

- Rigid Supports: These provide fixed points and prevent any movement. Examples include anchors and weldments directly attached to the building structure.

- Flexible Supports: These allow for some limited movement while still providing support. Examples include spring supports, constant support hangers, and variable spring hangers.

- Guides: These restrict pipe movement in one or two directions but allow movement in other directions. They prevent lateral movement or rotation.

- Snubbers: These energy-absorbing devices limit the movement of pipes during seismic events or sudden pressure surges.

- Restrainers: These prevent excessive movement and reduce stress on the piping system caused by thermal expansion, pressure fluctuations, or other loads.

Applications:

- Rigid Supports: Used for anchoring heavy equipment or in locations where movement is undesirable.

- Flexible Supports: Used in areas where expansion and contraction must be accommodated.

- Guides: Used to maintain alignment and prevent lateral or rotational movement.

- Snubbers: Used in seismic zones or critical systems to protect equipment during seismic events.

- Restrainers: Used to limit movements that could exceed the pipe’s capacity or damage connected equipment.

Example: A large diameter, high-temperature steam pipe might use a combination of rigid supports for anchoring, flexible supports for accommodating expansion, and guides to maintain alignment.

Q 14. How do you ensure compliance with relevant codes and standards during piping design?

Ensuring compliance with relevant codes and standards during piping design is critical for safety, reliability, and legal compliance. Ignoring these standards can lead to serious consequences, including equipment failure, environmental damage, and even loss of life.

- Identify Applicable Codes: The first step is to identify all relevant codes and standards applicable to the project. This will vary depending on factors such as the location, industry, fluid being transported, and pressure and temperature ratings.

- Material Specifications: Verify that all materials comply with the specified standards. This includes pipe, valves, fittings, flanges, and other components. Traceability is essential; you need to know where the materials came from and whether they’ve undergone appropriate quality control.

- Design Calculations: All design calculations, such as stress analysis and pressure drop calculations, must comply with relevant code requirements. Software used should also comply with relevant validation and verification.

- Fabrication and Installation: Fabrication and installation procedures must adhere to code requirements. Welders must be qualified, and welding procedures must be approved. Regular inspections are necessary to ensure adherence to specifications.

- Testing and Inspection: The piping system must undergo rigorous testing and inspection to verify its compliance with code requirements. This might include hydro-testing, leak testing, and non-destructive examination (NDE) methods.

- Documentation: Maintain thorough documentation throughout the design, fabrication, and installation process to prove compliance. This documentation should be readily available for audits and inspections.

Examples of Codes and Standards: ASME B31.1 (Power Piping), ASME B31.3 (Process Piping), ASME B31.4 (Liquid Petroleum Transportation Piping Systems), API standards.

Example: When designing a piping system for a refinery, compliance with ASME B31.3 is mandatory. This involves using approved materials, performing stress analysis according to the code’s requirements, ensuring proper weld quality, and conducting thorough inspections.

Q 15. Explain the concept of hydro testing and its importance.

Hydrotesting, also known as hydrostatic testing, is a crucial non-destructive examination (NDE) method used to verify the integrity of piping systems before they go into operation. It involves filling the piping system with water and pressurizing it to a specific level above its design pressure. This pressure is maintained for a set period, allowing any weaknesses or defects to manifest as leaks. The importance lies in proactively identifying potential failures before the system is commissioned, preventing costly repairs, production downtime, and potentially hazardous situations.

Imagine inflating a tire – you check for leaks before driving. Hydrotesting is the same principle, but on a much larger and more critical scale. The test results provide confidence that the system can withstand the intended operating pressures and prevent catastrophic failures.

The process typically involves:

- Isolating the piping section to be tested.

- Filling it with water.

- Pressurizing it to the specified test pressure.

- Holding the pressure for a predetermined duration.

- Inspecting for leaks.

Detailed documentation of the entire process, including pressure readings, duration, and observations, is essential for compliance and future reference.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of pipe failures and their causes?

Pipe failures can be broadly categorized into several types, each with its own set of contributing causes. Understanding these causes is crucial for preventing future failures.

- Corrosion: This is arguably the most common cause, leading to thinning of the pipe wall and eventual rupture. It can be caused by various factors, including chemical reactions with the transported fluid, electrochemical processes, and environmental factors like soil conditions.

- Stress Corrosion Cracking (SCC): This occurs when a combination of tensile stress and a corrosive environment causes cracking. It’s often seen in high-pressure systems or those transporting aggressive chemicals.

- Fatigue Failure: Repeated cycles of stress and strain, especially in areas with high vibration or pressure fluctuations, can weaken the pipe material leading to fatigue cracks and eventual failure.

- Creep Rupture: At high temperatures, materials slowly deform under sustained stress. This can eventually lead to rupture, especially in power generation or petrochemical applications.

- Brittle Fracture: This sudden catastrophic failure happens in materials that lack ductility. Low temperatures or high stress concentrations can trigger brittle fracture.

- Erosion: The continuous flow of fluids, especially those containing abrasive particles, can erode the pipe’s inner surface, leading to thinning and eventual failure.

Identifying the root cause of a pipe failure requires careful investigation, often involving metallurgical analysis and a thorough review of operating conditions.

Q 17. Describe your experience with different CAD software used in piping design.

Throughout my career, I’ve extensively used several CAD software packages for piping design, each with its strengths and weaknesses. My expertise includes:

- AutoCAD: I’m proficient in using AutoCAD for creating 2D isometric drawings, generating pipe schedules, and developing general arrangement drawings. Its familiarity and widespread use make it indispensable for collaboration.

- Autodesk Plant 3D: This is my go-to software for complex 3D piping models. Its capabilities extend to clash detection, automated component placement, and isometrics generation, significantly streamlining the design process and reducing errors.

- Bentley MicroStation: I have experience with MicroStation, particularly for projects requiring integration with other Bentley products like OpenPlant. Its capabilities in managing large-scale projects are beneficial.

- SP3D: I’ve used SP3D on several projects, appreciating its strength in managing large-scale projects and its excellent capabilities for collaboration and data management.

My proficiency in multiple software packages allows me to adapt to diverse project requirements and client preferences, ensuring optimal design efficiency and accuracy.

Q 18. How do you handle conflicts between different engineering disciplines during piping design?

Conflicts between engineering disciplines are inevitable in large projects. Effective communication and proactive collaboration are key to resolving them. My approach involves:

- Regular Coordination Meetings: Scheduling regular meetings with representatives from all disciplines (piping, structural, electrical, instrumentation, etc.) ensures open communication and early identification of potential conflicts.

- 3D Modeling and Clash Detection: Utilizing 3D modeling software with clash detection capabilities allows for early identification of physical interferences between different systems. This allows for design adjustments before construction begins.

- Clear Communication Protocols: Establishing clear communication channels and protocols ensures that all parties are informed of design changes and potential conflicts in a timely manner.

- Compromise and Collaboration: Finding mutually acceptable solutions often requires compromise and collaboration. This may involve minor design adjustments to accommodate other disciplines’ requirements.

- Documentation: Meticulous documentation of all design changes and conflict resolutions is essential to ensure that everyone is working from the same information.

For example, in one project, a conflict arose between the piping layout and the structural steel supports. By using 3D modeling and collaborative meetings, we identified the conflict early and adjusted the pipe routing to avoid interference with the structural supports, preventing costly rework.

Q 19. Explain the importance of proper documentation in piping design.

Proper documentation is the cornerstone of successful piping design and is crucial for several reasons:

- Compliance: Comprehensive documentation ensures adherence to relevant codes and standards (ASME B31.1, B31.3, etc.), minimizing legal and safety risks.

- Maintainability: Accurate and complete documentation simplifies maintenance, repair, and future modifications. It provides crucial information on materials, specifications, and installation details.

- Construction and Fabrication: Clear and detailed drawings and specifications are essential for efficient and accurate construction and fabrication. Ambiguous documentation leads to errors and delays.

- Cost Savings: Well-defined documentation reduces the likelihood of errors and rework, significantly saving costs in the long run.

- Risk Management: Proper documentation helps identify potential risks and facilitates the development of mitigation strategies.

Imagine trying to repair a complex system without proper documentation – it’s akin to trying to assemble a puzzle without the picture on the box. Comprehensive documentation safeguards against such difficulties.

Q 20. What are the common causes of piping leaks and how can they be prevented?

Piping leaks are a significant concern, potentially leading to environmental damage, safety hazards, and production losses. Common causes include:

- Corrosion: As discussed earlier, corrosion weakens pipe walls, making them susceptible to leaks.

- Improper Installation: Faulty welds, inadequate support, and incorrect pipe fitting installation are common causes.

- Erosion: The erosion of the internal pipe surface, especially in high-velocity flows, can cause leaks.

- Mechanical Damage: External factors such as impacts, vibrations, and ground movement can damage pipes and lead to leaks.

- Thermal Stress: Rapid temperature changes can induce thermal stresses that exceed the pipe’s capacity, causing cracks and leaks.

- Material Defects: Manufacturing defects, such as inclusions or cracks, can weaken the pipe material and create vulnerabilities.

Prevention involves a multi-pronged approach:

- Proper Material Selection: Choosing corrosion-resistant materials suitable for the transported fluid and operating conditions.

- Careful Installation Practices: Following proper installation procedures, including qualified welders and adequate support systems.

- Regular Inspection and Maintenance: Implementing a robust inspection and maintenance program, including visual inspections, non-destructive testing, and leak detection systems.

- Corrosion Protection: Employing appropriate corrosion protection measures, such as coatings, cathodic protection, or inhibitors.

Q 21. How do you determine the appropriate pipe wall thickness?

Determining the appropriate pipe wall thickness is a critical aspect of piping design, ensuring the system can withstand the operating pressures and other loads. This calculation involves several factors and is guided by relevant piping codes and standards, primarily ASME B31.1, B31.3, etc.

The basic formula incorporates:

- Internal pressure (P): The operating pressure within the pipe.

- Outside diameter (OD): The outside diameter of the pipe.

- Yield strength (S): The yield strength of the pipe material at the operating temperature.

- Design factor (F): A safety factor to account for uncertainties and variations.

A simplified formula (often used for initial estimations) is:

t = (P x OD) / (2 x S x F - 2 x P)Where ‘t’ is the minimum wall thickness. However, the actual calculation is more complex and takes into account other factors such as:

- Temperature effects: High temperatures reduce material strength, necessitating thicker walls.

- Corrosion allowance: Additional thickness is added to account for expected corrosion over the pipe’s lifespan.

- External loads: Loads from supports, wind, or seismic events are also considered.

- Specific code requirements: Piping codes like ASME B31.1 provide detailed formulas and tables for calculating required wall thicknesses based on material, fluid type, temperature, and pressure.

Specialized software is commonly employed to perform these calculations accurately, considering all relevant parameters and ensuring compliance with relevant standards. This ensures the piping system is adequately designed for safety and longevity.

Q 22. Describe your experience with piping system inspection and maintenance.

My experience in piping system inspection and maintenance spans over a decade, encompassing diverse projects across various industries including oil & gas, chemical processing, and power generation. I’m proficient in conducting both routine inspections and comprehensive assessments, utilizing a range of techniques such as visual inspections, non-destructive testing (NDT) methods like ultrasonic testing (UT) and radiographic testing (RT), and pressure testing. My approach is always risk-based, prioritizing critical systems and components based on their potential for failure and consequences. For example, in one project involving a refinery, we identified a critical flaw in a high-pressure steam line during a routine inspection, preventing a potential catastrophic failure and significant downtime. This involved meticulous documentation, detailed reporting, and collaborative work with maintenance teams to implement effective repairs.

My maintenance experience includes developing and implementing preventative maintenance (PM) programs, optimizing maintenance schedules based on risk analysis and equipment reliability data, and managing the execution of corrective maintenance actions. I’m well-versed in various maintenance strategies, including predictive maintenance using vibration analysis and thermography to prevent unplanned outages.

Q 23. How do you manage changes in design during the construction phase?

Managing design changes during construction requires a systematic and controlled approach to ensure safety, compliance, and project success. This typically involves a formal change management process, starting with a formal request outlining the proposed changes, the justification, and potential impact on the project schedule and budget. This request is then reviewed by a multi-disciplinary team, including engineering, procurement, construction, and safety representatives. The review process involves assessing the impact on the piping system’s integrity, compliance with relevant codes and standards (like ASME B31.1, B31.3, etc.), and potential environmental consequences.

Approved changes are documented and incorporated into the revised drawings and specifications. These changes need to be communicated effectively to all relevant parties and implemented meticulously, closely monitoring the fabrication and installation to ensure adherence to the revised design. Thorough quality control checks are essential throughout the process. For instance, a change in a pipe material might necessitate updates to welding procedures and NDT requirements. A well-defined change management process minimizes disruption and prevents errors.

Q 24. What are your familiar with different types of flanges and their applications?

I’m familiar with various flange types, each suitable for specific applications based on pressure, temperature, and the nature of the fluid being conveyed. Some common flange types include:

- Welding Neck Flanges: Offer excellent strength and fatigue resistance, ideal for high-pressure applications.

- Slip-on Flanges: Easy to install, but less resistant to fatigue compared to welding neck flanges.

- Socket Weld Flanges: Suitable for smaller diameter pipes and lower pressure applications.

- Blind Flanges: Used for closing off pipe ends, commonly for maintenance or testing.

- Lap Joint Flanges: Commonly used with raised face gaskets and offer good corrosion resistance.

- Threaded Flanges: Suitable for low-pressure applications with smaller pipe sizes.

The selection of a flange type is crucial and depends on factors like pressure class, temperature rating, material compatibility, and ease of installation and maintenance. Mismatched flange types can lead to leaks, damage to equipment, and potential safety hazards. For example, using slip-on flanges in a high-cycle fatigue environment would be inappropriate due to their lower fatigue resistance compared to welding neck flanges.

Q 25. Explain your experience with HAZOP studies and their relevance to piping systems.

HAZOP (Hazard and Operability) studies are a crucial part of piping system design and safety. I have extensive experience participating in and leading HAZOP studies, facilitating multidisciplinary team discussions to identify potential hazards and operability problems throughout the lifecycle of the piping system. A systematic approach is employed, using guide words (e.g., ‘no,’ ‘more,’ ‘less,’ ‘part of’) to challenge each piping system element and its operating parameters. Each identified deviation from the expected behavior is analyzed to determine its potential consequences, causes, and preventive measures.

For instance, in a recent project involving the handling of flammable chemicals, the HAZOP study highlighted a potential for a leak in a valve due to corrosion. Through this analysis, we implemented improved corrosion protection measures and enhanced inspection procedures, significantly mitigating the risk. The output of a HAZOP study is a documented report containing identified hazards, their associated risks, and recommended safeguards. This report forms an integral part of the project’s safety documentation and contributes significantly to risk mitigation.

Q 26. What are the key considerations for designing piping systems for hazardous materials?

Designing piping systems for hazardous materials demands meticulous attention to safety and regulatory compliance. Key considerations include:

- Material Selection: Choosing materials compatible with the hazardous material to prevent corrosion, degradation, or chemical reactions.

- Leak Detection and Prevention: Implementing reliable leak detection systems and incorporating features such as double containment and pressure relief valves.

- Pressure Rating and Design: Ensuring the piping system is designed to withstand the maximum operating pressure and temperature.

- Emergency Shutdown Systems (ESD): Integrating robust ESD systems to prevent catastrophic events in case of leaks or equipment malfunctions.

- Regulatory Compliance: Adhering to relevant codes and standards, including those related to hazardous materials handling, such as OSHA and EPA regulations.

- Environmental Protection: Designing the system to minimize the environmental impact of any potential leaks or spills.

For example, when designing a system for handling chlorine gas, special attention is paid to material selection (e.g., using carbon steel with appropriate coatings), leak detection methods (e.g., gas detectors), and emergency procedures (e.g., quick-closing valves). Each component is meticulously analyzed to assure absolute safety.

Q 27. How familiar are you with different types of pipe welding techniques?

My experience encompasses various pipe welding techniques, including:

- Shielded Metal Arc Welding (SMAW): A versatile technique suitable for various materials and environments.

- Gas Metal Arc Welding (GMAW): High-speed welding process, commonly used for larger diameter pipes.

- Gas Tungsten Arc Welding (GTAW): Ideal for precise welds with high-quality finishes, particularly suitable for thin-walled pipes and special alloys.

- Submerged Arc Welding (SAW): A highly productive method for large-diameter pipes, used in automated systems.

The choice of welding technique depends on several factors, including pipe material, diameter, wall thickness, and the required weld quality. Each technique necessitates adherence to specific welding procedures and quality control measures, including pre-weld inspection, welder qualification, and post-weld NDT examination to ensure the integrity of the weld.

For instance, in high-pressure applications, strict adherence to welding codes like ASME Section IX is crucial. This mandates qualified welders, specific welding procedures, and extensive NDT inspections to validate the strength and integrity of the weld joint.

Q 28. Describe your experience with the use of specialized piping software (e.g., CAESAR II, AutoPIPE).

I have significant experience using specialized piping software, including CAESAR II and AutoPIPE. These tools are invaluable for stress analysis, flexibility analysis, and overall piping system design optimization. CAESAR II, for example, allows me to model complex piping systems, apply various load cases (e.g., pressure, weight, thermal expansion), and analyze stress levels in piping components. This helps to ensure the system can safely withstand anticipated loads and prevents potential failures. AutoPIPE offers similar capabilities, enabling detailed analysis and optimization of piping networks.

Using this software, I can perform detailed calculations to determine pipe sizes, support locations, and component specifications, ensuring that the system is designed efficiently and economically while adhering to relevant codes and standards. The software also allows for the creation of detailed reports and drawings, facilitating effective communication and collaboration within the project team. For example, I used CAESAR II to analyze the stress levels in a critical pipeline during a major plant expansion, optimizing the support system and ensuring the system could safely handle the increased flow rate.

Key Topics to Learn for Piping Codes and Standards Interview

- Code Familiarization: Understand the fundamental principles and applications of major piping codes like ASME B31.1, B31.3, B31.4, and relevant international standards. Focus on the scope and limitations of each code.

- Material Selection & Specifications: Learn how to select appropriate piping materials based on pressure, temperature, fluid compatibility, and environmental conditions. Understand the role of material specifications and certifications.

- Design Calculations & Stress Analysis: Grasp the theoretical concepts behind pressure drop calculations, stress analysis (including thermal stress), and pipe support design. Be prepared to discuss practical application of these calculations.

- Fabrication & Construction: Familiarize yourself with welding procedures, inspection techniques, and quality control measures as they relate to piping systems. Understand common fabrication challenges and their solutions.

- Inspection & Testing: Know the different types of inspections and tests (e.g., hydrostatic testing, radiographic testing) used to ensure the integrity and safety of piping systems. Understand relevant acceptance criteria.

- Piping System Components: Demonstrate a strong understanding of various components such as valves, fittings, flanges, and expansion joints, including their selection criteria and function within a piping system.

- Safety & Regulations: Understand the safety considerations and regulatory compliance aspects associated with piping systems design, installation, and operation. This includes hazard identification and risk mitigation.

- Problem-Solving & Troubleshooting: Be prepared to discuss approaches to diagnosing and resolving common piping system issues, such as leaks, corrosion, and vibration. Practice using your problem-solving skills in a hypothetical context.

Next Steps

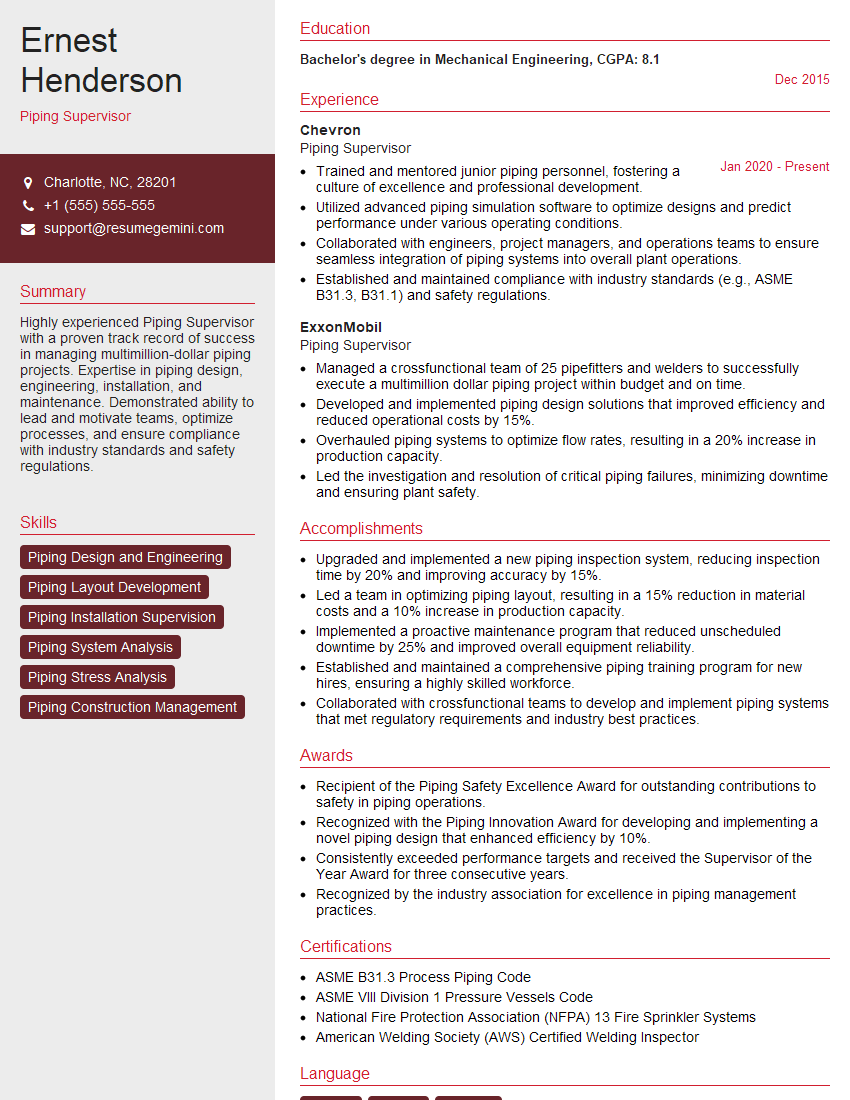

Mastering Piping Codes and Standards is crucial for career advancement in the engineering and construction industries, opening doors to higher-paying roles and leadership opportunities. An ATS-friendly resume is your key to unlocking these opportunities. To significantly improve your chances, create a compelling and keyword-rich resume that highlights your expertise in these vital areas. We recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini offers examples of resumes tailored specifically to Piping Codes and Standards expertise to guide you. Invest in your career success – build a powerful resume that showcases your knowledge and skills.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.