Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Service Plumber interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Service Plumber Interview

Q 1. Describe your experience with different types of pipe materials (e.g., PVC, copper, PEX).

My experience spans across various pipe materials, each with its own strengths and weaknesses. Let’s look at three common types:

- PVC (Polyvinyl Chloride): A lightweight, inexpensive, and corrosion-resistant plastic pipe. It’s ideal for cold water supply lines and drainage systems, especially in areas where freezing is a concern because it’s less prone to bursting than metal pipes. However, PVC isn’t suitable for hot water applications as it can soften and become brittle over time. I’ve used it extensively in residential renovations and new construction projects.

- Copper: A durable, reliable, and aesthetically pleasing metal pipe. It’s highly resistant to corrosion and can withstand both hot and cold water pressure. Copper pipes are a premium option, used frequently in high-end residential and commercial settings. However, they are more expensive than PVC and can be more challenging to work with, requiring specialized tools and soldering skills. I’ve extensively worked with copper on both repair and installation jobs, appreciating its longevity.

- PEX (Cross-linked Polyethylene): A flexible plastic pipe known for its ease of installation. PEX is resistant to freezing and corrosion, making it suitable for both hot and cold water applications. The flexible nature of PEX allows for easier maneuvering in tight spaces. It’s also relatively inexpensive, making it a popular choice for many homeowners. However, while durable, it doesn’t have the same longevity as copper. I’ve found PEX particularly useful in renovations where access is limited.

My experience encompasses the installation, repair, and maintenance of all three pipe materials, allowing me to select the best option based on project requirements and client preferences.

Q 2. Explain the process of troubleshooting a low water pressure issue.

Troubleshooting low water pressure requires a systematic approach. Think of it like investigating a crime scene – you need to gather clues to pinpoint the culprit.

- Check the main water shut-off valve: Ensure it’s fully open. This is the most common cause of low pressure and the easiest to fix!

- Inspect faucets and showerheads: Look for mineral buildup or debris restricting water flow. Cleaning or replacing the aerator or showerhead often resolves the problem. Imagine a partially clogged straw – it restricts the flow of liquid.

- Check the water meter: Verify that the meter is registering water usage. A faulty meter might indicate a problem with your water supply.

- Investigate the pressure regulator: If the pressure is low throughout the house, the problem might lie with the pressure regulator, which maintains consistent pressure. A faulty regulator needs professional attention.

- Look for leaks: Dripping faucets and running toilets significantly reduce water pressure. Fixing leaks is crucial for both conserving water and restoring proper pressure. A small leak can add up over time and significantly affect overall pressure.

- Examine the water pipes: Look for corrosion, clogs, or other damage. This might require specialized tools and potentially require replacing sections of pipe, especially if you suspect corrosion or significant blockages.

If the problem persists after these steps, calling a plumber is advisable as it may indicate a more serious issue requiring professional expertise.

Q 3. How do you identify and repair a leaking faucet?

Identifying and repairing a leaking faucet depends on the type of faucet. Generally, it involves identifying the source of the leak and replacing the faulty part.

- Identify the leak: Determine if it’s leaking from the spout, handle, or base. This pinpoints the problem area. It’s often as simple as observing where the water is dripping or running.

- Turn off the water supply: Before starting any repair, turn off the water supply to the faucet using the shut-off valves located under the sink.

- Disassemble the faucet: Carefully disassemble the faucet according to the manufacturer’s instructions or a suitable online guide. Take pictures as you go to aid reassembly.

- Inspect for worn parts: Common culprits include worn-out O-rings, washers, cartridges, or seats. These are small rubber or plastic parts that create a watertight seal. They wear down over time.

- Replace worn parts: Replace the worn parts with new ones. These parts are readily available at most hardware stores.

- Reassemble the faucet: Carefully reassemble the faucet, ensuring all parts are correctly aligned. Refer to your pictures if needed.

- Test for leaks: Turn the water supply back on and check for any remaining leaks. If a leak persists, carefully review each step.

If you’re uncomfortable disassembling the faucet, it’s best to call a plumber. A small repair can easily turn into a larger problem if not handled correctly.

Q 4. What are your methods for clearing clogged drains?

Clearing clogged drains is a common plumbing issue. My approach is multi-pronged, starting with the least invasive methods and progressing to more aggressive techniques if necessary.

- Boiling water: Pouring boiling water down the drain can often melt away grease and soap buildup. It’s a simple and effective first step.

- Plunger: A good old-fashioned plunger is remarkably effective for many clogs. Make sure to create a good seal around the drain opening. Think of it like creating suction to dislodge the blockage.

- Baking soda and vinegar: This natural cleaning solution is surprisingly powerful. Pour baking soda down the drain, followed by vinegar. The fizzing reaction helps break down clogs.

- Drain snake (plumber’s snake): For more stubborn clogs, a drain snake can navigate bends in the pipe to break up or retrieve the obstruction. This requires some skill to avoid scratching the pipes.

- Chemical drain cleaners: These are a last resort, as they can damage pipes if overused. Always follow the manufacturer’s instructions carefully.

- Hydro-jetting: For severe clogs or persistent blockages, hydro-jetting uses high-pressure water to clear blockages. It is best done by professionals. This is like power-washing your pipes.

The best method depends on the nature and severity of the clog. Always prioritize safety and avoid using harsh chemicals unless absolutely necessary.

Q 5. Describe your experience with different types of plumbing fixtures (e.g., toilets, sinks, showers).

My experience with plumbing fixtures is extensive, covering various types and brands. This includes installation, repair, and maintenance.

- Toilets: I’m proficient in installing, repairing, and maintaining various types of toilets, from standard one-piece models to two-piece designs and low-flow models. Understanding the inner workings of different flushing mechanisms is crucial for efficient repairs. I’ve worked on everything from simple repairs like replacing flappers to more complex issues like resolving leaks around the base.

- Sinks: My experience with sinks includes various materials (porcelain, stainless steel, composite) and styles (drop-in, undermount, vessel). I handle installations, repairs of leaky faucets, clogs, and damaged drains. I’m also familiar with garbage disposals and their related issues.

- Showers: From standard showerheads to complex shower systems with multiple sprayers and controls, my expertise includes installation, repair of leaks, and addressing water pressure problems. Understanding how different valve types work is key to effective repair and maintenance.

I am familiar with both common and less frequent issues, making sure to stay up-to-date with current plumbing technology and best practices.

Q 6. How do you diagnose and repair a running toilet?

A running toilet wastes water and money. Diagnosing the cause usually involves checking a few key components.

- Check the flapper: The flapper is a rubber seal in the tank that prevents water from constantly flowing into the bowl. If it’s worn or not sealing properly, water will continuously run into the bowl. A simple visual inspection is the first step.

- Inspect the fill valve: The fill valve controls how much water enters the tank. A malfunctioning fill valve might overfill the tank, causing water to constantly overflow into the bowl. Listen carefully for the sound of the fill valve running even when the tank is full.

- Examine the chain: The chain connects the handle to the flapper. A chain that’s too long or too short can prevent the flapper from sealing correctly. A simple adjustment might solve the problem.

- Check the float: The float regulates the water level in the tank. If it’s misaligned or damaged, it could cause the tank to overfill. Adjusting the float or replacing it might resolve the issue.

Most running toilet issues are fairly straightforward to diagnose and fix with readily available parts. However, if you’re unsure, calling a plumber is a safer option to avoid making the problem worse.

Q 7. Explain your understanding of water hammer and how to mitigate it.

Water hammer is the loud banging sound that occurs in pipes when water flow is suddenly stopped. Imagine slamming on the brakes of a car – the sudden stop creates a shockwave.

The sudden stop of water flow creates a pressure surge (the hammer) that travels through the pipes, causing the banging sound. It’s often caused by appliances like washing machines, dishwashers, and toilets that quickly shut off the water flow.

Mitigating water hammer involves installing water hammer arrestors. These devices are small pressure-absorbing devices that are typically installed near fixtures causing the problem. They act like shock absorbers for the water flow, reducing the pressure surges and preventing the banging noise. Placement is crucial; typically, they’re installed close to the source of the hammer, such as the supply lines for appliances.

In some instances, air chambers can be used instead. These are sections of pipe filled with air that absorb the shockwave. However, they require more space and are less common in modern plumbing systems. Sometimes the solution is as simple as tightening loose pipes or securing appliances to prevent vibrations from contributing to the problem.

Q 8. What are your experience with gas appliance installation and maintenance?

Gas appliance installation and maintenance requires meticulous attention to safety and adherence to strict codes. My experience encompasses the entire process, from initial inspection and planning to final testing and commissioning. This includes working with various gas appliances such as furnaces, water heaters, ranges, and fireplaces. I’m proficient in identifying potential hazards like gas leaks, improper venting, and inadequate air circulation. I’ve worked on both residential and light commercial projects, troubleshooting issues such as pilot light problems, burner malfunctions, and insufficient heating or hot water. For instance, I once diagnosed a faulty thermocouple in a furnace, preventing the pilot light from staying lit. Replacing the thermocouple resolved the problem safely and efficiently. I always prioritize safety checks including leak detection with specialized equipment before, during, and after any gas-related work.

Q 9. Describe your familiarity with plumbing codes and regulations.

Plumbing codes and regulations are paramount to ensuring safe and functional plumbing systems. My familiarity extends to both local and national codes, including the International Plumbing Code (IPC) and local variations. I understand requirements for water pressure, pipe sizing, fixture installations, and waste disposal. I’m adept at interpreting blueprints, identifying potential code violations, and implementing corrective measures. For example, I know the specific requirements for venting systems to prevent sewer gases from entering a building. Regularly updating my knowledge on code changes is a critical part of my professional development. Failure to comply with these regulations can lead to serious safety issues, property damage, and legal ramifications.

Q 10. How do you handle emergency plumbing calls?

Emergency plumbing calls require a swift and effective response. My protocol begins with a thorough assessment of the situation over the phone to determine the urgency and nature of the problem. I prioritize calls involving burst pipes, significant leaks, or complete system failures. Upon arrival, I quickly assess the situation, take appropriate safety precautions, and implement temporary fixes to mitigate damage. I always communicate clearly and transparently with the client throughout the process, providing updates and explaining necessary steps. For example, I once responded to a burst pipe in a basement, quickly isolating the water flow and preventing significant water damage. Effective communication and problem-solving skills are essential in handling the stress and urgency inherent in these situations.

Q 11. Explain your experience with backflow prevention devices.

Backflow prevention devices are crucial for protecting potable water supplies from contamination. My experience includes installing, inspecting, and maintaining various types of backflow preventers, including double check valves, reduced pressure zone backflow preventers, and pressure vacuum breakers. I understand the importance of regular testing and maintenance to ensure their proper functioning. I’m familiar with the testing procedures and documentation requirements, ensuring compliance with local regulations. I’ve worked on both residential and commercial projects involving backflow preventer installations, often collaborating with other professionals, such as fire protection specialists. For example, I recently serviced a backflow preventer for a large commercial building, ensuring its continued efficiency in preventing the backflow of potentially harmful substances into the municipal water supply.

Q 12. How do you determine the root cause of a sewer line blockage?

Determining the root cause of a sewer line blockage requires a systematic approach. I begin with a visual inspection, looking for obvious obstructions such as tree roots, debris, or collapsed sections of pipe. I then use specialized tools like drain snakes or sewer cameras to investigate further. The camera allows for a detailed view of the interior of the pipe, identifying the precise location and nature of the blockage. I often use a combination of techniques, such as hydro jetting (high-pressure water jetting to clear blockages) or chemical treatments, depending on the severity and cause of the blockage. In some cases, more extensive repairs, such as pipe replacement, might be necessary. For instance, I recently used a sewer camera to locate a collapsed section of pipe causing a persistent blockage, which then required excavation and replacement.

Q 13. What is your experience with water heater installation and repair?

Water heater installation and repair is a common service I provide. My experience covers various types of water heaters, including gas, electric, and tankless models. I’m skilled in installing water heaters according to code, ensuring proper venting, gas connections (for gas models), and electrical connections (for electric models). I also troubleshoot common problems such as leaks, insufficient hot water, and burner malfunctions (for gas models). I understand the importance of safety precautions during installation and repair to prevent gas leaks or electrical shocks. Recently, I replaced an old, inefficient tank water heater with a tankless model, resulting in significant energy savings for the client. I always explain the pros and cons of different types of water heaters to help clients make informed decisions.

Q 14. Describe your knowledge of different types of plumbing pumps.

Plumbing pumps serve various purposes, and I’m familiar with several types. These include sump pumps (removing water from basements), sewage pumps (moving wastewater), booster pumps (increasing water pressure), and circulator pumps (improving hot water circulation). My experience involves selecting the appropriate pump based on the specific application, ensuring proper sizing, installation, and maintenance. I understand the different operating principles and potential problems associated with each type of pump. I’ve had extensive experience troubleshooting pump failures; diagnosing issues such as impeller wear, motor burnout, or clogged intake lines. For example, I recently installed a new booster pump for a client experiencing low water pressure, significantly improving the flow throughout their house. Proper pump selection and installation are crucial for effective and reliable plumbing systems.

Q 15. How do you test for gas leaks?

Detecting gas leaks is crucial for safety. We primarily use electronic leak detectors, which are sensitive instruments that register the presence of combustible gases like natural gas or propane. These devices usually have a sensor that reacts to the gas and gives a visual or audible signal, often accompanied by a numerical reading indicating the concentration.

Before using the detector, ensure the area is well-ventilated to avoid false readings from accumulated gas. I systematically check all gas appliances (stoves, furnaces, water heaters), pipes, and connections, paying close attention to joints and fittings where leaks are most likely. If a leak is suspected, I’ll immediately shut off the gas supply at the main valve and contact the appropriate gas company. Never use a flame or lighter to check for leaks; this is extremely dangerous and could cause an explosion.

Beyond electronic detectors, a soapy water solution can be applied to suspected leak points. Bubbles forming indicate a leak, as the escaping gas interacts with the soap to create bubbles. This method is less precise than an electronic detector but can be helpful in certain situations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with soldering and brazing techniques.

Soldering and brazing are essential skills for a plumber. I’m proficient in both, having used them extensively throughout my career to join copper pipes in various applications, from residential to commercial settings. Soldering involves lower temperatures and uses a solder with a lower melting point, ideal for smaller diameter copper pipes. Brazing uses higher temperatures and a filler metal with a higher melting point, suitable for larger pipes and situations requiring a stronger joint.

My process always starts with proper preparation. This includes cleaning the pipe ends thoroughly to remove any dirt, grease, or oxidation which would prevent a strong bond. Then, I flux the surfaces to promote the flow of the solder/brazing rod. I utilize the appropriate torch, controlling the flame size and heat to achieve an even melt. I then apply the solder or brazing rod to the joint, ensuring complete capillary action for a secure connection.

I regularly inspect my work visually, ensuring a smooth, even bead, free from imperfections, which could indicate weak points or future leaks. Safety is paramount; I always work in a well-ventilated area and use appropriate safety glasses and gloves to protect myself from burns and fumes.

Q 17. How do you use a pipe threader?

A pipe threader is a tool used to create precisely cut threads on the end of a pipe, allowing for the secure connection of fittings. The process involves several steps. First, I ensure the pipe is securely clamped in the pipe threader. Then, I select the appropriate die head that matches the pipe’s diameter. The die head is then attached to the threader. I carefully rotate the handle of the pipe threader, ensuring a slow, even pressure to cut the threads.

Throughout the process, I frequently check the depth and consistency of the threads, ensuring a smooth, even cut. This prevents cross-threading and ensures a tight, leak-proof fit. I also use cutting oil lubricant to facilitate the cutting process and reduce friction. It also helps prevent damage to the die heads and extends the life of the tool. After threading, I clean the pipe and fittings to ensure debris doesn’t interfere with the connection. Using a pipe threader requires precision and patience to avoid damage to the pipe and the tool.

Q 18. What are your safety procedures when working with plumbing systems?

Safety is my top priority. My safety procedures include, but aren’t limited to: always wearing appropriate Personal Protective Equipment (PPE), such as safety glasses, gloves, and sturdy work boots. When working with gas lines, I follow specific procedures for leak detection and gas shut-off. I ensure the area is well-ventilated and use electronic leak detectors before and after any work on gas appliances.

I always follow lock-out/tag-out procedures when working on electrical systems that might be near plumbing. I use caution when working at heights and utilize appropriate fall protection equipment when necessary. I’m also trained in handling hazardous materials, including proper disposal and decontamination. Regular toolbox talks and safety training are crucial to keep my safety practices up-to-date and effective.

Furthermore, I continuously assess the job site for potential hazards and adapt my approach as needed. Client safety is also a critical consideration, and I always maintain a clean and organized work area to minimize the risk of accidents.

Q 19. Describe your experience with using various plumbing tools.

My experience with plumbing tools is extensive. I’m proficient in using a wide range of tools, including pipe wrenches (various sizes), basin wrenches, pipe cutters, tubing benders, hacksaws, reamers, and various types of pliers. I also frequently use specialized tools like torque wrenches for precise tightening of fittings, and various drain augers and snakes for clearing clogs. My experience extends to using both manual and power tools efficiently and safely.

For example, I’m adept at choosing the right size wrench for the job to avoid damaging the fittings and ensuring a proper grip. I’m familiar with different types of pipe cutters and select the appropriate one based on the pipe material and diameter. I regularly maintain my tools to ensure they are in proper working order, increasing both efficiency and safety. Understanding the limitations of each tool and using them correctly is just as important as having a vast tool collection.

Q 20. How do you manage your time effectively during a busy day?

Managing time effectively on busy days requires a structured approach. Before starting my workday, I prioritize tasks based on urgency and importance. I often create a schedule or to-do list, outlining the specific tasks I need to complete and allocating time accordingly. I focus on one task at a time, avoiding multitasking, which can lead to errors and inefficiency.

I strive to be organized and efficient in my work, minimizing wasted time by planning my routes effectively, gathering all necessary tools and materials beforehand. If unexpected delays occur, I reassess my schedule and adjust accordingly, communicating any changes to clients promptly and professionally. I also utilize technology where appropriate, using apps to manage appointments and track my progress. Effective time management is crucial for delivering quality service and meeting client expectations, even during periods of high demand.

Q 21. How do you communicate effectively with clients?

Effective communication with clients is paramount. I begin by actively listening to their concerns, asking clarifying questions to ensure I fully understand the problem. I then clearly explain the issue, the proposed solutions, and any associated costs in a straightforward and easy-to-understand manner, avoiding technical jargon. I use visual aids like diagrams or photos when necessary to help clients visualize the problem and solution.

I maintain open and honest communication throughout the process, keeping clients updated on my progress and addressing any questions or concerns they may have. I strive to be professional and courteous at all times, fostering a positive and trusting relationship. After completing the work, I follow up with clients to ensure they are satisfied and to address any lingering concerns. Building rapport with clients through clear, respectful, and proactive communication is essential for a successful plumbing business.

Q 22. Describe your experience with reading and interpreting blueprints.

Reading blueprints is fundamental to my work. It’s like reading a map for a plumbing system. I’m proficient in interpreting architectural and plumbing drawings, understanding symbols representing various components like pipes, fittings, fixtures, and valves. I can identify pipe sizes, materials, and locations, and understand the flow of water and waste through the system. For example, I can readily discern the diameter of a pipe from the blueprint’s notation and understand the implications for water pressure and flow rate. I’ve worked on projects ranging from small residential renovations to large-scale commercial builds, always relying on accurate blueprint interpretation to ensure efficient and effective installation or repair.

I’m comfortable with both hand-drawn and CAD blueprints and can easily visualize the three-dimensional layout from the two-dimensional representation. I pay close attention to details like elevations, to avoid costly mistakes during installation. A missed detail on a blueprint can lead to significant rework, so accuracy is paramount.

Q 23. Explain your experience with different types of pipe fittings.

My experience encompasses a wide range of pipe fittings, crucial for joining and directing pipes within a plumbing system. These fittings are selected based on factors like pipe material (e.g., copper, PVC, PEX), pipe diameter, application (e.g., water supply, drainage), and pressure requirements. I’m familiar with:

- Couplings: Used to join pipes of the same diameter.

- Elbows: Used to change the direction of pipes, available in various angles (e.g., 45°, 90°).

- Tees: Used to create a branch connection from a main pipe.

- Unions: Allow for easy pipe disassembly without cutting.

- Reducers: Connect pipes of different diameters.

- Flanges: Large fittings used in high-pressure applications.

Choosing the right fitting is critical. For instance, using a PVC coupling for high-pressure copper piping would be a serious mistake. Over the years, I’ve encountered situations needing specialized fittings, such as those for specific types of valves or when adapting older systems to new materials. I always ensure the correct fitting is selected and properly installed to avoid leaks and maintain system integrity.

Q 24. How do you ensure the quality of your work?

Ensuring quality is central to my approach. It’s not just about completing the job; it’s about ensuring it’s done right, the first time. My quality control measures include:

- Thorough planning: Carefully reviewing blueprints and understanding the scope of work before starting.

- Careful material selection: Using high-quality, code-compliant materials.

- Precise measurements and cutting: Avoiding any sloppy work that might lead to leaks or other issues.

- Meticulous installation: Following proper installation techniques for each fitting and joint.

- Rigorous testing: After completion, I always pressure test all work to identify any leaks immediately.

- Clean-up: Leaving the work area spotless and ensuring the client is satisfied. A clean jobsite reflects the quality of the work itself.

For example, in a recent repiping project, a meticulous pressure test revealed a small leak that I was able to fix promptly, before any significant damage could occur. This proactive approach has saved clients from potential water damage and expensive repairs down the line.

Q 25. Describe your experience with preventative maintenance on plumbing systems.

Preventative maintenance is key to extending the life of plumbing systems and avoiding costly repairs. This often involves inspecting various components to ensure efficient and safe operation. My experience includes:

- Regular inspections: Checking for leaks, corrosion, and signs of wear and tear.

- Water heater maintenance: Flushing sediment, inspecting the anode rod, checking the thermostat.

- Drain cleaning: Using appropriate tools to clear blockages and prevent future clogs.

- Toilet maintenance: Checking for leaks and ensuring proper flushing.

- Fixture inspection: Checking faucets, showerheads, and other fixtures for leaks or malfunctions.

I advise clients on the importance of preventative maintenance and offer tailored plans based on their specific needs and system type. Regular maintenance is like getting your car serviced—it prevents larger problems from developing later.

Q 26. How do you maintain a clean and organized work area?

Maintaining a clean and organized work area is essential for safety, efficiency, and professionalism. My strategies include:

- Proper tool organization: Keeping tools in their designated places in my toolboxes.

- Waste disposal: Immediately disposing of debris and scraps in appropriate containers.

- Cable management: Keeping electrical cords and hoses organized to prevent tripping hazards.

- Protective measures: Using drop cloths and other protective measures to prevent damage to client’s property.

- Regular clean-up: Cleaning the work area at the end of each day and ensuring that all materials are safely stored.

A clean and organized work area shows respect for the client’s property and allows me to work more efficiently and safely. It also minimizes the risk of accidents or damage during the project.

Q 27. What are your strategies for troubleshooting complex plumbing problems?

Troubleshooting complex plumbing problems requires a systematic approach. My strategy typically involves:

- Gathering information: Listening carefully to the client’s description of the problem, observing the situation firsthand, and asking clarifying questions.

- Visual inspection: Carefully examining all visible components to identify potential issues.

- Testing and pressure checks: Using pressure gauges and other testing tools to determine where the problem lies.

- Systematic elimination: Working through potential causes one by one to isolate the problem.

- Using specialized equipment: Employing tools like sewer cameras or electronic leak detectors when necessary.

- Consulting resources: Referring to manuals, online resources, or contacting experienced colleagues when needed.

For example, I once diagnosed a recurring clog in a main drain line by using a sewer camera to discover a significant tree root intrusion. This systematic investigation ensured the right solution—the proper excavation and repair—was implemented.

Q 28. How do you stay up-to-date with the latest plumbing technologies?

Staying current in the plumbing field is crucial. I utilize various methods to keep my skills and knowledge updated:

- Professional organizations: I’m an active member of [Mention relevant professional organizations], attending conferences and workshops to learn about the latest technologies and best practices.

- Industry publications and journals: I regularly read trade publications and journals to stay informed about new products and techniques.

- Online resources and training: I leverage online courses and webinars provided by manufacturers and educational institutions.

- Manufacturer training: I participate in manufacturer-provided training sessions on new products and systems.

- Networking: I maintain a strong network of colleagues and fellow plumbers to exchange information and learn from shared experiences.

For example, recently I completed a course on PEX piping systems, a more efficient and cost-effective piping technique compared to traditional copper piping. Keeping my skills sharp allows me to deliver the best possible service to my clients.

Key Topics to Learn for Service Plumber Interview

- Water Supply Systems: Understanding pressure regulators, water meters, pipe materials (copper, PVC, PEX), and common fitting types. Practical application: Diagnosing low water pressure issues and explaining repair solutions.

- Drain and Waste Systems: Familiarity with drain cleaning techniques (snaking, hydro-jetting), vent systems, sewer lines, and troubleshooting blockages. Practical application: Explaining the process of clearing a clogged drain and preventing future occurrences.

- Gas Piping Systems: Knowledge of gas appliance installation and maintenance, gas leak detection, safety regulations, and proper use of gas line testing equipment. Practical application: Describing the steps to safely repair a gas leak.

- Water Heater Repair and Installation: Understanding different types of water heaters (tankless, tank), troubleshooting malfunctions, and performing routine maintenance. Practical application: Explaining the process of replacing a faulty thermostat in a water heater.

- Plumbing Codes and Regulations: Familiarity with local and national plumbing codes and safety regulations. Practical application: Demonstrating knowledge of permit requirements and adherence to safety standards.

- Customer Service and Communication: Effectively communicating technical information to non-technical clients, handling customer complaints professionally, and building rapport. Practical application: Describing a challenging customer interaction and how it was successfully resolved.

- Troubleshooting and Problem-Solving: Systematically diagnosing plumbing issues, utilizing diagnostic tools, and developing effective repair strategies. Practical application: Explaining a complex plumbing problem you solved and the steps you took.

- Safety Procedures and Practices: Following proper safety protocols, using personal protective equipment (PPE), and maintaining a safe work environment. Practical application: Describing your understanding and application of relevant safety regulations on the job.

Next Steps

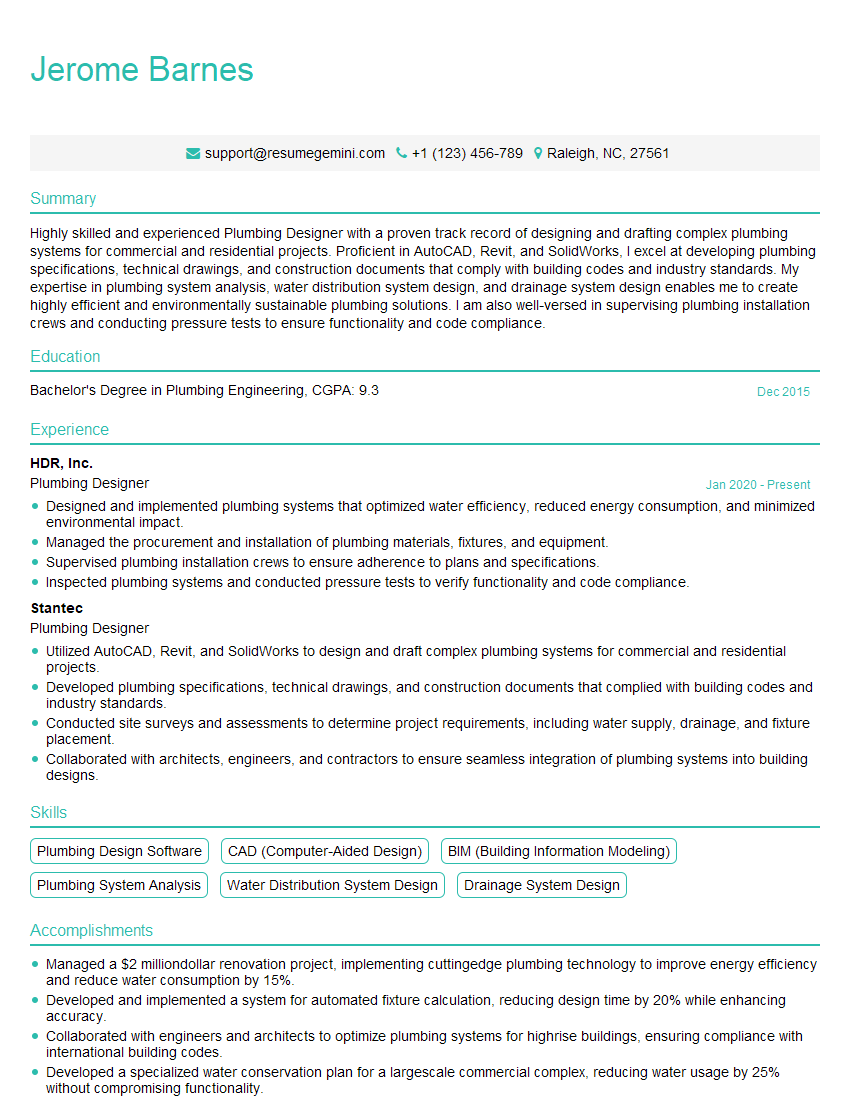

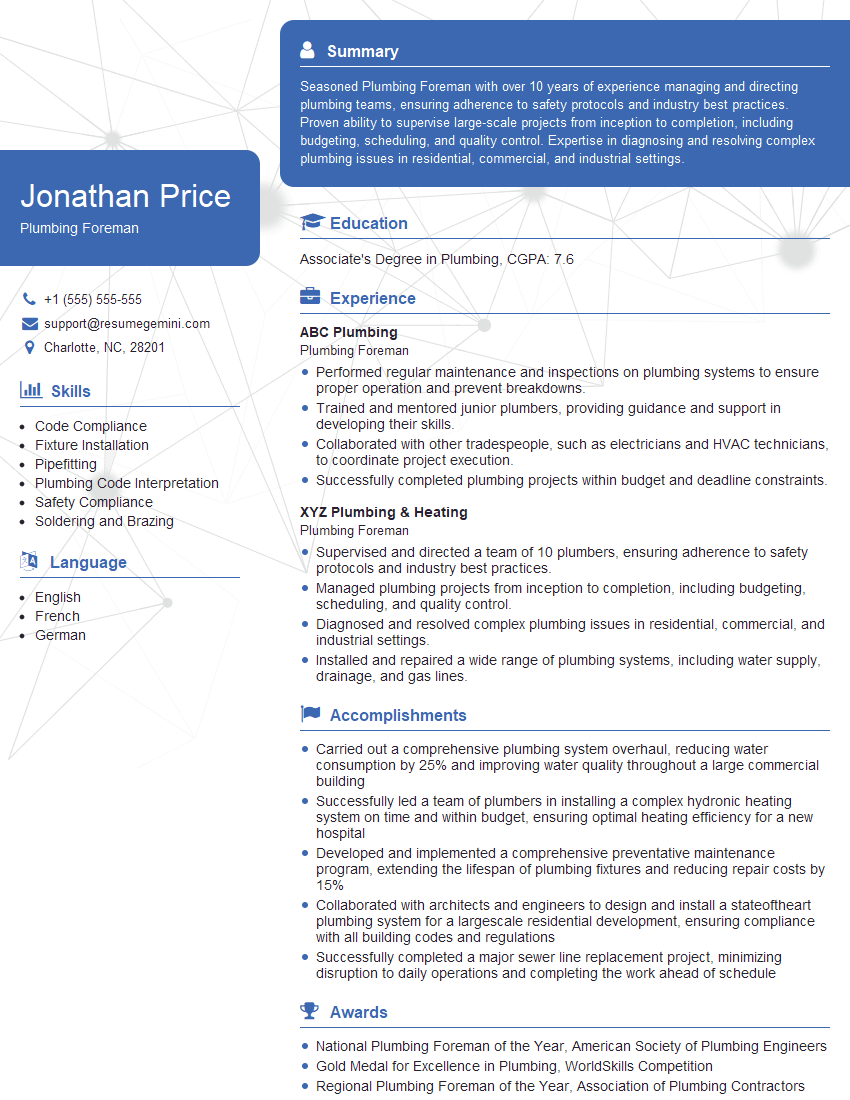

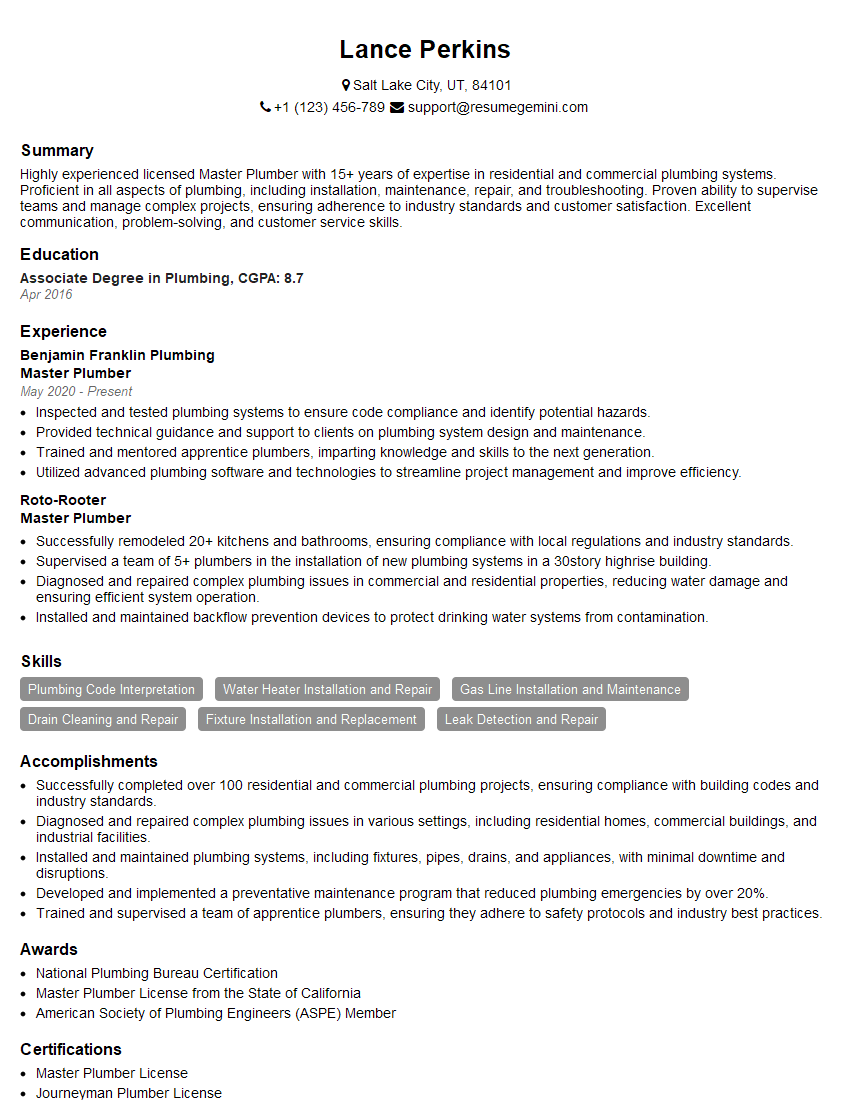

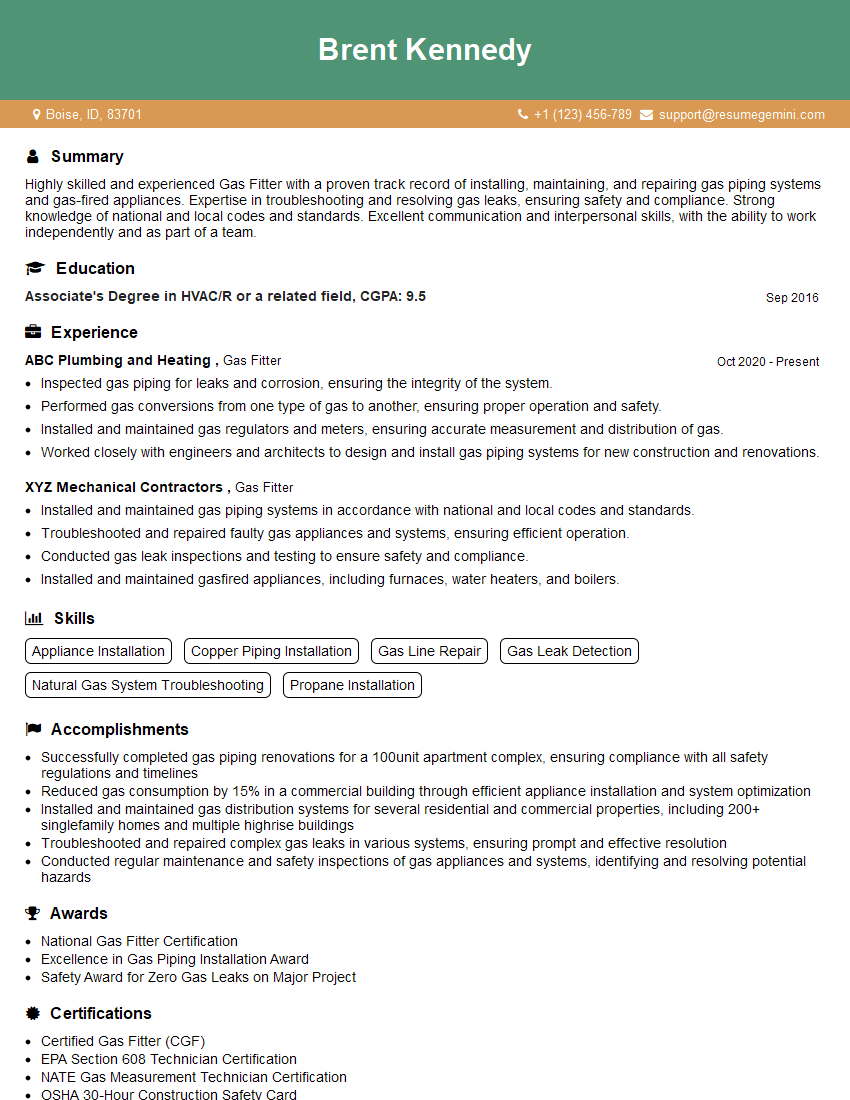

Mastering the skills and knowledge of a Service Plumber opens doors to a rewarding and stable career with excellent growth potential. Advancement opportunities include specializing in areas like commercial plumbing, becoming a supervisor, or starting your own business. To maximize your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource for building professional resumes that make a lasting impression on potential employers. Examples of resumes tailored to the Service Plumber profession are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.