Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential ISO 9001 Standards in Paradi Operation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in ISO 9001 Standards in Paradi Operation Interview

Q 1. Explain the core principles of ISO 9001:2015.

ISO 9001:2015’s core principles revolve around a customer-centric approach to quality management. It emphasizes building a robust Quality Management System (QMS) based on several key pillars. These include:

- Customer focus: Understanding and meeting customer needs and expectations is paramount. In Paradi Operations, this might involve regular feedback surveys and proactive communication to ensure client satisfaction.

- Leadership: Top management must actively demonstrate commitment to the QMS and drive continuous improvement. This means setting clear quality objectives and providing the necessary resources.

- Engagement of people: Empowering employees at all levels to contribute to quality improvement is crucial. In Paradi Operations, this could involve regular training sessions and open communication channels.

- Process approach: Managing activities as interconnected processes helps improve efficiency and effectiveness. In a Paradi operation, mapping out the entire workflow from resource acquisition to final product delivery would help identify potential bottlenecks and improvement areas.

- Improvement: Continuously seeking improvement in the QMS is essential. This might include using data analysis to pinpoint areas for improvement and implementing corrective actions.

- Evidence-based decision making: Using data and analysis to inform decisions ensures objectivity and effectiveness. This might involve analyzing production data to identify patterns and inform future strategies.

- Relationship management: Managing relationships with suppliers and other stakeholders improves the overall quality of the system. This could involve implementing robust supplier selection and management processes.

Essentially, ISO 9001:2015 provides a framework for building a system that consistently delivers products and services that meet customer requirements and enhance customer satisfaction.

Q 2. Describe the Plan-Do-Check-Act (PDCA) cycle and its application in Paradi Operations.

The Plan-Do-Check-Act (PDCA) cycle is a continuous improvement methodology. It’s a cyclical process that encourages iterative refinements. In Paradi Operations, it could be applied to numerous areas such as improving safety protocols, streamlining production processes, or enhancing customer service.

- Plan: Define the problem, objectives, and the actions needed. For example, if the goal is to reduce production defects, the plan might involve identifying the root causes of defects, setting a target reduction percentage, and designing a new training program for operators.

- Do: Implement the planned actions. This could include delivering the training, implementing new quality control measures, and monitoring the effects.

- Check: Monitor the results and compare them to the objectives. Gather data, analyze trends, and assess the effectiveness of the implemented changes. This would involve analyzing defect rates before and after the training program.

- Act: Based on the results, take corrective action or standardize the process if successful. This might involve adjusting the training program if the defect rate hasn’t improved sufficiently or documenting the improved process as standard operating procedure.

The PDCA cycle, when consistently applied, promotes continuous improvement within Paradi Operations, contributing to an effective ISO 9001 compliant system.

Q 3. How do you ensure traceability in Paradi Operations under ISO 9001?

Traceability in Paradi Operations, within an ISO 9001 framework, means being able to track any product or service throughout its entire lifecycle. This is crucial for identifying and rectifying issues, managing recalls, and demonstrating compliance. Methods for ensuring traceability include:

- Unique Identification: Assign unique identification numbers or codes to every product or component. This could be a serial number, barcode, or RFID tag.

- Detailed Records: Maintain comprehensive records of all processes, including raw materials, processing steps, testing results, and handling information. This might involve using a computerized system to track every stage of production.

- Supplier Traceability: Track the origin and quality of all materials and components from suppliers. This includes thorough supplier audits and robust documentation procedures.

- Calibration Tracking: Maintain detailed records of all calibration activities for measurement equipment. This ensures that measurement data is accurate and reliable.

- Documented Processes: Implement clearly defined and documented processes for each stage of production, testing, and distribution. This provides a clear audit trail for each product.

In a Paradi operation, robust traceability helps to quickly identify the source of any nonconformities, enhancing efficiency and reducing potential losses.

Q 4. What are the key requirements for internal audits in a Paradi Operation environment?

Key requirements for internal audits within a Paradi Operation adhering to ISO 9001 include:

- Audit Planning: Define the scope, objectives, and criteria for the audit. This includes identifying the areas to be audited and the relevant ISO 9001 clauses.

- Competent Auditors: Auditors must be trained and competent in ISO 9001 requirements and auditing techniques. They should have a good understanding of the Paradi operation’s processes.

- Objective Evidence Gathering: Auditors should collect objective evidence to verify the effectiveness of the QMS. This might involve interviewing staff, reviewing documentation, and observing processes.

- Audit Reporting: A comprehensive audit report outlining findings, nonconformities, and recommendations for corrective actions should be prepared. This report should be factual and unbiased.

- Management Review: The audit report and findings must be reviewed by management to ensure appropriate actions are taken.

- Follow-up: Follow-up actions are crucial to ensure that identified nonconformities are addressed and corrective actions are implemented effectively.

Regular internal audits ensure the QMS remains effective and compliant with ISO 9001 standards in the Paradi Operation.

Q 5. How do you manage nonconformances within an ISO 9001 compliant Paradi Operation?

Managing nonconformances in an ISO 9001 compliant Paradi Operation involves a structured approach:

- Identification and Reporting: Establish a system for identifying and promptly reporting any nonconformances, whether related to products, processes, or the QMS itself. This might involve using a dedicated reporting system.

- Investigation: Thoroughly investigate the root cause of the nonconformance. This often involves using tools like fishbone diagrams or 5 Whys analysis to determine the underlying issue.

- Containment: Implement actions to prevent further nonconformances from occurring. This could involve isolating defective products, modifying processes, or training employees.

- Corrective Action: Correct the immediate nonconformance, ensuring that the affected products or processes are brought back to compliance. This could involve repairing or replacing defective products.

- Preventive Action: Implement actions to prevent similar nonconformances from happening in the future. This might involve reviewing and improving processes, updating training materials, or modifying equipment.

- Verification: Verify the effectiveness of the corrective and preventive actions taken. This involves monitoring the affected processes to ensure the issue is resolved and won’t recur.

Effective nonconformance management prevents recurring issues, minimizes financial losses, and protects the reputation of the Paradi Operation.

Q 6. Explain the importance of corrective and preventive actions (CAPA) in Paradi Operations.

Corrective and Preventive Actions (CAPA) are essential for continuous improvement in any ISO 9001-compliant operation, especially in Paradi Operations, where the consequences of failure can be significant.

Corrective Actions address existing problems. For example, if a batch of products fails quality control, corrective action would involve identifying the root cause (perhaps faulty equipment), fixing the equipment, and managing the non-conforming batch (rework, scrap, etc.).

Preventive Actions anticipate and prevent future problems. If the root cause analysis reveals a recurring issue with a particular piece of equipment, preventative action would involve implementing a preventative maintenance schedule to reduce future failures. Or, if operator error was identified, improved training procedures would be developed and implemented.

Both are vital for ensuring that the QMS continuously improves, minimizing the risk of recurring failures and enhancing efficiency within Paradi operations. A documented CAPA system ensures that all issues are addressed systematically and effectively, contributing significantly to the overall quality of the Paradi operation.

Q 7. How do you ensure customer satisfaction within the context of ISO 9001 in Paradi Operations?

Ensuring customer satisfaction within an ISO 9001 framework in Paradi Operations requires a proactive and systematic approach:

- Understanding Customer Needs: Regularly gather feedback from customers through surveys, focus groups, and individual interactions. This will help in understanding expectations and areas for potential improvements.

- Meeting Requirements: Ensure that all products and services consistently meet specified customer requirements. This involves clearly defining requirements in contracts and consistently monitoring performance against these requirements.

- Proactive Communication: Maintain open and clear communication channels with customers, keeping them informed about the progress of their projects and addressing any concerns promptly.

- Complaint Handling: Establish a robust system for handling customer complaints and resolving issues efficiently and effectively. This shows commitment to customer satisfaction.

- Regular Monitoring: Regularly monitor customer satisfaction levels through various metrics, such as customer feedback surveys and repeat business rates. This allows for early identification of trends and potential issues.

By actively focusing on these elements, Paradi Operations can consistently exceed customer expectations and foster strong, lasting relationships, crucial for sustained success in a competitive market.

Q 8. Describe your experience with conducting internal audits according to ISO 9001.

Internal audits are crucial for ensuring our Quality Management System (QMS) remains effective and compliant with ISO 9001. My experience involves planning, conducting, and reporting on these audits within Paradi Operations. This includes selecting audit criteria based on risk assessment, developing audit checklists, performing on-site observations and document reviews, and interviewing personnel at all levels. I focus on identifying nonconformities, confirming their root causes, and verifying the effectiveness of corrective actions.

For example, during an audit of our production line, I identified a discrepancy in the calibration records for a critical piece of machinery. This led to a deeper dive into the calibration process and the implementation of a new, more robust system, ensuring all equipment is calibrated and documented correctly. The audit report detailed the findings, the root cause, the corrective actions taken, and the effectiveness of those actions – all vital for continuous improvement.

In another instance, I reviewed the effectiveness of our training program, identifying gaps in employee understanding of certain quality procedures. This prompted a revision of the training material and the implementation of a more engaging and effective training delivery method.

Q 9. How do you manage document control within a Paradi Operation under ISO 9001?

Document control in Paradi Operations under ISO 9001 is paramount. We maintain a centralized document management system, ensuring all documents are readily accessible, up-to-date, and controlled. This involves a clearly defined process for creating, reviewing, approving, distributing, and revising documents. Each document is uniquely identified, version-controlled, and stored securely, using appropriate access controls.

We utilize a digital document management system to streamline this process. Every document undergoes a review cycle, marked with revision numbers, ensuring everyone uses the most current version. Obsolete documents are retired following a defined retention policy. We also have a change management process to control changes and avoid inadvertent use of outdated documents. Think of it like a library, but instead of books, we manage all our operational procedures, quality records, and work instructions.

This controlled system ensures consistency in our processes and reduces the risk of errors caused by using outdated or incorrect information.

Q 10. What are your experiences with root cause analysis in Paradi Operations?

Root cause analysis (RCA) is vital in Paradi Operations for preventing recurrence of nonconformities. My experience with RCA frequently involves using tools such as the 5 Whys, fishbone diagrams (Ishikawa diagrams), and fault tree analysis. We delve beyond the surface to understand the underlying causes of defects or problems, avoiding merely treating the symptoms.

For instance, if a batch of products failed a quality inspection due to inconsistent material properties, we wouldn’t simply scrap the batch. Instead, we’d use the 5 Whys to investigate: Why did the material properties vary? Why wasn’t this detected earlier? Why was the supplier’s quality control insufficient? This systematic approach helps us identify systemic issues rather than addressing individual failures.

The findings from the RCA are crucial in implementing corrective and preventive actions (CAPA), ensuring that the root cause is addressed and the issue doesn’t reoccur. This ultimately improves our overall quality and efficiency.

Q 11. Explain your understanding of risk-based thinking in ISO 9001 and its application to Paradi Operations.

Risk-based thinking is integrated into all aspects of our QMS. It’s not just a checklist item, but a fundamental approach to proactively identifying, assessing, and controlling risks that could affect our ability to meet customer requirements and achieve our quality objectives. In Paradi Operations, this means regularly identifying potential risks throughout our processes and implementing controls to mitigate these risks.

We use risk assessments to identify potential hazards, assigning severity, likelihood, and impact ratings. This could range from risks related to equipment malfunction impacting production to risks associated with supplier performance affecting product quality. For each risk identified, we develop appropriate control measures, regularly monitoring their effectiveness.

For example, we might identify a risk of power outages disrupting our production. Our risk mitigation would involve implementing a backup generator system and establishing clear procedures for managing power disruptions. Regular testing of the backup generator forms part of our risk control monitoring process.

Q 12. How would you handle a situation where a nonconformity affects a customer’s product?

If a nonconformity impacts a customer’s product, our immediate priority is to contain the issue, prevent further damage, and communicate promptly with the customer. We would initiate a formal nonconformity report, fully documenting the event, the affected products, and the potential impact on the customer.

Following this, we’d conduct a thorough RCA to understand the root cause of the nonconformity. This would be followed by implementing corrective actions to address the root cause and prevent recurrence. We’d also collaborate with the customer to determine the best course of action, whether it involves replacing the affected product, providing compensation, or implementing other remedial measures. Transparency and proactive communication are vital to maintaining customer trust and satisfaction. We’d document all actions taken and monitor their effectiveness.

Our goal is to not only resolve the immediate problem but to learn from it and strengthen our processes to prevent similar situations from occurring in the future.

Q 13. How do you measure the effectiveness of your quality management system?

Measuring the effectiveness of our QMS involves a multi-faceted approach, using key performance indicators (KPIs) and regular reviews. We monitor metrics like customer satisfaction (through surveys and feedback), defect rates, nonconformity rates, internal audit findings, and the effectiveness of corrective and preventive actions.

Regular management reviews analyze these KPIs, identifying trends and areas for improvement. We also assess the effectiveness of our training programs and the proficiency of our employees in adhering to established quality procedures. These reviews ensure our QMS remains relevant, effective, and aligned with evolving customer needs and business objectives.

For example, if our customer satisfaction scores decline, we would investigate the root cause, identify the areas needing improvement, and implement corrective actions such as improved communication or revised product specifications.

Q 14. Describe your experience with implementing or maintaining an ISO 9001 compliant system.

My experience includes the full lifecycle of ISO 9001 implementation and maintenance. I’ve been involved in gap analyses, defining the scope of the QMS, developing and implementing procedures, conducting internal audits, and managing corrective actions. This included training personnel, ensuring compliance with the standard, and facilitating external audits.

One project involved implementing ISO 9001 in a newly established Paradi Operation facility. This required a systematic approach, starting with a gap analysis to determine our existing strengths and weaknesses, developing necessary procedures and documentation, and conducting thorough training for all personnel. We worked to align our processes with ISO 9001 requirements, creating a robust and effective QMS. We successfully achieved certification, demonstrating our commitment to quality.

Ongoing maintenance involves continuous monitoring of our QMS effectiveness, regular internal audits, management reviews, and adapting our system to evolving business needs and customer requirements. It’s an iterative process that demands ongoing attention and improvement.

Q 15. How familiar are you with the ISO 9001 requirements for management review?

ISO 9001 mandates regular management reviews to ensure the effectiveness of the quality management system (QMS). Think of it as a health check for your entire operation. It’s not just about ticking boxes; it’s about proactively identifying areas for improvement and ensuring the QMS remains fit for purpose.

The review process typically involves evaluating the following:

- Performance against quality objectives: Are we meeting our targets for customer satisfaction, defect rates, and on-time delivery?

- Effectiveness of the QMS: Are our processes efficient, effective, and compliant with ISO 9001?

- Opportunities for improvement: Where can we streamline processes, reduce waste, or enhance customer satisfaction?

- Resources: Do we have the necessary resources (personnel, equipment, budget) to support the QMS?

- Changes that affect the QMS: Have any significant internal or external changes impacted our ability to meet quality objectives?

The output of the management review should be documented and includes actions to address any identified issues or opportunities. For example, a review might reveal a high defect rate in a specific process. The action plan might include staff training, process optimization, or the purchase of new equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strategies for continuous improvement within Paradi Operations?

My strategy for continuous improvement in Paradi Operations centers around a structured approach using the Plan-Do-Check-Act (PDCA) cycle, also known as Deming Cycle, a cornerstone of ISO 9001. It’s a cyclical process that allows for continuous refinement.

- Plan: We define quality objectives, identify improvement areas, and develop action plans.

- Do: We implement the action plans and monitor the results.

- Check: We analyze the results and identify any deviations from the plan.

- Act: We take corrective or preventive action to address deviations and standardize improvements.

In addition to PDCA, we actively engage in data analysis (discussed later), employee suggestions, and regular process audits to proactively identify areas needing improvement. For instance, if customer feedback reveals dissatisfaction with a specific service, we use this feedback to initiate a PDCA cycle, analyzing the root cause, implementing changes, and monitoring the impact on customer satisfaction.

Q 17. How would you address employee resistance to adopting new quality procedures?

Addressing employee resistance to new procedures requires a multi-pronged approach that focuses on communication, training, and engagement.

- Open Communication: Explain the *why* behind the new procedures, highlighting the benefits for both the employees and the organization. Transparency is key. For example, explain how the new procedure will reduce workload or improve safety.

- Comprehensive Training: Provide thorough training on the new procedures, ensuring employees understand how to implement them correctly. Hands-on training and opportunities for practice are crucial.

- Active Engagement: Involve employees in the implementation process. This could involve soliciting feedback, allowing for trial runs, or even having employees lead the implementation in their respective areas.

- Address Concerns: Actively listen to employee concerns and address them openly and honestly. If there are legitimate issues, find solutions collaboratively.

- Incentives and Recognition: Reward employees for their cooperation and successful adoption of new procedures.

Think of it like introducing a new tool – if employees don’t understand how to use it effectively or see its value, they won’t embrace it. Clear communication, training, and engagement make all the difference.

Q 18. Explain your understanding of the relationship between ISO 9001 and other relevant standards.

ISO 9001 is often complementary to other management system standards. For instance, ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can integrate seamlessly with an ISO 9001 QMS. These standards share similar structures, focusing on risk management, continuous improvement, and documented processes.

Integrating these standards avoids duplication of effort and creates a more efficient and holistic management system. For example, a process improvement addressing waste reduction (ISO 9001) could simultaneously contribute to environmental sustainability (ISO 14001). The key is to identify overlaps and synergies to streamline processes and create a unified approach to management.

Q 19. How do you ensure the competence of personnel involved in Paradi Operations under ISO 9001?

Ensuring personnel competence is vital for a successful ISO 9001 implementation. This involves a systematic approach that focuses on training, evaluation, and ongoing development.

- Job Descriptions: Clear job descriptions outline the necessary skills and competencies for each role.

- Training Programs: Tailored training programs are developed to address identified skills gaps.

- Skills Matrices: These matrices track the skills and qualifications of each employee, highlighting areas needing further development.

- Performance Evaluations: Regular performance evaluations assess employee competency and identify areas for improvement.

- Certification: Where appropriate, employees receive relevant certifications to demonstrate their competence.

For example, if a new piece of equipment is introduced, we ensure that all relevant personnel receive training on its safe and efficient operation before they are allowed to use it. This approach minimizes errors and ensures consistent quality output.

Q 20. Describe your experience with data analysis to improve quality in Paradi Operations.

Data analysis plays a crucial role in improving quality within Paradi Operations. We use various techniques to identify trends, pinpoint root causes of defects, and measure the effectiveness of improvement initiatives.

- Statistical Process Control (SPC): We use control charts to monitor process variation and identify deviations from expected performance. This allows for early detection of potential problems.

- Defect Tracking: We meticulously track defects, identifying patterns and root causes. This data helps us prioritize improvement efforts.

- Customer Feedback Analysis: We analyze customer feedback to understand their satisfaction levels and identify areas needing improvement.

- Process Capability Analysis: We analyze process capability to determine if processes are capable of meeting specified requirements.

For instance, if we notice a spike in customer complaints about a specific product, we can use data analysis to identify the root cause (e.g., a problem with a supplier, a flaw in the manufacturing process). This data-driven approach ensures that our improvement efforts are targeted and effective.

Q 21. How do you handle supplier quality management in your Paradi Operations?

Supplier quality management is a critical aspect of our Paradi Operations. We use a multi-faceted approach to ensure that our suppliers consistently provide high-quality products and services.

- Supplier Selection: We carefully select suppliers based on their quality systems, capabilities, and track record.

- Supplier Audits: We conduct regular audits to assess supplier performance and compliance with our requirements.

- Quality Agreements: We establish clear quality agreements that define expectations and responsibilities.

- Incoming Inspection: We inspect incoming materials and components to ensure they meet specifications.

- Performance Monitoring: We continuously monitor supplier performance, using key performance indicators (KPIs) to track quality, delivery, and cost.

For example, we might require suppliers to provide certification demonstrating compliance with relevant industry standards. If a supplier consistently fails to meet our quality standards, we work with them to identify and rectify the issue; if the problems persist, we may need to find an alternative supplier.

Q 22. What is your experience with using quality management software?

My experience with quality management software (QMS) spans over eight years, encompassing various systems like ISOTools, MasterControl, and more recently, a cloud-based solution from a leading provider. I’ve been involved in every stage, from the initial selection and implementation to ongoing maintenance and improvement. This includes configuring the software to align with our specific ISO 9001 requirements within Paradi Operations, integrating it with other business systems, and training staff on its effective usage. For instance, in my previous role, I successfully implemented ISOTools to streamline our document control process, reducing errors by 15% and significantly accelerating approval times. I’m proficient in using these systems to manage documents, track non-conformances, conduct internal audits, and analyze key performance indicators (KPIs).

Q 23. How would you develop and implement a new quality control procedure for Paradi Operations?

Developing and implementing a new quality control procedure for Paradi Operations follows a structured approach based on the PDCA (Plan-Do-Check-Act) cycle, a cornerstone of ISO 9001.

- Plan: This involves defining the scope of the new procedure, identifying potential risks and opportunities, and setting clear objectives. We’d use process mapping techniques to visualize the current state and identify areas for improvement. For example, if we were implementing a new QC procedure for a specific manufacturing process, this stage would involve detailed analysis of the existing process, potential failure points, and the required quality attributes of the end product.

- Do: We’d then develop the new procedure, including detailed work instructions, checklists, and acceptance criteria. This document would be reviewed and approved by relevant stakeholders. Pilot testing on a small scale would be crucial to identify and address any unforeseen issues before full implementation.

- Check: Monitoring and evaluation of the new procedure is critical. This involves data collection, analysis, and comparison against established KPIs (discussed further in the next answer). Regular internal audits would be conducted to ensure compliance and effectiveness.

- Act: Based on the monitoring and evaluation results, improvements would be implemented and the procedure updated accordingly. This is a continuous improvement cycle; regular reviews and updates ensure the procedure remains relevant and effective.

Throughout the entire process, communication and training would be key to successful implementation, ensuring all personnel are aware of and comply with the new procedure.

Q 24. What are the key performance indicators (KPIs) you would use to measure the effectiveness of the QMS in Paradi Operations?

The KPIs used to measure the effectiveness of the QMS in Paradi Operations would be carefully selected to reflect various aspects of quality performance. These would include:

- Defect Rate: The number of defective products or services compared to the total output. A lower rate indicates better quality control.

- Customer Complaints: Tracking the number and nature of customer complaints provides valuable feedback on product or service quality and customer satisfaction.

- On-Time Delivery Rate: This reflects the efficiency and effectiveness of the processes within Paradi Operations and its impact on customer satisfaction. Consistent delivery aligns with quality expectations.

- Process Cycle Time: This measures the time taken to complete a process. Reducing this time while maintaining quality is a key efficiency indicator.

- Customer Satisfaction Score (CSAT): Surveys and feedback mechanisms directly measure customer satisfaction with the product and service provided.

- Internal Audit Effectiveness: This assesses the effectiveness of our internal audit system in identifying and addressing non-conformances.

These KPIs would be regularly monitored and analyzed to identify areas for improvement within our QMS. Regular reports summarizing these indicators would be presented to management.

Q 25. How would you deal with a conflict between production targets and quality standards?

Conflicts between production targets and quality standards are a common challenge. The solution requires a balanced approach that prioritizes both. Simply prioritizing production at the expense of quality is unsustainable in the long term and damages brand reputation. My approach would be to:

- Clearly Define Quality Standards: Ensure that quality standards are clearly defined, documented, and understood by all personnel. This reduces ambiguity and provides a clear benchmark.

- Analyze the Root Cause: Investigate why the conflict is occurring. Is it due to unrealistic production targets, inadequate resources, or deficiencies in the production process?

- Collaborate and Negotiate: Engage with production and quality control teams to find a mutually acceptable solution. This may involve adjusting production targets, improving process efficiency, or investing in additional resources.

- Prioritize Risk Management: If compromises must be made, prioritize them based on risk assessment. Focus on reducing the risk of significant quality issues.

- Continuous Improvement: Use the conflict as an opportunity for improvement. Identify areas where the process can be optimized to achieve both high quality and efficient production.

Ultimately, a culture that values quality as paramount will reduce the frequency and severity of these conflicts.

Q 26. Describe your experience with monitoring and measuring customer satisfaction in a Paradi Operation context.

Monitoring and measuring customer satisfaction within Paradi Operations involves a multi-faceted approach. This includes employing various methods to collect customer feedback, analyze the data, and implement improvement plans.

- Customer Surveys: Regular surveys can be sent out to assess satisfaction levels with different aspects of our products or services.

- Feedback Forms: Providing simple feedback forms online or physically allows customers to share their experiences.

- Customer Interviews: In-depth interviews provide richer, qualitative feedback which can reveal the underlying reasons for dissatisfaction.

- Complaint Tracking: Analyzing the nature and frequency of complaints provides insights into recurring issues and areas needing improvement.

- Social Media Monitoring: Analyzing social media mentions allows us to capture spontaneous customer feedback.

This data is compiled and analyzed to identify trends and areas for improvement. The results are then used to inform process improvements, training initiatives, and product development.

Q 27. How would you ensure the effectiveness of internal communication regarding quality within Paradi Operations?

Effective internal communication regarding quality within Paradi Operations is crucial for maintaining a strong QMS. My strategy would involve several key elements:

- Regular Meetings: Conducting regular meetings, both formal and informal, at all levels of the organization facilitates open communication and the sharing of quality-related information.

- Internal Communication Platforms: Utilizing intranets, instant messaging, or email ensures timely dissemination of quality-related updates, news, and procedures.

- Training Programs: Regular training programs reinforce knowledge and understanding of quality policies and procedures among employees.

- Open Door Policy: Fostering an open and transparent work environment empowers employees to raise concerns or suggestions related to quality without fear of retribution.

- Quality Dashboards: Utilizing dashboards to visualize key quality metrics makes it easier for everyone to understand the overall performance and identify potential problem areas.

By creating a culture of open communication and collaboration, we can ensure that quality-related information is shared effectively, ultimately leading to a more robust and effective QMS.

Key Topics to Learn for ISO 9001 Standards in Paradi Operation Interview

- Understanding the ISO 9001 Framework: Grasp the core principles and clauses of ISO 9001, focusing on their application within a Paradi Operation context. Consider the relationship between quality management and operational efficiency.

- Paradi Operation-Specific Processes: Analyze how ISO 9001 requirements translate into specific procedures and workflows within Paradi Operations. Focus on areas like risk management, process mapping, and continuous improvement.

- Document Control and Records Management: Learn the importance of maintaining accurate and readily accessible documentation within the ISO 9001 framework, specifically as it applies to Paradi Operation’s unique data and reporting needs. Understand the audit trail and its significance.

- Internal Audits and Corrective Actions: Prepare for questions on conducting internal audits, identifying nonconformities, and implementing effective corrective and preventive actions within the Paradi Operation setting. Practice describing your approach to problem-solving in this context.

- Management Review and Continuous Improvement: Understand the role of management review in driving continuous improvement within Paradi Operations. Be prepared to discuss examples of how data analysis informs decision-making and process optimization.

- Customer Focus and Satisfaction: Demonstrate understanding of how ISO 9001 principles support customer satisfaction within the Paradi Operation. Be ready to discuss metrics and strategies for ensuring customer needs are met and exceeded.

Next Steps

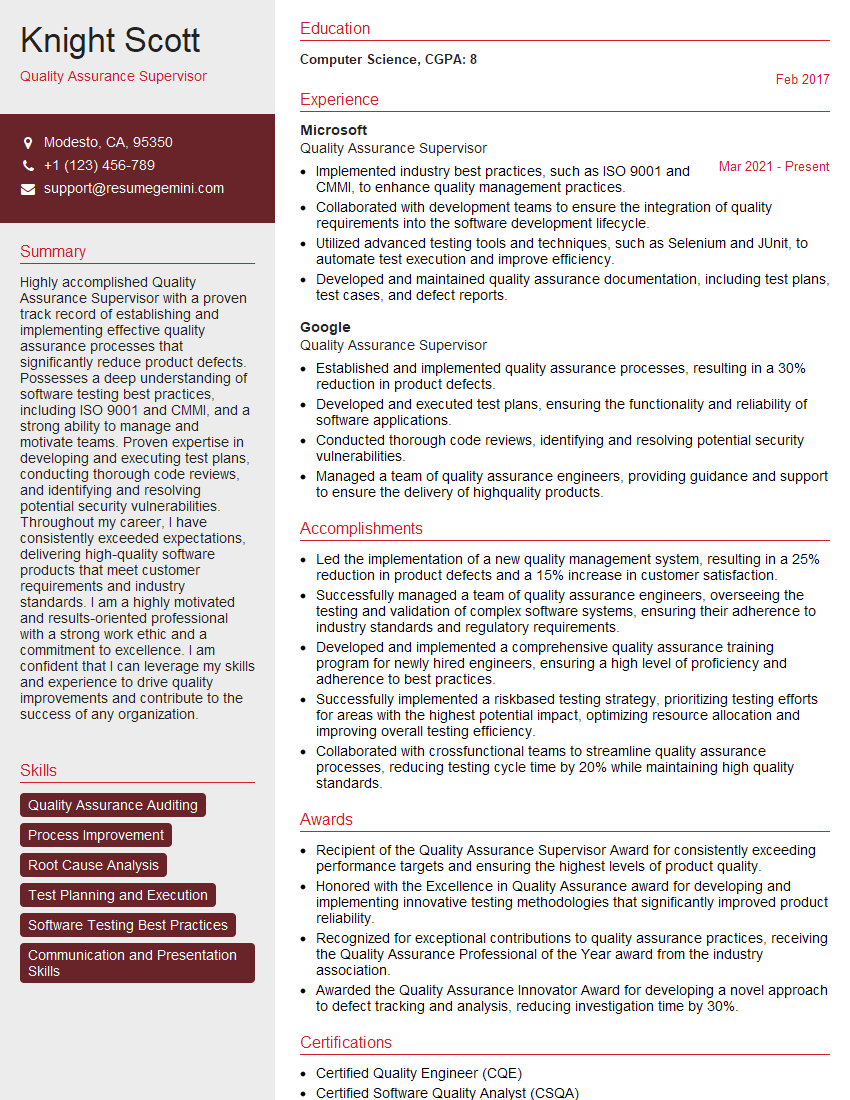

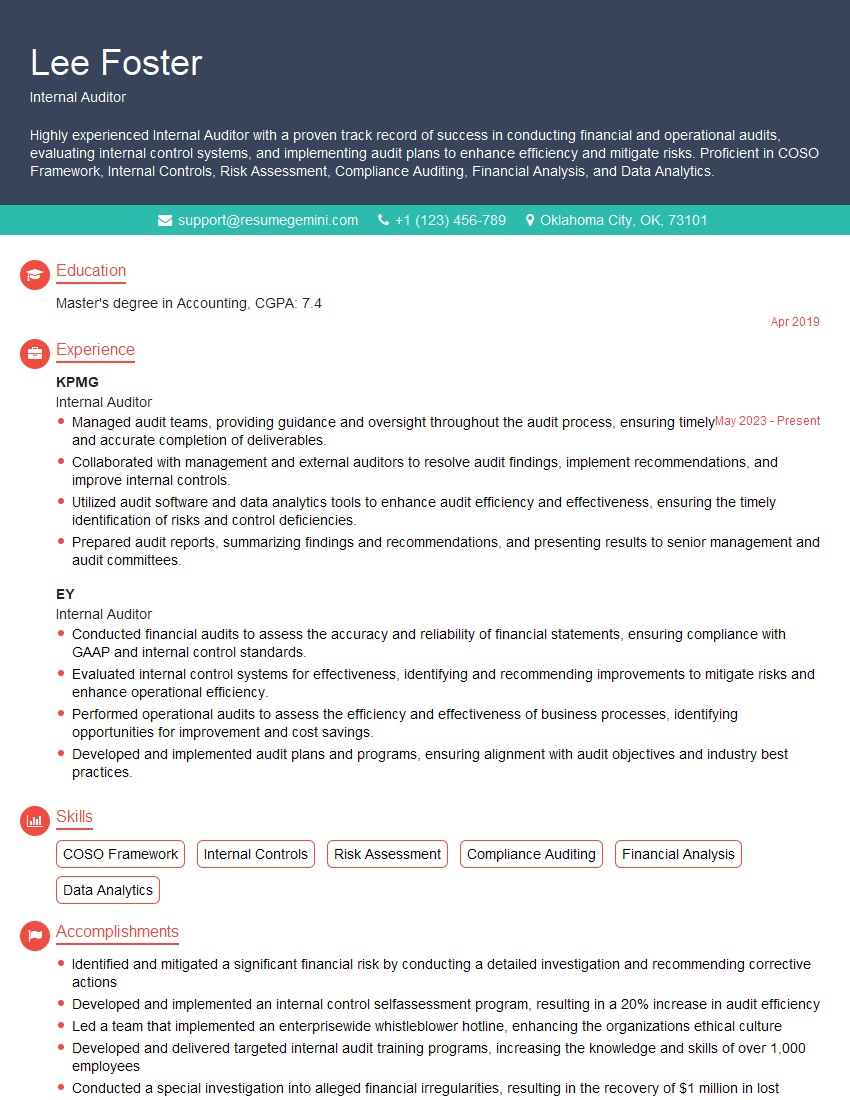

Mastering ISO 9001 Standards in Paradi Operation significantly enhances your career prospects, demonstrating your commitment to quality and operational excellence. A strong understanding of these standards is highly valued by employers seeking individuals capable of driving efficiency and improvement within their organizations. To maximize your job search success, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource for building professional resumes that make a lasting impression on recruiters. Examples of resumes tailored to ISO 9001 Standards in Paradi Operation are available to help guide you in crafting your own compelling application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.