Unlock your full potential by mastering the most common Rebar OSHA 1926.18 interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Rebar OSHA 1926.18 Interview

Q 1. Explain the key requirements of OSHA 1926.18 regarding rebar handling and storage.

OSHA 1926.18 focuses on ensuring safe handling and storage of reinforcing steel (rebar) to prevent injuries. Key requirements revolve around preventing hazards like falls, punctures, and crushing injuries. This includes proper storage to prevent collapse, clear walkways, and secure handling methods.

- Storage: Rebar should be stored in a stable manner, preventing tipping or collapse. Think of it like stacking firewood – you wouldn’t haphazardly toss it; you’d create a stable structure. This often means using racks, supports, or bundling techniques.

- Handling: Rebar should be lifted and moved using appropriate equipment, like forklifts or cranes, rather than manually handling long, heavy pieces. If manual handling is unavoidable, it should be done with multiple workers and proper lifting techniques to prevent back injuries.

- Designated Areas: Rebar storage areas need to be clearly marked and separated from walkways and other work areas. Imagine a designated parking spot – it’s safer for everyone if rebar has its own ‘parking spot’ too.

- Pointing Upward: When storing rebar vertically, the pointed ends should be directed upwards to minimize the risk of puncture injuries.

Q 2. Describe the proper methods for securing and tying rebar.

Securing and tying rebar is crucial for structural integrity and worker safety. Improper tying can lead to collapses and injuries. Several methods exist, each with its own advantages and appropriate use cases:

- Wire Ties: These are common for smaller diameter rebar. They should be tightly twisted to secure the bars and prevent loosening. Think of them like a strong knot that won’t come undone.

- Rebar Couplers: For joining longer lengths of rebar, couplers provide a strong mechanical connection. They offer superior strength and consistency compared to wire ties, crucial for larger projects.

- Welding: Welding is used for particularly critical connections. However, this requires specialized training and equipment due to the risk of burns and fire hazards.

- Tying Techniques: Proper tying techniques are essential. The ties must be secure enough to prevent the rebar from shifting during concrete placement. Insufficiently tight ties can create weak points in the structure.

Regardless of the method, all ties must be strong and secure, inspected regularly, and replaced if damaged or loose.

Q 3. How do you ensure compliance with fall protection regulations when working with rebar at heights?

Fall protection is paramount when working with rebar at heights. OSHA 1926 Subpart M mandates fall protection for employees working at elevations of 6 feet or more above a lower level. With rebar work at heights, this often translates to:

- Guardrails: Erecting guardrails around elevated work platforms is a common solution. These provide a physical barrier, preventing falls.

- Safety Nets: When guardrails aren’t feasible, safety nets can catch falling workers. They must be properly installed and inspected regularly.

- Personal Fall Arrest Systems (PFAS): Harnesses and lifelines are critical, especially when working near edges or on uneven surfaces. They arrest a fall, preventing a fatal impact.

- Fall Protection Training: All workers must receive thorough training on the proper use and limitations of fall protection equipment. Knowing when to use a safety net versus a harness is a life-saving difference.

Remember: always ensure proper anchorage points for fall protection systems.

Q 4. What are the potential hazards associated with rebar work, and how can they be mitigated?

Rebar work presents several potential hazards:

- Punctures: Sharp rebar ends can cause serious punctures. This is mitigated by pointing rebar upwards during storage and handling, wearing appropriate footwear, and using protective gloves.

- Cuts and Abrasions: Rough rebar surfaces can cause cuts and abrasions. Protective clothing, including long sleeves and gloves, is crucial.

- Crushing Injuries: Rebar can crush body parts during handling and installation. This is prevented through proper lifting techniques, equipment, and secure storage practices.

- Falls: Working at heights with rebar increases fall risks. Employing fall protection is essential.

- Struck-by Hazards: Falling rebar or other materials can strike workers. This is mitigated by securing materials properly and designating clear work zones.

Mitigation strategies include proper training, adequate PPE, safe work practices, and regular safety inspections.

Q 5. Describe your experience with using personal protective equipment (PPE) specific to rebar work.

My experience encompasses consistent and appropriate PPE use for every rebar-related task. This includes:

- Safety Glasses/Goggles: Protecting my eyes from flying debris during cutting and handling.

- Cut-resistant Gloves: Protecting my hands from cuts and abrasions during rebar placement and tying.

- Steel-toe Boots: Protecting my feet from falling objects and crushing hazards.

- Hard Hats: Protecting my head from falling objects. This is crucial, especially at height.

- High-visibility clothing: Enhancing visibility and increasing safety, especially in crowded work areas.

- Hearing protection: Mitigating potential noise exposure when using power tools.

I consistently inspect my PPE for damage before each use and report any defects immediately. Proper PPE is non-negotiable; it’s my first line of defense against injury.

Q 6. How do you identify and report unsafe conditions related to rebar on a construction site?

Identifying and reporting unsafe conditions is a critical part of maintaining a safe work environment. My approach is proactive:

- Regular Site Inspections: I regularly inspect the site for hazards, including improperly stored rebar, unsecured materials, and inadequate fall protection.

- Immediate Reporting: If I identify an unsafe condition, I immediately report it to my supervisor. I don’t wait; immediate action is paramount.

- Documentation: I document all unsafe conditions, including photos or sketches if necessary, to provide a clear record.

- Communication: I communicate clearly and effectively to ensure that everyone understands the risks and appropriate corrective actions.

- Refusal to Work: In situations where the hazards are significant and immediate, I will refuse to work in the unsafe area until the situation is resolved.

Safety is a shared responsibility, and reporting unsafe conditions is a critical part of that shared responsibility.

Q 7. Explain the process for inspecting rebar for defects and ensuring proper installation.

Inspecting rebar for defects and ensuring proper installation is crucial for structural integrity. My process includes:

- Visual Inspection: Checking rebar for bends, cracks, rust, or other damage before and after placement.

- Dimensional Checks: Verifying that rebar dimensions and spacing meet the specifications laid out in the project plans.

- Proper Placement: Ensuring rebar is correctly positioned and secured according to the design drawings. This includes checking the cover depth (distance between rebar and the concrete surface).

- Concrete Cover: Verifying the correct concrete cover is maintained to protect the steel reinforcement from corrosion.

- Documentation: Maintaining detailed records of inspections and any identified defects.

- Remediation: If defects are found, taking corrective action and documenting the repairs made.

Thorough inspection and documentation create a verifiable record of the quality and safety of the rebar installation.

Q 8. How do you handle damaged or incorrectly placed rebar?

Damaged or incorrectly placed rebar poses significant safety hazards. My approach involves a multi-step process starting with immediate identification and reporting. Any rebar exhibiting cracks, bends exceeding allowable tolerances, or rust that compromises structural integrity must be removed from the site and replaced. Incorrectly placed rebar, deviating from the approved plans, must be corrected immediately. This may involve carefully removing and repositioning the bar, ensuring accurate placement per the engineer’s drawings and specifications. We document all such instances, including photographic evidence, along with corrective actions taken. This documentation is crucial for maintaining project records and ensuring compliance with OSHA 1926.18. We would also review the root cause of the damage or misplacement (e.g., faulty delivery, improper handling, or inadequate supervision) to prevent recurrence.

For example, if we discover rebar that has been bent beyond the acceptable limit during transportation, I would immediately flag it for rejection, have it removed from the construction area, and initiate a review of our material handling procedures. A new batch of correctly specified rebar would be ordered and checked rigorously before use.

Q 9. Describe your understanding of the different types of rebar and their applications.

Rebar, or reinforcing steel, comes in various grades and sizes, each suited for different applications. Common grades include Grade 40, Grade 60, and Grade 80, indicating their yield strength in thousands of pounds per square inch (ksi). Higher grade numbers mean stronger rebar, better suited for high-stress applications. The size, or diameter, of the bar is expressed in terms of its number (e.g., #3, #4, #5, #6, etc.), with a larger number indicating a thicker bar.

- Grade 40: Often used in less demanding applications.

- Grade 60: A common choice for many general construction projects.

- Grade 80: Used for high-strength concrete applications and areas with extreme stress.

The selection of rebar type and size depends critically on the structural design and the engineer’s specifications. For example, a high-rise building would utilize high-grade, thicker rebar (#6 and above) in critical structural elements, while a smaller residential foundation might use lower-grade, thinner rebar (#3 or #4).

Q 10. What are your methods for calculating the required amount of rebar for a given project?

Calculating rebar quantity requires a thorough understanding of the structural plans and specifications. This is usually done by experienced estimators or engineers using specialized software or manual calculations. The process involves:

- Reviewing the structural drawings: This determines the required size, spacing, and length of rebar for each element (columns, beams, slabs, footings, etc.).

- Calculating the total length: This involves considering the length of individual rebar pieces, accounting for overlaps and waste.

- Determining the number of bars: Based on the spacing and dimensions provided in the drawings.

- Accounting for waste: A percentage (typically 5-10%) is added to compensate for cuts, bends, and unavoidable losses.

- Total quantity calculation: Multiplying the total length by the number of bars yields the overall quantity required.

Software programs often automate these calculations, but a solid understanding of the underlying principles is critical for accurate estimation and quality control. Ignoring waste can lead to material shortages and project delays. A thorough understanding of bending schedules is also essential.

Q 11. Explain the importance of following proper material handling procedures for rebar.

Proper material handling is paramount for rebar safety. Improper handling can lead to injuries from cuts, punctures, or falling objects. We adhere to strict procedures, including:

- Using appropriate lifting equipment: For heavier bundles, using forklifts or cranes with proper attachments prevents strains and potential drops.

- Employing safe lifting techniques: Workers should use appropriate lifting equipment and techniques to prevent back injuries. Team lifts should be properly coordinated.

- Secure storage: Rebar should be stored in designated areas, neatly stacked, and away from walkways to avoid tripping hazards. Bundles are secured to prevent shifting and collapse.

- Personal Protective Equipment (PPE): Workers must wear safety gloves, safety glasses, and steel-toed boots at all times when handling rebar.

For instance, before unloading a shipment, we would ensure the ground is level and the unloading zone is clear. We’d use appropriate lifting equipment, ensuring the rebar is securely fastened during the movement. Training is crucial in reducing accidents related to material handling.

Q 12. Describe the safe procedures for cutting and bending rebar.

Cutting and bending rebar requires specialized tools and safe practices. We strictly prohibit using hand-held saws, opting for powered tools like chop saws with appropriate safety guards. Bending is typically done using hydraulic benders, which greatly reduces the risk of injury compared to manual bending. All workers involved in these operations receive thorough training, emphasizing:

- Use of appropriate cutting tools: Chop saws must be equipped with safety guards, and workers should stand to the side of the cutting line to avoid flying debris.

- Proper bending techniques: Hydraulic benders should be operated according to manufacturer instructions. Ensuring proper alignment of the rebar in the bender prevents mishaps.

- PPE: Safety glasses, gloves, hearing protection are mandatory.

- Clear work area: Removing obstacles prevents tripping and accidents.

Ignoring these guidelines can easily lead to serious injuries like severed limbs or eye damage. The use of a chop saw must always include safety guards in place and clear of obstacles.

Q 13. How do you ensure the stability of stacked rebar to prevent collapse?

Stacking rebar improperly leads to instability and potential collapse, creating a serious hazard. To prevent this, we follow a rigorous approach that emphasizes:

- Stable base: Rebar stacks must be placed on a level, firm surface.

- Proper stacking: Bars are bundled and stacked neatly, following a pattern to ensure balance. Using horizontal supports or racking to prevent outward movement is crucial for tall stacks.

- Limited height: The height of the stacks is carefully monitored to prevent toppling. Limiting the height prevents unstable stacks.

- Regular inspections: Stacks are frequently inspected to address any signs of instability, such as leaning or uneven weight distribution. This includes regular checking to identify shifting and potential problems before they worsen.

Consider a scenario where rebar is stacked haphazardly, forming an unstable pyramid. A minor disturbance could cause the whole stack to collapse, resulting in serious injury to anyone nearby. Our structured approach minimizes this risk.

Q 14. What are the requirements for rebar placement near excavations?

When placing rebar near excavations, extra precautions are necessary to prevent cave-ins and other hazards. Our procedures follow the requirements of OSHA 1926 Subpart P, which addresses excavation and trenching safety. Key considerations include:

- Safe distances: Maintaining sufficient distance between the rebar and the edge of the excavation prevents undermining and instability. These distances are usually specified in the project plans.

- Support systems: If rebar is placed close to the excavation, adequate shoring or other support systems must be in place to prevent the collapse of the excavation.

- Protective barriers: Protective barriers are often used to prevent workers from falling into excavations.

- Inspection and maintenance: Excavation supports and barriers are frequently inspected to identify any signs of failure or damage.

For example, if we need to place rebar near a deep trench, we would ensure that the trench is properly shored and that sufficient clearance is maintained between the rebar and the excavation’s edge to prevent damage to the trench supports or undermining.

Q 15. What are the OSHA requirements for using tools and machinery in relation to rebar installation?

OSHA 1926.18, specifically Subpart R, addresses the safe use of tools and machinery in construction, directly impacting rebar installation. This means every tool, from rebar cutters and benders to powered equipment like tie wire guns, must be properly maintained, inspected before each use, and operated only by trained and authorized personnel.

- Proper Maintenance: Tools should be regularly lubricated, sharpened, and repaired as needed. A dull rebar cutter, for instance, increases the force needed to cut, leading to fatigue and potential injury.

- Pre-use Inspection: A visual check should identify any damage or wear before each use. A cracked handle on a sledgehammer could lead to the tool breaking during use.

- Authorized Personnel: Only trained individuals who understand the safe operating procedures for each piece of equipment should be allowed to operate it. This is especially critical for powered equipment like cut-off saws or tie wire guns.

- Personal Protective Equipment (PPE): Appropriate PPE, such as safety glasses, gloves, and hearing protection, must always be used when operating rebar tools and machinery. This minimizes the risk of eye injuries from flying debris, hand injuries from sharp rebar, and hearing damage from loud equipment.

For example, a rebar bender needs regular maintenance to ensure smooth operation and prevent the user from exerting excessive force. A poorly maintained bender increases the risk of injury, making it vital to follow OSHA’s preventative maintenance guidelines.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of the consequences of non-compliance with OSHA 1926.18.

Non-compliance with OSHA 1926.18 regarding rebar installation carries severe consequences. These can range from relatively minor citations and fines to significant penalties, even criminal charges in cases involving serious injury or death.

- Fines: OSHA can issue significant fines for each violation, escalating with the severity and number of violations.

- Citations: Publicly available citations can damage a company’s reputation and make it harder to secure future contracts.

- Injury/Death: Serious injuries or fatalities resulting from violations can lead to extensive legal action, including lawsuits and significant financial penalties.

- Work Stoppages: OSHA may order a work stoppage until safety violations are rectified, halting progress on a project and potentially impacting deadlines and budgets.

Think of it like this: Ignoring traffic laws might result in a fine. Ignoring OSHA regulations regarding rebar safety can have far more serious consequences, potentially leading to devastating injuries or fatalities for workers. The potential costs—financial and human—of non-compliance far outweigh the cost of implementing safe work practices.

Q 17. How do you contribute to a safe work environment during rebar installation?

Contributing to a safe work environment during rebar installation involves a multi-faceted approach:

- Enforcing safety rules: I ensure that everyone on my crew understands and follows all OSHA regulations and company safety policies. This includes consistent monitoring and immediate correction of unsafe practices.

- Proper planning and layout: I carefully plan the placement of rebar to minimize tripping hazards and ensure sufficient space for safe movement and operation of equipment.

- Pre-task planning: Conducting thorough pre-task planning, including risk assessments, helps identify and mitigate potential hazards before work begins. This could involve assessing the stability of the ground, checking the condition of scaffolding, and ensuring all necessary equipment is safely positioned.

- Leading by example: I always model safe practices myself, demonstrating the correct use of PPE and tools. My actions set a tone of respect for safety on the worksite.

- Communication: Clear and consistent communication with my crew is paramount, both before and during the project, to address and resolve any safety concerns that arise.

For example, before starting a project, I would ensure that the work area is clear of debris, that proper scaffolding is in place, and that each crew member has the proper PPE and has received adequate training on the specific tools and techniques that will be used for that day’s tasks.

Q 18. Describe a time you had to address a safety violation related to rebar work.

On a previous project, I noticed a worker using a rebar cutter without safety glasses. This was a clear violation of OSHA 1926.18 and our company’s safety policy.

My response: I immediately stopped the work, explained the potential dangers of flying debris causing eye injury, and reinforced the importance of always wearing safety glasses when operating power tools. I provided the worker with a new pair of safety glasses and ensured they understood the consequences of non-compliance. I then conducted a brief retraining session with the entire crew, emphasizing the need for consistent PPE use.

This incident underscored the need for constant vigilance and proactive safety enforcement. The potential consequences of an eye injury are severe; even a seemingly minor violation can lead to serious harm.

Q 19. How do you effectively communicate safety concerns to your crew?

Effective communication of safety concerns requires a combination of approaches:

- Regular toolbox talks: I hold short, regular meetings to discuss relevant safety topics, addressing recent incidents, reviewing procedures, and answering questions.

- Direct and open communication: I encourage my crew to openly express any safety concerns they might have, without fear of reprisal. A culture of open communication helps identify and address issues early.

- Visual aids: Using visual aids such as posters, diagrams, and demonstrations can help enhance understanding and retention of safety information.

- One-on-one discussions: For specific concerns or individual training needs, I use one-on-one conversations to address the issue directly and ensure comprehension.

For example, if a worker expresses concern about the stability of scaffolding, I would immediately address their concerns, inspect the scaffolding, and either make corrections or halt the work until it’s deemed safe.

Q 20. How do you ensure proper housekeeping practices around the rebar storage and work areas?

Maintaining proper housekeeping around rebar storage and work areas is crucial for safety.

- Designated storage areas: Rebar should be stored neatly and securely in designated areas to prevent tripping hazards and ensure stability. This prevents the rebar from shifting and creating unsafe conditions.

- Regular cleanup: Regular removal of debris, scrap rebar, and waste material minimizes trip-and-fall hazards and prevents the accumulation of potential hazards.

- Clear walkways: Work areas must have clearly marked and unobstructed walkways to facilitate safe movement of personnel and equipment.

- Proper waste disposal: All waste materials must be disposed of appropriately, in compliance with local and company regulations.

Think of it as maintaining a clean and organized workspace; this not only helps prevent accidents but also fosters a more productive and safer work environment for everyone.

Q 21. How familiar are you with different types of rebar couplings and connections?

I am familiar with various types of rebar couplings and connections, including mechanical splices, threaded couplers, and welded connections.

- Mechanical Splices: These rely on mechanical means, such as compression, to join rebar pieces. They are often quicker to install than welding but need to be carefully installed to meet design strength requirements.

- Threaded Couplers: These involve threading the ends of rebar and screwing them into couplers. They are relatively easy to install and disassemble but strength considerations must be given based on the rebar diameter and coupling design.

- Welded Connections: This method involves welding the ends of the rebar to form a permanent joint. Welding requires specialized skills and equipment and needs to comply with specific welding codes.

The choice of coupling or connection depends on factors such as the rebar diameter, required strength, access limitations, and project specifications. It’s crucial to always use the correct type of coupling or connection and to ensure proper installation to meet safety and structural integrity requirements. Incorrect installation of a coupler or weld can lead to catastrophic failures which can have severe consequences.

Q 22. What are the procedures for working near energized lines while installing rebar?

Working near energized power lines while installing rebar is extremely dangerous and requires strict adherence to OSHA 1926 Subpart V and other relevant regulations. The primary procedure is prevention – avoiding work near energized lines whenever possible. If proximity is unavoidable, a qualified professional, such as a professional engineer or electrical lineman, must be consulted to develop a comprehensive safety plan.

This plan will likely include:

- Establishing a safe distance: This distance depends on voltage and other factors, and will be determined by the qualified professional. Workers must maintain this distance at all times.

- Utilizing spotters: Trained spotters should constantly monitor the location of workers and the power lines, alerting everyone to any potential hazards.

- Implementing protective measures: This could involve using insulated tools, protective barriers, or de-energizing the lines if feasible and safe to do so. Only qualified personnel should perform de-energization.

- Proper grounding: All equipment and materials should be properly grounded to prevent accidental contact with energized lines.

- Emergency response plan: A detailed plan for responding to emergencies, including electrical shocks, must be in place, with clear instructions and readily accessible emergency equipment.

Ignoring these precautions can lead to severe injury or death. Safety must always be prioritized over speed or productivity.

Q 23. Describe your understanding of the role of a competent person in relation to rebar work.

A competent person, as defined by OSHA, is someone who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them. In rebar work, this means a person with the necessary training, experience, and authority to:

- Inspect the jobsite: Identifying potential hazards like uneven ground, improperly stored materials, or damaged equipment.

- Enforce safety regulations: Ensuring all workers are following established safety procedures, using proper PPE, and working within established safety guidelines.

- Train workers: Providing proper training on safe rebar handling, tying techniques, and hazard recognition.

- Correct hazards: Taking immediate action to address identified hazards, such as removing tripping hazards or replacing damaged tools.

- Implement and maintain a safety program: Developing and overseeing a comprehensive safety plan specific to the rebar installation project.

Think of the competent person as the safety leader on-site, responsible for ensuring everyone goes home safe at the end of the day. Their authority and expertise are crucial for preventing accidents.

Q 24. How do you address conflicts between productivity and safety on a rebar project?

Balancing productivity and safety is a constant challenge in construction. The key is to remember that safety is not a trade-off; it’s a prerequisite for productivity. Compromising safety to meet deadlines almost always leads to greater losses in the long run – delays caused by accidents, increased insurance costs, and potential legal ramifications.

Here’s how I address this:

- Proper planning: Thorough job planning that includes realistic timelines and integrates safety measures from the start. This avoids rushing and encourages proactive hazard identification.

- Training and communication: Well-trained workers understand and appreciate safety procedures. Open communication ensures concerns are addressed promptly.

- Effective supervision: Active monitoring of work practices by competent supervisors ensures compliance with safety protocols and early identification of potential issues.

- Incentivizing safe work practices: Rewarding safe behavior reinforces positive safety culture. This may include incentives, safety awards, or positive feedback.

- Using appropriate tools and equipment: Investing in quality equipment and tools reduces the risk of accidents and improves efficiency.

Ultimately, a proactive safety approach, focusing on prevention, leads to both higher productivity and a safer work environment. It’s not a conflict, but a synergy.

Q 25. How do you stay up-to-date on changes and updates to OSHA 1926.18?

Staying current with OSHA 1926.18 and other relevant regulations is vital. I utilize several methods:

- OSHA Website: Regularly checking the official OSHA website for updates, revisions, and new interpretations of the standards.

- Industry Publications: Subscribing to industry publications and newsletters that provide updates on OSHA changes and best practices in construction safety.

- Professional Development Courses: Attending training courses and seminars on OSHA compliance and rebar safety to gain in-depth knowledge of new regulations and best practices.

- Networking with Other Professionals: Discussing updates and best practices with other safety professionals and contractors in my network.

- Following Safety Organizations: Joining and actively participating in professional organizations focused on construction safety for access to resources and updates.

Proactive updating ensures I’m not just compliant, but also employing the latest safety strategies to protect workers.

Q 26. What are the specific requirements for rebar placement in seismic zones?

Rebar placement in seismic zones is critical for structural integrity and requires adherence to stricter standards than non-seismic areas. These standards often involve specific detailing and placement requirements as dictated by local building codes and engineering specifications which often exceed minimum OSHA standards.

Generally, this includes:

- Increased density of rebar: More rebar is typically required to withstand higher seismic forces.

- Specific lap splice requirements: Overlapping rebar sections (lap splices) must meet stringent length and placement requirements to ensure adequate strength and prevent failure during an earthquake.

- Careful detailing of rebar placement: Precise placement of rebar within the concrete formwork is essential to optimize load distribution and prevent weak points. This often requires detailed engineering drawings.

- Use of high-strength rebar: Higher grade rebar may be required to handle increased stress.

- Inspection and quality control: Rigorous inspection throughout the process to ensure adherence to specifications is paramount.

Failure to follow these specifications could lead to catastrophic structural failure in a seismic event. It’s vital to consult with a structural engineer to ensure compliance with all applicable building codes and seismic design standards.

Q 27. How would you respond to a rebar-related injury on the jobsite?

Responding to a rebar-related injury requires immediate and decisive action:

- First Aid: Immediately provide first aid to the injured worker, ensuring the safety of both the injured person and those providing assistance. This might involve controlling bleeding, stabilizing injuries, and calling emergency medical services.

- Emergency Services: Call 911 or the appropriate emergency services immediately. Clearly explain the nature of the injury, location, and any relevant details.

- Secure the Scene: Isolate the area where the injury occurred to prevent further accidents. This could involve cordoning off the area and stopping work until the scene is secured.

- Preserve Evidence: Photograph the scene, if possible, and document the circumstances of the accident. Do not disturb the scene unnecessarily.

- Incident Report: Complete a thorough incident report detailing the circumstances, time, location, injuries sustained, and any witnesses.

- OSHA Reporting: Report the incident to OSHA if it meets their reportable injury criteria (e.g., hospitalization, death, lost workdays). This is critical for compliance.

- Follow Up: Follow up with the injured worker, ensuring they are receiving proper medical care and support, and conduct a thorough investigation to identify the root cause of the accident to prevent future occurrences.

Effective response minimizes further harm and promotes a culture of safety and accountability.

Q 28. Explain your understanding of the importance of proper documentation in relation to rebar installation and safety.

Proper documentation is the backbone of a safe and compliant rebar installation project. It serves multiple purposes:

- Compliance with OSHA and other regulations: Detailed records demonstrate adherence to safety standards, facilitating audits and investigations. Examples include daily safety reports, training records, incident reports, and inspection checklists.

- Tracking Safety Performance: Documentation allows for monitoring safety trends, identifying areas for improvement, and measuring the effectiveness of safety programs.

- Legal Protection: Thorough records can protect the company from liability in case of accidents or disputes.

- Quality Control: Documentation ensures accurate tracking of material usage, placement, and inspection results, contributing to the overall quality of the construction project.

- Communication and Collaboration: Comprehensive documentation aids communication among workers, supervisors, and engineers, facilitating a clear understanding of procedures and expectations.

Consider it a safety and project management tool. Thorough documentation isn’t just compliance; it’s a proactive measure that enhances safety, quality, and efficiency.

Key Topics to Learn for Rebar OSHA 1926.18 Interview

- Hazard Recognition and Prevention: Understanding common hazards associated with rebar handling, placement, and fabrication, and the preventative measures outlined in 1926.18.

- Personal Protective Equipment (PPE): Identifying and correctly using appropriate PPE for rebar work, including hard hats, safety glasses, gloves, and footwear. Be prepared to discuss selection criteria based on specific tasks.

- Fall Protection: Understanding fall protection requirements when working with rebar at heights, including the use of guardrails, safety nets, and personal fall arrest systems.

- Handling and Storage of Rebar: Safe practices for lifting, carrying, and storing rebar to prevent injuries. This includes understanding weight limits and proper techniques.

- Cutting and Bending Rebar: Safe procedures for cutting and bending rebar, including the use of appropriate tools and equipment, and awareness of potential hazards like flying debris.

- Excavation and Trenching Safety (as it relates to rebar): Understanding how rebar placement interacts with excavation safety and the potential for collapse or injury.

- Emergency Procedures: Knowing the proper procedures to follow in case of an accident or injury involving rebar, including reporting procedures and first aid knowledge.

- Inspection and Maintenance: Understanding the importance of regular inspections of rebar and related equipment to identify and address potential hazards.

- Compliance and Documentation: Familiarize yourself with record-keeping requirements and the importance of following all OSHA regulations.

- Practical Application & Problem Solving: Be prepared to discuss how you would apply your knowledge of 1926.18 to solve real-world scenarios involving rebar safety.

Next Steps

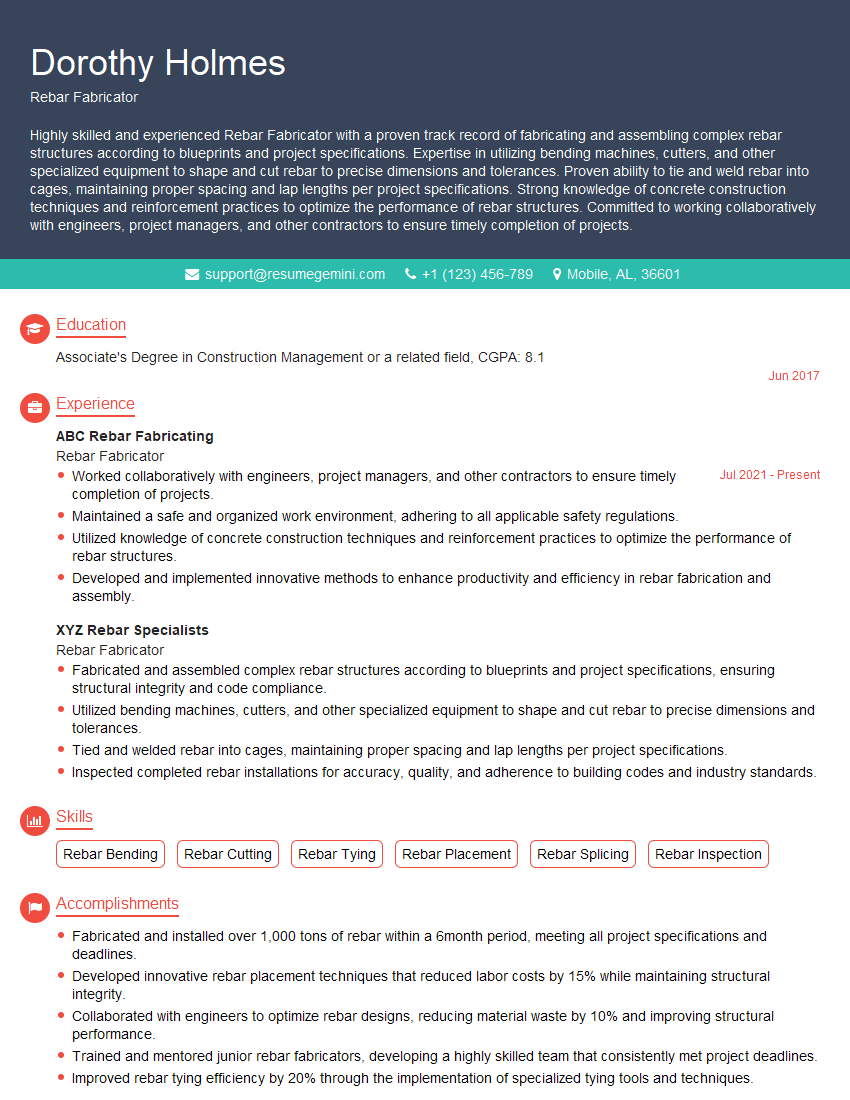

Mastering Rebar OSHA 1926.18 demonstrates your commitment to safety and significantly enhances your marketability within the construction industry. It showcases your professionalism and understanding of crucial safety regulations, leading to increased job opportunities and career advancement. To maximize your chances of landing your dream role, focus on creating an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you craft a compelling and effective resume. Examples of resumes tailored to Rebar OSHA 1926.18 expertise are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.